check transmission fluid RENAULT ESPACE 2000 J66 / 3.G Technical Note 3426A Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2000, Model line: ESPACE, Model: RENAULT ESPACE 2000 J66 / 3.GPages: 52, PDF Size: 0.98 MB

Page 13 of 52

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Engine and transmission assembly

10

10-9

REFITTING - Special points

Pre-position the gearbox control cables.

Position the engine/gearbox assembly in its

compartment. Check the rear of the gearbox in relation

to the sub-frame.

Fitting suspended mountings: see section 19

"Suspended mountings".

Tighten all the bolts, nuts and studs to the

recommended torques.

Refitting is the reverse of removal.

Press the brake pedal several times to bring the

pistons into contact with the brake pads.

Reprogram all the components deprogrammed by

disconnecting the battery.

Fill the refrigerant circuit using the filling station (see

section 62 "Air conditioning").

Refrigerant fluid R134a: 800 ± 20 g.

Carry out:

–filling and bleeding of the cooling circuit (see

section 19),

–filling and bleeding of the power assisted steering

circuit,–bleed the hydraulic clutch circuit.

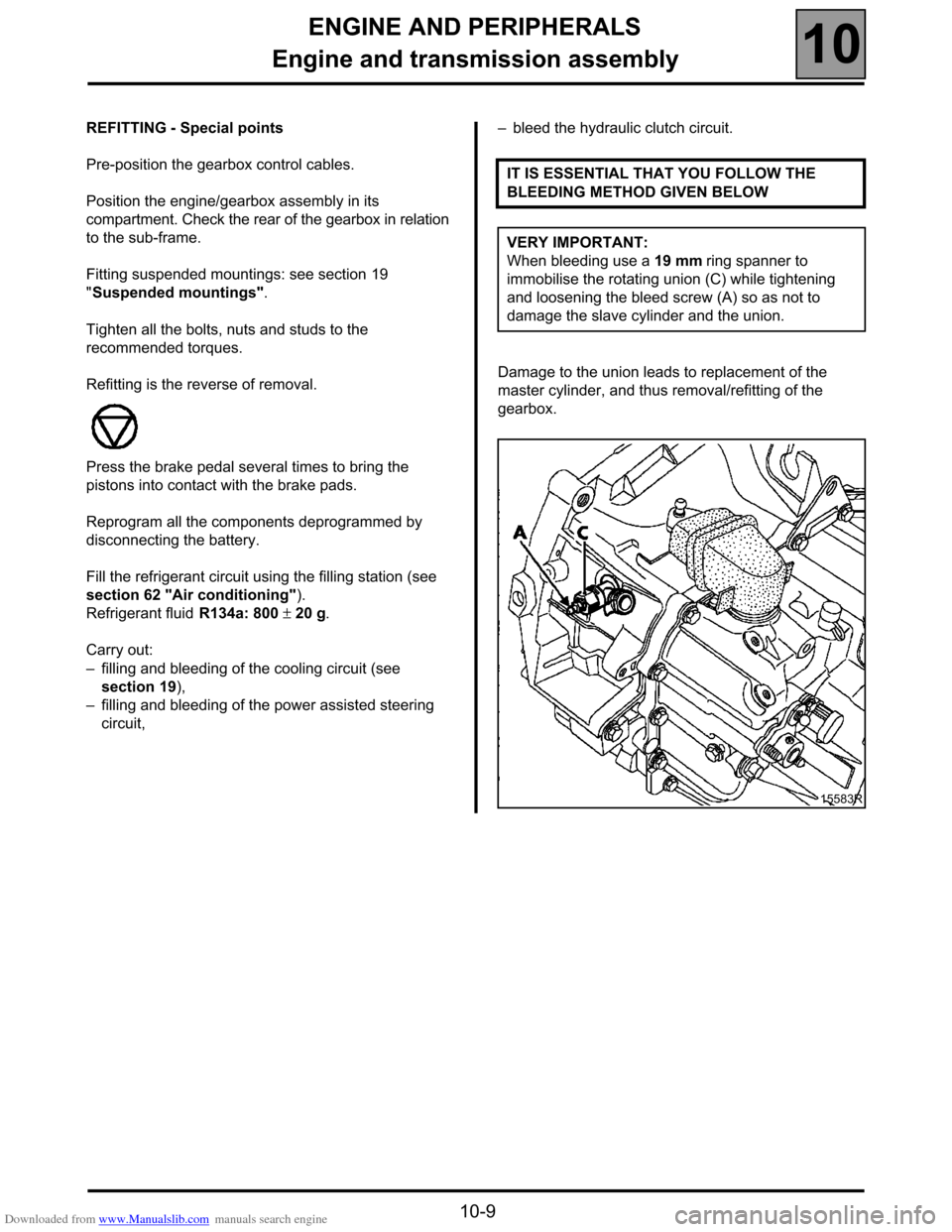

Damage to the union leads to replacement of the

master cylinder, and thus removal/refitting of the

gearbox.IT IS ESSENTIAL THAT YOU FOLLOW THE

BLEEDING METHOD GIVEN BELOW

VERY IMPORTANT:

When bleeding use a 19 mm ring spanner to

immobilise the rotating union (C) while tightening

and loosening the bleed screw (A) so as not to

damage the slave cylinder and the union.

15583R

Page 14 of 52

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Engine and transmission assembly

10

10-10

BLEEDING METHOD TO BE USED:

(for two people).

1) Filling the circuit:

Check that the clutch pedal is in the top position; put

it in this position and hold it by hand if necessary.

Fill the hydraulic circuit by connecting a filling system

and applying pressure to the tank, open the bleed

screw (A) (always compensate for the force using a

counter-spanner) and allow a little fluid to escape

(approximately 0.5 l) through a transparent tube

connected to the bleed screw. Close the bleed

screw.

2) Final bleeding of the circuit:

One operator slowly disengages fully and keeps the

pedal depressed. Wait approximately ten seconds in

this situation. With the pedal still depressed, a

second operator opens the bleed screw briefly (A).

With the bleed screw closed again, the operator

inside the vehicle releases the clutch pedal and

slowly lifts it to top position by hand (It is normal that

the pedal does not return independently in this

configuration).

After a few seconds repeat the operations described

above in 2) as often as required until no more

bubbles escape when bleeding. Then repeat these

operations five times to ensure that the system has

been bled correctly.

These repeated bleedings allow the slave cylinder to

eject all the air trapped in any section between the

stop and the bleed screw and which has not been

"cleaned" by the flow of liquid when refilling using the

traditional pressurisation system.

An air bubble in the circuit, no matter how small, may

lead to operating faults such as: incorrect pedal

return, crashing of the gears,..., which may lead to

incorrect fault finding and unnecessary replacement

of a component in the clutch circuit.