electric RENAULT ESPACE 2000 J66 / 3.G Technical Note 3426A Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2000, Model line: ESPACE, Model: RENAULT ESPACE 2000 J66 / 3.GPages: 52, PDF Size: 0.98 MB

Page 10 of 52

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Engine and transmission assembly

10

10-6

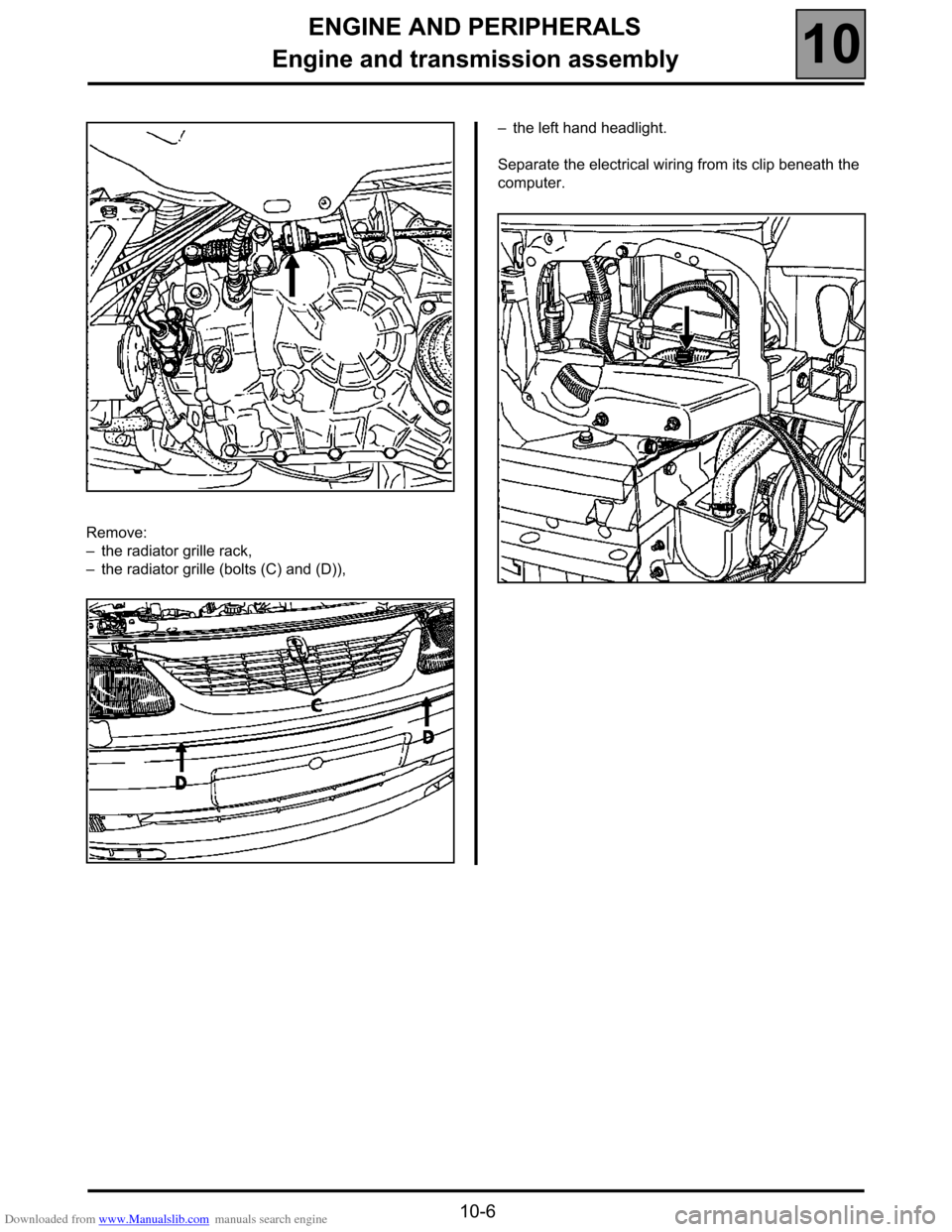

Remove:

–the radiator grille rack,

–the radiator grille (bolts (C) and (D)),–the left hand headlight.

Separate the electrical wiring from its clip beneath the

computer.

Page 11 of 52

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Engine and transmission assembly

10

10-7

Disconnect the lead from the engine compartment

connection unit; be sure to mark the location of the

various connections correctly.

Separate:

–a connector from the battery tray,

–the control solenoid valve from the turbocharger

regulation valve.

Fit hose pliers on the clutch master cylinder supply

pipe (on the brake fluid tank side).

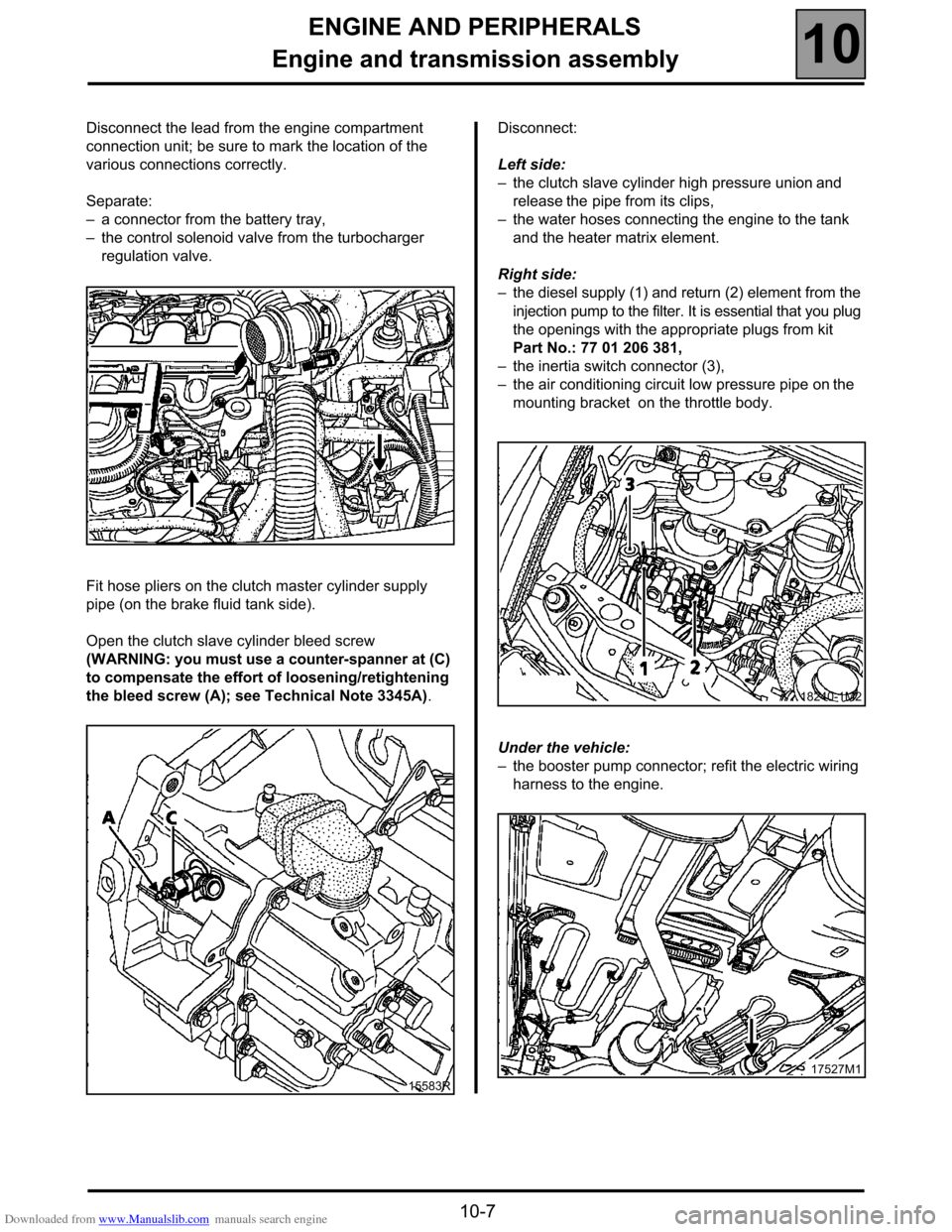

Open the clutch slave cylinder bleed screw

(WARNING: you must use a counter-spanner at (C)

to compensate the effort of loosening/retightening

the bleed screw (A); see Technical Note 3345A).Disconnect:

Left side:

–the clutch slave cylinder high pressure union and

release the pipe from its clips,

–the water hoses connecting the engine to the tank

and the heater matrix element.

Right side:

–the diesel supply (1) and return (2) element from the

injection pump to the filter. It is essential that you plug

the openings with the appropriate plugs from kit

Part No.: 77 01 206 381,

–the inertia switch connector (3),

–the air conditioning circuit low pressure pipe on the

mounting bracket on the throttle body.

Under the vehicle:

–the booster pump connector; refit the electric wiring

harness to the engine.

15583R

18240-1M2

17527M1

Page 27 of 52

Downloaded from www.Manualslib.com manuals search engine FUEL MIXTURE

Air intake

12

12-5

REMOVAL

Put the vehicle on a two post lift.

Disconnect the battery.

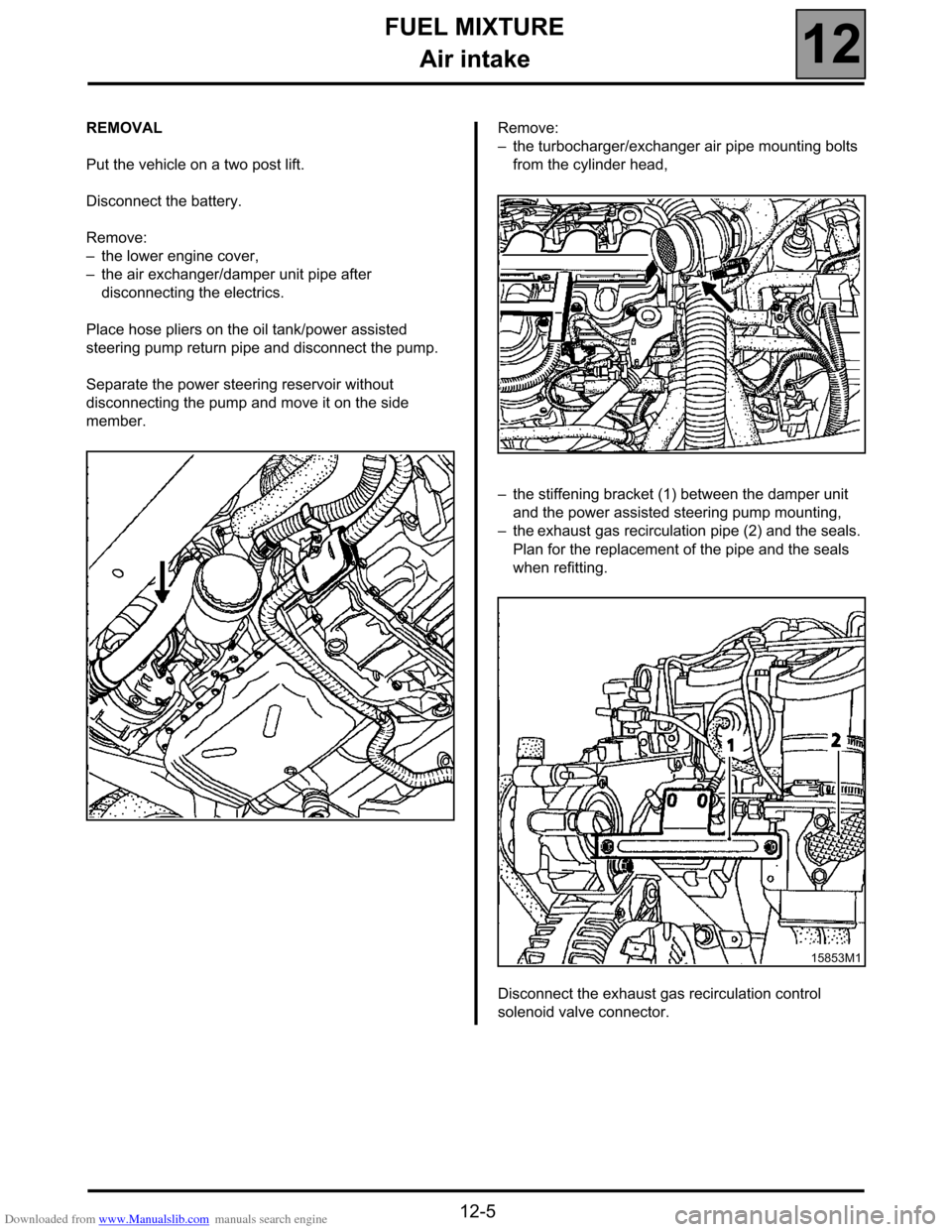

Remove:

–the lower engine cover,

–the air exchanger/damper unit pipe after

disconnecting the electrics.

Place hose pliers on the oil tank/power assisted

steering pump return pipe and disconnect the pump.

Separate the power steering reservoir without

disconnecting the pump and move it on the side

member.Remove:

–the turbocharger/exchanger air pipe mounting bolts

from the cylinder head,

–the stiffening bracket (1) between the damper unit

and the power assisted steering pump mounting,

–the exhaust gas recirculation pipe (2) and the seals.

Plan for the replacement of the pipe and the seals

when refitting.

Disconnect the exhaust gas recirculation control

solenoid valve connector.

15853M1

Page 28 of 52

Downloaded from www.Manualslib.com manuals search engine FUEL MIXTURE

Air intake

12

12-6

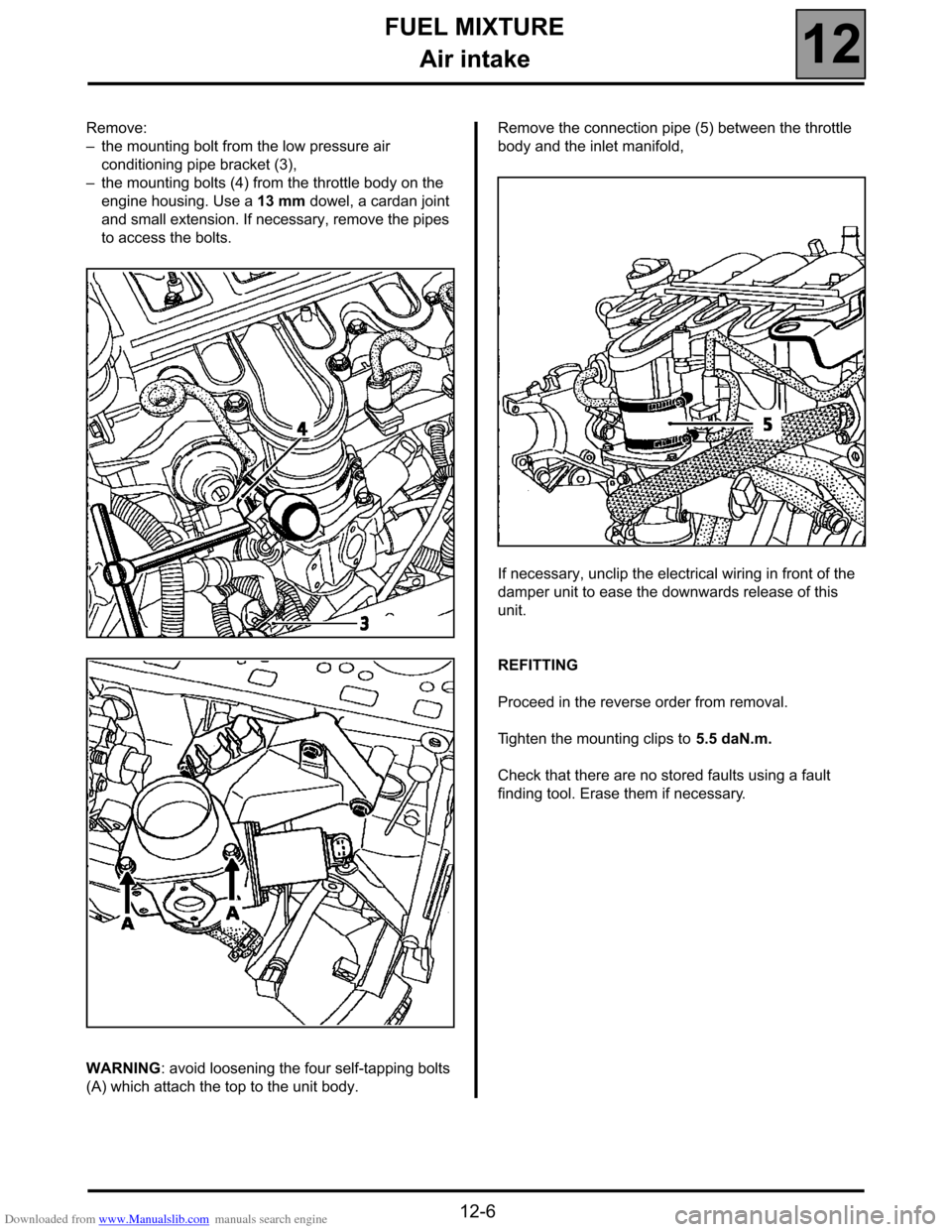

Remove:

–the mounting bolt from the low pressure air

conditioning pipe bracket (3),

–the mounting bolts (4) from the throttle body on the

engine housing. Use a 13 mm dowel, a cardan joint

and small extension. If necessary, remove the pipes

to access the bolts.

WARNING: avoid loosening the four self-tapping bolts

(A) which attach the top to the unit body.Remove the connection pipe (5) between the throttle

body and the inlet manifold,

If necessary, unclip the electrical wiring in front of the

damper unit to ease the downwards release of this

unit.

REFITTING

Proceed in the reverse order from removal.

Tighten the mounting clips to 5.5 daN.m.

Check that there are no stored faults using a fault

finding tool. Erase them if necessary.

Page 33 of 52

Downloaded from www.Manualslib.com manuals search engine STARTING - CHARGING

Alternator

16

16-2

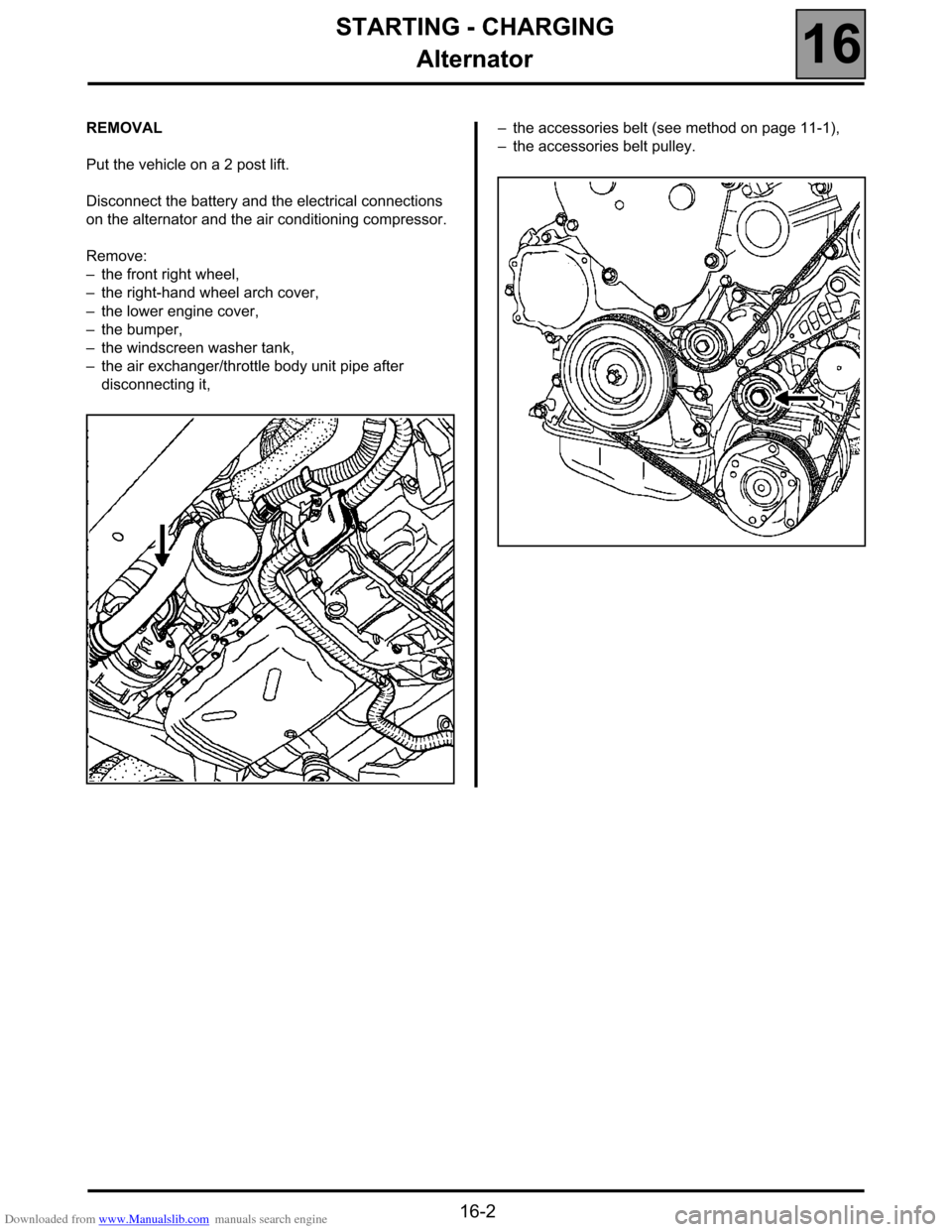

REMOVAL

Put the vehicle on a 2 post lift.

Disconnect the battery and the electrical connections

on the alternator and the air conditioning compressor.

Remove:

–the front right wheel,

–the right-hand wheel arch cover,

–the lower engine cover,

–the bumper,

–the windscreen washer tank,

–the air exchanger/throttle body unit pipe after

disconnecting it,–the accessories belt (see method on page 11-1),

–the accessories belt pulley.

Page 36 of 52

Downloaded from www.Manualslib.com manuals search engine STARTING - CHARGING

Starter

16

16-5

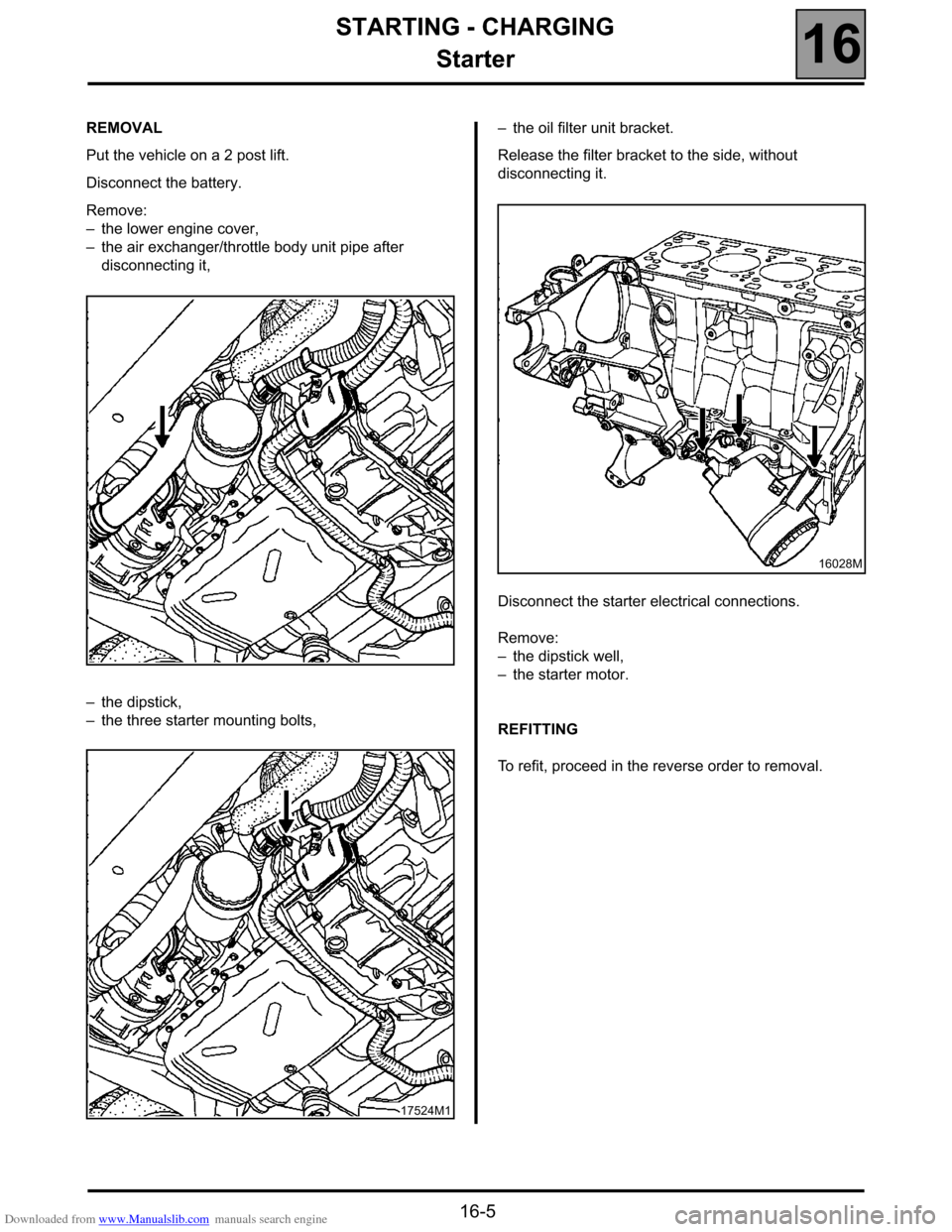

REMOVAL

Put the vehicle on a 2 post lift.

Disconnect the battery.

Remove:

–the lower engine cover,

–the air exchanger/throttle body unit pipe after

disconnecting it,

–the dipstick,

–the three starter mounting bolts,–the oil filter unit bracket.

Release the filter bracket to the side, without

disconnecting it.

Disconnect the starter electrical connections.

Remove:

–the dipstick well,

–the starter motor.

REFITTING

To refit, proceed in the reverse order to removal.

17524M1

16028M

Page 41 of 52

Downloaded from www.Manualslib.com manuals search engine COOLING SYSTEM

Cooling system

19

19-5

COOLING SYSTEM

Cooling system

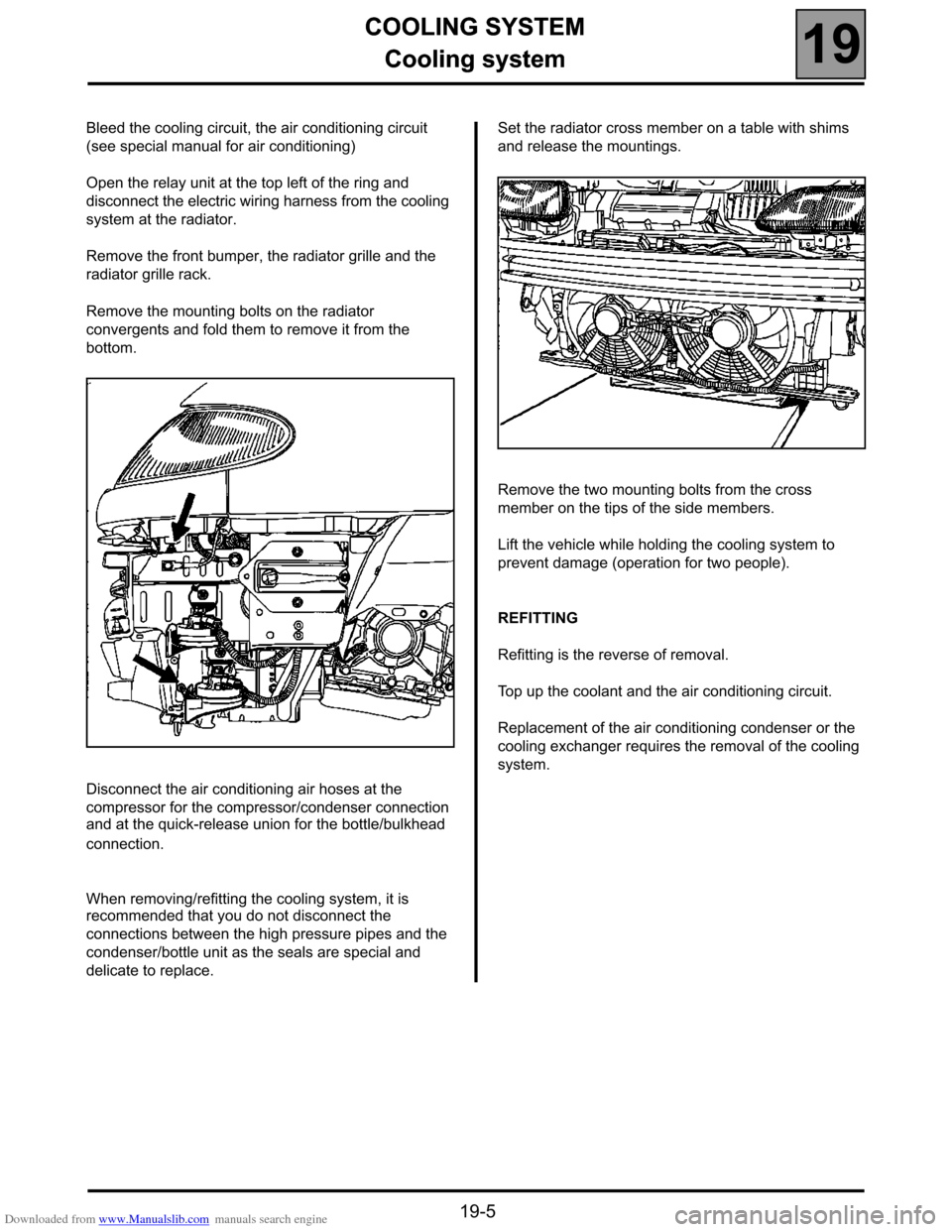

Bleed the cooling circuit, the air conditioning circuit

(see special manual for air conditioning)

Open the relay unit at the top left of the ring and

disconnect the electric wiring harness from the cooling

system at the radiator.

Remove the front bumper, the radiator grille and the

radiator grille rack.

Remove the mounting bolts on the radiator

convergents and fold them to remove it from the

bottom.

Disconnect the air conditioning air hoses at the

compressor for the compressor/condenser connection

and at the quick-release union for the bottle/bulkhead

connection.

When removing/refitting the cooling system, it is

recommended that you do not disconnect the

connections between the high pressure pipes and the

condenser/bottle unit as the seals are special and

delicate to replace.Set the radiator cross member on a table with shims

and release the mountings.

Remove the two mounting bolts from the cross

member on the tips of the side members.

Lift the vehicle while holding the cooling system to

prevent damage (operation for two people).

REFITTING

Refitting is the reverse of removal.

Top up the coolant and the air conditioning circuit.

Replacement of the air conditioning condenser or the

cooling exchanger requires the removal of the cooling

system.

Page 47 of 52

Downloaded from www.Manualslib.com manuals search engine HEATING

Additional heating

61

61-2

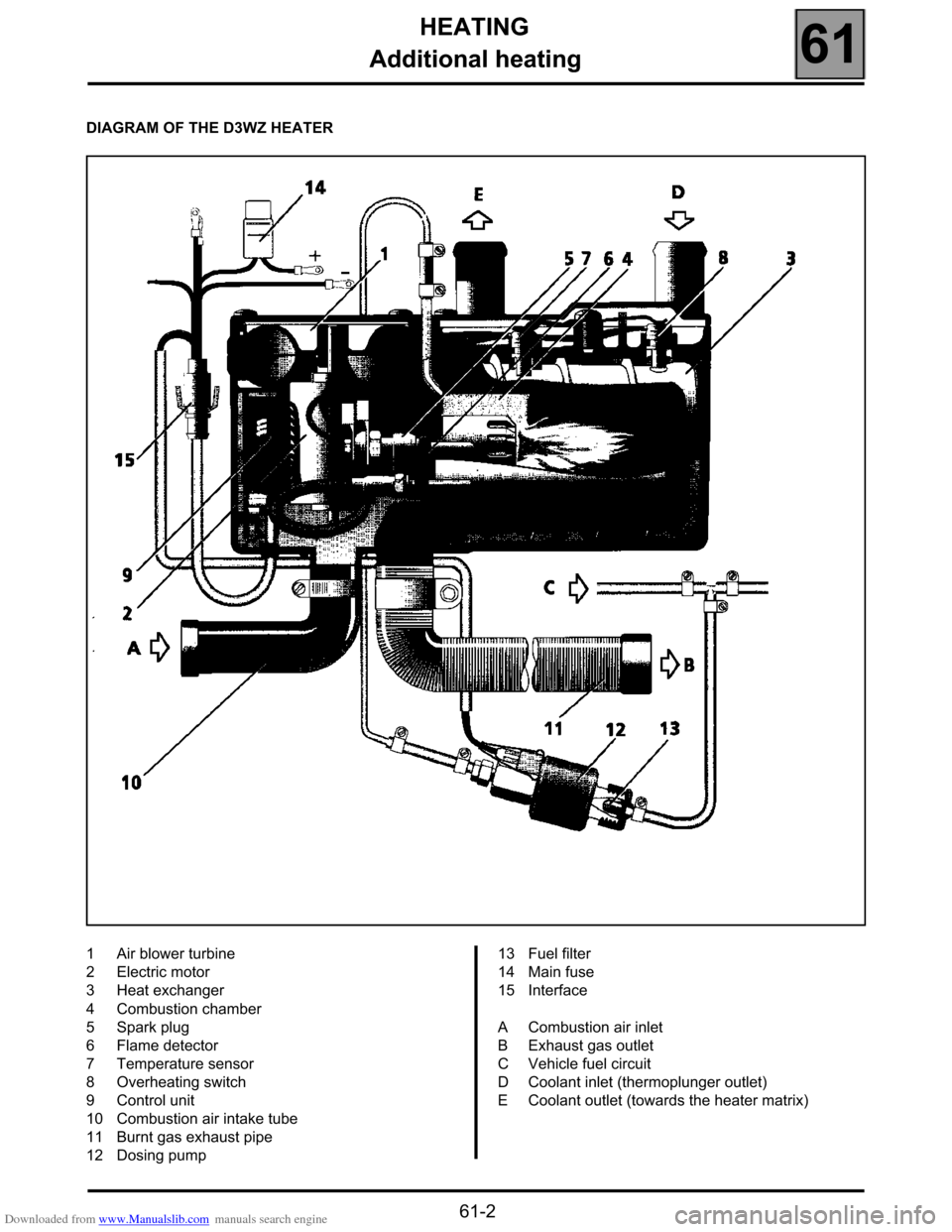

DIAGRAM OF THE D3WZ HEATER

1Air blower turbine

2Electric motor

3Heat exchanger

4Combustion chamber

5Spark plug

6Flame detector

7Temperature sensor

8Overheating switch

9Control unit

10 Combustion air intake tube

11 Burnt gas exhaust pipe

12 Dosing pump 13 Fuel filter

14 Main fuse

15 Interface

ACombustion air inlet

BExhaust gas outlet

CVehicle fuel circuit

DCoolant inlet (thermoplunger outlet)

ECoolant outlet (towards the heater matrix)

Page 51 of 52

Downloaded from www.Manualslib.com manuals search engine HEATING

Additional heating

61

61-6

MAINTENANCE

The principal maintenance operations on this

assembly are:

–replacing the ignition spark plug (5),

–cleaning the filter at the pump inlet (13) (see

page 61-2).

REMOVING - REFITTING COMPONENTS

FUEL PUMP INLET FILTER (13)

Remove the front bumper.

Rotate the pump (12) (see page 61-2) if it turns and

loosen the union covering the filter (13). Clean or

replace the filter if there is a combustion problem.

IGNITION SPARK PLUG

Disconnect and remove the heater without draining the

cooling circuit (use pliers Mot. 453-01).

Remove:

–the turbine cover (1),

–the control unit (9) and the cap (16),

–the spark plug (5) after disconnecting it.

FLAME DETECTOR

Disconnect and remove the heater without draining the

cooling circuit (use pliers Mot. 453-01).

Remove:

–the turbine cover (1),

–the control unit (9) and the cap (16).

Disconnect the flame connector by pulling the flat

terminals from the connector.

Remove the flame detector.

(WARNING: fragile part)COMBUSTION CHAMBER (4) AND EXCHANGER (3)

Remove:

–the flame detector and spark plug,

–the wiring harness fitted on the overheating

detector (8) and the temperature sensor (7),

–the turbine support (1).

Remove the combustion chamber (4) and the

exchanger (3) if necessary.

FAULT FINDING

In case of a fault, check:

–if there is fuel in the tank,

–if the fuses are intact

–if the pipes, connections and electrical unions are

intact,

–if the combustion air ducts or exhaust gas ducts are

blocked (unblock them if necessary).

In the even of combustion with the production of soot,

check:

–if the combustion air ducts or exhaust gas ducts are

blocked (unblock them if necessary),

–if there is a deposit in the exchanger (3) or the

combustion chamber (4); clean these if necessary,

–if the dosing pump flow is correct;

To do this:

â—Źremove the bumper,

â—Źdisconnect the electric pump inlet fuel pipe (12),

from the side opposite the fuel filter (13),

â—Źconnect a pipe to the electric pump so that the flow

can be collected in a glass at the same height as

the heater,

â—Źstart the heater (if necessary, bridge the

temperature sensor located in front of the battery

screen). After approximately 40 seconds, the fuel

arrives and begins to bleed the circuit. Switch off

the ignition. Empty the glass and start again,

collecting the stabilised flow for approximately

30 seconds. Switch off the heater and measure the

quantity of fuel collected.

Normal flow: between 6.8 cm

3 and 7.8 cm3 for

90 seconds of operation.