lock RENAULT ESPACE 2000 J66 / 3.G Technical Note 3426A Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2000, Model line: ESPACE, Model: RENAULT ESPACE 2000 J66 / 3.GPages: 52, PDF Size: 0.98 MB

Page 7 of 52

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Engine and transmission assembly

10

10-3

Engine and transmission assembly

Parts to order: high pressure circuit plugs kit

Part No.: 77 01 206 381. SPECIAL TOOLING REQUIRED

Mot. 1390 Universal mounting

Mot. 1410 Tool for unlocking the snap

couplings in the refrigerant

circuit

Dir. 1282 -01 Spanner for undoing the

steering rack union

Dir. 1282 -02 Spanner for undoing the

steering rack union

ESSENTIAL SPECIAL TOOLING

Two-post lift

Safety pad or belts

TIGHTENING TORQUES (in daN.m)

Shock absorber base mounting bolts

Ø M16 x 200 20

Driveshaft gaiter mounting bolt 2.5

Wheel bolts 10

Engine tie-bar bolts 10

Suspended mounting bolt to gearbox 5.5 to 6.5

Rubber suspended mounting nut to

the front left side member 5.5 to 8

Mounting bolt for front right

suspended mounting cover to engine 6.2

Mounting bolt for the movement

limiter of the upper front right hand

suspended engine mounting 10.5

Mounting nut for the rubber pad on

the front right suspended engine

mounting cover 3 to 4.5

Page 15 of 52

Downloaded from www.Manualslib.com manuals search engine TOP AND FRONT OF ENGINE

Accessories belt

11

111TOP AND FRONT OF ENGINE

Accessories belt

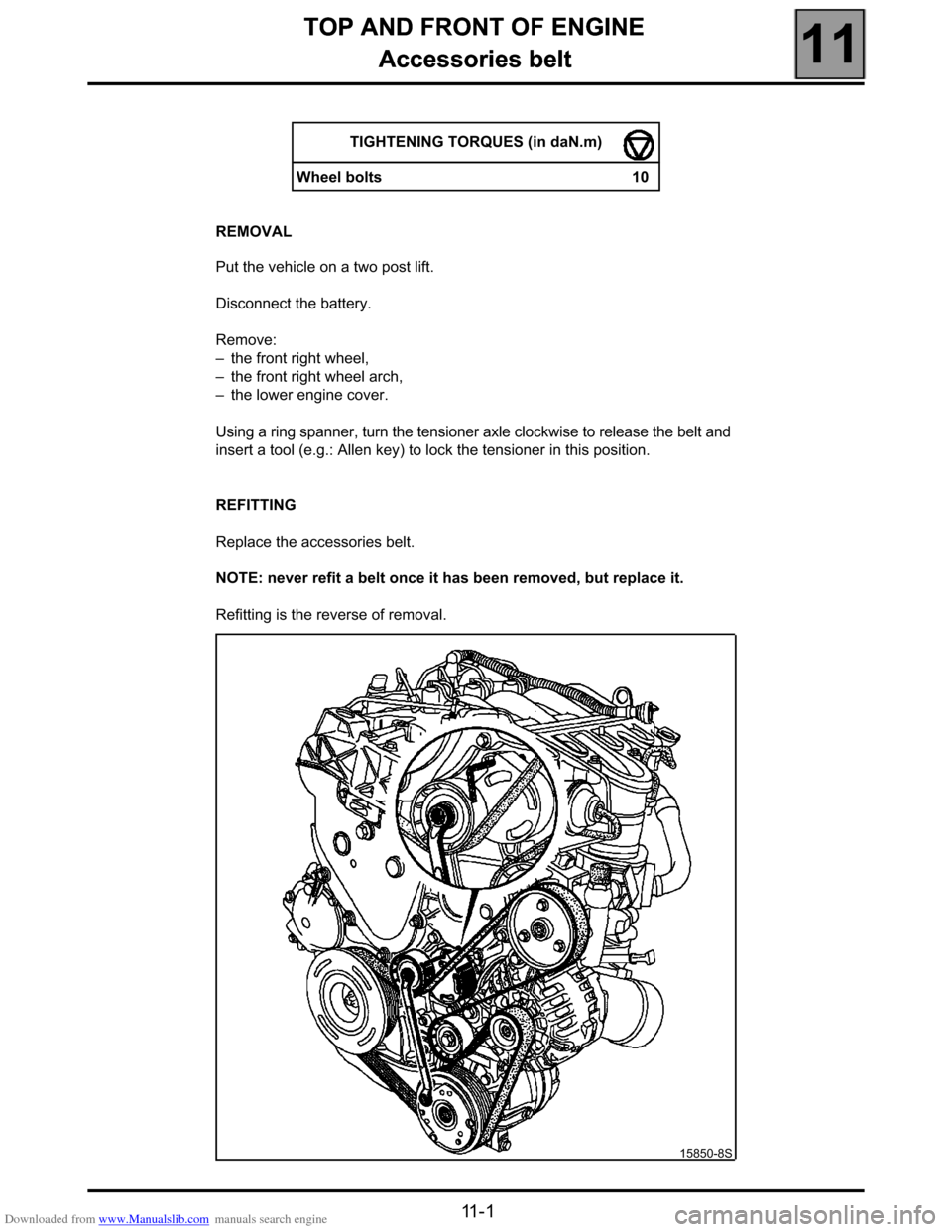

REMOVAL

Put the vehicle on a two post lift.

Disconnect the battery.

Remove:

–the front right wheel,

–the front right wheel arch,

–the lower engine cover.

Using a ring spanner, turn the tensioner axle clockwise to release the belt and

insert a tool (e.g.: Allen key) to lock the tensioner in this position.

REFITTING

Replace the accessories belt.

NOTE: never refit a belt once it has been removed, but replace it.

Refitting is the reverse of removal.TIGHTENING TORQUES (in daN.m)

Wheel bolts 10

15850-8S

11 - 1

Page 16 of 52

Downloaded from www.Manualslib.com manuals search engine TOP AND FRONT OF ENGINE

Timing belt

11

11 - 2

Timing belt

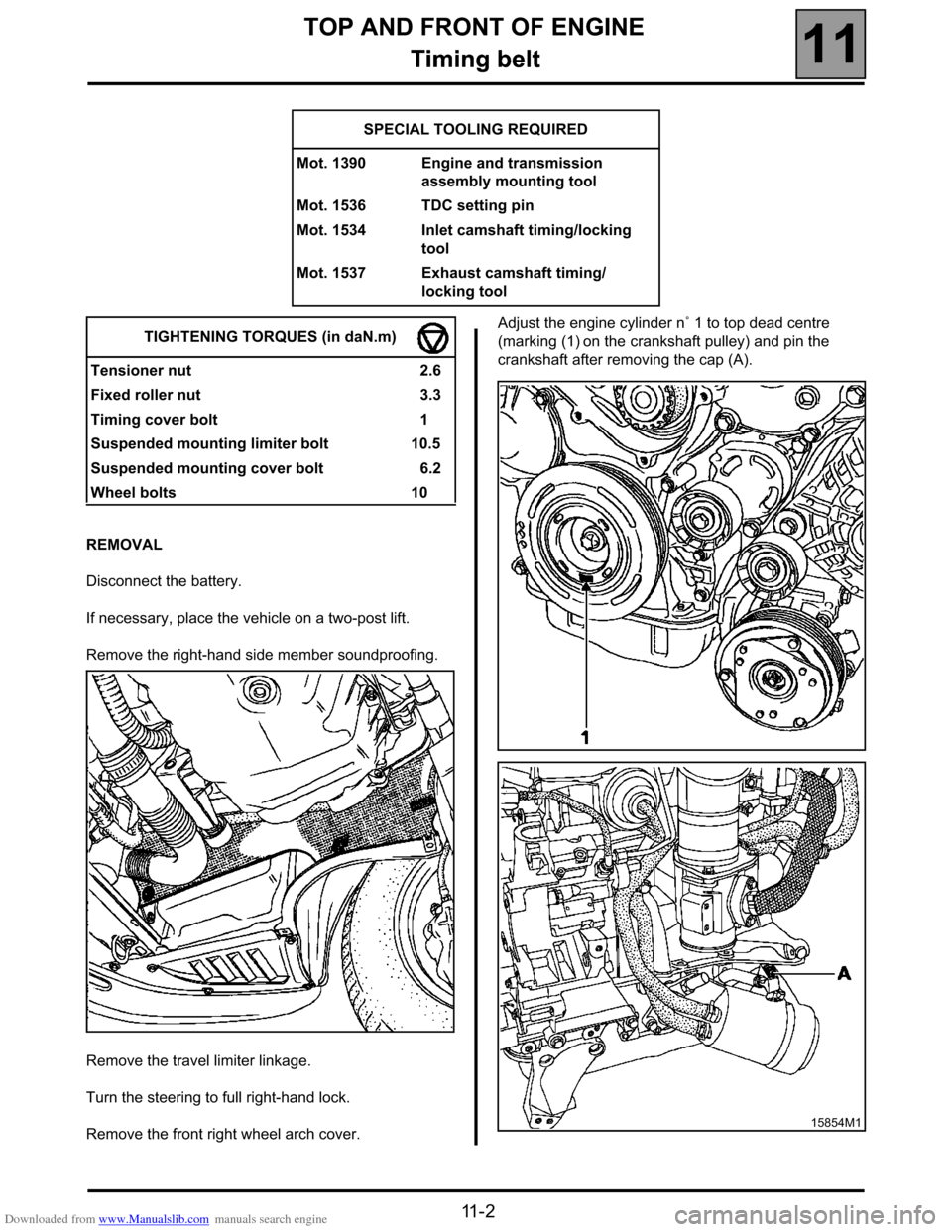

REMOVAL

Disconnect the battery.

If necessary, place the vehicle on a two-post lift.

Remove the right-hand side member soundproofing.

Remove the travel limiter linkage.

Turn the steering to full right-hand lock.

Remove the front right wheel arch cover. Adjust the engine cylinder n˚ 1 to top dead centre

(marking (1) on the crankshaft pulley) and pin the

crankshaft after removing the cap (A). SPECIAL TOOLING REQUIRED

Mot. 1390 Engine and transmission

assembly mounting tool

Mot. 1536 TDC setting pin

Mot. 1534 Inlet camshaft timing/locking

tool

Mot. 1537 Exhaust camshaft timing/

locking tool

TIGHTENING TORQUES (in daN.m)

Tensioner nut 2.6

Fixed roller nut 3.3

Timing cover bolt 1

Suspended mounting limiter bolt 10.5

Suspended mounting cover bolt 6.2

Wheel bolts 10

15854M1

Page 18 of 52

Downloaded from www.Manualslib.com manuals search engine TOP AND FRONT OF ENGINE

Timing belt

11

11 - 4

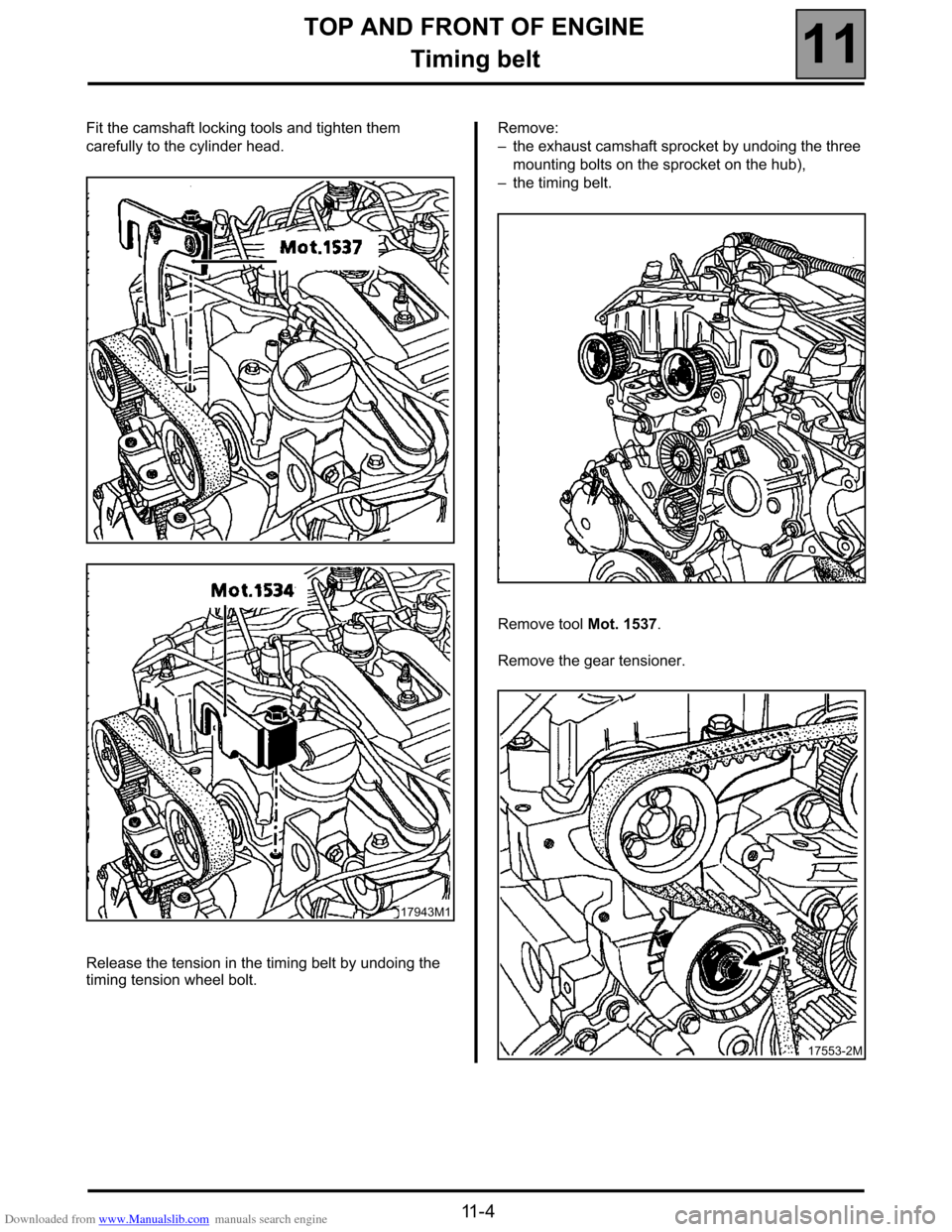

Fit the camshaft locking tools and tighten them

carefully to the cylinder head.

Release the tension in the timing belt by undoing the

timing tension wheel bolt.Remove:

–the exhaust camshaft sprocket by undoing the three

mounting bolts on the sprocket on the hub),

–the timing belt.

Remove tool Mot. 1537.

Remove the gear tensioner.

17943M1

15850M1

17553-2M

Page 19 of 52

Downloaded from www.Manualslib.com manuals search engine TOP AND FRONT OF ENGINE

Timing belt

11

11 - 5

–the pulley; remove the nut and take the pulley out

without removing the stud.

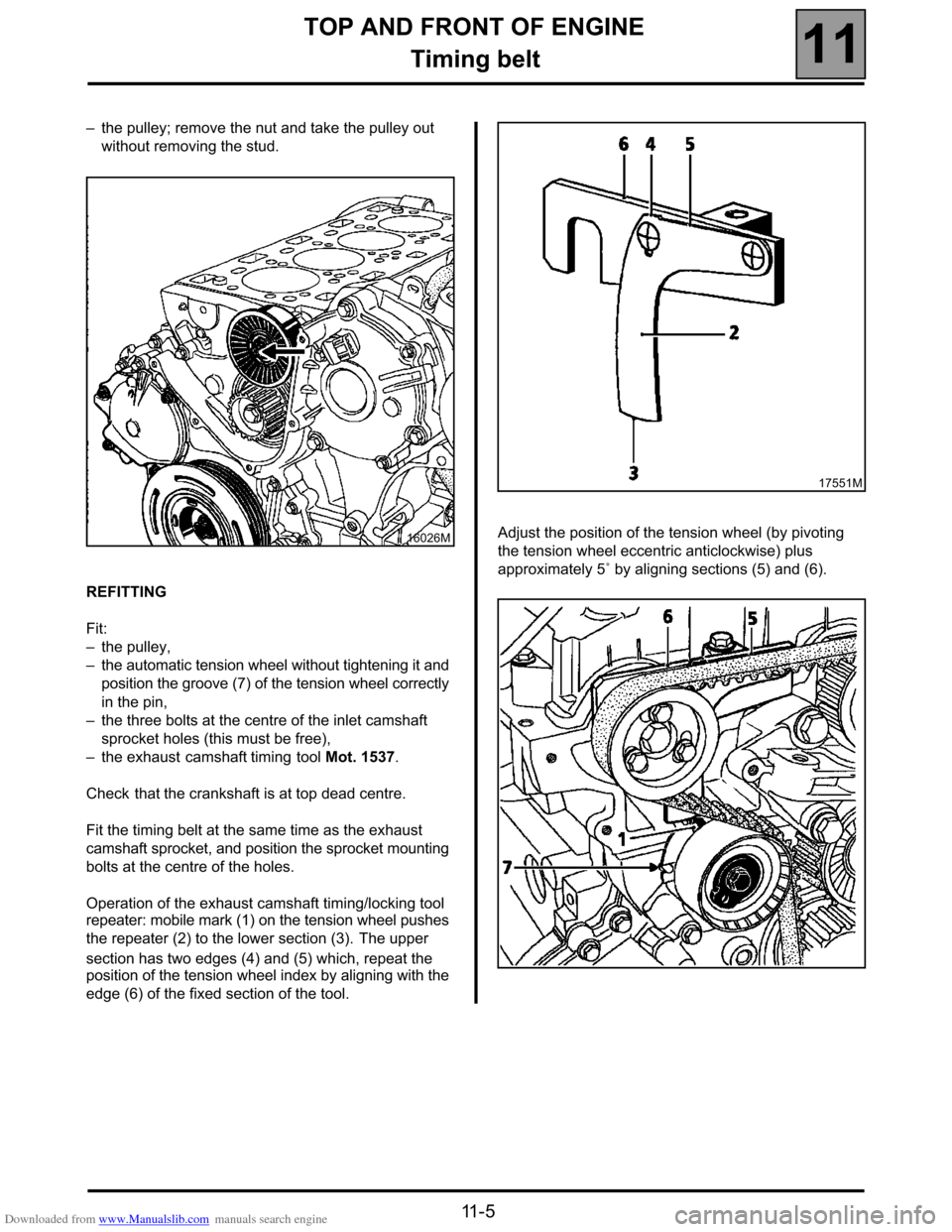

REFITTING

Fit:

–the pulley,

–the automatic tension wheel without tightening it and

position the groove (7) of the tension wheel correctly

in the pin,

–the three bolts at the centre of the inlet camshaft

sprocket holes (this must be free),

–the exhaust camshaft timing tool Mot. 1537.

Check that the crankshaft is at top dead centre.

Fit the timing belt at the same time as the exhaust

camshaft sprocket, and position the sprocket mounting

bolts at the centre of the holes.

Operation of the exhaust camshaft timing/locking tool

repeater: mobile mark (1) on the tension wheel pushes

the repeater (2) to the lower section (3). The upper

section has two edges (4) and (5) which, repeat the

position of the tension wheel index by aligning with the

edge (6) of the fixed section of the tool.Adjust the position of the tension wheel (by pivoting

the tension wheel eccentric anticlockwise) plus

approximately 5˚ by aligning sections (5) and (6).

16026M

17551M

Page 20 of 52

Downloaded from www.Manualslib.com manuals search engine TOP AND FRONT OF ENGINE

Timing belt

11

11 - 6

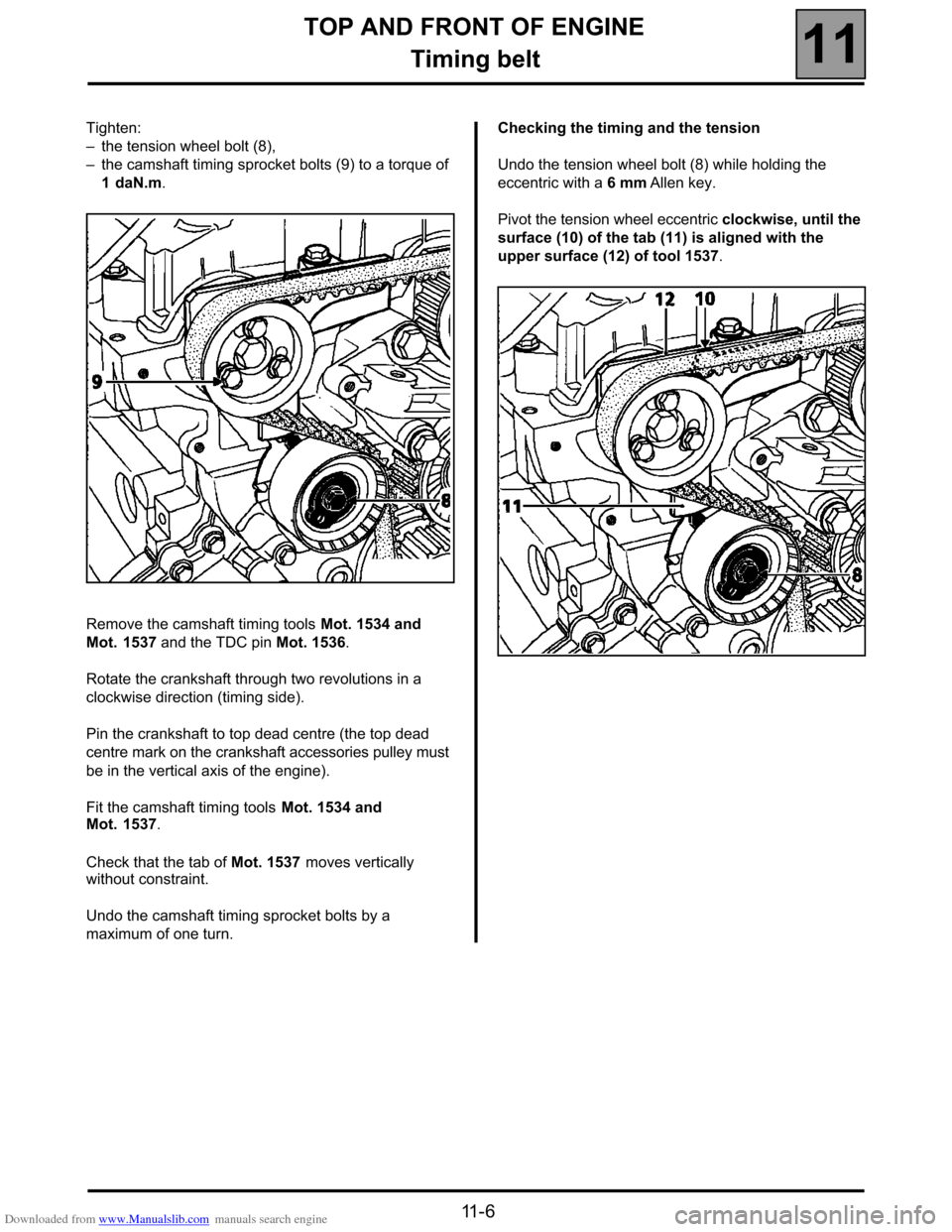

Tighten:

–the tension wheel bolt (8),

–the camshaft timing sprocket bolts (9) to a torque of

1 daN.m.

Remove the camshaft timing tools Mot. 1534 and

Mot. 1537 and the TDC pin Mot. 1536.

Rotate the crankshaft through two revolutions in a

clockwise direction (timing side).

Pin the crankshaft to top dead centre (the top dead

centre mark on the crankshaft accessories pulley must

be in the vertical axis of the engine).

Fit the camshaft timing tools Mot. 1534 and

Mot. 1537.

Check that the tab of Mot. 1537 moves vertically

without constraint.

Undo the camshaft timing sprocket bolts by a

maximum of one turn. Checking the timing and the tension

Undo the tension wheel bolt (8) while holding the

eccentric with a 6 mm Allen key.

Pivot the tension wheel eccentric clockwise, until the

surface (10) of the tab (11) is aligned with the

upper surface (12) of tool 1537.

Page 24 of 52

Downloaded from www.Manualslib.com manuals search engine TURBOCHARGING

Turbocharger

12

12-2

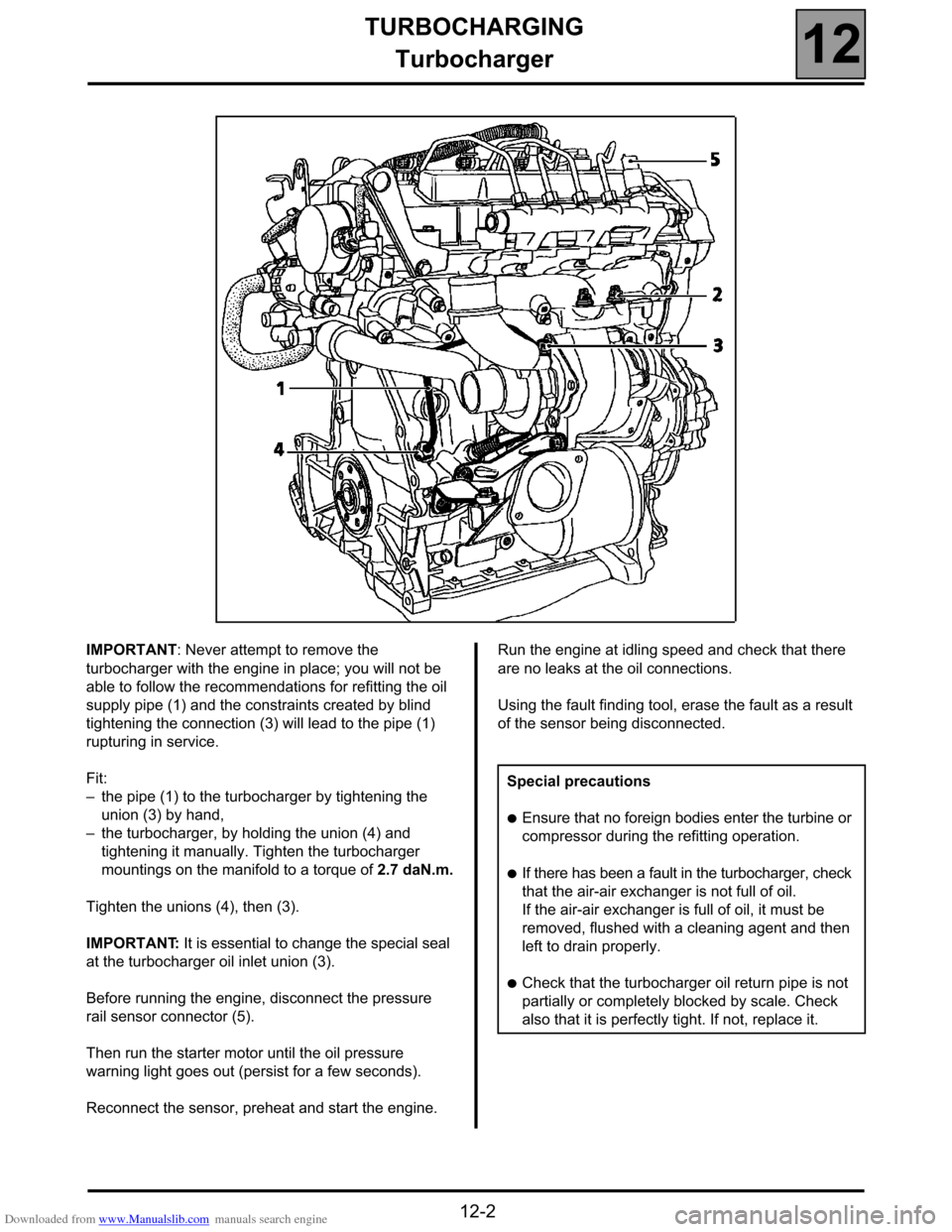

IMPORTANT: Never attempt to remove the

turbocharger with the engine in place; you will not be

able to follow the recommendations for refitting the oil

supply pipe (1) and the constraints created by blind

tightening the connection (3) will lead to the pipe (1)

rupturing in service.

Fit:

–the pipe (1) to the turbocharger by tightening the

union (3) by hand,

–the turbocharger, by holding the union (4) and

tightening it manually. Tighten the turbocharger

mountings on the manifold to a torque of 2.7 daN.m.

Tighten the unions (4), then (3).

IMPORTANT: It is essential to change the special seal

at the turbocharger oil inlet union (3).

Before running the engine, disconnect the pressure

rail sensor connector (5).

Then run the starter motor until the oil pressure

warning light goes out (persist for a few seconds).

Reconnect the sensor, preheat and start the engine.Run the engine at idling speed and check that there

are no leaks at the oil connections.

Using the fault finding tool, erase the fault as a result

of the sensor being disconnected.

Special precautions

●Ensure that no foreign bodies enter the turbine or

compressor during the refitting operation.

●If there has been a fault in the turbocharger, check

that the air-air exchanger is not full of oil.

If the air-air exchanger is full of oil, it must be

removed, flushed with a cleaning agent and then

left to drain properly.

●Check that the turbocharger oil return pipe is not

partially or completely blocked by scale. Check

also that it is perfectly tight. If not, replace it.

Page 39 of 52

Downloaded from www.Manualslib.com manuals search engine COOLING SYSTEM

Coolant pump

19

19-3

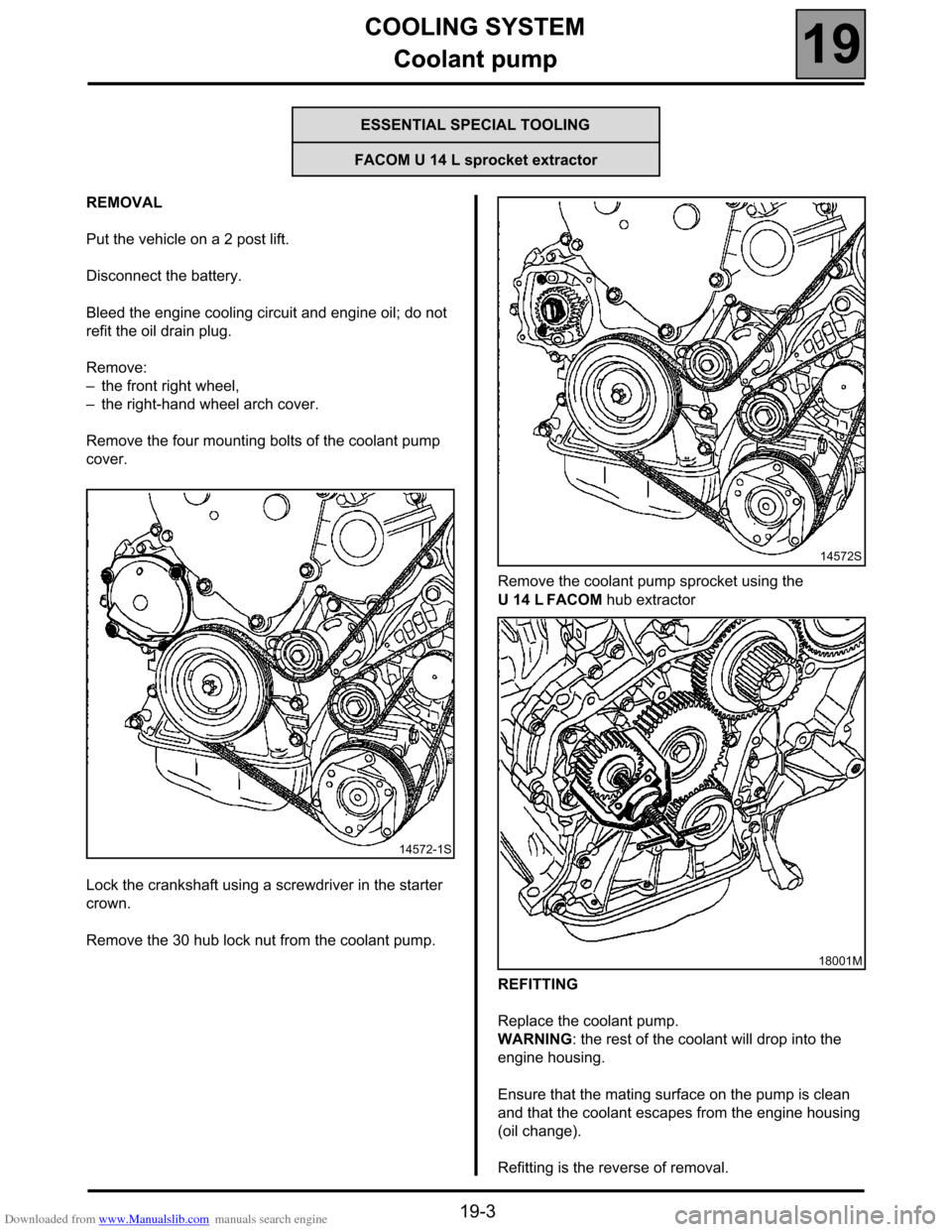

Coolant pump

REMOVAL

Put the vehicle on a 2 post lift.

Disconnect the battery.

Bleed the engine cooling circuit and engine oil; do not

refit the oil drain plug.

Remove:

–the front right wheel,

–the right-hand wheel arch cover.

Remove the four mounting bolts of the coolant pump

cover.

Lock the crankshaft using a screwdriver in the starter

crown.

Remove the 30 hub lock nut from the coolant pump.Remove the coolant pump sprocket using the

U 14 L FACOM hub extractor

REFITTING

Replace the coolant pump.

WARNING: the rest of the coolant will drop into the

engine housing.

Ensure that the mating surface on the pump is clean

and that the coolant escapes from the engine housing

(oil change).

Refitting is the reverse of removal.

ESSENTIAL SPECIAL TOOLING

FACOM U 14 L sprocket extractor

14572-1S

14572S

18001M

Page 51 of 52

Downloaded from www.Manualslib.com manuals search engine HEATING

Additional heating

61

61-6

MAINTENANCE

The principal maintenance operations on this

assembly are:

–replacing the ignition spark plug (5),

–cleaning the filter at the pump inlet (13) (see

page 61-2).

REMOVING - REFITTING COMPONENTS

FUEL PUMP INLET FILTER (13)

Remove the front bumper.

Rotate the pump (12) (see page 61-2) if it turns and

loosen the union covering the filter (13). Clean or

replace the filter if there is a combustion problem.

IGNITION SPARK PLUG

Disconnect and remove the heater without draining the

cooling circuit (use pliers Mot. 453-01).

Remove:

–the turbine cover (1),

–the control unit (9) and the cap (16),

–the spark plug (5) after disconnecting it.

FLAME DETECTOR

Disconnect and remove the heater without draining the

cooling circuit (use pliers Mot. 453-01).

Remove:

–the turbine cover (1),

–the control unit (9) and the cap (16).

Disconnect the flame connector by pulling the flat

terminals from the connector.

Remove the flame detector.

(WARNING: fragile part)COMBUSTION CHAMBER (4) AND EXCHANGER (3)

Remove:

–the flame detector and spark plug,

–the wiring harness fitted on the overheating

detector (8) and the temperature sensor (7),

–the turbine support (1).

Remove the combustion chamber (4) and the

exchanger (3) if necessary.

FAULT FINDING

In case of a fault, check:

–if there is fuel in the tank,

–if the fuses are intact

–if the pipes, connections and electrical unions are

intact,

–if the combustion air ducts or exhaust gas ducts are

blocked (unblock them if necessary).

In the even of combustion with the production of soot,

check:

–if the combustion air ducts or exhaust gas ducts are

blocked (unblock them if necessary),

–if there is a deposit in the exchanger (3) or the

combustion chamber (4); clean these if necessary,

–if the dosing pump flow is correct;

To do this:

●remove the bumper,

●disconnect the electric pump inlet fuel pipe (12),

from the side opposite the fuel filter (13),

●connect a pipe to the electric pump so that the flow

can be collected in a glass at the same height as

the heater,

●start the heater (if necessary, bridge the

temperature sensor located in front of the battery

screen). After approximately 40 seconds, the fuel

arrives and begins to bleed the circuit. Switch off

the ignition. Empty the glass and start again,

collecting the stabilised flow for approximately

30 seconds. Switch off the heater and measure the

quantity of fuel collected.

Normal flow: between 6.8 cm

3 and 7.8 cm3 for

90 seconds of operation.