Downloaded from www.Manualslib.com manuals search engine TURBOCHARGING

Turbocharger

12

12-2

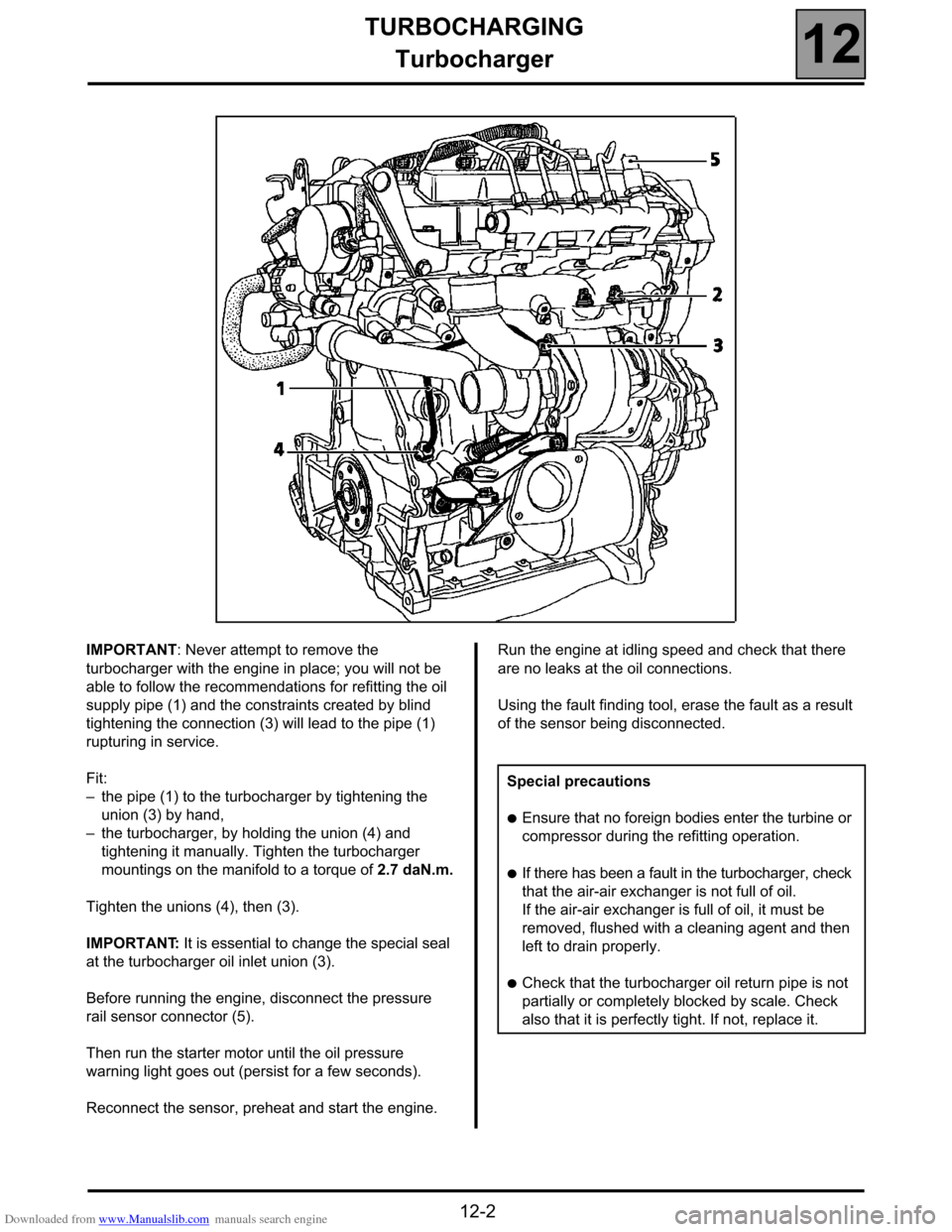

IMPORTANT: Never attempt to remove the

turbocharger with the engine in place; you will not be

able to follow the recommendations for refitting the oil

supply pipe (1) and the constraints created by blind

tightening the connection (3) will lead to the pipe (1)

rupturing in service.

Fit:

–the pipe (1) to the turbocharger by tightening the

union (3) by hand,

–the turbocharger, by holding the union (4) and

tightening it manually. Tighten the turbocharger

mountings on the manifold to a torque of 2.7 daN.m.

Tighten the unions (4), then (3).

IMPORTANT: It is essential to change the special seal

at the turbocharger oil inlet union (3).

Before running the engine, disconnect the pressure

rail sensor connector (5).

Then run the starter motor until the oil pressure

warning light goes out (persist for a few seconds).

Reconnect the sensor, preheat and start the engine.Run the engine at idling speed and check that there

are no leaks at the oil connections.

Using the fault finding tool, erase the fault as a result

of the sensor being disconnected.

Special precautions

●Ensure that no foreign bodies enter the turbine or

compressor during the refitting operation.

●If there has been a fault in the turbocharger, check

that the air-air exchanger is not full of oil.

If the air-air exchanger is full of oil, it must be

removed, flushed with a cleaning agent and then

left to drain properly.

●Check that the turbocharger oil return pipe is not

partially or completely blocked by scale. Check

also that it is perfectly tight. If not, replace it.