check engine RENAULT KANGOO Z.E. 2018 User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2018, Model line: KANGOO Z.E., Model: RENAULT KANGOO Z.E. 2018Pages: 230, PDF Size: 5.03 MB

Page 140 of 230

3.12

AIR CONDITIONING: information and operating instructions (1/2)

Do not open the refriger-

ant fluid circuit. The fluid

may damage eyes or skin.

Operating faults

As a general rule, contact your ap-

proved Dealer in the event of an oper-

ating fault.

– Reduction in de-icing, demisting or air conditioning performance.

This may be caused by the passen-

ger compartment filter cartridge be-

coming clogged.

– No cold air is being produced.

Check that the controls are set cor-

rectly and that the fuses are sound.

Otherwise, switch off the system.

Range

It is normal to notice an increase in

energy usage when the air conditioning

is operating.

Switch off the system when it is not re-

quired.

Advice for reducing consumption

and helping to preserve the environ-

ment

Drive with the air vents on and the win-

dows closed.

If the vehicle has been parked in the

sun, open the doors for a few moments

to let the hot air escape before starting

the engine.

MaintenanceRefer to the Maintenance Document

for your vehicle for the inspection fre-

quency.

Below approximately 10°C, with the

engine off it is normal to notice cold

air enter the passenger compart-

ment via the vents when ventilation

has not stopped (refer to the infor-

mation on “Heating, air condition-

ing” in section 3). It is recommended

to position the ventilation control at

0 in case of brief stops.

Presence of water under the

vehicle.

After prolonged use of the air condi-

tioning system, it is normal for water

to be present under the vehicle. This is

caused by condensation.

Noise

Each time the ignition is switched off,

the ventilation will be switched off after

about ten seconds.

Vehicles equipped with

mode ECO

Once activated, ECO mode may

reduce air conditioning perform-

ance. Please refer to the informa-

tion on “Driving advice, Eco-driving”

in Section 2.

Use the air conditioning system reg-

ularly, even in cold weather, running

it at least once a month for approxi-

mately 5 minutes.

Page 157 of 230

4.3

Ensure that the bonnet is

properly locked.

Check that nothing is pre-

venting the catch from lock-

ing (gravel, cloth, etc.).

BONNET (2/2)

Closing the bonnet

Check that nothing has been left in the

engine compartment.

To close the bonnet again, hold the

bonnet in the middle and lower it to 30

cm above the closed position, then re-

lease it.

After carrying out any work

in the engine compart-

ment, check that nothing

has been left behind (cloth,

tools, etc.).

These may damage the engine or

cause a fire.

In the event of even a slight

impact involving the radia-

tor grille or bonnet, have

the bonnet lock checked by

an approved dealer as soon as pos-

sible.

Page 158 of 230

4.4

Replacement intervals

Refer to the Maintenance Document for

your vehicle.

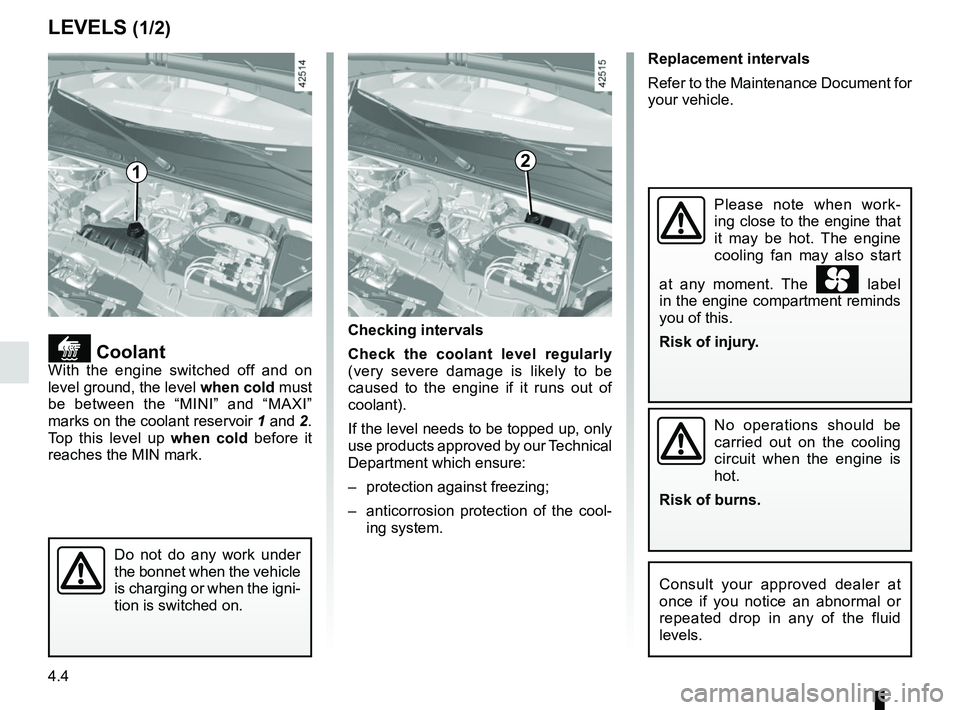

LEVELS (1/2)

CoolantWith the engine switched off and on

level ground, the level when cold must

be between the “MINI” and “MAXI”

marks on the coolant reservoir 1 and 2.

Top this level up when cold before it

reaches the MIN mark. Checking intervals

Check the coolant level regularly

(very severe damage is likely to be

caused to the engine if it runs out of

coolant).

If the level needs to be topped up, only

use products approved by our Technical

Department which ensure:

– protection against freezing;

– anticorrosion protection of the cool-

ing system.

No operations should be

carried out on the cooling

circuit when the engine is

hot.

Risk of burns.

Consult your approved dealer at

once if you notice an abnormal or

repeated drop in any of the fluid

levels.

12

Do not do any work under

the bonnet when the vehicle

is charging or when the igni-

tion is switched on.

Please note when work-

ing close to the engine that

it may be hot. The engine

cooling fan may also start

at any moment. The

label

in the engine compartment reminds

you of this.

Risk of injury.

Page 159 of 230

4.5

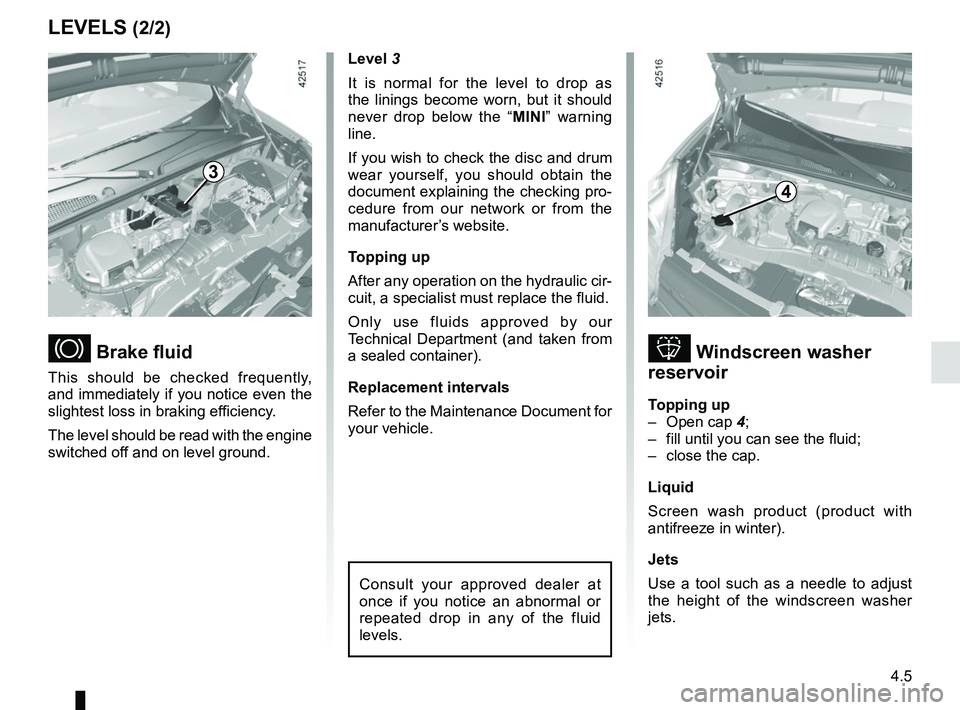

Windscreen washer

reservoir

Topping up

– Open cap 4;

– fill until you can see the fluid;

– close the cap.

Liquid

Screen wash product (product with

antifreeze in winter).

Jets

Use a tool such as a needle to adjust

the height of the windscreen washer

jets.

4

Level 3

It is normal for the level to drop as

the linings become worn, but it should

never drop below the “ MINI” warning

line.

If you wish to check the disc and drum

wear yourself, you should obtain the

document explaining the checking pro-

cedure from our network or from the

manufacturer’s website.

Topping up

After any operation on the hydraulic cir-

cuit, a specialist must replace the fluid.

Only use fluids approved by our

Technical Department (and taken from

a sealed container).

Replacement intervals

Refer to the Maintenance Document for

your vehicle.

Consult your approved dealer at

once if you notice an abnormal or

repeated drop in any of the fluid

levels.

Brake fluid

This should be checked frequently,

and immediately if you notice even the

slightest loss in braking efficiency.

The level should be read with the engine

switched off and on level ground.

3

LEVELS (2/2)

Page 166 of 230

4.12

Using a roller type car wash

Return the windscreen wiper stalk to

the Park position (refer to the informa-

tion on the “Windscreen washer, wiper”

in Section 1). Check the mounting of

external accessories, additional lights

and mirrors, and ensure that the wiper

blades are secured with adhesive tape.

Remove the radio aerial mast if your

vehicle is fitted with this equipment.

Remember to remove the tape and refit

the antenna after washing.

BODYWORK MAINTENANCE (3/3)Cleaning the headlights

As the headlights are made of plastic

“glass”, use a soft cloth or cotton wool

to clean them. If this does not clean

them properly, moisten the cloth with

soapy water, then wipe clean with a soft

damp cloth or cotton wool.

Finally, carefully dry off with a soft dry

cloth.

Do not use cleaning products con-

taining alcohol or utensils (e.g.: a

scraper).

Washing the vehicle

Never wash the engine

compartment, the charging

connection or the traction

battery with a high-pressure jet.

This risks damaging the electric cir-

cuit.

Never wash the vehicle while it is

charging.

Risk of electric shock and a risk to

life.

Vehicles with a matte paint

finish

This type of paint requires certain pre-

cautions.

Do not do the following

Use wax-based products (polishing).

Rub too hard.

Wash the vehicle in a roller-type car

wash.

Wash the vehicle using a high-pressure

device.

Attach stickers to the paintwork (risk of

leaving marks).

Wash the vehicle

using a high-pressure

cleaning device.

You should do the following

Wash the vehicle by hand using plenty

of water, using a soft cloth or a gentle

sponge.

Page 189 of 230

5.21

To comply with local legislation, or

as a precaution, you can obtain an

emergency kit containing a set of

spare bulbs and fuses from an ap-

proved Dealer.

FUSES (1/2)

Fuse box

If any electrical component does not

work, check the condition of the fuses.

Unclip cover A. To locate the fuses, please see the fol-

lowing page.

It is not advisable to use the free fuse

locations.

Some functions are protected by fuses

located in the engine compartment.

However, because of their reduced ac-

cessibility,

it is recommended to have

these fuses replaced by an autho-

rised dealer.

Check the fuse in question and replace it, if necessary, with a fuse of

the same rating.

If a fuse is fitted where the rating is too high, it may cause the elect\

rical

circuit to overheat (risk of fire) in the event of an item of equipmen\

t using

an excessive amount of current.

A

1

Tweezers 1

Remove the fuse using tweezers 1, lo-

cated at the back of cover A.

To remove the fuse from the tweezers,

slide the fuse to the side.

Page 205 of 230

6.1

Section 6: Technical specifications

Vehicle identification plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . 6.2

Engine identification plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . . . . . . 6.3

Engine specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . 6.3

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.4

Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.6

Replacement parts and repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . 6.7

Service sheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.8

Anticorrosion check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . 6.14