RENAULT MASTER 2016 X62 / 2.G Owners Manual

Manufacturer: RENAULT, Model Year: 2016, Model line: MASTER, Model: RENAULT MASTER 2016 X62 / 2.GPages: 284, PDF Size: 6.69 MB

Page 221 of 284

5.13

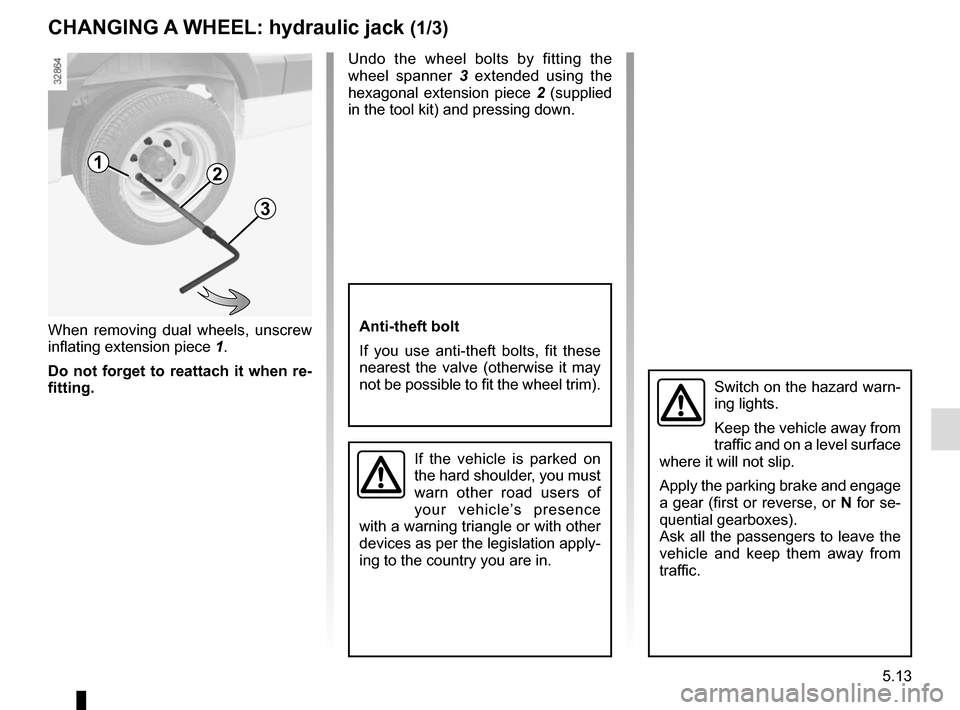

When removing dual wheels, unscrew

inflating extension piece 1.

Do not forget to reattach it when re-

fitting. Undo the wheel bolts by fitting the

wheel spanner

3 extended using the

hexagonal extension piece 2 (supplied

in the tool kit) and pressing down.

1

CHANGING A WHEEL: hydraulic jack (1/3)

Switch on the hazard warn-

ing lights.

Keep the vehicle away from

traffic and on a level surface

where it will not slip.

Apply the parking brake and engage

a gear (first or reverse, or N for se-

quential gearboxes).

Ask all the passengers to leave the

vehicle and keep them away from

traffic.

If the vehicle is parked on

the hard shoulder, you must

warn other road users of

your vehicle’s presence

with a warning triangle or with other

devices as per the legislation apply-

ing to the country you are in.

Anti-theft bolt

If you use anti-theft bolts, fit these

nearest the valve (otherwise it may

not be possible to fit the wheel trim).

2

3

Page 222 of 284

5.14

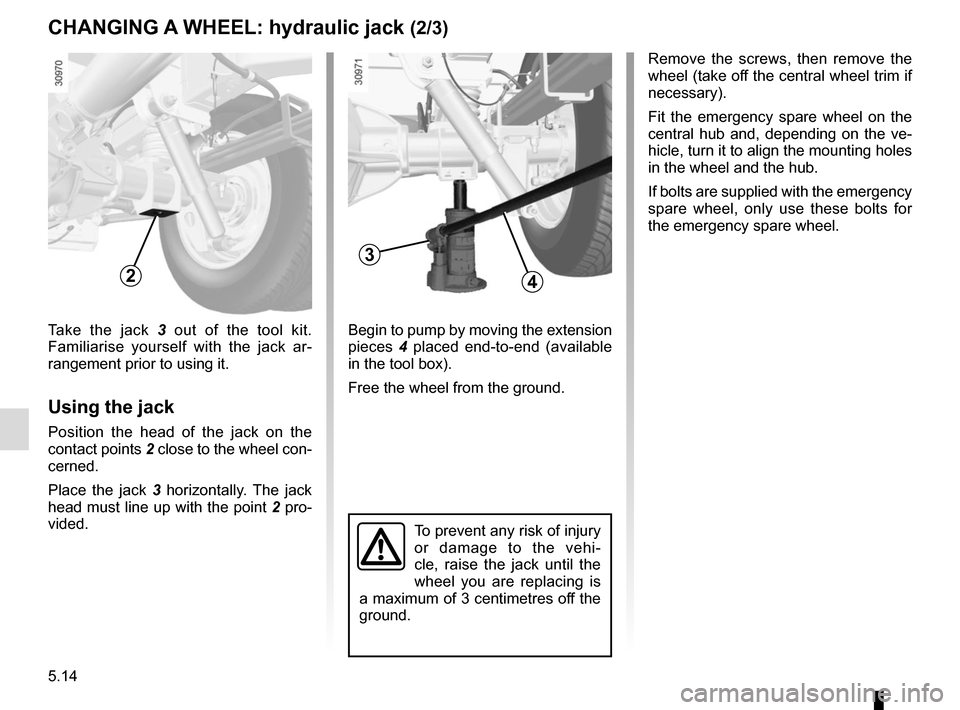

Begin to pump by moving the extension

pieces 4 placed end-to-end (available

in the tool box).

Free the wheel from the ground.Take the jack 3 out of the tool kit.

Familiarise yourself with the jack ar-

rangement prior to using it.

Using the jack

Position the head of the jack on the

contact points 2 close to the wheel con- cerned.

Place the jack 3 horizontally. The jack

head must line up with the point 2 pro-

vided.

3

CHANGING A WHEEL: hydraulic jack (2/3)

24

To prevent any risk of injury

or damage to the vehi-

cle, raise the jack until the

wheel you are replacing is

a maximum of 3 centimetres off the

ground.

Remove the screws, then remove the

wheel (take off the central wheel trim if

necessary).

Fit the emergency spare wheel on the

central hub and, depending on the ve-

hicle, turn it to align the mounting holes

in the wheel and the hub.

If bolts are supplied with the emergency

spare wheel, only use these bolts for

the emergency spare wheel.

Page 223 of 284

5.15

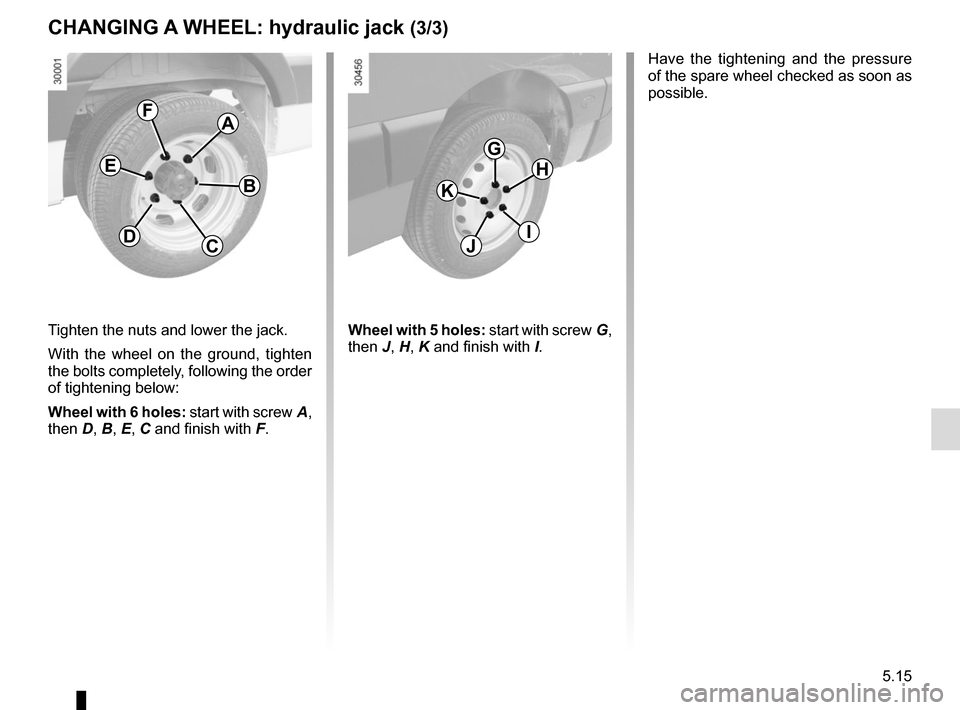

Tighten the nuts and lower the jack.

With the wheel on the ground, tighten

the bolts completely, following the order

of tightening below:

Wheel with 6 holes: start with screw A,

then D, B, E, C and finish with F.

A

B

CD

E

F

G

I

K

H

J

CHANGING A WHEEL: hydraulic jack (3/3)

Have the tightening and the pressure

of the spare wheel checked as soon as

possible.

Wheel with 5 holes: start with screw G,

then J, H, K and finish with I.

Page 224 of 284

5.16

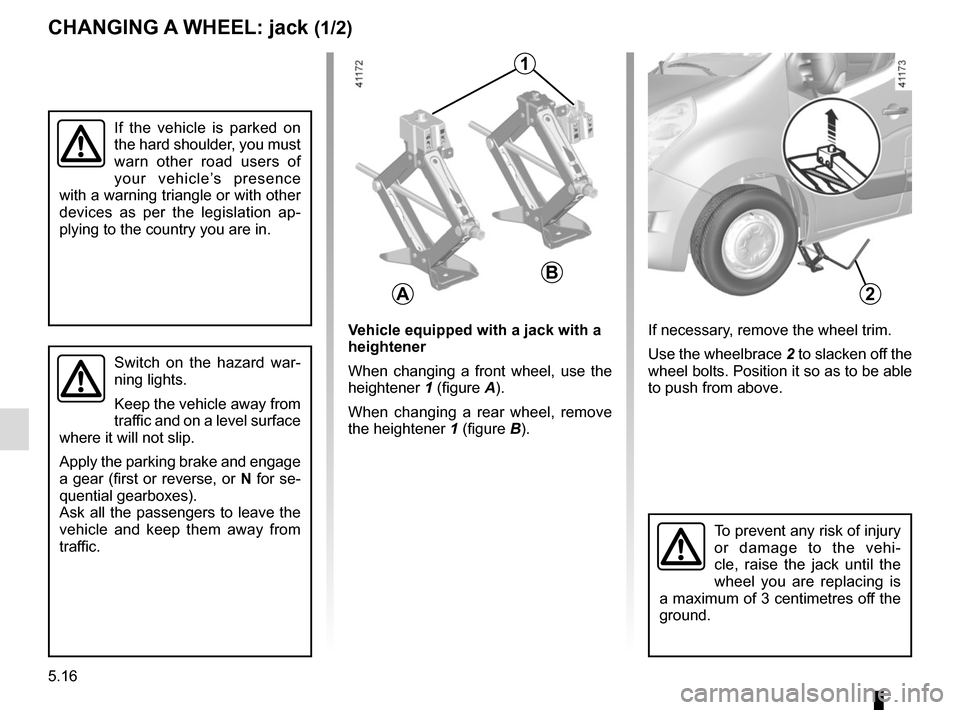

CHANGING A WHEEL: jack (1/2)

2

If the vehicle is parked on

the hard shoulder, you must

warn other road users of

your vehicle’s presence

with a warning triangle or with other

devices as per the legislation ap-

plying to the country you are in.

Switch on the hazard war-

ning lights.

Keep the vehicle away from

traffic and on a level surface

where it will not slip.

Apply the parking brake and engage

a gear (first or reverse, or N for se-

quential gearboxes).

Ask all the passengers to leave the

vehicle and keep them away from

traffic.

To prevent any risk of injury

or damage to the vehi-

cle, raise the jack until the

wheel you are replacing is

a maximum of 3 centimetres off the

ground.

If necessary, remove the wheel trim.

Use the wheelbrace 2 to slacken off the

wheel bolts. Position it so as to be able

to push from above.Vehicle equipped with a jack with a

heightener

When changing a front wheel, use the

heightener 1 (figure A).

When changing a rear wheel, remove

the heightener 1 (figure B).

A

B

1

Page 225 of 284

5.17

CHANGING A WHEEL: jack (2/2)

If you have a puncture, re-

place the wheel as soon as

possible.

A tyre which has been

punctured should always be inspec-

ted (and repaired, where possible)

by a specialist.

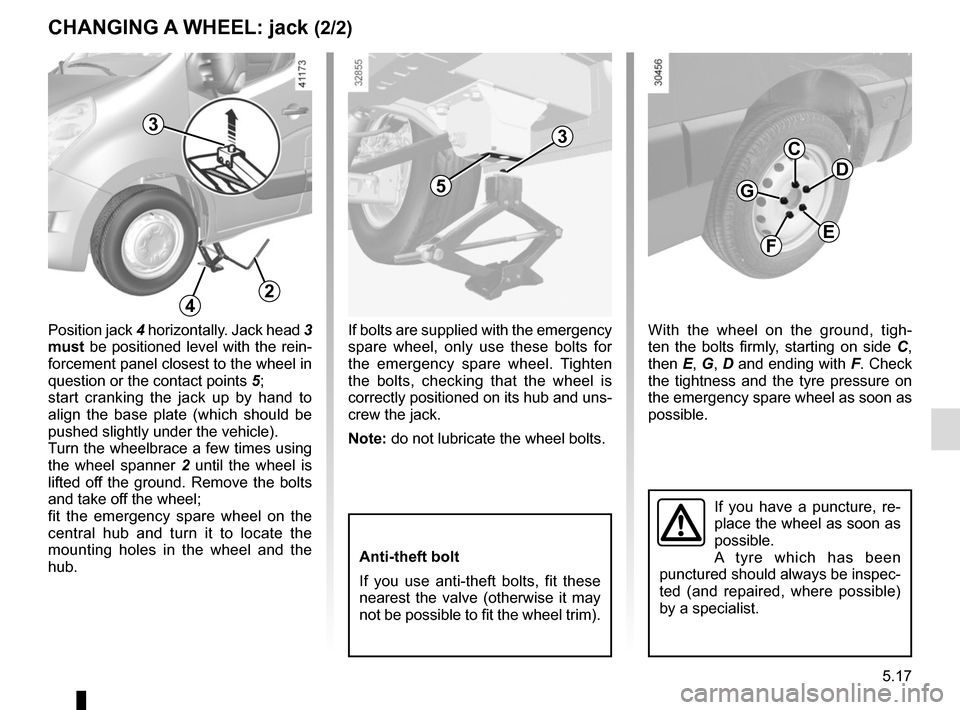

With the wheel on the ground, tigh-

ten the bolts firmly, starting on side C,

then E, G, D and ending with F. Check

the tightness and the tyre pressure on

the emergency spare wheel as soon as

possible.

C

E

G

D

F

If bolts are supplied with the emergency

spare wheel, only use these bolts for

the emergency spare wheel. Tighten

the bolts, checking that the wheel is

correctly positioned on its hub and uns-

crew the jack.

Note: do not lubricate the wheel bolts.

Anti-theft bolt

If you use anti-theft bolts, fit these

nearest the valve (otherwise it may

not be possible to fit the wheel trim).

Position jack 4 horizontally. Jack head 3

must be positioned level with the rein-

forcement panel closest to the wheel in

question or the contact points 5;

start cranking the jack up by hand to

align the base plate (which should be

pushed slightly under the vehicle).

Turn the wheelbrace a few times using

the wheel spanner 2 until the wheel is

lifted off the ground. Remove the bolts

and take off the wheel;

fit the emergency spare wheel on the

central hub and turn it to locate the

mounting holes in the wheel and the

hub.

3

5

3

24

Page 226 of 284

5.18

TYRES (1/3)

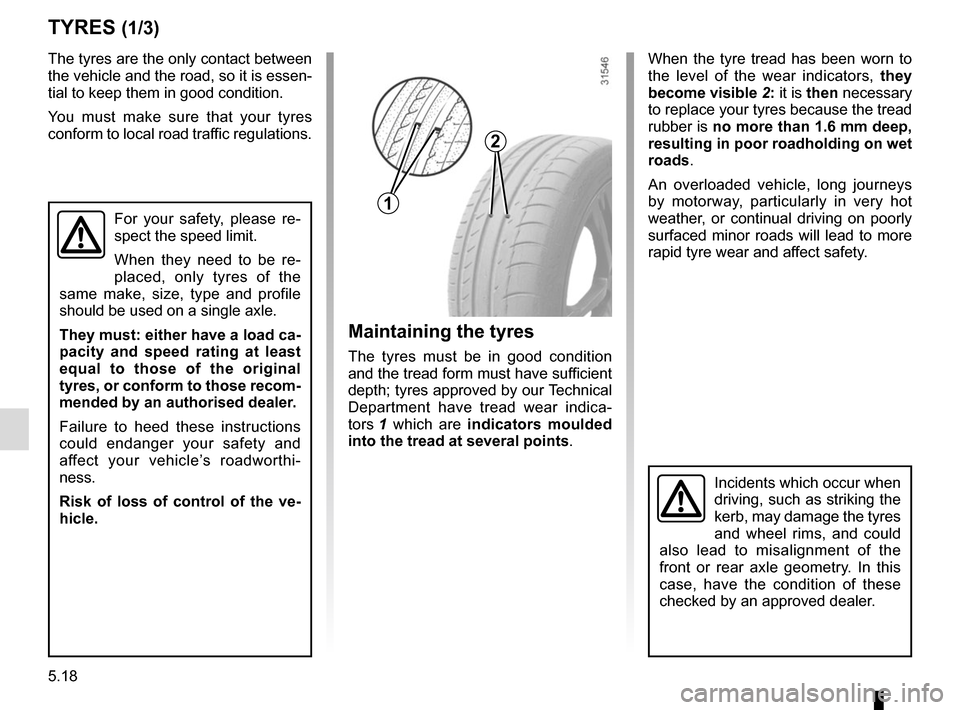

Maintaining the tyres

The tyres must be in good condition

and the tread form must have sufficient

depth; tyres approved by our Technical

Department have tread wear indica-

tors 1 which are indicators moulded

into the tread at several points .

The tyres are the only contact between

the vehicle and the road, so it is essen-

tial to keep them in good condition.

You must make sure that your tyres

conform to local road traffic regulations.

When the tyre tread has been worn to

the level of the wear indicators,

they

become visible 2: it is then necessary

to replace your tyres because the tread

rubber is no more than 1.6 mm deep,

resulting in poor roadholding on wet

roads.

An overloaded vehicle, long journeys

by motorway, particularly in very hot

weather, or continual driving on poorly

surfaced minor roads will lead to more

rapid tyre wear and affect safety.

For your safety, please re-

spect the speed limit.

When they need to be re-

placed, only tyres of the

same make, size, type and profile

should be used on a single axle.

They must: either have a load ca-

pacity and speed rating at least

equal to those of the original

tyres, or conform to those recom-

mended by an authorised dealer.

Failure to heed these instructions

could endanger your safety and

affect your vehicle’s roadworthi-

ness.

Risk of loss of control of the ve-

hicle.

Incidents which occur when

driving, such as striking the

kerb, may damage the tyres

and wheel rims, and could

also lead to misalignment of the

front or rear axle geometry. In this

case, have the condition of these

checked by an approved dealer.

1

2

Page 227 of 284

5.19

Fitting new tyres

TYRES (2/3)

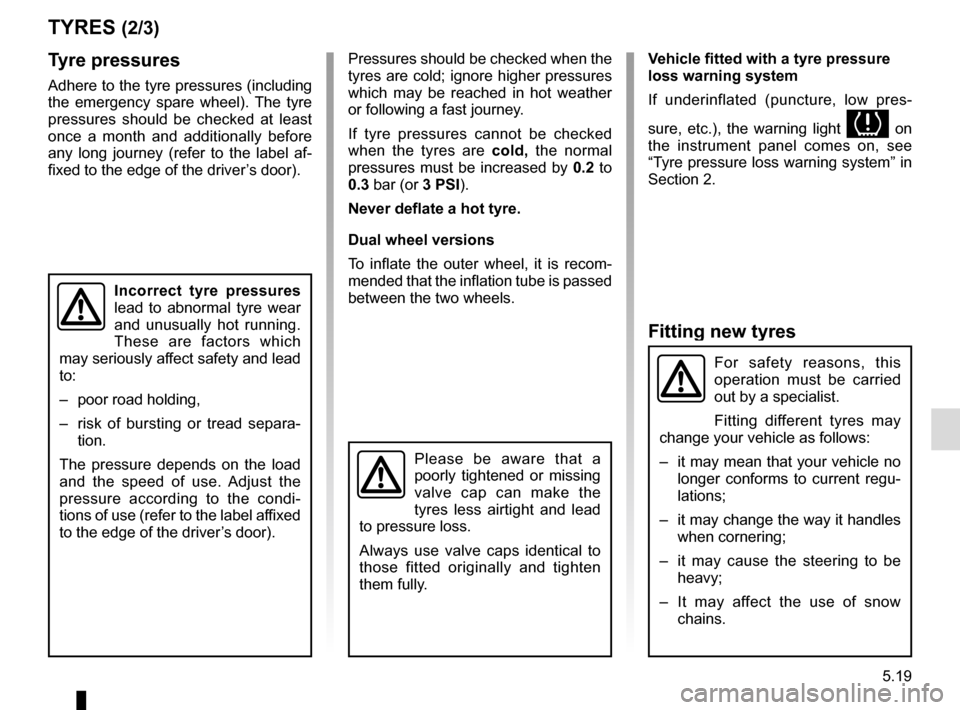

Tyre pressures

Adhere to the tyre pressures (including

the emergency spare wheel). The tyre

pressures should be checked at least

once a month and additionally before

any long journey (refer to the label af-

fixed to the edge of the driver’s door).

Incorrect tyre pressures

lead to abnormal tyre wear

and unusually hot running.

These are factors which

may seriously affect safety and lead

to:

– poor road holding,

– risk of bursting or tread separa- tion.

The pressure depends on the load

and the speed of use. Adjust the

pressure according to the condi-

tions of use (refer to the label affixed

to the edge of the driver’s door).

Please be aware that a

poorly tightened or missing

valve cap can make the

tyres less airtight and lead

to pressure loss.

Always use valve caps identical to

those fitted originally and tighten

them fully.

For safety reasons, this

operation must be carried

out by a specialist.

Fitting different tyres may

change your vehicle as follows:

– it may mean that your vehicle no longer conforms to current regu-

lations;

– it may change the way it handles when cornering;

– it may cause the steering to be heavy;

– It may affect the use of snow chains.

Pressures should be checked when the

tyres are cold; ignore higher pressures

which may be reached in hot weather

or following a fast journey.

If tyre pressures cannot be checked

when the tyres are cold, the normal

pressures must be increased by 0.2 to

0.3 bar (or 3 PSI).

Never deflate a hot tyre.

Dual wheel versions

To inflate the outer wheel, it is recom-

mended that the inflation tube is passed

between the two wheels. Vehicle fitted with a tyre pressure

loss warning system

If underinflated (puncture, low pres-

sure, etc.), the warning light

on

the instrument panel comes on, see

“Tyre pressure loss warning system” in

Section 2.

Page 228 of 284

5.20

TYRES (3/3)

Changing wheels around

This practice is not recommended.

Emergency spare wheel

Refer to the information on the

“Emergency spare wheel” and

“Changing a wheel” in Section 5.

Use in winter

Chains

Chains must not be fitted to tyres

which are larger than those originally

fitted to the vehicle.

Chains may only be fitted

to tyres of the same size

as those originally fitted to

your vehicle.

Only certain chains can be fitted to

tyres. Consult an approved Dealer.

Front wheel drive versions

For safety reasons, fitting snow

chains to the rear axle is strictly for-

bidden.

Rear wheel drive versions

For safety reasons, only fit chains

on the rear axle.

Note: for rear wheel drive, dual wheel

versions, fit chains on the outer rear

wheels.

Snow or winter tyres

We would recommend that these be

fitted to all four wheels to ensure that

your vehicle retains maximum grip.

Note: be aware that these tyres may

sometimes have:

– a direction of travel ;

– a maximum speed index which may be lower than the maximum speed of

your vehicle.

In all cases, we would recommend

that you contact an approved dealer

who will be able to advise you on

the choice of equipment which is

most suitable for your vehicle.

Studded tyres

This type of equipment may only be

used for a limited period and as laid

down by local legislation.

It is necessary to observe the speed

specified by current legislation.

These tyres must, as a minimum, be

fitted to the two wheels on the front

axle for front wheel drive versions and

all the rear wheels for rear wheel drive

versions.

Page 229 of 284

5.21

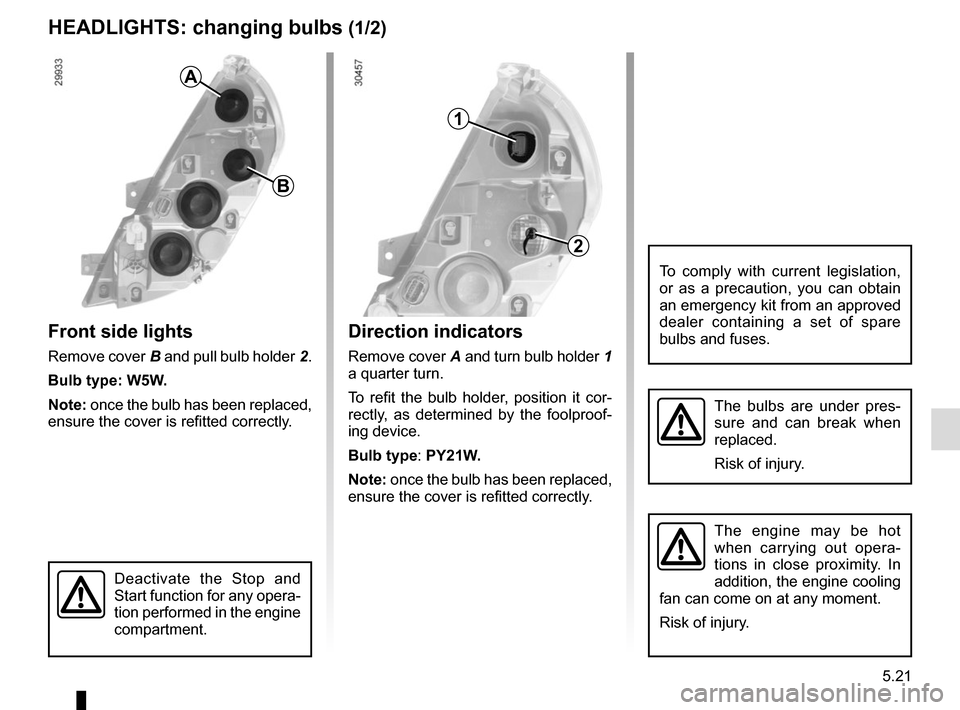

Direction indicators

Remove cover A and turn bulb holder 1

a quarter turn.

To refit the bulb holder, position it cor-

rectly, as determined by the foolproof-

ing device.

Bulb type: PY21W.

Note: once the bulb has been replaced,

ensure the cover is refitted correctly.

HEADLIGHTS: changing bulbs (1/2)

Front side lights

Remove cover B and pull bulb holder 2.

Bulb type: W5W.

Note: once the bulb has been replaced,

ensure the cover is refitted correctly.

The bulbs are under pres-

sure and can break when

replaced.

Risk of injury.

To comply with current legislation,

or as a precaution, you can obtain

an emergency kit from an approved

dealer containing a set of spare

bulbs and fuses.

B

A

2

1

The engine may be hot

when carrying out opera-

tions in close proximity. In

addition, the engine cooling

fan can come on at any moment.

Risk of injury.

Deactivate the Stop and

Start function for any opera-

tion performed in the engine

compartment.

Page 230 of 284

5.22

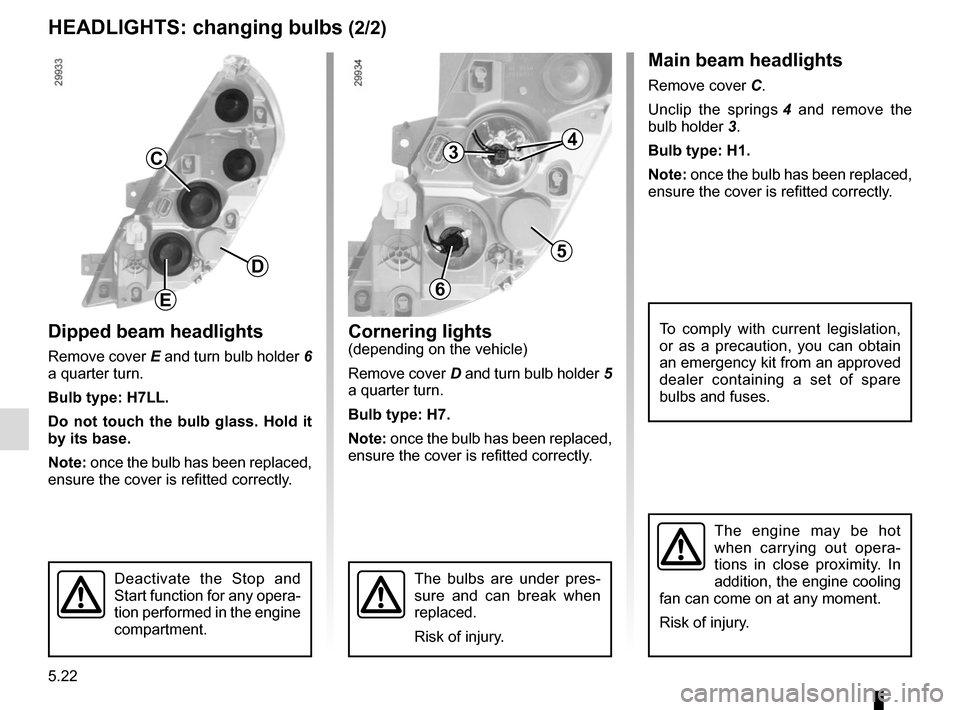

Dipped beam headlights

Remove cover E and turn bulb holder 6

a quarter turn.

Bulb type: H7LL.

Do not touch the bulb glass. Hold it

by its base.

Note: once the bulb has been replaced,

ensure the cover is refitted correctly.

Main beam headlights

Remove cover C.

Unclip the springs 4 and remove the

bulb holder 3.

Bulb type: H1.

Note: once the bulb has been replaced,

ensure the cover is refitted correctly.

The bulbs are under pres-

sure and can break when

replaced.

Risk of injury.

To comply with current legislation,

or as a precaution, you can obtain

an emergency kit from an approved

dealer containing a set of spare

bulbs and fuses.

HEADLIGHTS: changing bulbs (2/2)

Cornering lights

(depending on the vehicle)

Remove cover D and turn bulb holder 5

a quarter turn.

Bulb type: H7.

Note: once the bulb has been replaced,

ensure the cover is refitted correctly.

C

D

E

3

5

6

4

The engine may be hot

when carrying out opera-

tions in close proximity. In

addition, the engine cooling

fan can come on at any moment.

Risk of injury.

Deactivate the Stop and

Start function for any opera-

tion performed in the engine

compartment.