check engine RENAULT MASTER 2016 X62 / 2.G Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2016, Model line: MASTER, Model: RENAULT MASTER 2016 X62 / 2.GPages: 284, PDF Size: 6.69 MB

Page 193 of 284

4.3

BONNET (2/2)

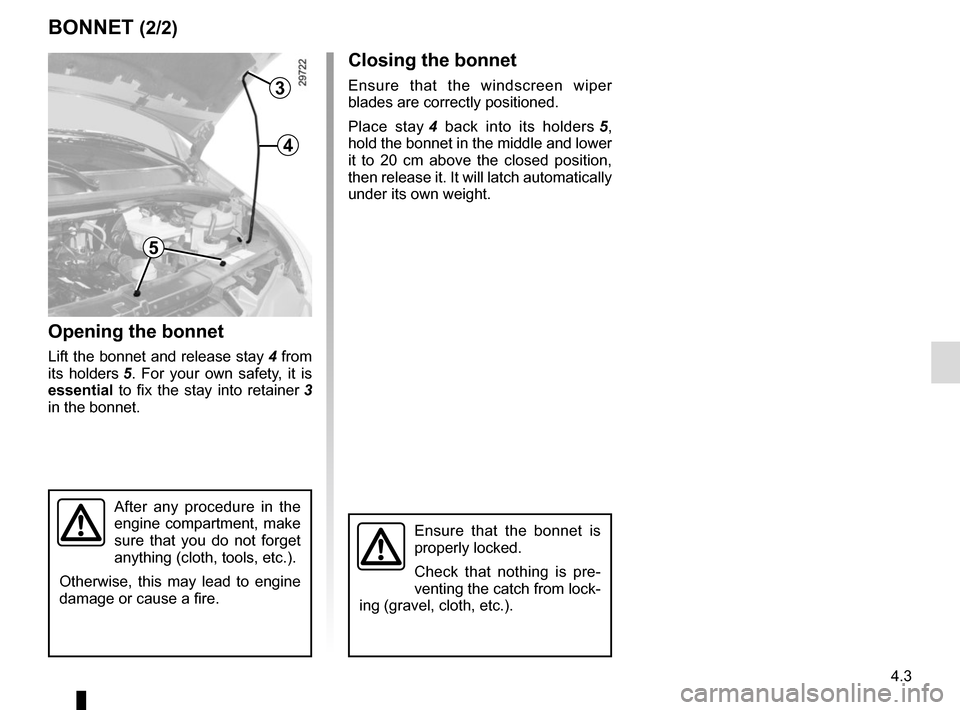

3

4

5

Closing the bonnet

Ensure that the windscreen wiper

blades are correctly positioned.

Place stay 4 back into its holders 5,

hold the bonnet in the middle and lower

it to 20 cm above the closed position,

then release it. It will latch automatically

under its own weight.

Ensure that the bonnet is

properly locked.

Check that nothing is pre-

venting the catch from lock-

ing (gravel, cloth, etc.).

Opening the bonnet

Lift the bonnet and release stay 4 from

its holders 5. For your own safety, it is

essential to fix the stay into retainer 3

in the bonnet.

After any procedure in the

engine compartment, make

sure that you do not forget

anything (cloth, tools, etc.).

Otherwise, this may lead to engine

damage or cause a fire.

Page 194 of 284

4.4

ENGINE OIL LEVEL: general information (1/2)

If the level is at the minimum

The “TOP-UP OIL LEVEL” message

and warning light

© are displayed

on the instrument panel.

It is vital to top up the oil as soon as

possible.

The display only warns the

driver if the oil level is at the

minimum level. It does not

inform the driver that the oil

level has exceeded the maximum

level as this can only be measured

using a dipstick.

It is normal for an engine to use oil for

lubrication and cooling of moving parts

and it is normal to top up the level be-

tween oil changes.

However, contact an approved Dealer

if more than 0.5 litres is being consu-

med every 600 miles (1,000 km) after

the running in period.

Oil change frequency: check the oil

level from time to time and certainly

before any long journey to avoid the

risk of damaging your engine.

Reading the oil level

The oil level should be read with the

vehicle on level ground, after the engine

has been switched off for some time.

The dipstick must be used to read

the exact oil level and make sure

that the maximum level has not been

exceeded (risk of engine damage).

Refer to the following pages.

The instrument panel display only

alerts the driver when the oil level is at

its minimum.

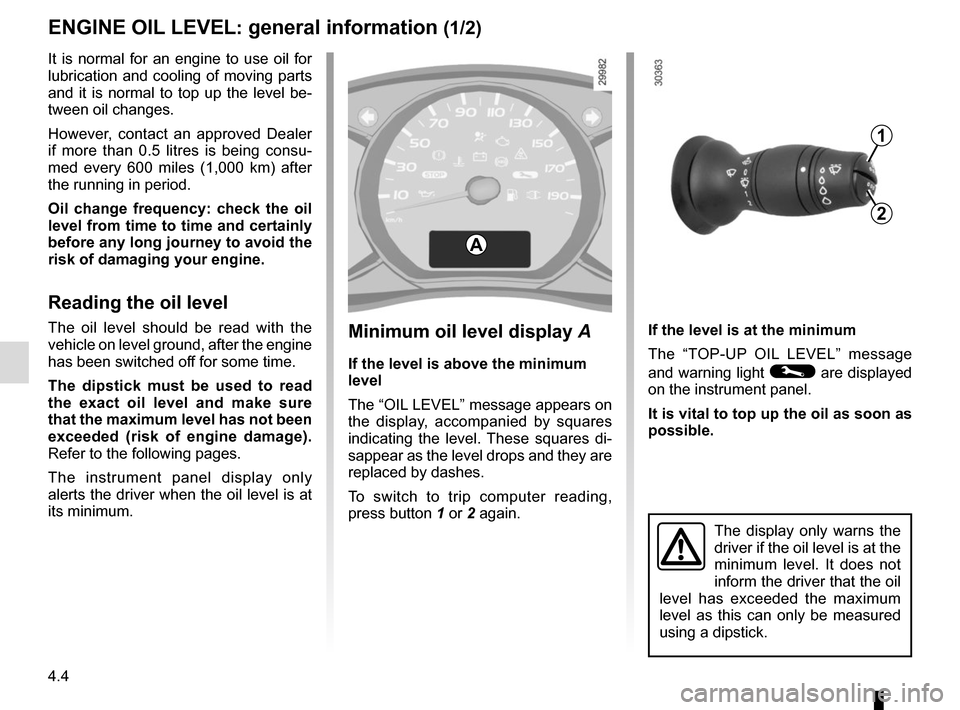

A

1

2

Minimum oil level display A

If the level is above the minimum

level

The “OIL LEVEL” message appears on

the display, accompanied by squares

indicating the level. These squares di-

sappear as the level drops and they are

replaced by dashes.

To switch to trip computer reading,

press button 1 or 2 again.

Page 196 of 284

4.6

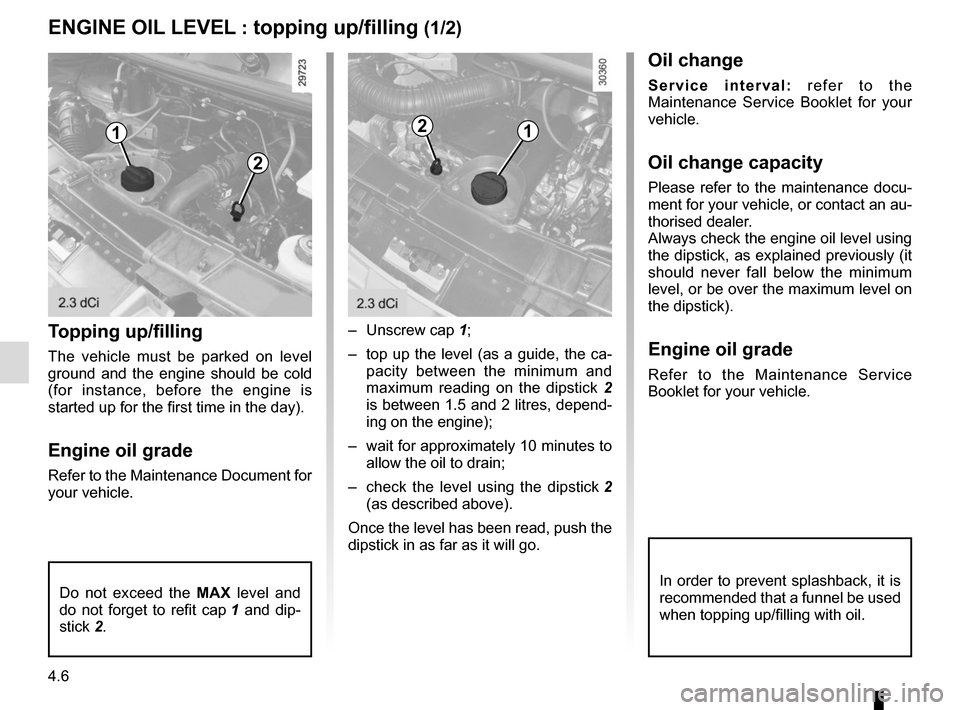

Topping up/filling

The vehicle must be parked on level

ground and the engine should be cold

(for instance, before the engine is

started up for the first time in the day).

Engine oil grade

Refer to the Maintenance Document for

your vehicle.– Unscrew cap

1;

– top up the level (as a guide, the ca- pacity between the minimum and

maximum reading on the dipstick 2

is between 1.5 and 2 litres, depend-

ing on the engine);

– wait for approximately 10 minutes to allow the oil to drain;

– check the level using the dipstick 2

(as described above).

Once the level has been read, push the

dipstick in as far as it will go.

Do not exceed the MAX level and

do not forget to refit cap 1 and dip-

stick 2.

ENGINE OIL LEVEL : topping up/filling (1/2)

In order to prevent splashback, it is

recommended that a funnel be used

when topping up/filling with oil.

1

2

12

Oil change

Service interval: refer to the

Maintenance Service Booklet for your

vehicle.

Oil change capacity

Please refer to the maintenance docu-

ment for your vehicle, or contact an au-

thorised dealer.

Always check the engine oil level using

the dipstick, as explained previously (it

should never fall below the minimum

level, or be over the maximum level on

the dipstick).

Engine oil grade

Refer to the Maintenance Service

Booklet for your vehicle.

Page 198 of 284

4.8

LEVELS (1/3)

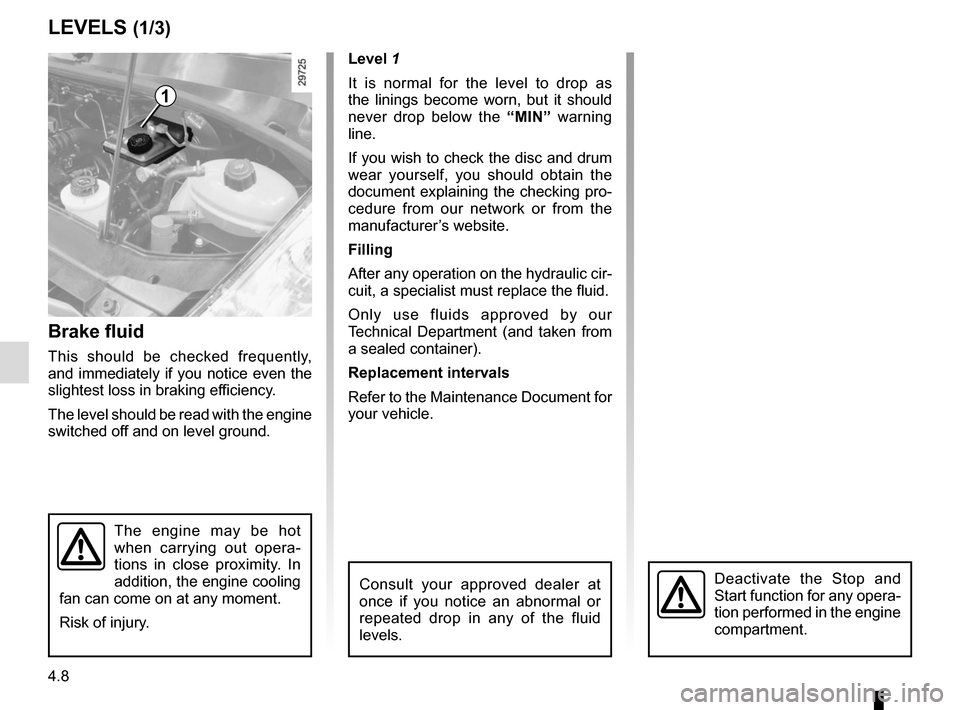

Brake fluid

This should be checked frequently,

and immediately if you notice even the

slightest loss in braking efficiency.

The level should be read with the engine

switched off and on level ground. Level 1

It is normal for the level to drop as

the linings become worn, but it should

never drop below the

“MIN” warning

line.

If you wish to check the disc and drum

wear yourself, you should obtain the

document explaining the checking pro-

cedure from our network or from the

manufacturer’s website.

Filling

After any operation on the hydraulic cir-

cuit, a specialist must replace the fluid.

Only use fluids approved by our

Technical Department (and taken from

a sealed container).

Replacement intervals

Refer to the Maintenance Document for

your vehicle.

Consult your approved dealer at

once if you notice an abnormal or

repeated drop in any of the fluid

levels.

1

The engine may be hot

when carrying out opera-

tions in close proximity. In

addition, the engine cooling

fan can come on at any moment.

Risk of injury.

Deactivate the Stop and

Start function for any opera-

tion performed in the engine

compartment.

Page 199 of 284

4.9

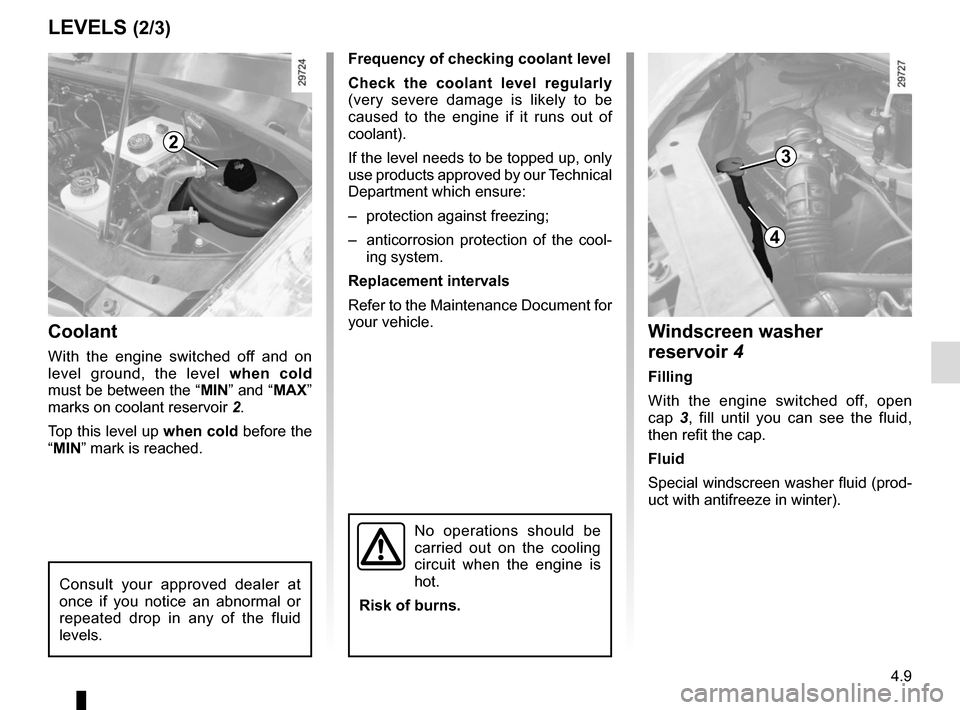

Coolant

With the engine switched off and on

level ground, the level when cold

must be between the “MIN” and “MAX”

marks on coolant reservoir 2.

Top this level up when cold before the

“MIN” mark is reached.

LEVELS (2/3)

Frequency of checking coolant level

Check the coolant level regularly

(very severe damage is likely to be

caused to the engine if it runs out of

coolant).

If the level needs to be topped up, only

use products approved by our Technical

Department which ensure:

– protection against freezing;

– anticorrosion protection of the cool- ing system.

Replacement intervals

Refer to the Maintenance Document for

your vehicle.

2

Windscreen washer

reservoir 4

Filling

With the engine switched off, open

cap 3, fill until you can see the fluid,

then refit the cap.

Fluid

Special windscreen washer fluid (prod-

uct with antifreeze in winter).

3

4

Consult your approved dealer at

once if you notice an abnormal or

repeated drop in any of the fluid

levels.

No operations should be

carried out on the cooling

circuit when the engine is

hot.

Risk of burns.

Page 203 of 284

4.13

When the ignition is off, some consu-

mers may also be switched off (dipped

beam headlights, radio, ventilation,

etc.). On the instrument panel, the mes-

sage “BATTERY MODE: ECONOMY”

appears when switched off. When the

level is extremely low, the message

“BATTERY LOW START ENGINE” is

displayed.

The charge status of the battery can

decrease, especially if you use your

vehicle:

– for short journeys;

– for driving in town;

– when the temperature drops;

– with the vehicle stopped and the engine off.

Replacing the battery

As this operation is complex, we advise

you to contact an approved Dealer.

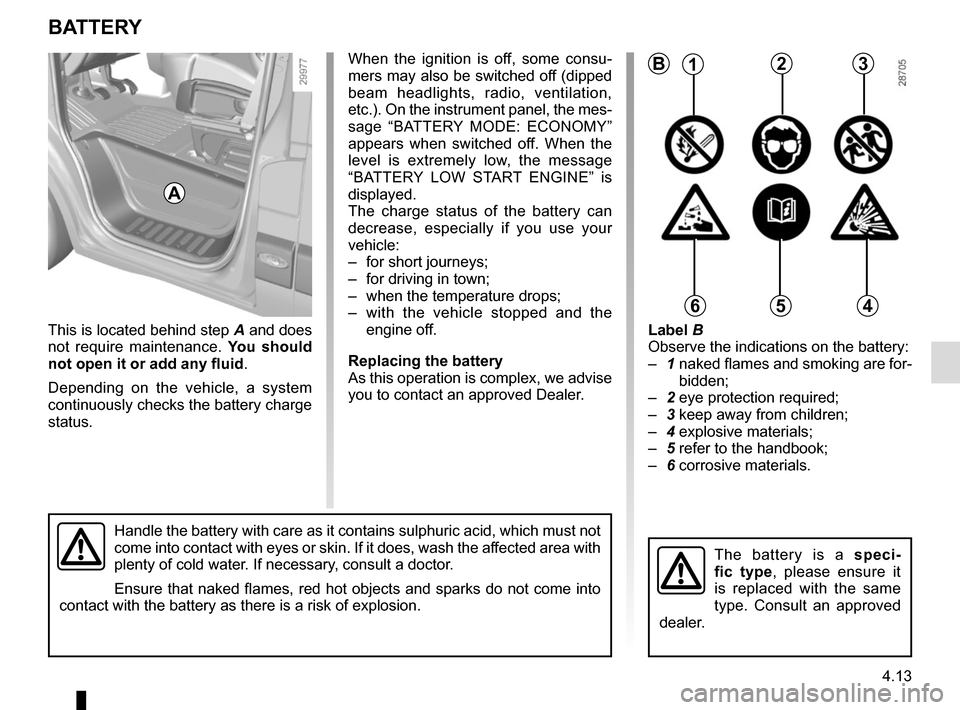

BATTERY

123

456

This is located behind step A and does

not require maintenance. You should

not open it or add any fluid .

Depending on the vehicle, a system

continuously checks the battery charge

status.

Handle the battery with care as it contains sulphuric acid, which must n\

ot

come into contact with eyes or skin. If it does, wash the affected area with

plenty of cold water. If necessary, consult a doctor.

Ensure that naked flames, red hot objects and sparks do not come into

contact with the battery as there is a risk of explosion.

Label B

Observe the indications on the battery:

– 1 naked flames and smoking are for-

bidden;

– 2 eye protection required;

– 3 keep away from children;

– 4 explosive materials;

– 5 refer to the handbook;

– 6 corrosive materials.

The battery is a speci-

fic type, please ensure it

is replaced with the same

type. Consult an approved

dealer.

B

A

Page 215 of 284

5.7

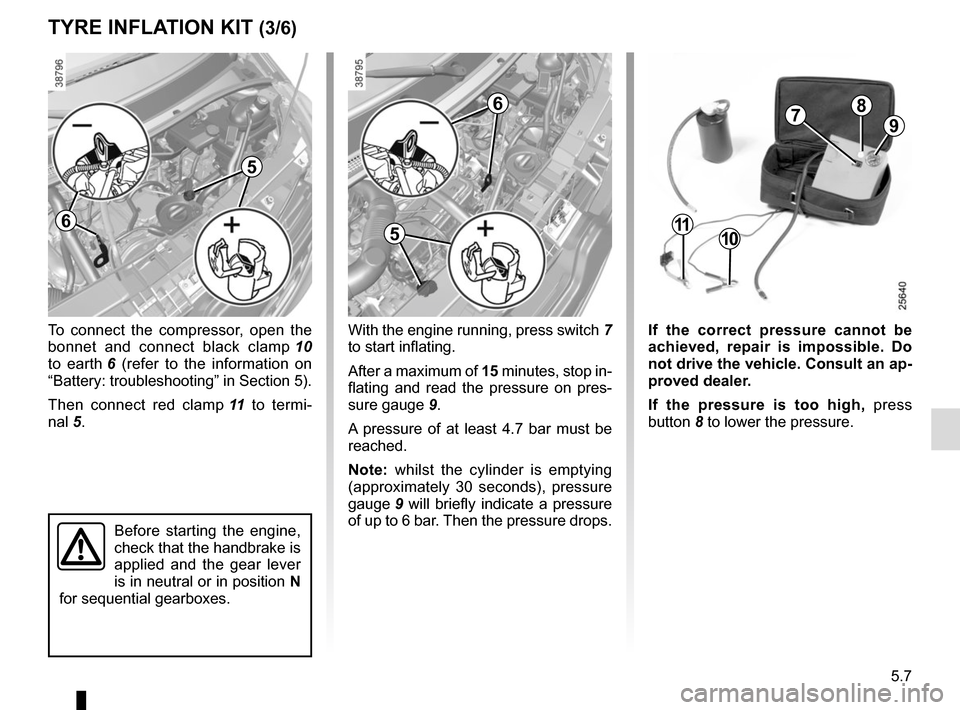

TYRE INFLATION KIT (3/6)

To connect the compressor, open the

bonnet and connect black clamp 10

to earth 6 (refer to the information on

“Battery: troubleshooting” in Section 5).

Then connect red clamp 11 to termi-

nal 5.

Before starting the engine,

check that the handbrake is

applied and the gear lever

is in neutral or in position N

for sequential gearboxes.

With the engine running, press switch 7

to start inflating.

After a maximum of 15 minutes, stop in-

flating and read the pressure on pres-

sure gauge 9.

A pressure of at least 4.7 bar must be

reached.

Note: whilst the cylinder is emptying

(approximately 30 seconds), pressure

gauge 9 will briefly indicate a pressure

of up to 6 bar. Then the pressure drops.

1110

7

If the correct pressure cannot be

achieved, repair is impossible. Do

not drive the vehicle. Consult an ap-

proved dealer.

If the pressure is too high, press

button 8 to lower the pressure.

8

9

5

6

6

5

Page 236 of 284

5.28

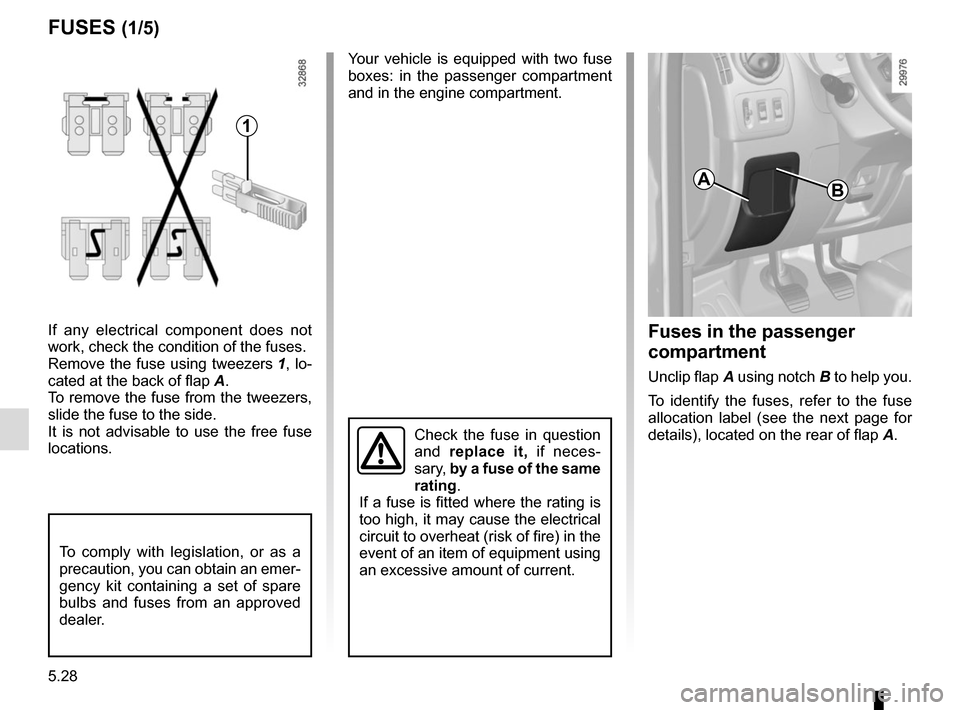

FUSES (1/5)

1

If any electrical component does not

work, check the condition of the fuses.

Remove the fuse using tweezers 1, lo-

cated at the back of flap A.

To remove the fuse from the tweezers,

slide the fuse to the side.

It is not advisable to use the free fuse

locations.

To comply with legislation, or as a

precaution, you can obtain an emer-

gency kit containing a set of spare

bulbs and fuses from an approved

dealer.

Your vehicle is equipped with two fuse

boxes: in the passenger compartment

and in the engine compartment.

A

Fuses in the passenger

compartment

Unclip flap A using notch B to help you.

To identify the fuses, refer to the fuse

allocation label (see the next page for

details), located on the rear of flap A.

B

Check the fuse in question

and replace it, if neces-

sary, by a fuse of the same

rating.

If a fuse is fitted where the rating is

too high, it may cause the electrical

circuit to overheat (risk of fire) in the

event of an item of equipment using

an excessive amount of current.

Page 238 of 284

5.30

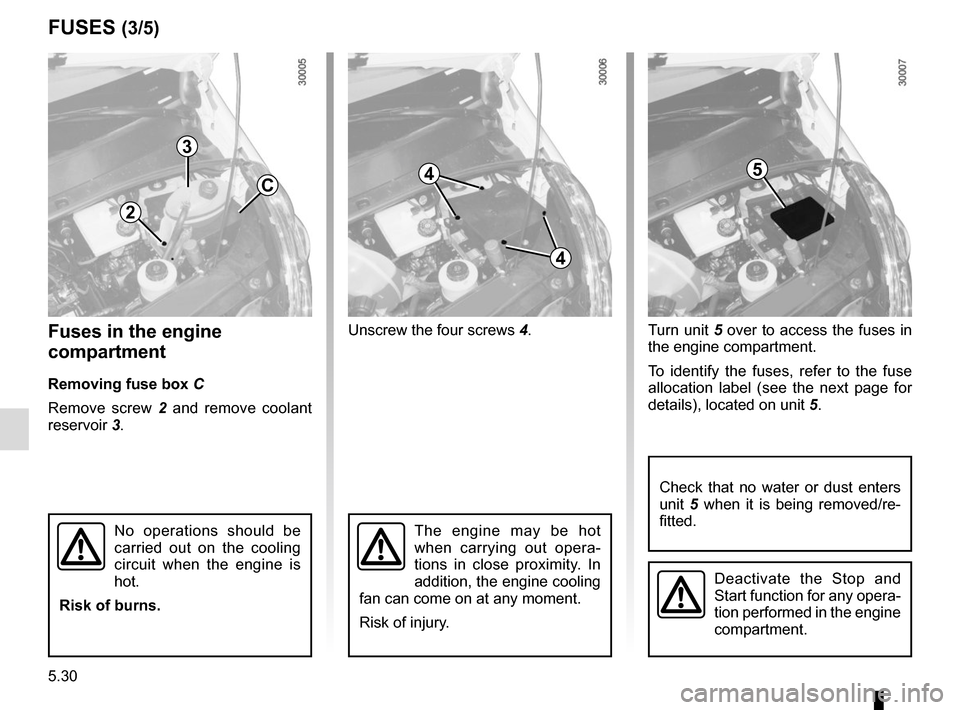

Fuses in the engine

compartment

Removing fuse box C

Remove screw 2 and remove coolant

reservoir 3. Unscrew the four screws

4.Turn unit 5 over to access the fuses in

the engine compartment.

To identify the fuses, refer to the fuse

allocation label (see the next page for

details), located on unit 5.

FUSES (3/5)

2

3

C4

4

5

The engine may be hot

when carrying out opera-

tions in close proximity. In

addition, the engine cooling

fan can come on at any moment.

Risk of injury.No operations should be

carried out on the cooling

circuit when the engine is

hot.

Risk of burns.

Check that no water or dust enters

unit 5 when it is being removed/re-

fitted.

Deactivate the Stop and

Start function for any opera-

tion performed in the engine

compartment.

Page 242 of 284

5.34

BATTERY: troubleshooting (2/2)

Attach the positive lead (+) A to termi-

nal 3, then to terminal 2 (+) of the bat-

tery supplying the current.

Attach negative lead (–) B to terminal 1

(–) of the battery supplying the current,

then to earth 4 (–).

Start the engine as normal. As soon as

it is running, disconnect leads A and B

in the reverse order ( 4-3-2-1).

Starting the vehicle using the

battery from another vehicle

If you have to use the battery from an-

other vehicle to start, obtain suitable

jump leads (with a large cross section)

from an approved dealer or, if you al-

ready have jump leads, ensure that

they are in perfect condition.

The two batteries must have an iden-

tical nominal voltage of 12 volts. The

battery supplying the current should

have a capacity (amp-hours, Ah) which

is at least the same as that of the dis-

charged battery.

Ensure that there is no risk of contact

between the two vehicles (risk of short

circuiting when the positive terminals

are connected). Switch off your vehicle

ignition.

Start the engine of the vehicle supply-

ing the current and run it at a moderate

speed.

A

B

21

Check that there is no contact between leads A and B and that the posi-

tive lead A is not touching any metal parts on the vehicle supplying the

current.

Risk of injury and/or damage to the vehicle.

3

4

4

3