check engine light RENAULT MEGANE 2017 4.G User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2017, Model line: MEGANE, Model: RENAULT MEGANE 2017 4.GPages: 346, PDF Size: 7.04 MB

Page 131 of 346

2.19

Operating faults

– If there is a fault, the © warning

light illuminates on the instrument

panel accompanied by the “Check

parking brake” message and, in

some cases, the

} warning

light.

Please contact an authorised dealer

as soon as possible.

– If there is an assisted parking brake fault, the warning light

® comes

on, along with the message “Braking

system fault”, a beep and, in some

cases, the warning light

}.

This means that you must stop as

soon as traffic conditions allow.

Versions with an automatic

gearbox

For safety reasons, automatic release

is deactivated when the driver’s door

is open or not shut properly and the

engine is running (in order to prevent

the vehicle from moving without the

driver). The “Release parking brake

manually” message appears on the

instrument panel when the driver de-

presses the accelerator.

ELECTRONIC PARKING BRAKE (3/3)

It is therefore essential to

immobilise the vehicle by

engaging first gear (manual

gearbox) or position P (au-

tomatic gearbox). If the slope re-

quires it, chock the vehicle.

Never leave your vehicle

without moving the selec-

tor lever to position P and

switching off the engine.

This is because when the vehicle is

stationary with the engine running

and a gear engaged, the vehicle

may begin to move.

There is a risk of accidents.If no lights or sounds are ap-

parent, this indicates a fault

in the instrument panel. This

indicates that it is essential

to stop immediately (as soon as traf-

fic conditions allow). Ensure that the

vehicle is correctly immobilised and

contact an approved Dealer.

In the event of message

“Electric failure DANGER”

or “Check battery”, manu-

ally activate the electronic

parking brake by pulling switch 2 (or

position the gear lever in P for au-

tomatic gearboxes) before stopping

the engine.

Risk of loss of immobilisation of the

vehicle.

Contact an authorised dealer.

Page 137 of 346

2.25

MAINTENANCE AND ANTIPOLLUTION ADVICE

Your vehicle complies with criteria for

recycling and recovering vehicles at the

end of their service life which will come

into force in 2015.

Some parts of your vehicle have there-

fore been designed to facilitate future

recycling.

These parts are easy to remove so

that they can be recovered and reproc-

essed by recycling companies.

By virtue of its design, moderate fuel

consumption and initial settings, your

vehicle also conforms to current anti-

pollution regulations. The manufac-

turer is actively striving to reduce pol-

lutant exhaust gas emissions and to

save energy. But the fuel consumption

of your vehicle and the level of pollutant

exhaust gas emissions are also your

responsibility. Ensure that it is main-

tained and used correctly.

Maintenance

It is important to remember that fail-

ure to respect antipollution regulations

could lead to legal action being taken

against the vehicle owner.In addition, replacing engine, fuel

supply system and exhaust compo-

nents with parts other than those origi-

nally recommended by the manufac-

turer may alter your vehicle so that it

no longer complies with anti-pollution

regulations.

Have your vehicle adjusted and

checked by an authorised dealer, in ac-

cordance with the instructions given in

your maintenance schedule: they will

have all the equipment necessary for

ensuring that your vehicle is maintained

to its original standard.

Engine adjustments

– Spark plugs:

for optimum condi-

tions of use, output and performance

the specifications laid down by our

Design Department must be strictly

applied.

If the spark plugs have to be changed, use the make, type and gap specified

for your vehicle’s engine. Contact an

authorised dealer for this.

– Air filter, fuel filter: a choked ele-

ment will reduce efficiency. It must

be replaced.

– Ignition and idle speed: no adjust-

ment is needed.

Exhaust gas monitoring

system

The exhaust gas monitoring system will

detect any operating faults in the vehi-

cle’s antipollution system.

If this system malfunctions, toxic sub-

stances may be released into the at-

mosphere or damage may occur.

ÄThis warning light on the in-

strument panel will indicate if

there are any faults in the system:

This lights up when the ignition is

switched on and goes out when the

engine is started.

– If it lights up continuously, consult an approved Dealer as soon as possi-

ble;

– if it flashes, reduce the engine speed until the light stops flashing. Contact

an authorised dealer as soon as pos-

sible.

Page 143 of 346

2.31

DRIVER CORRECTION DEVICES AND AIDS (2/10)

Operating faults:

–

© and x lit up on the in-

strument panel alongside mes-

sages “Check ABS”, “Check braking

system” and “Check ESC”: indicates

the ABS, ESC and emergency brake

assist are deactivated. Braking is

always enabled;

–

x, D, © and ® lit

up on the instrument panel alongside

the message “Braking system fault”:

this indicates a fault in the braking

system.

In both cases, consult an approved

dealer.

Your braking systems

are partially operational.

However, it is dangerous

to brake suddenly and

it is essential to stop immediately,

as soon as traffic conditions allow.

Contact an approved dealer.Warning light ® re-

quires you to stop immedi-

ately, for your own safety,

as soon as traffic conditions

allow. Switch off the engine and do

not restart it. Contact an approved

Dealer.

Page 144 of 346

2.32

Electronic stability control

ESC with understeer control

and traction control

Electronic stability control ESC

This system helps you to keep control

of the vehicle in critical driving condi-

tions (avoiding an obstacle, loss of grip

on a bend, etc.).

Operating principle

A sensor in the steering wheel detects

the direction selected by the driver.

Other sensors throughout the vehicle

measure the actual direction.

The system compares driver input to

the actual trajectory of the vehicle and

corrects the trajectory if necessary by

controlling the braking of certain wheels

and/or engine power. In the event that

the system is engaged, indicator light

flashes on the instrument panel.Understeer control

This system optimises the action of the

ESC in the case of pronounced under-

steer (loss of front axle road holding).

Traction control

This system helps to limit wheelspin of

the drive wheels and to control the ve-

hicle when pulling away accelerating or

decelerating.

Operating principle

Using the wheel sensors, the system

measures and compares the speed of

the drive wheels at all times and slows

down their over-rotation. If a wheel is

starting to slip, the system brakes au-

tomatically until the drive supplied be-

comes compatible with the level of grip

under the wheel again.

The system also adjusts the engine

speed to the grip available under the

wheels, independently of the pressure

exerted on the accelerator pedal.

Operating faults

When the system detects an operat-

ing fault the message “Check ESC” and

warning light

© and appear

on the instrument panel.

In this case, the ESC and traction con-

trol system are deactivated. Consult an

authorised dealer.

DRIVER CORRECTION DEVICES AND AIDS (3/10)

Page 158 of 346

2.46

Operating faults

If the system detects a fault, the mes-

sage “Check blind spot alert” is dis-

played on the instrument panel. Consult

an authorised dealer.

Note: when the engine is started, the

indicator light 6, display B , flashes

three times. It is normal.

– The system’s detection

range operates according

to a standard lane width. If

you are driving in wide traf-

fic lanes, the system might not

be able to detect a vehicle in the

blind spot.

– The system might be disrupted momentarily if it is exposed to

strong electromagnetic waves

(as beneath high-tension power

lines) or to very poor weather

conditions (heavy rain, snow,

etc.). Remain aware of driving

conditions.

There is a risk of accidents.

BLIND SPOT WARNING (4/4)

Because sensors have

been installed in the bump-

ers, any work (repairs, re-

placements, touching up of

paintwork) must be carried out by a

qualified professional.

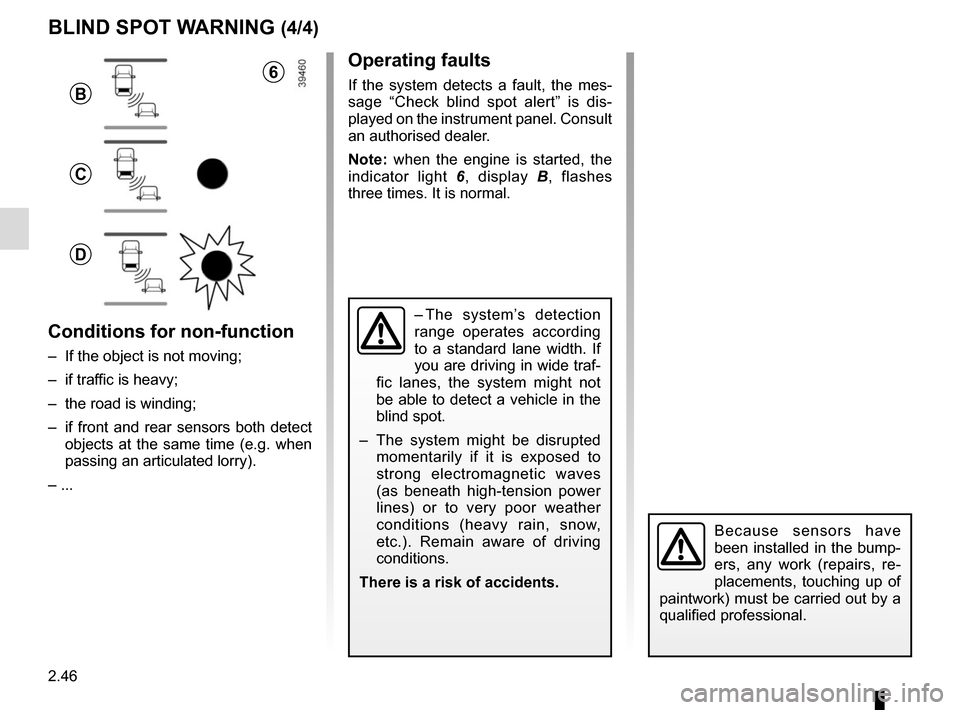

6

B

C

D

Conditions for non-function

– If the object is not moving;

– if traffic is heavy;

– the road is winding;

– if front and rear sensors both detect objects at the same time (e.g. when

passing an articulated lorry).

– ...

Page 178 of 346

2.66

ADAPTIVE CRUISE CONTROL (6/7)

This function is an additional driving aid. This function is not under any

circumstances intended to replace the due care and attention of the

driver, who should at all times be in control of the vehicle.

The driver should always adapt their speed to the traffic conditions, re-

gardless of the system indications.

The system should under no circumstances be taken to be an obstacle dete\

ctor

or an anti-collision system.

System servicing/repairs

– In the event of an impact, the sensor alignment may become changed, and \

its operation will consequently be affected. Deactivate the function, then consult

an authorised dealer.

– Any work in the area where the radar is located (repairs, replacements,\

touch- ing up of paintwork) must be carried out by a qualified professional.

System disturbance

In a complex environment (metal bridge, etc.), the system may be affected.

Risk of inadvertent braking.

Operating faults

When the system detects an operating

fault, the

warning light lights up

on the instrument panel, with the mes-

sage “Check cruise control”.

There are two possibilities:

– the system is temporarily disrupted (for example: radar obscured by

dirt, mud, snow etc.). In this case,

park the vehicle and switch off the

engine. Clean the detection zone of

the radar. When you next start the

engine, the warning light and the

message go out.

– Otherwise, this may be caused by another fault. Consult an approved

dealer

Page 255 of 346

4.3

BONNET (2/2)

Closing the bonnet

Check that nothing has been left in the

engine compartment.

To close the bonnet again, hold the

bonnet in the middle and guide it down,

allowing a 30 cm gap before it is closed,

then release it. It will latch automatically

under its own weight.

Ensure that the bonnet is

properly locked.

Check that nothing is pre-

venting the catch from lock-

ing (gravel, cloth, etc.).

After carrying out any work

in the engine compart-

ment, check that nothing

has been left behind (cloth,

tools, etc.).

These may damage the engine or

cause a fire.

In the event of even a slight

impact involving the radia-

tor grille or bonnet, have the

bonnet lock checked by an

authorised dealer as soon as pos-

sible.

Page 261 of 346

4.9

LEVELS (2/3)

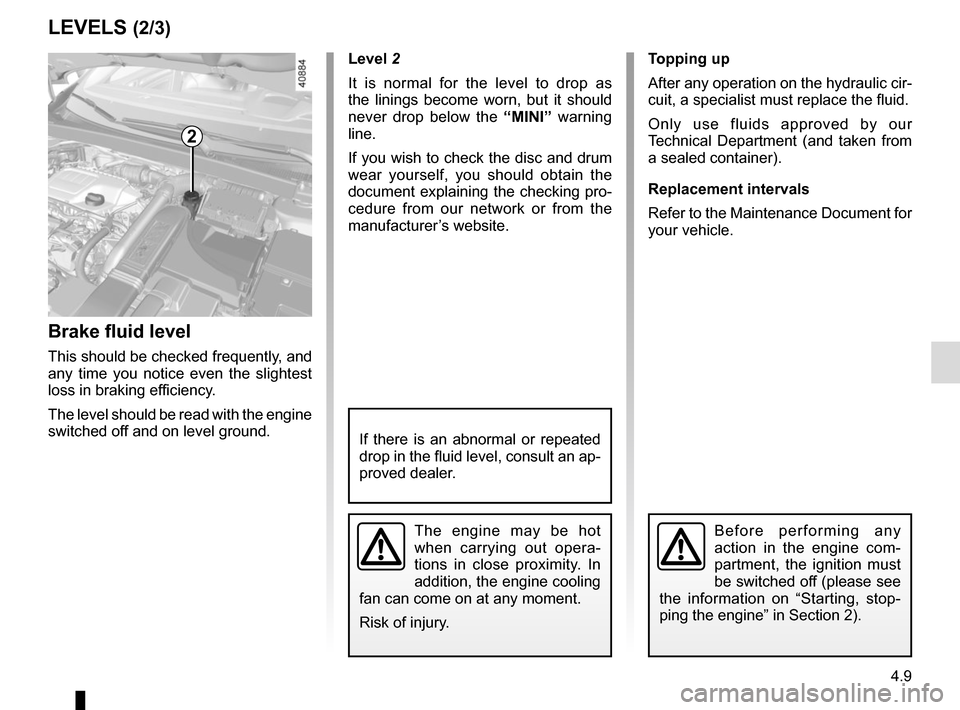

Brake fluid level

This should be checked frequently, and

any time you notice even the slightest

loss in braking efficiency.

The level should be read with the engine

switched off and on level ground.Level 2

It is normal for the level to drop as

the linings become worn, but it should

never drop below the “MINI” warning

line.

If you wish to check the disc and drum

wear yourself, you should obtain the

document explaining the checking pro-

cedure from our network or from the

manufacturer’s website. Topping up

After any operation on the hydraulic cir-

cuit, a specialist must replace the fluid.

Only use fluids approved by our

Technical Department (and taken from

a sealed container).

Replacement intervals

Refer to the Maintenance Document for

your vehicle.

The engine may be hot

when carrying out opera-

tions in close proximity. In

addition, the engine cooling

fan can come on at any moment.

Risk of injury.

2

Before performing any

action in the engine com-

partment, the ignition must

be switched off (please see

the information on “Starting, stop-

ping the engine” in Section 2).

If there is an abnormal or repeated

drop in the fluid level, consult an ap-

proved dealer.

Page 284 of 346

5.14

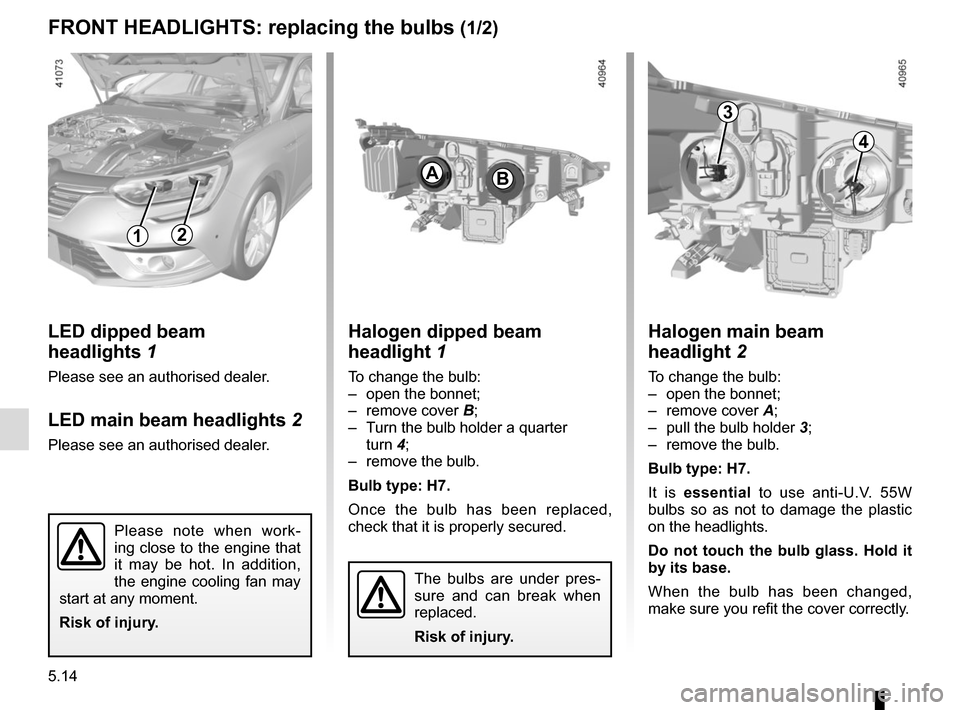

FRONT HEADLIGHTS: replacing the bulbs (1/2)

3

4

Halogen dipped beam

headlight 1

To change the bulb:

– open the bonnet;

– remove cover B;

– Turn the bulb holder a quarter turn 4;

– remove the bulb.

Bulb type: H7.

Once the bulb has been replaced,

check that it is properly secured.

BA

Halogen main beam

headlight 2

To change the bulb:

– open the bonnet;

– remove cover A;

– pull the bulb holder 3;

– remove the bulb.

Bulb type: H7.

It is essential to use anti-U.V. 55W

bulbs so as not to damage the plastic

on the headlights.

Do not touch the bulb glass. Hold it

by its base.

When the bulb has been changed,

make sure you refit the cover correctly.

The bulbs are under pres-

sure and can break when

replaced.

Risk of injury.

12

Please note when work-

ing close to the engine that

it may be hot. In addition,

the engine cooling fan may

start at any moment.

Risk of injury.

LED dipped beam

headlights 1

Please see an authorised dealer.

LED main beam headlights 2

Please see an authorised dealer.

Page 305 of 346

5.35

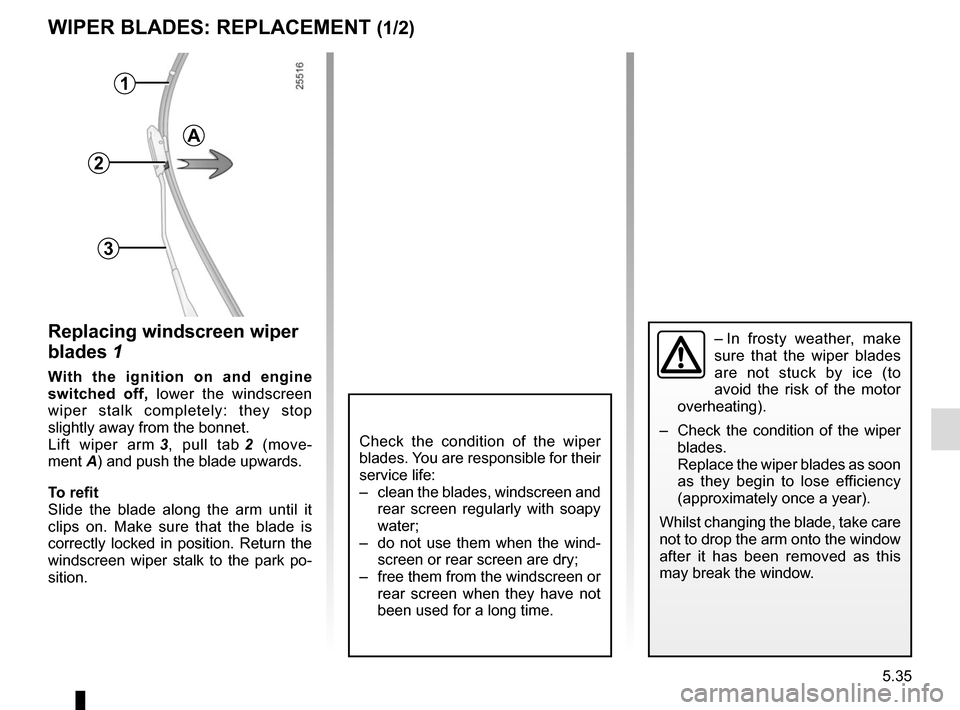

WIPER BLADES: REPLACEMENT (1/2)

Replacing windscreen wiper

blades 1

With the ignition on and engine

switched off, lower the windscreen

wiper stalk completely: they stop

slightly away from the bonnet.

Lift wiper arm 3, pull tab 2 (move-

ment A) and push the blade upwards.

To refit

Slide the blade along the arm until it

clips on. Make sure that the blade is

correctly locked in position. Return the

windscreen wiper stalk to the park po-

sition.

1

2

3

Check the condition of the wiper

blades. You are responsible for their

service life:

– clean the blades, windscreen and rear screen regularly with soapy

water;

– do not use them when the wind- screen or rear screen are dry;

– free them from the windscreen or rear screen when they have not

been used for a long time.

A

– In frosty weather, make

sure that the wiper blades

are not stuck by ice (to

avoid the risk of the motor

overheating).

– Check the condition of the wiper

blades.

Replace the wiper blades as soon

as they begin to lose efficiency

(approximately once a year).

Whilst changing the blade, take care

not to drop the arm onto the window

after it has been removed as this

may break the window.