coolant RENAULT SCENIC 2010 J95 / 3.G Engine And Pheripherals DCM 1.2 Injection Service Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2010, Model line: SCENIC, Model: RENAULT SCENIC 2010 J95 / 3.GPages: 269

Page 190 of 269

13B-190

AFTER REPAIRDeal with any faults displayed by the diagnostic tool. Clear the computer fault

memory.

Carry out a road test followed by another check with the diagnostic tool.

V10 MR-372-J84-13B100$170.mif

DIESEL INJECTION

Fault finding – Interpretation of parameters13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

PR125POWER ABSORBED BY THE AIR CONDITIONING COMPRESSOR*

PARAMETER

DEFINITIONThis parameter indicates the power absorbed by the air conditioning compressor in W.

Conformity check: Engine stopped and ignition on, or engine running without electrical consumer,

and engine coolant temperature > 80

°C

PR125 = 0 W

Conformity check: With engine running and compressor activation request active

PR125 = 1200 W

DCM1.2_V48_PR125/DCM1.2_V4C_PR125/DCM1.2_V50_PR125/DCM1.2_V54_PR125/DCM1.2_V58_PR125/DCM1.2_V5C_PR125

Page 191 of 269

13B-191

AFTER REPAIRDeal with any faults displayed by the diagnostic tool. Clear the computer fault

memory.

Carry out a road test followed by another check with the diagnostic tool.

V10 MR-372-J84-13B100$170.mif

DIESEL INJECTION

Fault finding – Interpretation of parameters13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

PR130CRUISE CONTROL SETPOINT

PARAMETER

DEFINITIONThis parameter indicates the cruise control speed setpoint in mph (km/h).

NOTESThere must be no faults present.

Perform this fault finding procedure:

–after finding an inconsistency in the parameter,

–or after a customer complaint (lack of power, smoke etc.).

Conformity check: Engine stopped and ignition on, or engine running and engine coolant

temperature > 80

°C

Indicates the cruise control cruising speed.

Cruise control can only be activated for a speed greater than 18 mph (30 km/h).

DCM1.2_V48_PR130/DCM1.2_V4C_PR130/DCM1.2_V50_PR130/DCM1.2_V54_PR130/DCM1.2_V58_PR130/DCM1.2_V5C_PR130

Page 192 of 269

13B-192

AFTER REPAIRDeal with any faults displayed by the diagnostic tool. Clear the computer fault

memory.

Carry out a road test followed by another check with the diagnostic tool.

V10 MR-372-J84-13B100$170.mif

DIESEL INJECTION

Fault finding – Interpretation of parameters13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

PR132AIR FLOW

PARAMETER

DEFINITIONThis parameter indicates the inlet air flow in mg/st.

NOTESSpecial notes:

For vehicles that are not equipped with a flowmeter, the air flow is estimated using

the following parameters:

–Inlet air temperature,

–The atmospheric pressure,

–The EGR valve position,

–The fuel flow,

–The engine speed.

There must be no faults present.

Perform this fault finding procedure:

–after finding an inconsistency in the parameter,

–or after a customer complaint (lack of power, smoke etc.).

See the Wiring diagrams Technical Note for the vehicle.

Conformity check with engine stopped and ignition on.

Indicates the inlet air flow PR132 ≈ 0 mg/st.

Conformity check: Engine running at idle speed and engine coolant temperature > 80

°C

Indicates the inlet air flow PR132 ≈ 200 mg/st.

DCM1.2_V48_PR132/DCM1.2_V4C_PR132/DCM1.2_V50_PR132/DCM1.2_V54_PR132/DCM1.2_V58_PR132/DCM1.2_V5C_PR132

Page 198 of 269

13B-198

AFTER REPAIRDeal with any faults displayed by the diagnostic tool. Clear the computer fault

memory.

Carry out a road test followed by another check with the diagnostic tool.

V10 MR-372-J84-13B100$170.mif

DIESEL INJECTION

Fault finding – Interpretation of parameters13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

PR730AIR FLOW SENSOR TEMPERATURE

PARAMETER

DEFINITIONThis parameter indicates the air temperature of the flowmeter in °C.

NOTESSpecial notes:

Depending on the engine type, the air temperature is given by the air flowmeter or the

exterior air temperature sensor.

Conformity check: Engine stopped and ignition on, or engine running and engine coolant

temperature > 80

°C

Check the condition of the air flow sensor connections.

If the connector is faulty and there is a repair method (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

If necessary, replace the sensor (see MR 364 (Mégane II), MR 370 (Scénic II), MR 385 (Modus), MR 392 (Clio III),

MR 411 (New Twingo), MR 417 (Kangoo 2), Mechanical, 12A, Fuel mixture, Air flowmeter: Removal -

Refitting).

Measure the resistance between the following connections:

(vehicle with flowmeter)

–3B and 3DW of component 799;

(vehicle without flowmeter)

–3PB and 3KQ of component 272,

–3SH and 3KQ of component 272,

–3JQ and 3KQ of component 272.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

DCM1.2_V48_PR730/DCM1.2_V4C_PR730/DCM1.2_V50_PR730/DCM1.2_V54_PR730/DCM1.2_V58_PR730/DCM1.2_V5C_PR730

Page 202 of 269

13B-202

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V10 MR-372-J84-13B100$170.mif

DIESEL INJECTION

Fault finding – Interpretation of parameters13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 54

PR879MAXIMUM AUTHORISED SPEED

PARAMETER

DEFINITIONThis parameter indicates the maximum authorised speed in mph (km/h) requested by

the customer using command SC040 Speed limiter.

NOTESSpecial notes:

It is possible to modify the value of PR879 using command SC040 Speed limiter.

This parameter is valid only on Kangoo 2.

Conformity check: Engine stopped and ignition on, or engine running and engine coolant

temperature > 80

°C

If ET741 "Optional vehicle speed restriction" is ACTIVE, the value of PR879 is between 18 mph (30 km/h) and

150 mph (250 km/h).

In the event of a fault or modification of this speed, use command SC040 Speed limiter.

DCM1.2_V54_PR879

Page 212 of 269

13B-212V10 MR-372-J84-13B100$190.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

TEST 6 High pressure system check

NOTESSpecial note:

Certain faults make it impossible to carry out this test - deal with these first.

WARNING

Running the starter motor for more than 5 seconds is dangerous and serves no

useful purpose.

Preliminary checks:

–Check for the presence of fuel

–Check that there is no air in the low pressure circuit. Run TEST 1 Low pressure circuit check.

–Ensure that the correct fuel is being used. Run test 13 Diesel fuel conformity check.

The pump's capacity to produce high pressure can be checked by the following procedure:

–With the ignition off, disconnect the low pressure actuator from the pump (IMV brown connector)

and connect a test IMV or the adapter of MOT. 1711.

–Electrically disconnect the four injectors.

–Switch on the ignition, connect the diagnostic tool and re-establish dialogue with the injection system.

–Go to the Main computer statuses and parameters screen.

–Run the test cold, PR064 "Coolant temperature" < 30

°C or equal to ambient temperature.

–Engage the starter for 5 seconds.

–Read the maximum rail pressure value PR038 Rail pressure during the test on the diagnostic tool.

A

DCM1.2_V48_TEST6/DCM1.2_V4C_TEST6/DCM1.2_V50_TEST6/DCM1.2_V54_TEST6/DCM1.2_V58_TEST6/DCM1.2_V5C_TEST6

Page 215 of 269

13B-215V10 MR-372-J84-13B100$190.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

TEST 8 Injector return flow

NOTESSpecial note:

Certain faults make it impossible to carry out this test - deal with these first.

Does the engine start?

Command AC029 High pressure circuit sealing also checks the return volume of each injector to detect

any leaks inside the injectors.

Be careful with any objects (tool or other) on the engine housing during the four cycles of the operation

(possible vibrations).

Tooling required

–Mot. 1711 Injector flow measuring kit.

Or: Use four tubes of internal diameter 4 mm and approximately 50 cm long, and four graduated measuring

cylinders.

Procedure

–Check that the engine coolant temperature is above 60

°C,

–switch off the ignition,

–disconnect the return pipes from the four injectors,

–cap the pump venturi tube to prevent the low-pressure circuit from depriming,

–connect the four transparent tubes in place of the return pipes,

–put the other ends of the four pipes into four graduated measuring cylinders.

When all the preparations are complete, start the engine and leave it running:

30 secondsfor Euro 4 engines: K9K 766 - 768 (Clio III and Modus); K9K 724 (Mégane II

and Scénic II); K9K 740 -718 (New Twingo); K9K 800 - 802 - 812 (Kangoo 2).

Let it idle for 2 minutesfor Euro 3 type engines: K9K 750 - 752 (Clio III and Modus).

Note:

These time periods must be respected for the test results to be interpreted correctly.

–Run command AC029 High pressure circuit sealing check.

The engine will carry out automatically a cycle of four accelerations to increase the rail pressure and measure

internal injector leaks under these conditions.

–When the cycle has finished, run command AC029 High pressure circuit sealing test a second time to

obtain the correct return volume reading for each injector.

–Switch off the engine at the end of the cycle.

NOA

YES

DCM1.2_V48_TEST8/DCM1.2_V4C_TEST8/DCM1.2_V50_TEST8/DCM1.2_V54_TEST8/DCM1.2_V58_TEST8/DCM1.2_V5C_TEST8

Page 219 of 269

13B-219V10 MR-372-J84-13B100$190.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

TEST 10 Turbocharger solenoid valve check

Note:

No turbocharger control solenoid valve present on the K9K 740 engine for New Twingo and the K9K 800

engine for Kangoo 2.

Checking the vacuum at the pressure regulator inlet

Run the engine at idle speed.

Check the engine temperature using the CLIP parameter PR064 Coolant temperature.

Let the engine warm up until the temperature reaches 80

°C.

Disconnect the vacuum pipe from the end piece of the pressure regulator.

Connect a vacuum pressure gauge to the end of the disconnected pipe and put it in the vacuum measurement

position.

Perform a quick acceleration by depressing the accelerator pedal completely and then releasing it immediately.

The total duration of pressing and holding in the full load position must not exceed 1 second.

During this acceleration, the engine speed must reach a value between 3000 and 4000 rpm.

Repeat the operation 3 times.

Read the maximum vacuum posted by the pressure gauge during the increase and decrease in the speed and after

the return to idle speed.

Tolerance intervals for the vacuum are:

–1 bar < CORRECT vacuum value < - 0.6 bar

–0.6 bar < INCORRECT vacuum value < 0 bar

Is the vacuum at the turbocharging pressure regulator inlet displayed on the vacuum gauge within

the tolerance interval?

The solenoid valve is in order.

NOYES

A

DCM1.2_V48_TEST10/DCM1.2_V4C_TEST10/DCM1.2_V50_TEST10/DCM1.2_V54_TEST10/DCM1.2_V58_TEST10/DCM1.2_V5C_TEST10

Page 237 of 269

13B-237V10 MR-372-J84-13B100$210.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

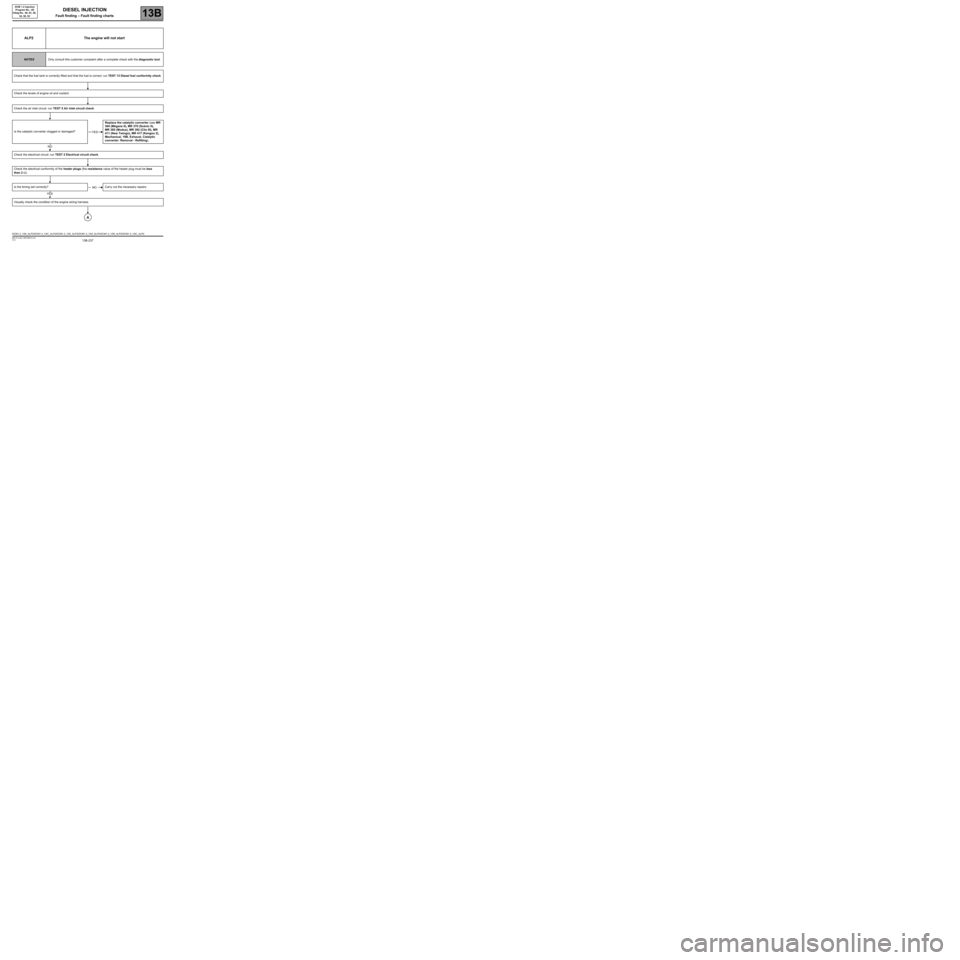

ALP2 The engine will not start

NOTESOnly consult this customer complaint after a complete check with the diagnostic tool.

Check that the fuel tank is correctly filled and that the fuel is correct: run TEST 13 Diesel fuel conformity check.

Check the levels of engine oil and coolant.

Check the air inlet circuit: run TEST 5 Air inlet circuit check.

Is the catalytic converter clogged or damaged?Replace the catalytic converter (see MR

364 (Mégane II), MR 370 (Scénic II),

MR 385 (Modus), MR 392 (Clio III), MR

411 (New Twingo), MR 417 (Kangoo 2),

Mechanical, 19B, Exhaust, Catalytic

converter: Removal - Refitting).

Check the electrical circuit: run TEST 2 Electrical circuit check.

Check the electrical conformity of the heater plugs (the resistance value of the heater plug must be less

than 2 Ω).

Is the timing set correctly? Carry out the necessary repairs.

Visually check the condition of the engine wiring harness.

YES

NO

NO

YES

A

DCM1.2_V48_ALP2/DCM1.2_V4C_ALP2/DCM1.2_V50_ALP2/DCM1.2_V54_ALP2/DCM1.2_V58_ALP2/DCM1.2_V5C_ALP2

Page 240 of 269

13B-240V10 MR-372-J84-13B100$210.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

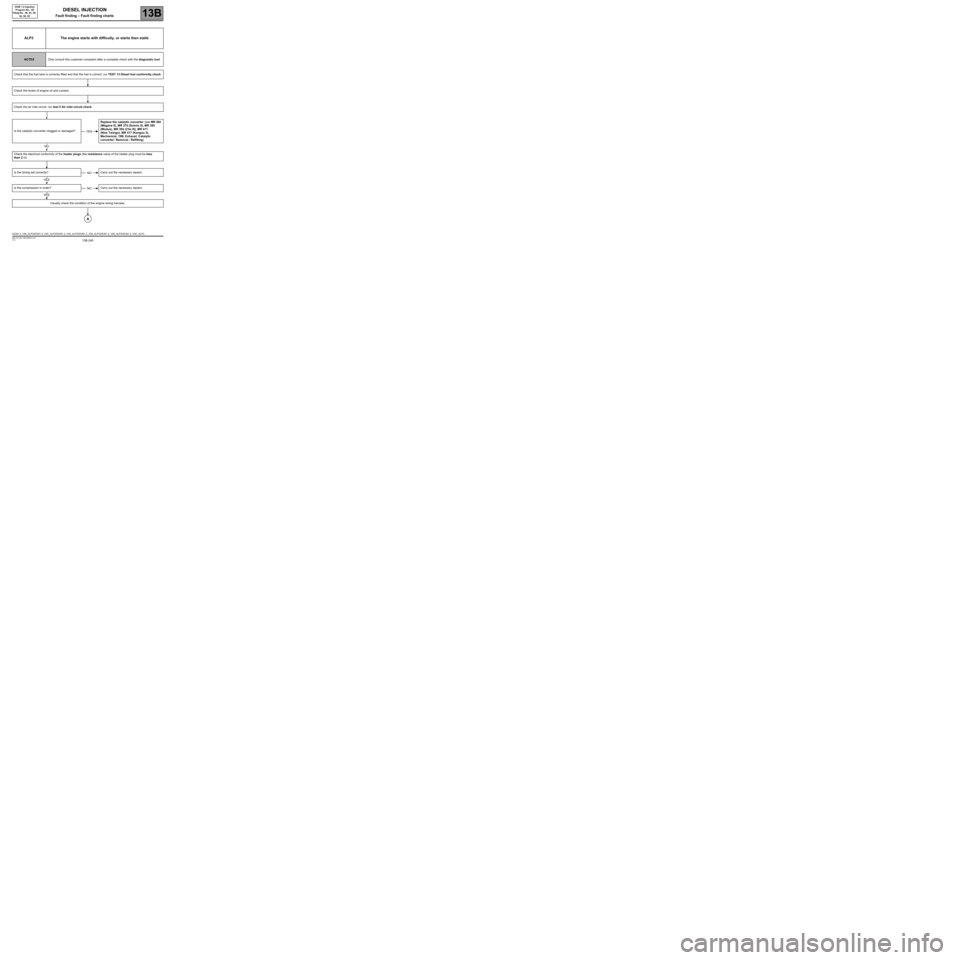

ALP3 The engine starts with difficulty, or starts then stalls

NOTESOnly consult this customer complaint after a complete check with the diagnostic tool.

Check that the fuel tank is correctly filled and that the fuel is correct: run TEST 13 Diesel fuel conformity check.

Check the levels of engine oil and coolant.

Check the air inlet circuit: run test 5 Air inlet circuit check.

Is the catalytic converter clogged or damaged?Replace the catalytic converter (see MR 364

(Mégane II), MR 370 (Scénic II), MR 385

(Modus), MR 392 (Clio III), MR 411

(New Twingo), MR 417 (Kangoo 2),

Mechanical, 19B, Exhaust, Catalytic

converter: Removal - Refitting).

Check the electrical conformity of the heater plugs (the resistance value of the heater plug must be less

than 2 Ω).

Is the timing set correctly? Carry out the necessary repairs.

Is the compression in order? Carry out the necessary repairs.

Visually check the condition of the engine wiring harness.

YES

NO

NO

YES

NO

YES

A

DCM1.2_V48_ALP3/DCM1.2_V4C_ALP3/DCM1.2_V50_ALP3/DCM1.2_V54_ALP3/DCM1.2_V58_ALP3/DCM1.2_V5C_ALP3