stop start RENAULT SCENIC 2010 J95 / 3.G Engine And Pheripherals DCM 1.2 Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2010, Model line: SCENIC, Model: RENAULT SCENIC 2010 J95 / 3.GPages: 269

Page 19 of 269

13B-19V10 MR-372-J84-13B100$040.mif

DIESEL INJECTION

Fault finding – Function13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

Instrument panel display

The computer manages the data display on the instrument panel relating to engine operation. This covers five

functions: the OBD warning light for European On Board Diagnostics (EOBD), pre-postheating, coolant temperature,

and Level 1 (non critical fault) and Level 2 (emergency stop) engine faults. These five functions are represented by

five warning lights or messages displayed by the trip computer.

Pre-postheating warning light

This warning light indicates that preheating is active.

Engine coolant temperature warning light

This warning light is used as an engine overheating indicator.

–In the event of overheating, it is up to the driver whether to stop the vehicle or continue driving.

OBD warning light

The OBD fault warning light is used to warn the driver of the presence of injection faults producing excessive

pollution or that the EOBD system is deactivated.

The injection computer requests illumination of the OBD warning light for a present fault only after three consecutive

driving cycles.

The visual check of the warning light when the power is switched on (automatic test procedure managed by

the instrument panel) is carried out by the injection computer. It lasts 3 seconds or until the engine starts for

the New Twingo and Kangoo 2.

If a confirmed OBD fault causes the OBD warning light to come on, there should be no flashing after the warning

light illumination test. The instrument panel will also display the message: Check emission control.

The gearbox computer, if fitted, may also request the illumination of this warning light.

Level 1 warning

If there is a minor fault, the computer may request a level 1 warning to be displayed. Usually, the instrument panel

switches on the SERVICE warning light and sends out a "Check the injection" message. Refer to the operation of the

instrument panel (see 83A, instrument panel). Note:

This warning light comes on only if the vehicle is EOBD approved.

Note:

The SERVICE warning light will come on if the instrument panel is configured as cruise control - speed

limiter present, but the function has not yet been detected by the injection computer.

Page 23 of 269

13B-23V10 MR-372-J84-13B100$060.mif

13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

COMPUTER REPLACEMENT OR REPROGRAMMING OPERATIONS

Before removing any old computer as an After-Sales operation, save the following data using the diagnostic

tool:

–The C2I (individual injector correction) parameters and the engine adaptives using command SC003 Save

computer data.

The system can be programmed by the diagnostic socket using the RENAULT CLIP diagnostic tool (refer to

Technical Note 3585A, Computer programming and reprogramming procedure, and follow the instructions

provided by the diagnostic tool).

After replacing or reprogramming the computer

–Switch the ignition off and then on again.

–Use the diagnostic tool command SC001 Enter saved data to restore the C2I and the engine adaptives.

–On Kangoo 2, use the diagnostic tool command SC040 Speed limiter, if necessary.

–Use command AC028 Static test to reinitialise the computer (fan assembly, etc.).

–Switch the ignition off and then on again.

–When changing the pump, refer to the high pressure pump replacement procedure (consult Technical Note

5011A, Repriming Delphi high pressure pumps on K9K engines).

–Activate the starter without releasing the key until the engine starts (the engine start time can be up to

20 seconds).

–Stop the engine (to initialise the computer) and wait 30 seconds.

–Switch the ignition back on and use the diagnostic tool to carry out the following steps:

–Run command VP010 Enter VIN.

–After injection system programming, stored faults may appear on other computers. Clear the memory of these

computers.

–Switch the ignition off and then on again. IMPORTANT

–Switch on the diagnostic tool (mains or cigarette lighter supply).

–Connect a battery charger.

–Switch off all electrical consumers (lights, interior lights, air conditioning, radio/CD, etc.).

Wait for the engine to cool (engine coolant temperature less than 60

°C and air temperature less than 50°C).

IMPORTANT

Before reprogramming the injection computer, move the main cruise control - speed limiter switch to the rest

position. The information about the cruise control or the speed limiter displayed on the instrument panel

disappears.

Otherwise, if the main switch remains in the cruise control or speed limiter position during and after reprogramming,

the cruise control - speed limiter function will not be operational.

The procedure for resetting the function is as follows:

Vehicle ignition on.

Main switch in rest position (the computer then detects the rest position).

Switch in the Cruise control position to activate the Cruise control function.

Switch in the Speed limiter position to activate the Speed limiter function.

IMPORTANT

AFTER A PROGRAMMING OPERATION, DO NOT CONNECT THE BATTERY FOR AT LEAST 30 minutes (to

carry out other work on the vehicle).

DIESEL INJECTION

Fault finding – Replacement of components

Page 34 of 269

13B-34

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V10 MR-372-J84-13B100$090.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

DF005

PRESENT

OR STOREDENGINE SPEED SENSOR CIRCUIT1.DEF: Inconsistency

2.DEF: No signal

3.DEF: Too many additional teeth

4.DEF: Teeth missing

5.DEF: Additional teeth

6.DEF: Too many teeth missing

NOTESSpecial note:

If 1.DEF, 2.DEF, 3.DEF, or 6.DEF is present: the engine stops and the level 2 warning

light illuminates, with the message Faulty injection displayed on the instrument panel.

If 4.DEF or 5 DEF is present: the engine performance is reduced to 75% and the level

1 warning light illuminates.

Conditions for applying fault finding procedures to stored faults:

The fault is present when the starter motor is operating or the engine is running at idle

speed.

See the Technical Note Wiring Diagrams for the vehicle.

Check the connection and condition of the engine speed sensor connector, component code 149.

Check the connection and condition of connector B of the injection computer, component code 120.

If the connector(s) is faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Measure the resistance of the engine speed sensor, component code 149 between connections 3BL and 3BG.

If the resistance of the engine speed sensor, component code 149 is not between 510 Ω et 850 Ω (at 20

°C), replace

the engine speed sensor (see MR 364 (Mégane II), MR 370 (Scénic II), MR 385 (Modus), MR 392 (Clio III), MR

411 (New Twingo), MR 417 (Kangoo 2) Mechanical, 13B Diesel injection, Crankshaft position sensor:

Removal - Refitting).

Check the insulation and continuity of the following connections:

–3BG between components 149 and 120,

–3BL between components 149 and 120.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

If the fault is still present, replace the engine speed sensor, component code 149 (see MR 364 (Mégane II),

MR 370 (Scénic II), MR 385 (Modus), MR 392 (Clio III), MR 411 (New Twingo), MR 417 (Kangoo 2) Mechanical,

13B Diesel injection, Crankshaft position sensor: Removal - Refitting).

If the fault is still present, contact the Techline.

DCM1.2_V48_DF005/DCM1.2_V4C_DF005/DCM1.2_V50_DF005/DCM1.2_V54_DF005/DCM1.2_V58_DF005/DCM1.2_V5C_DF005

Page 35 of 269

13B-35

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V10 MR-372-J84-13B100$090.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

DF007

PRESENT

OR STOREDRAIL PRESSURE SENSOR CIRCUITCC.0: Short circuit to earth

C0.1: Open circuit or short circuit to +12 V

1.DEF: Inconsistency

2.DEF: Below minimum threshold

3.DEF: Above maximum threshold

4.DEF: Value outside permitted tolerance

NOTESPriority for dealing with a combination of faults:

–DF113 Sensor supply voltage.

Conditions for applying fault finding procedures to stored faults:

The fault is declared present after the engine starts.

Special note:

If fault DF007 is present: the engine stops and cannot be restarted and the level 2

warning light illuminates, with the message Faulty injection displayed on the

instrument panel.

See the Technical Note Wiring Diagrams for the vehicle.

Check the connection and condition of the rail pressure sensor connector, component code 1032.

Check the connection and condition of connector B (brown 48-track) of the injection computer, component

code 120.

If the connector(s) is faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check for +5 V on connection 3LX of component 1032.

Check for earth on connection 3LZ of component 1032.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

Check the insulation and continuity of the following connections:

–3LX between components 1032 and 120,

–3LY between components 1032 and 120,

–3LZ between components 1032 and 120.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

DCM1.2_V48_DF007/DCM1.2_V4C_DF007/DCM1.2_V50_DF007/DCM1.2_V54_DF007/DCM1.2_V58_DF007/DCM1.2_V5C_DF007

Page 47 of 269

13B-47

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V10 MR-372-J84-13B100$090.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

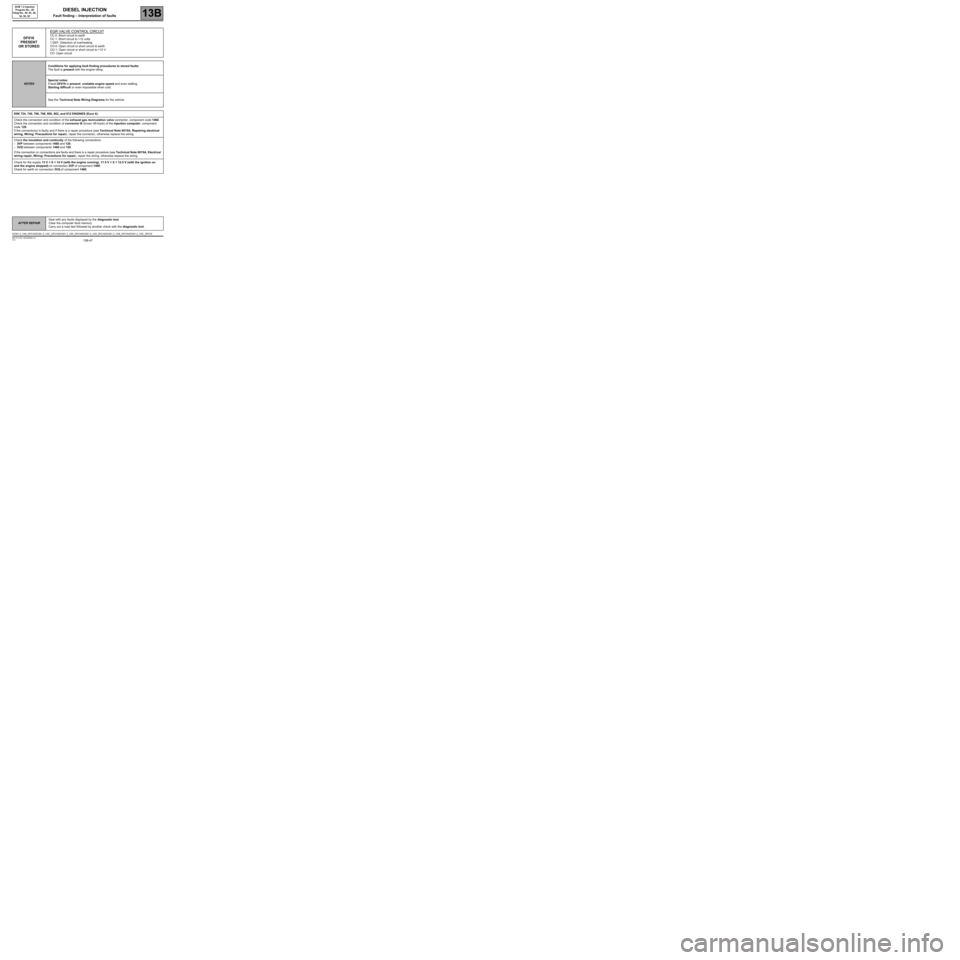

DF016

PRESENT

OR STOREDEGR VALVE CONTROL CIRCUITCC.0: Short circuit to earth

CC.1: Short circuit to +12 volts

1.DEF: Detection of overheating

CO.0: Open circuit or short circuit to earth

CO.1: Open circuit or short circuit to +12 V

CO: Open circuit

NOTESConditions for applying fault finding procedures to stored faults:

The fault is present with the engine idling.

Special notes:

If fault DF016 is present: unstable engine speed and even stalling.

Starting difficult or even impossible when cold.

See the Technical Note Wiring Diagrams for the vehicle.

K9K 724, 740, 766, 768, 800, 802, and 812 ENGINES (Euro 4):

Check the connection and condition of the exhaust gas recirculation valve connector, component code 1460.

Check the connection and condition of connector B (brown 48-track) of the injection computer, component

code 120.

If the connector(s) is faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the insulation and continuity of the following connections:

–3VP between components 1460 and 120,

–3VQ between components 1460 and 120.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

Check for the supply 13 V < X < 14 V (with the engine running), 11.5 V < X < 12.5 V (with the ignition on

and the engine stopped) on connection 3VP of component 1460.

Check for earth on connection 3VQ of component 1460.

DCM1.2_V48_DF016/DCM1.2_V4C_DF016/DCM1.2_V50_DF016/DCM1.2_V54_DF016/DCM1.2_V58_DF016/DCM1.2_V5C_DF016

Page 98 of 269

13B-98

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V10 MR-372-J84-13B100$110.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

* C2I: Individual injector correction

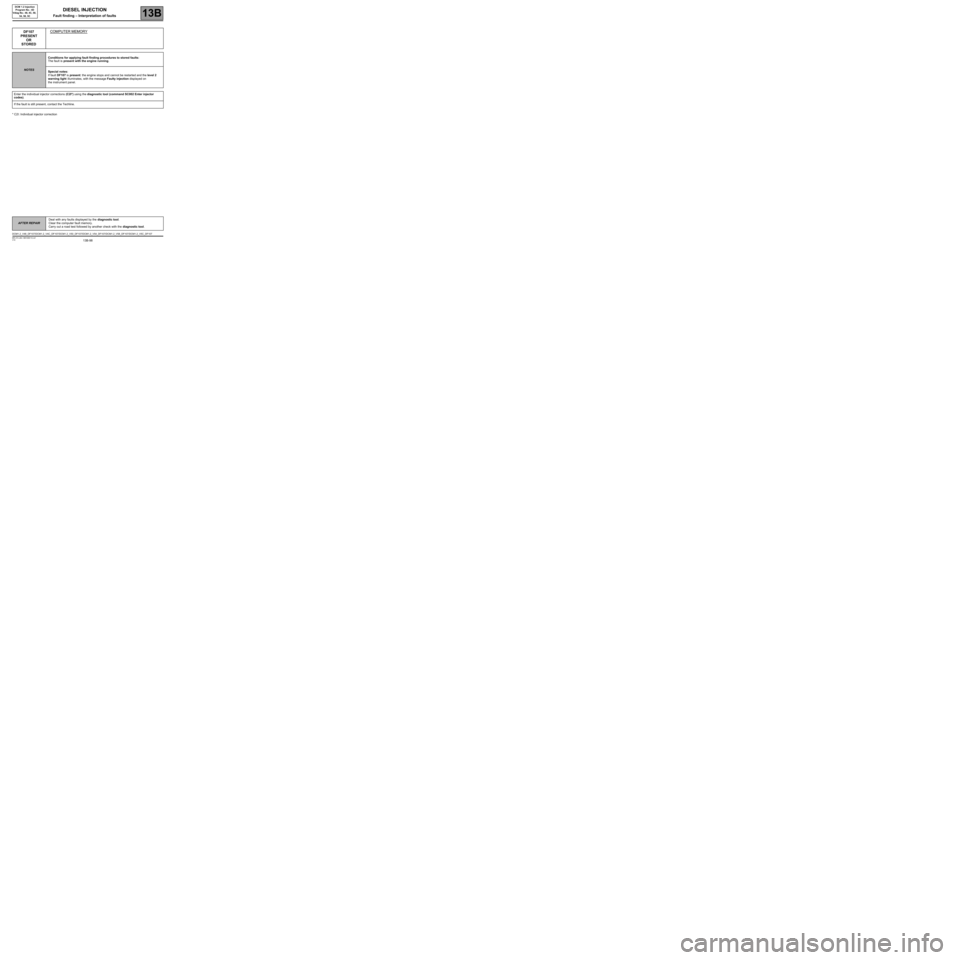

DF107

PRESENT

OR

STOREDCOMPUTER MEMORY

NOTESConditions for applying fault finding procedures to stored faults:

The fault is present with the engine running.

Special notes:

If fault DF107 is present: the engine stops and cannot be restarted and the level 2

warning light illuminates, with the message Faulty injection displayed on

the instrument panel.

Enter the individual injector corrections (C2I*) using the diagnostic tool (command SC002 Enter injector

codes).

If the fault is still present, contact the Techline.

DCM1.2_V48_DF107/DCM1.2_V4C_DF107/DCM1.2_V50_DF107/DCM1.2_V54_DF107/DCM1.2_V58_DF107/DCM1.2_V5C_DF107

Page 100 of 269

13B-100

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V10 MR-372-J84-13B100$110.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

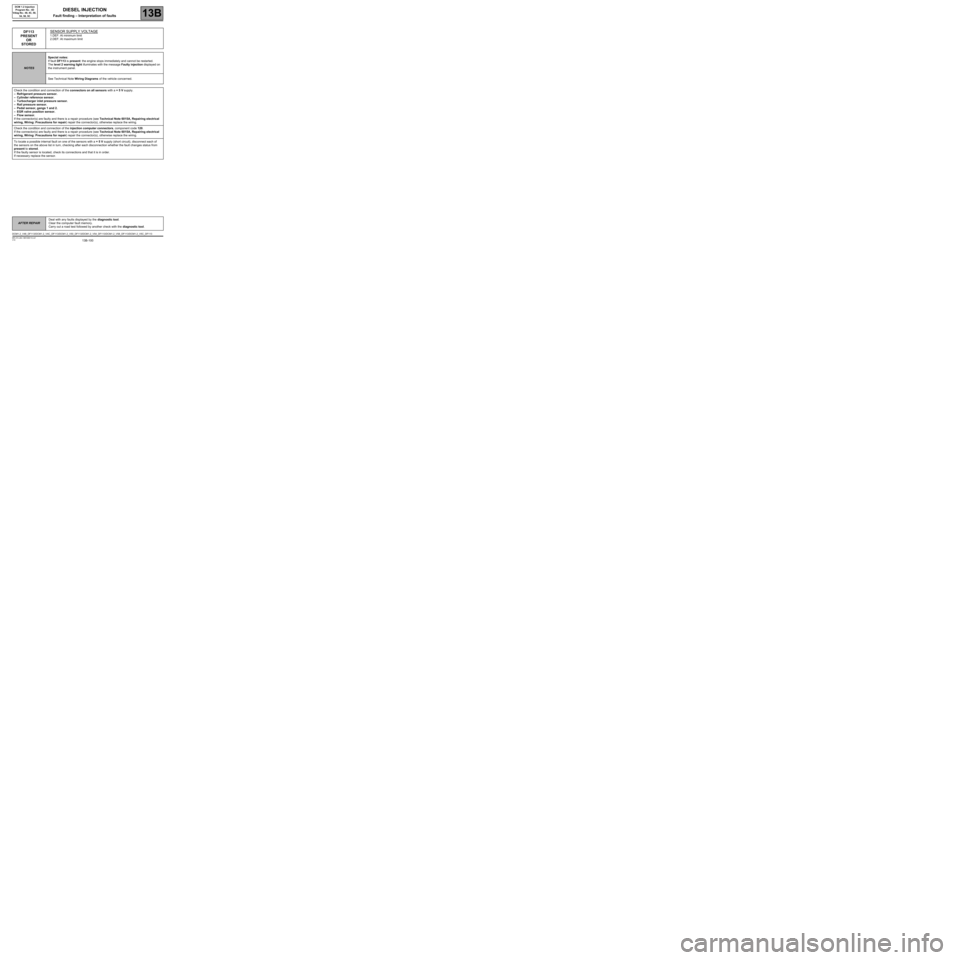

DF113

PRESENT

OR

STOREDSENSOR SUPPLY VOLTAGE

1.DEF: At minimum limit

2.DEF: At maximum limit

NOTESSpecial notes:

If fault DF113 is present: the engine stops immediately and cannot be restarted.

The level 2 warning light illuminates with the message Faulty injection displayed on

the instrument panel.

See Technical Note Wiring Diagrams of the vehicle concerned.

Check the condition and connection of the connectors on all sensors with a + 5 V supply.

–Refrigerant pressure sensor.

–Cylinder reference sensor.

–Turbocharger inlet pressure sensor.

–Rail pressure sensor.

–Pedal sensor, gangs 1 and 2.

–EGR valve position sensor.

–Flow sensor.

If the connector(s) are faulty and there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair) repair the connector(s), otherwise replace the wiring.

Check the condition and connection of the injection computer connectors, component code 120.

If the connector(s) are faulty and there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair) repair the connector(s), otherwise replace the wiring.

To locate a possible internal fault on one of the sensors with a + 5 V supply (short circuit), disconnect each of

the sensors on the above list in turn, checking after each disconnection whether the fault changes status from

present to stored.

If the faulty sensor is located, check its connections and that it is in order.

If necessary replace the sensor.

DCM1.2_V48_DF113/DCM1.2_V4C_DF113/DCM1.2_V50_DF113/DCM1.2_V54_DF113/DCM1.2_V58_DF113/DCM1.2_V5C_DF113

Page 128 of 269

13B-128

AFTER REPAIRCarry out another fault finding check on the system.

Deal with any other faults.

Clear the stored faults.

V10 MR-372-J84-13B100$150.mif

DIESEL INJECTION

Fault finding – Interpretation of statuses13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

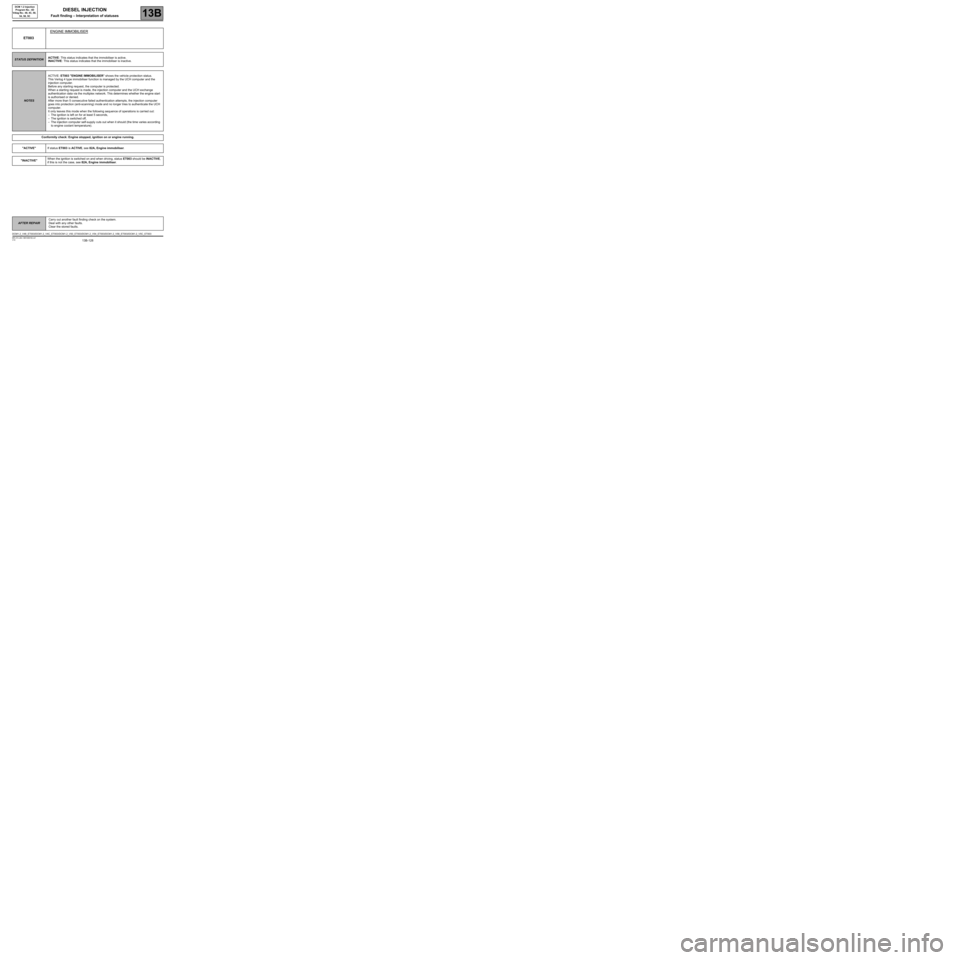

ET003ENGINE IMMOBILISER

STATUS DEFINITIONACTIVE: This status indicates that the immobiliser is active.

INACTIVE: This status indicates that the immobiliser is inactive.

NOTESACTIVE: ET003 "ENGINE IMMOBILISER" shows the vehicle protection status.

This Verlog 4 type immobiliser function is managed by the UCH computer and the

injection computer.

Before any starting request, the computer is protected.

When a starting request is made, the injection computer and the UCH exchange

authentication data via the multiplex network. This determines whether the engine start

is authorised or denied.

After more than 5 consecutive failed authentication attempts, the injection computer

goes into protection (anti-scanning) mode and no longer tries to authenticate the UCH

computer.

It only leaves this mode when the following sequence of operations is carried out:

–The ignition is left on for at least 5 seconds,

–The ignition is switched off,

–The injection computer self-supply cuts out when it should (the time varies according

to engine coolant temperature).

Conformity check: Engine stopped, ignition on or engine running.

"ACTIVE"If status ET003 is ACTIVE, see 82A, Engine immobiliser.

"INACTIVE"When the ignition is switched on and when driving, status ET003 should be INACTIVE,

if this is not the case, see 82A, Engine immobiliser.

DCM1.2_V48_ET003/DCM1.2_V4C_ET003/DCM1.2_V50_ET003/DCM1.2_V54_ET003/DCM1.2_V58_ET003/DCM1.2_V5C_ET003

Page 130 of 269

13B-130

AFTER REPAIRDeal with any faults. Clear the faults from the computer memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

V10 MR-372-J84-13B100$150.mif

DIESEL INJECTION

Fault finding – Interpretation of statuses13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

ET006CODE PROGRAMMED

STATUS DEFINITIONYES: This status indicates that the immobiliser code has been programmed.

NO: This status indicates that the immobiliser code has not been programmed.

NOTESThe injection immobiliser code is not written in the injection computer.

The programming of this code in the injection computer is managed by the UCH.

To carry out programming:

–establish communication with the UCH see 87B, Passenger compartment

connection unit.

–run command SC017 Program injection immobiliser code,

–follow the instructions for the procedure.

As long as this phase has not been completed, ET006 "Code programmed" is "NO".

IMPORTANT:

the immobiliser code is written in the injection computer memory at the end of the

computer auto-feed phase. Do not disconnect the battery before the end of this phase.

Conformity check: Engine stopped, ignition on or engine running.

YESStatus ET006 is YES if dialogue is possible between the UCH computer and the injection

computer and the key code is recognised.

The engine is only authorised to start if the code is recognised by the UCH computer and

if status ET003 Immobiliser is INACTIVE.

In the event of a fault, (see 87B, Passenger compartment connection unit,

conformity check).

DCM1.2_V48_ET006/DCM1.2_V4C_ET006/DCM1.2_V50_ET006/DCM1.2_V54_ET006/DCM1.2_V58_ET006/DCM1.2_V5C_ET006

Page 138 of 269

13B-138

AFTER REPAIRDeal with any faults. Clear the faults from the computer memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

V10 MR-372-J84-13B100$150.mif

DIESEL INJECTION

Fault finding – Interpretation of statuses13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

ET038ENGINE

STATUS DEFINITION"RUNNING": The engine is running.

"NOT RUNNING": The engine is not running.

Conformity check with engine stopped and ignition on.

NOT RUNNINGStatus ET038 is not running if the engine has stopped.

Conformity check: Engine running

RUNNINGStatus ET038 is running if the engine has started.

DCM1.2_V48_ET038/DCM1.2_V4C_ET038/DCM1.2_V50_ET038/DCM1.2_V54_ET038/DCM1.2_V58_ET038/DCM1.2_V5C_ET038