tire pressure RENAULT SCENIC 2010 J95 / 3.G Engine And Pheripherals DCM 1.2 Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2010, Model line: SCENIC, Model: RENAULT SCENIC 2010 J95 / 3.GPages: 269

Page 12 of 269

13B-12V10 MR-372-J84-13B100$040.mif

13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

System outline

The DCM1.2 injection system used on the K9K engine is an electronically-managed high pressure injection system.

The fuel is compressed by a high pressure pump then stored in a rail that feeds the injectors. Injection takes place

when a current pulse is applied to the injector holders. The amount injected is proportional to the rail pressure

and the applied pulse length, and the start of injection is synchronised with the start of the pulse.

The system includes two subsystems, which have different fuel pressure levels:

–The low pressure circuit contains the tank, the diesel fuel filter, the transfer pump and the injector holder

return pipes,

–the high-pressure system includes the high-pressure pump, rail, injector holders and high-pressure pipes.

Finally, there are a certain number of sensors and regulating actuators for controlling and monitoring the entire

system.

Functions performed:

Function: Fuel supply management (timing, flow and pressure).

Quantity of fuel injected and injection timing setting

The injection checking parameters are the quantities to be injected and their respective timing.

These are calculated by the computer using signals from the following sensors:

–engine speed sensor (Crankshaft + Cam lobe for synchronisation),

–accelerator pedal sensor,

–coolant temperature sensor,

–rail pressure sensor,

–atmospheric pressure sensor,

–accelerometer,

–inlet manifold pressure sensor.

Specific vehicle / engine suffix details:

Modus

K9K 750 752 (Euro 3)Inlet manifold temperature and pressure sensor (a sensor which has two functions),

management by the turbocharger control solenoid valve inlet pressure.

K9K 766 (Euro 4)Either a flow sensor with an integrated temperature sensor or a temperature sensor

instead of a flow sensor with inlet manifold temperature sensor, inlet manifold pressure

sensor, management by turbocharger control solenoid valve programming.

K9K 768 (Euro 4)Flow sensor with integrated temperature sensor, inlet manifold pressure sensor,

management by the turbocharger control solenoid valve inlet pressure.

DIESEL INJECTION

Fault finding – Function

Page 15 of 269

13B-15V10 MR-372-J84-13B100$040.mif

DIESEL INJECTION

Fault finding – Function13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

Angular position measurement

Engine speed sensor:

The angular position is measured using a magneto-inductive sensor triggered by machined teeth on the shaft

flywheel. This flywheel has sixty teeth, six degrees apart, minus two missing teeth that form a notch.

Cylinder reference sensor:

A second sensor (Hall effect) triggered by a machined tooth on the high pressure pump drive pulley (synchronised

with the camshaft), turning at half the engine speed, supplies a signal about the progress of the injection cycle.

By comparing the signals from these two sensors, the computer's APS module (Angular Position Subsystem) can

supply the entire system with the synchronisation factors, which are: the angular position of the flywheel, the engine

speed, the number of the active injector and the injection cycle timing.

This module also supplies the system with the engine speed signal.

New pump chamber filling procedure (pump boosting)

The pump lubrication goes through a booster cycle during which the pump is filled and pressurised before

"transferring" the diesel fuel to the rail.

This lubrication goes through a procedure called new pump chamber filling, which prevents starting for

approximately 10 seconds, which is the time required for filling the pump and starting. For vehicles with keys,

if the key is released before the end of this "initial starting" phase there is no need for a power latch phase to be

completed before a fresh attempt to start the vehicle.

This procedure is run after the first start in the factory, after a computer is replaced if the parameters relating to

the rail pressure have not been copied into the new computer, and also after reprogramming of the injection

computer.

Variable Low Capacity (VLC) output function

Because of the combination of several parameters such as the diesel fuel temperature, part wear, clogging of

the diesel filter etc., the system limit may be reached during its service life. If this happens, the rail pressure cannot

be maintained because the pump lacks the necessary capacity. If the pump lacks the necessary capacity, this

programming will therefore reduce the requested flow to a value that will enable the pressure monitoring system to

control the pressure again.

The customer may have noticed a loss of vehicle performance when this program is activated (depending on

the vehicle, this programming can be confirmed by ET563 Flow capacity function). This is normal operation of

the injection system.

Function: Air flow management

EGR valve control

K9K 766 and 768 (Euro 4) engines (fitted on Clio III and Modus) and K9K 724 (Euro 4) engines (fitted on

Mégane II and Scénic II) and K9K 740 engines (fitted on New Twingo) and K9K 800, 802 and 812 engines

(fitted on Kangoo 2):

The EGR (Exhaust Gas Recirculation) system consists of a DC proportional EGR valve, which incorporates

a valve position feedback potentiometer. The EGR valve is closed-loop controlled based on its position via

the potentiometer and/or based on changes in the estimated air flow.

K9K 750 and 752 (Euro 3) engines (fitted on Clio III and Modus):

The EGR system (Exhaust Gas Recirculation) consists of an EGR solenoid valve, which incorporates a valve

position feedback potentiometer. The EGR valve is closed-loop controlled based on its position via

the potentiometer and/or based on changes in the estimated air flow.

Page 205 of 269

13B-205V10 MR-372-J84-13B100$180.mif

13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

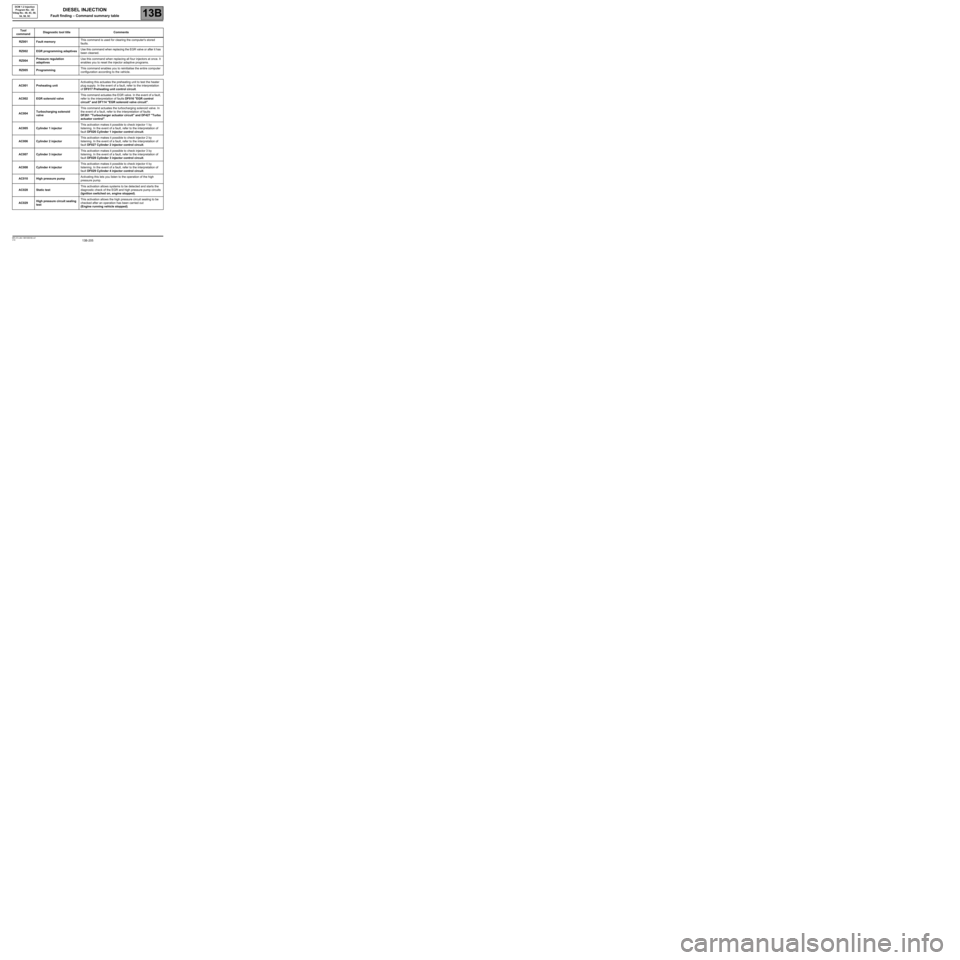

Tool

commandDiagnostic tool titleComments

RZ001 Fault memoryThis command is used for clearing the computer's stored

faults.

RZ002 EGR programming adaptivesUse this command when replacing the EGR valve or after it has

been cleaned.

RZ004Pressure regulation

adaptivesUse this command when replacing all four injectors at once. It

enables you to reset the injector adaptive programs.

RZ005 ProgrammingThis command enables you to reinitialise the entire computer

configuration according to the vehicle.

AC001 Preheating unitActivating this actuates the preheating unit to test the heater

plug supply. In the event of a fault, refer to the interpretation

of DF017 Preheating unit control circuit.

AC002 EGR solenoid valveThis command actuates the EGR valve. In the event of a fault,

refer to the interpretation of faults DF016 "EGR control

circuit" and DF114 "EGR solenoid valve circuit".

AC004Turbocharging solenoid

valveThis command actuates the turbocharging solenoid valve. In

the event of a fault, refer to the interpretation of faults

DF261 "Turbocharger actuator circuit" and DF427 "Turbo

actuator control".

AC005 Cylinder 1 injectorThis activation makes it possible to check injector 1 by

listening. In the event of a fault, refer to the interpretation of

fault DF026 Cylinder 1 injector control circuit.

AC006 Cylinder 2 injectorThis activation makes it possible to check injector 2 by

listening. In the event of a fault, refer to the interpretation of

fault DF027 Cylinder 2 injector control circuit.

AC007 Cylinder 3 injectorThis activation makes it possible to check injector 3 by

listening. In the event of a fault, refer to the interpretation of

fault DF028 Cylinder 3 injector control circuit.

AC008 Cylinder 4 injectorThis activation makes it possible to check injector 4 by

listening. In the event of a fault, refer to the interpretation of

fault DF029 Cylinder 4 injector control circuit.

AC010 High pressure pumpActivating this lets you listen to the operation of the high

pressure pump.

AC028 Static testThis activation allows systems to be detected and starts the

diagnostic check of the EGR and high pressure pump circuits

(Ignition switched on, engine stopped).

AC029High pressure circuit sealing

testThis activation allows the high pressure circuit sealing to be

checked after an operation has been carried out

(Engine running vehicle stopped).

DIESEL INJECTION

Fault finding – Command summary table