DF095 RENAULT SCENIC 2010 J95 / 3.G Petrol Injection S3000 Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2010, Model line: SCENIC, Model: RENAULT SCENIC 2010 J95 / 3.GPages: 230, PDF Size: 0.92 MB

Page 18 of 230

PETROL INJECTION

Fault finding - System operation

17B

17B - 18

PETROL INJECTION

Fault finding - System operation

17B

17B - 18V9 MR-372-J84-17B050$094.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

Table of defect modes:

Type 1 Type 2 Type 3 Type 4 Type 5 Type 6

DF004 Turbocharging pressure

sensor circuit---2.DEF1.DEF

2.DEF1.DEF

2.DEF

DF011 Sensor feed voltage no. 11.DEF 1.DEF - 1.DEF - -

DF012 Sensor feed voltage no. 2---1.DEF1.DEF-

DF038 Computer1.DEF 1.DEF - - 1.DEF -

DF046 Battery voltage1.DEF 1.DEF - - - -

DF054 Turbocharging solenoid valve

control circuit-----CO/CC.0./

CC.1

DF078 Motorised throttle control

circuit1.DEF 1.DEF - - - -

DF079 Motorised throttle valve

automatic control6.DEF/CO 6.DEF/CO -2.DEF

3.DEF

4.DEF--

DF089 Inlet manifold pressure sensor

circuit----1.DEF

2.DEF-

DF095 Throttle potentiometer circuit

gang 1CO.0/

CC.1CO.0/

CC.1-CO.0/

CC.1--

DF096 Throttle potentiometer circuit

gang 2CO.0/

CC.1CO.0/

CC.1-CO.0/

CC.1--

DF196 Pedal potentiometer circuit

gang 1--1.DEFCO/CC.0./

CC.1

1.DEF--

DF198 Pedal potentiometer circuit

gang 2--CO/CC.0./

CC.1CO/CC.0./

CC.1--

DF650 Accelerator pedal position

signal--1.DEF1.DEF--

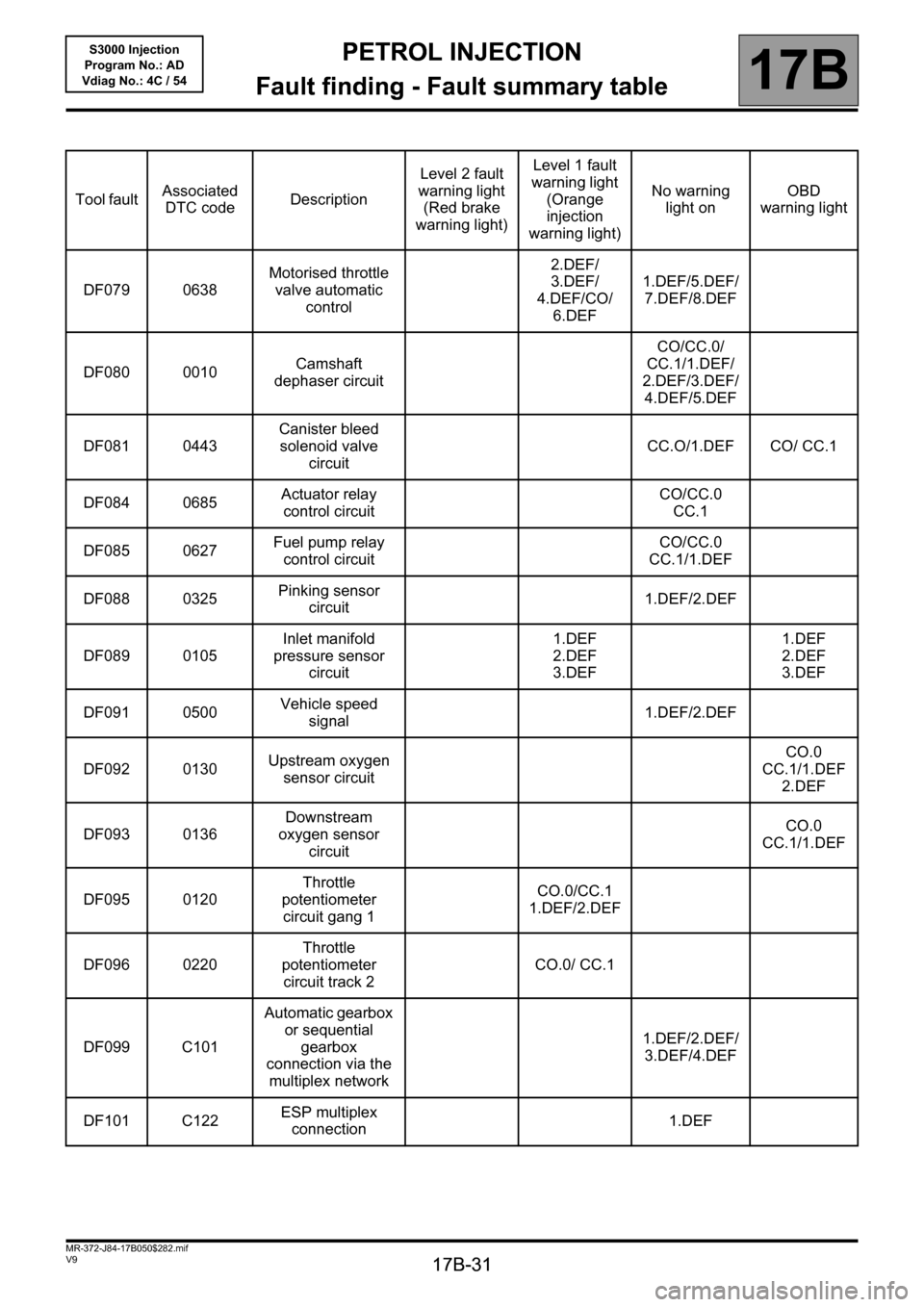

Page 31 of 230

PETROL INJECTION

Fault finding - Fault summary table

17B

17B-31

PETROL INJECTION

Fault finding - Fault summary table

17B

17B-31V9 MR-372-J84-17B050$282.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

Tool faultAssociated

DTC codeDescriptionLevel 2 fault

warning light

(Red brake

warning light)Level 1 fault

warning light

(Orange

injection

warning light)No warning

light onOBD

warning light

DF079 0638Motorised throttle

valve automatic

control2.DEF/

3.DEF/

4.DEF/CO/

6.DEF1.DEF/5.DEF/

7.DEF/8.DEF

DF080 0010Camshaft

dephaser circuitCO/CC.0/

CC.1/1.DEF/

2.DEF/3.DEF/

4.DEF/5.DEF

DF081 0443Canister bleed

solenoid valve

circuitCC.O/1.DEF CO/ CC.1

DF084 0685Actuator relay

control circuitCO/CC.0

CC.1

DF085 0627Fuel pump relay

control circuitCO/CC.0

CC.1/1.DEF

DF088 0325Pinking sensor

circuit1.DEF/2.DEF

DF089 0105Inlet manifold

pressure sensor

circuit1.DEF

2.DEF

3.DEF1.DEF

2.DEF

3.DEF

DF091 0500Vehicle speed

signal1.DEF/2.DEF

DF092 0130Upstream oxygen

sensor circuitCO.0

CC.1/1.DEF

2.DEF

DF093 0136Downstream

oxygen sensor

circuitCO.0

CC.1/1.DEF

DF095 0120Throttle

potentiometer

circuit gang 1CO.0/CC.1

1.DEF/2.DEF

DF096 0220Throttle

potentiometer

circuit track 2CO.0/ CC.1

DF099 C101Automatic gearbox

or sequential

gearbox

connection via the

multiplex network1.DEF/2.DEF/

3.DEF/4.DEF

DF101 C122ESP multiplex

connection1.DEF

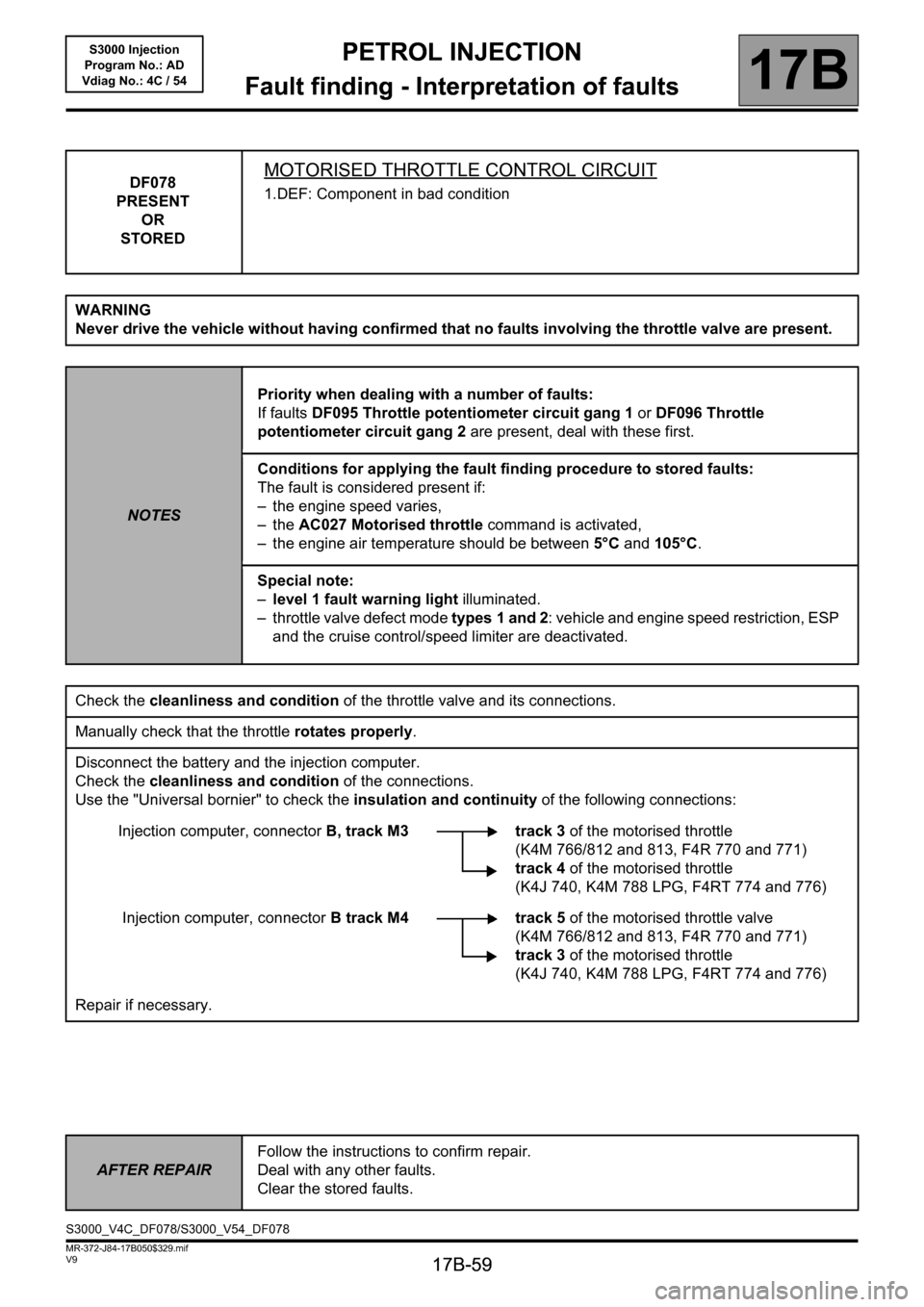

Page 59 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-59

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-59V9 MR-372-J84-17B050$329.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

DF078

PRESENT

OR

STOREDMOTORISED THROTTLE CONTROL CIRCUIT

1.DEF: Component in bad condition

WARNING

Never drive the vehicle without having confirmed that no faults involving the throttle valve are present.

NOTESPriority when dealing with a number of faults:

If faults DF095 Throttle potentiometer circuit gang 1 or DF096 Throttle

potentiometer circuit gang 2 are present, deal with these first.

Conditions for applying the fault finding procedure to stored faults:

The fault is considered present if:

– the engine speed varies,

–the AC027 Motorised throttle command is activated,

– the engine air temperature should be between 5°C and 105°C.

Special note:

–level 1 fault warning light illuminated.

– throttle valve defect mode types 1 and 2: vehicle and engine speed restriction, ESP

and the cruise control/speed limiter are deactivated.

Check the cleanliness and condition of the throttle valve and its connections.

Manually check that the throttle rotates properly.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Use the "Universal bornier" to check the insulation and continuity of the following connections:

Injection computer, connectorB, track M3 track 3 of the motorised throttle

(K4M 766/812 and 813, F4R 770 and 771)

track 4of the motorised throttle

(K4J 740, K4M 788 LPG, F4RT 774 and 776)

Injection computer, connectorB track M4 track 5 of the motorised throttle valve

(K4M 766/812 and 813, F4R 770 and 771)

track 3 of the motorised throttle

(K4J 740, K4M 788 LPG, F4RT 774 and 776)

Repair if necessary.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF078/S3000_V54_DF078

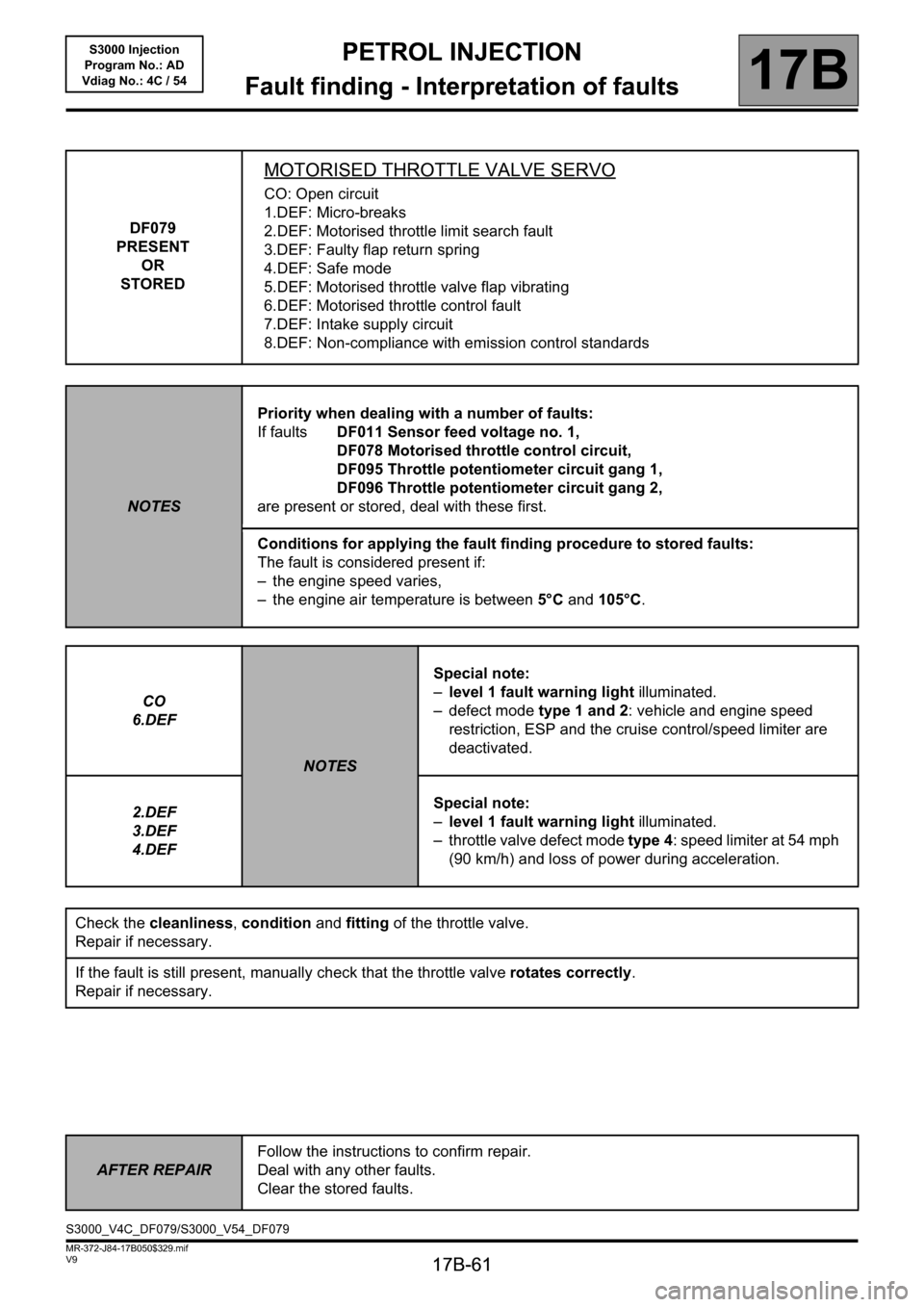

Page 61 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-61

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-61V9 MR-372-J84-17B050$329.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

DF079

PRESENT

OR

STORED

MOTORISED THROTTLE VALVE SERVO

CO: Open circuit

1.DEF: Micro-breaks

2.DEF: Motorised throttle limit search fault

3.DEF: Faulty flap return spring

4.DEF: Safe mode

5.DEF: Motorised throttle valve flap vibrating

6.DEF: Motorised throttle control fault

7.DEF: Intake supply circuit

8.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

If faultsDF011 Sensor feed voltage no. 1,

DF078 Motorised throttle control circuit,

DF095 Throttle potentiometer circuit gang 1,

DF096 Throttle potentiometer circuit gang 2,

are present or stored, deal with these first.

Conditions for applying the fault finding procedure to stored faults:

The fault is considered present if:

– the engine speed varies,

– the engine air temperature is between 5°C and 105°C.

CO

6.DEF

NOTESSpecial note:

–level 1 fault warning light illuminated.

– defect mode type 1 and 2: vehicle and engine speed

restriction, ESP and the cruise control/speed limiter are

deactivated.

2.DEF

3.DEF

4.DEFSpecial note:

–level 1 fault warning light illuminated.

– throttle valve defect mode type 4: speed limiter at 54 mph

(90 km/h) and loss of power during acceleration.

Check the cleanliness, condition and fitting of the throttle valve.

Repair if necessary.

If the fault is still present, manually check that the throttle valve rotates correctly.

Repair if necessary.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF079/S3000_V54_DF079

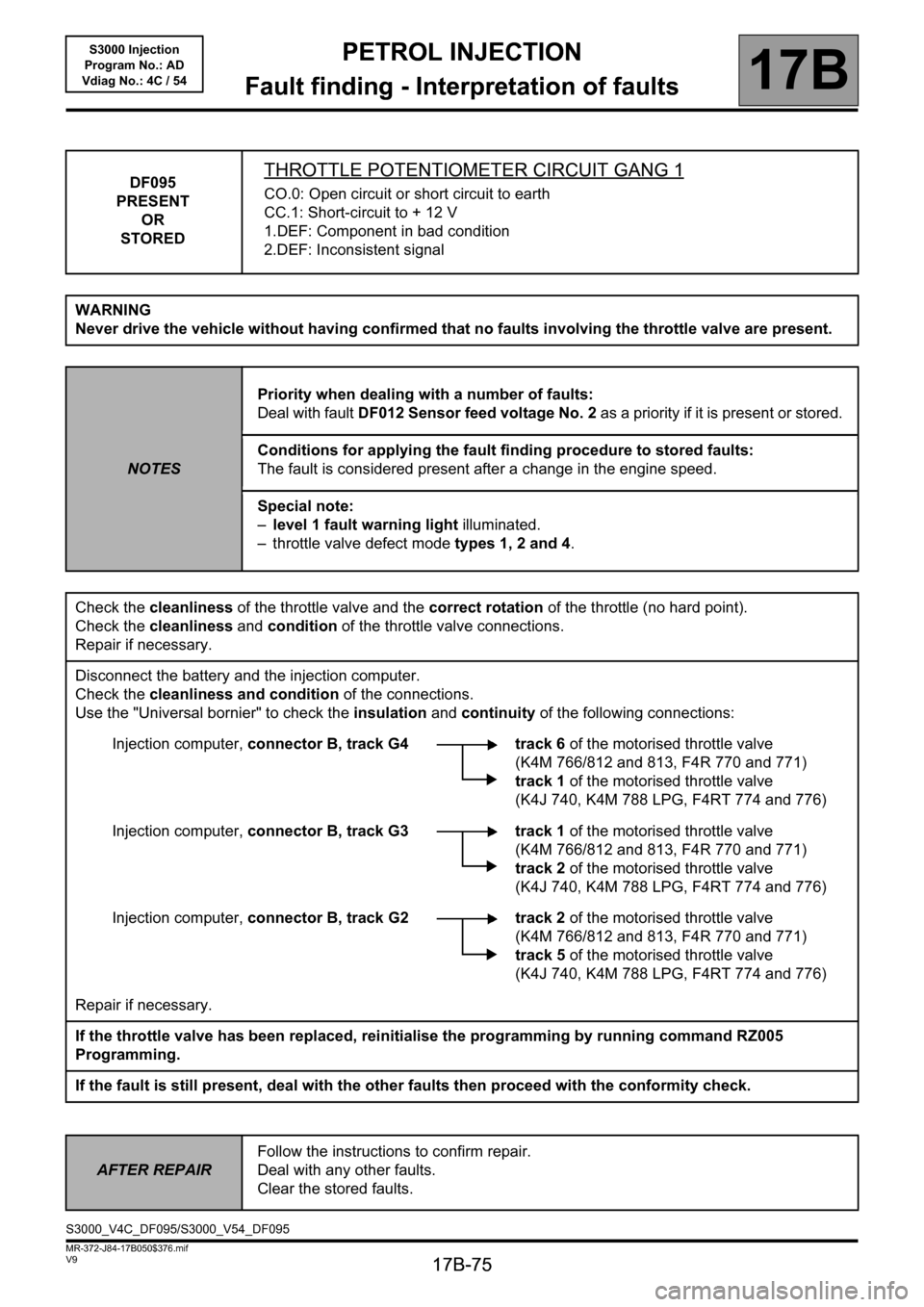

Page 75 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-75

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-75V9 MR-372-J84-17B050$376.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

DF095

PRESENT

OR

STOREDTHROTTLE POTENTIOMETER CIRCUIT GANG 1

CO.0: Open circuit or short circuit to earth

CC.1: Short-circuit to + 12 V

1.DEF: Component in bad condition

2.DEF: Inconsistent signal

WARNING

Never drive the vehicle without having confirmed that no faults involving the throttle valve are present.

NOTESPriority when dealing with a number of faults:

Deal with fault DF012 Sensor feed voltage No. 2 as a priority if it is present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is considered present after a change in the engine speed.

Special note:

–level 1 fault warning light illuminated.

– throttle valve defect mode types 1, 2 and 4.

Check the cleanliness of the throttle valve and the correct rotation of the throttle (no hard point).

Check the cleanliness and condition of the throttle valve connections.

Repair if necessary.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Use the "Universal bornier" to check the insulation and continuity of the following connections:

Injection computer, connector B, track G4 track 6 of the motorised throttle valve

(K4M 766/812 and 813, F4R 770 and 771)

track 1 of the motorised throttle valve

(K4J 740, K4M 788 LPG, F4RT 774 and 776)

Injection computer, connector B, track G3 track 1 of the motorised throttle valve

(K4M 766/812 and 813, F4R 770 and 771)

track 2 of the motorised throttle valve

(K4J 740, K4M 788 LPG, F4RT 774 and 776)

Injection computer, connector B, track G2 track 2 of the motorised throttle valve

(K4M 766/812 and 813, F4R 770 and 771)

track 5 of the motorised throttle valve

(K4J 740, K4M 788 LPG, F4RT 774 and 776)

Repair if necessary.

If the throttle valve has been replaced, reinitialise the programming by running command RZ005

Programming.

If the fault is still present, deal with the other faults then proceed with the conformity check.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF095/S3000_V54_DF095

Page 122 of 230

PETROL INJECTION

Fault finding - Conformity check

17B

17B-122

PETROL INJECTION

Fault finding - Conformity check

17B

17B-122V9 MR-372-J84-17B050$470.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

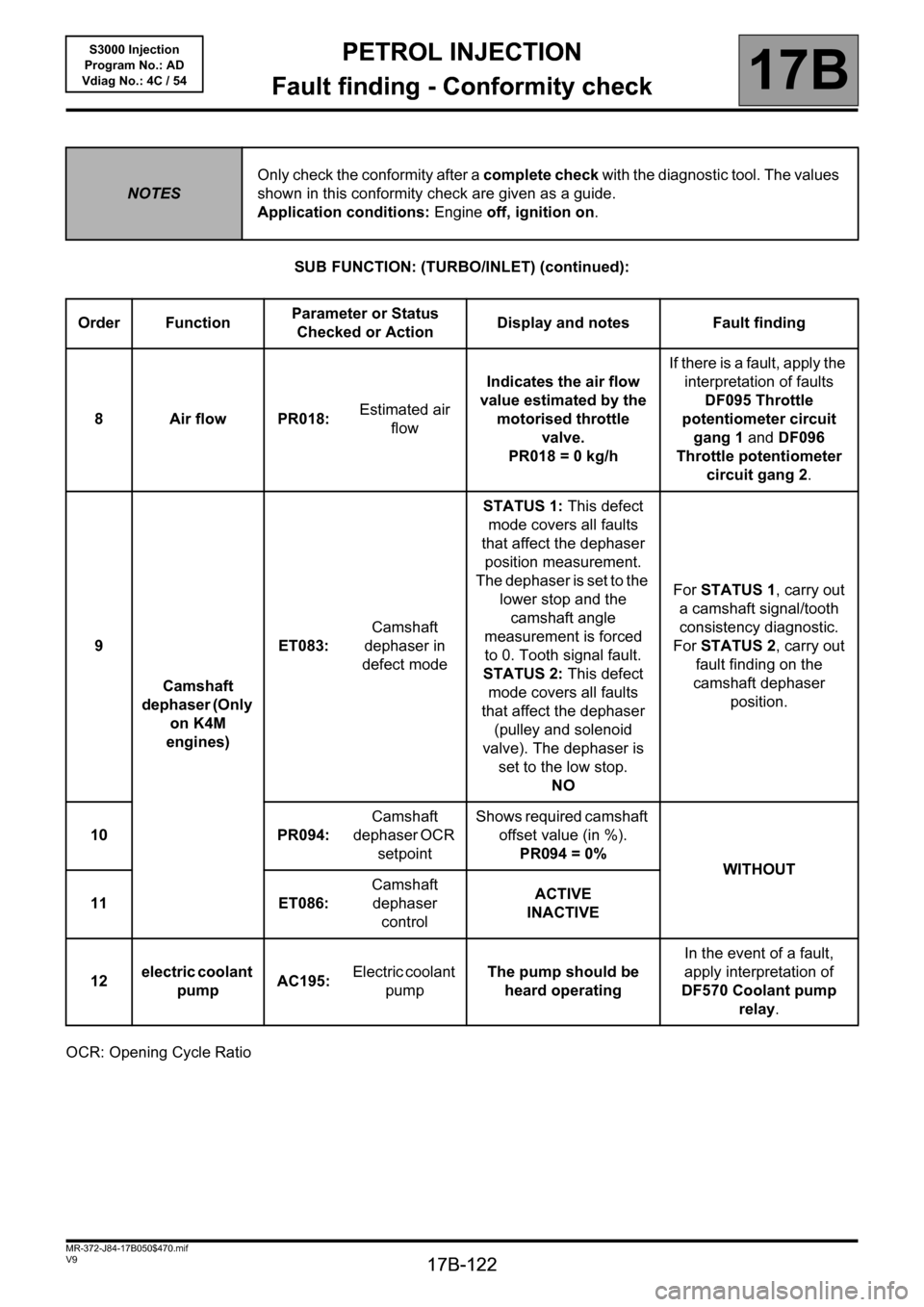

SUB FUNCTION: (TURBO/INLET) (continued):

OCR: Opening Cycle Ratio

NOTESOnly check the conformity after a complete check with the diagnostic tool. The values

shown in this conformity check are given as a guide.

Application conditions: Engine off, ignition on.

Order FunctionParameter or Status

Checked or ActionDisplay and notes Fault finding

8 Air flow PR018:Estimated air

flowIndicates the air flow

value estimated by the

motorised throttle

valve.

PR018= 0kg/hIf there is a fault, apply the

interpretation of faults

DF095 Throttle

potentiometer circuit

gang 1 and DF096

Throttle potentiometer

circuit gang 2.

9

Camshaft

dephaser (Only

on K4M

engines)ET083:Camshaft

dephaser in

defect modeSTATUS 1: This defect

mode covers all faults

that affect the dephaser

position measurement.

The dephaser is set to the

lower stop and the

camshaft angle

measurement is forced

to 0. Tooth signal fault.

STATUS 2: This defect

mode covers all faults

that affect the dephaser

(pulley and solenoid

valve). The dephaser is

set to the low stop.

NOFor STATUS 1, carry out

a camshaft signal/tooth

consistency diagnostic.

For STATUS 2, carry out

fault finding on the

camshaft dephaser

position.

10 PR094:Camshaft

dephaser OCR

setpointShows required camshaft

offset value (in %).

PR094 = 0%

WITHOUT

11 ET086:Camshaft

dephaser

controlACTIVE

INACTIVE

12electric coolant

pumpAC195:Electric coolant

pumpThe pump should be

heard operatingIn the event of a fault,

apply interpretation of

DF570 Coolant pump

relay.

Page 129 of 230

PETROL INJECTION

Fault finding - Conformity check

17B

17B-129

PETROL INJECTION

Fault finding - Conformity check

17B

17B-129V9 MR-372-J84-17B050$470.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

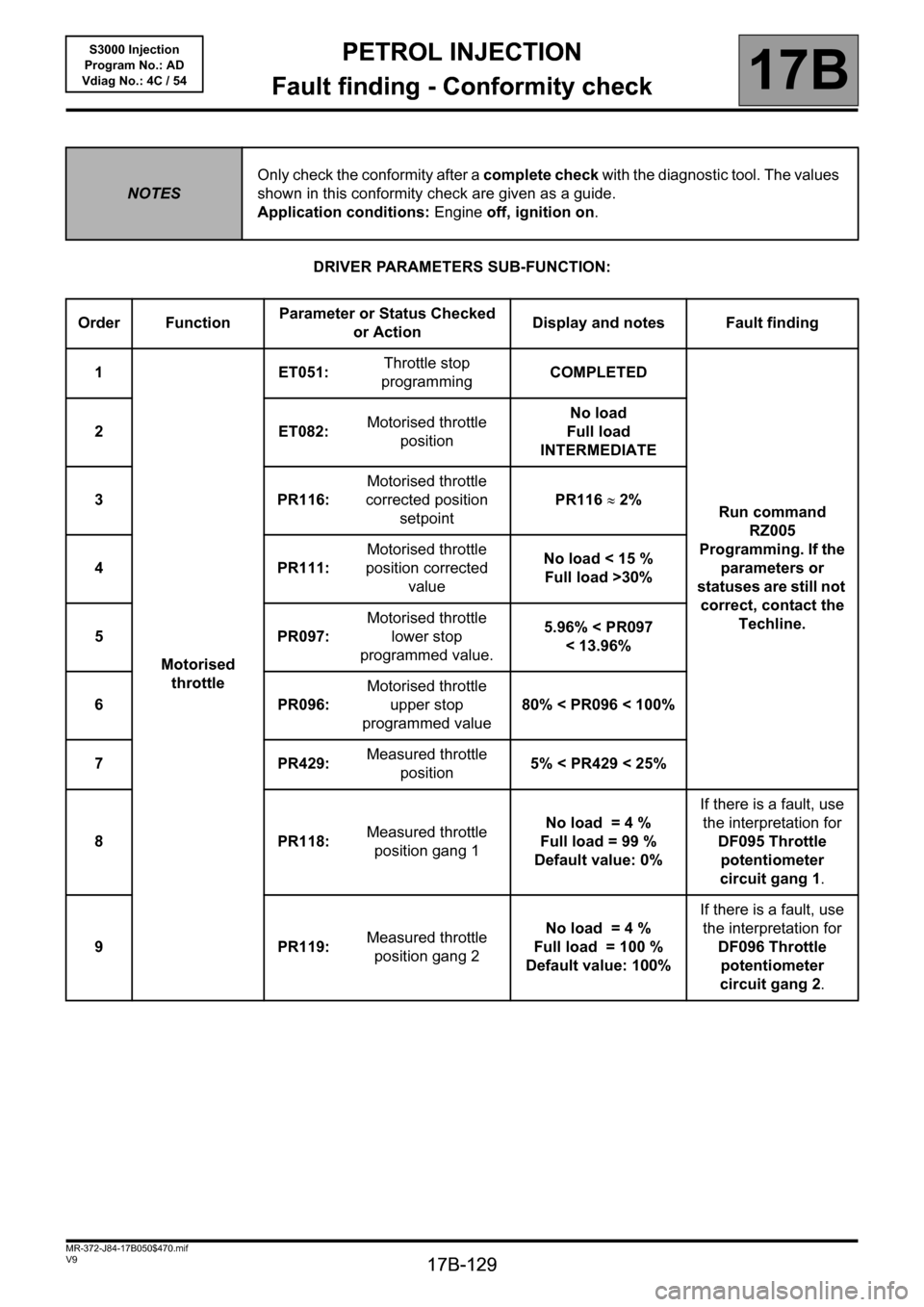

DRIVER PARAMETERS SUB-FUNCTION:

NOTESOnly check the conformity after a complete check with the diagnostic tool. The values

shown in this conformity check are given as a guide.

Application conditions: Engine off, ignition on.

Order FunctionParameter or Status Checked

or ActionDisplay and notes Fault finding

1

Motorised

throttleET051:Throttle stop

programmingCOMPLETED

Run command

RZ005

Programming. If the

parameters or

statuses are still not

correct, contact the

Techline. 2ET082:Motorised throttle

positionNo load

Full load

INTERMEDIATE

3 PR116:Motorised throttle

corrected position

setpointPR116 ≈ 2%

4 PR111:Motorised throttle

position corrected

valueNo load < 15 %

Full load >30%

5 PR097:Motorised throttle

lower stop

programmed value.5.96% < PR097

< 13.96%

6 PR096:Motorised throttle

upper stop

programmed value80%

position5% < PR429 < 25%

8 PR118:Measured throttle

position gang 1No load = 4 %

Full load = 99 %

Default value: 0%If there is a fault, use

the interpretation for

DF095 Throttle

potentiometer

circuit gang 1.

9 PR119:Measured throttle

position gang 2No load = 4 %

Full load = 100 %

Default value: 100%If there is a fault, use

the interpretation for

DF096 Throttle

potentiometer

circuit gang 2.

Page 132 of 230

PETROL INJECTION

Fault finding - Conformity check

17B

17B-132

PETROL INJECTION

Fault finding - Conformity check

17B

17B-132V9 MR-372-J84-17B050$470.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

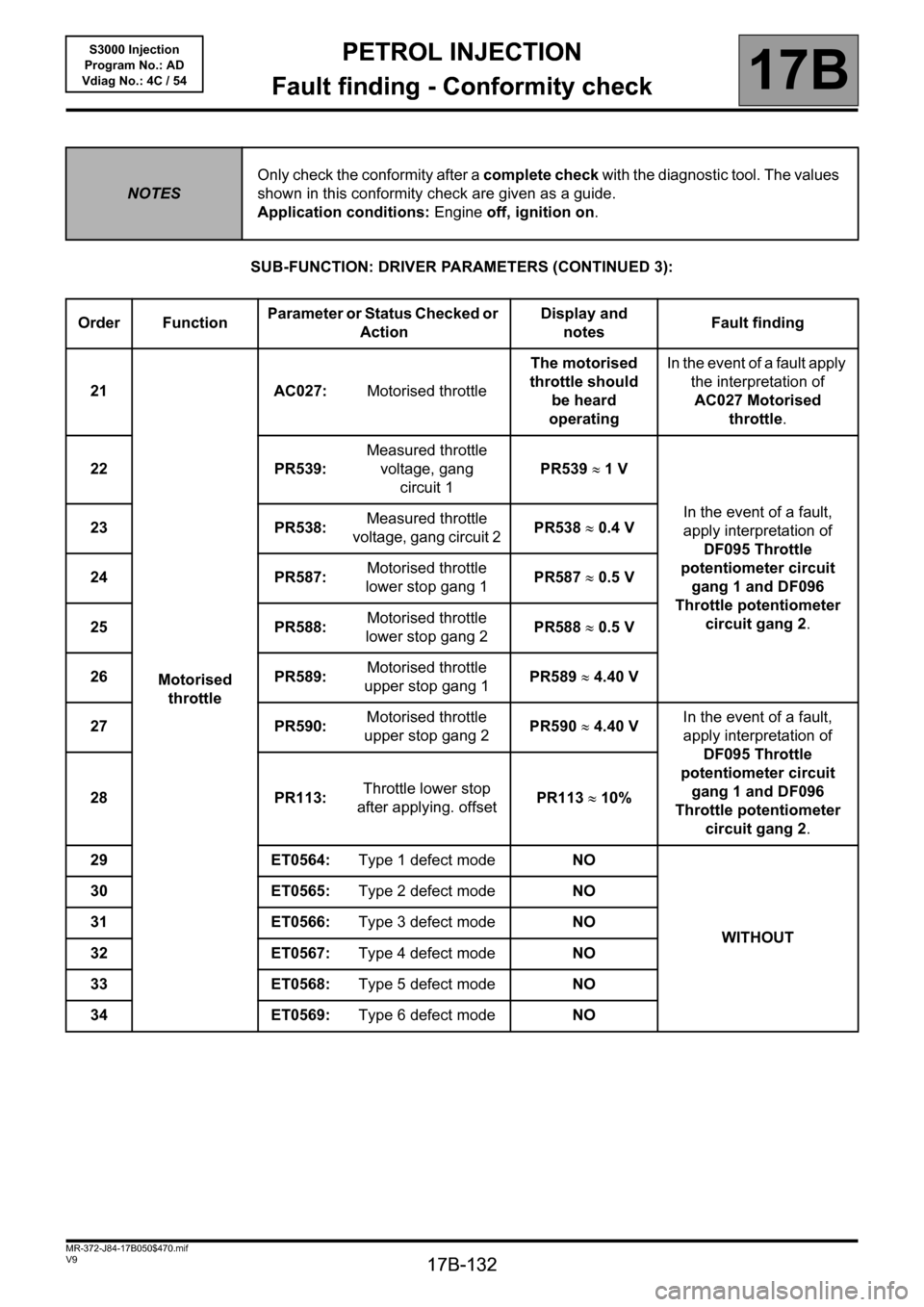

SUB-FUNCTION: DRIVER PARAMETERS (CONTINUED 3):

NOTESOnly check the conformity after a complete check with the diagnostic tool. The values

shown in this conformity check are given as a guide.

Application conditions: Engine off, ignition on.

Order FunctionParameter or Status Checked or

ActionDisplay and

notes Fault finding

21

Motorised

throttleAC027:Motorised throttleThe motorised

throttle should

be heard

operatingIn the event of a fault apply

the interpretation of

AC027 Motorised

throttle.

22 PR539:Measured throttle

voltage, gang

circuit 1PR539≈ 1 V

In the event of a fault,

apply interpretation of

DF095 Throttle

potentiometer circuit

gang 1 and DF096

Throttle potentiometer

circuit gang 2. 23 PR538:Measured throttle

voltage, gang circuit 2PR538≈ 0.4 V

24 PR587:Motorised throttle

lower stop gang 1PR587≈ 0.5 V

25 PR588:Motorised throttle

lower stop gang 2PR588≈ 0.5 V

26 PR589:Motorised throttle

upper stop gang 1PR589≈ 4.40 V

27 PR590:Motorised throttle

upper stop gang 2PR590≈ 4.40 VIn the event of a fault,

apply interpretation of

DF095 Throttle

potentiometer circuit

gang 1 and DF096

Throttle potentiometer

circuit gang 2. 28 PR113:Throttle lower stop

after applying. offsetPR113≈ 10%

29 ET0564:Type 1 defect modeNO

WITHOUT 30 ET0565:Type 2 defect modeNO

31 ET0566:Type 3 defect modeNO

32 ET0567:Type 4 defect mode

NO

33 ET0568:Type 5 defect modeNO

34 ET0569:Type 6 defect modeNO

Page 146 of 230

PETROL INJECTION

Fault finding - Conformity check

17B

17B-146

PETROL INJECTION

Fault finding - Conformity check

17B

17B-146V9 MR-372-J84-17B050$470.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

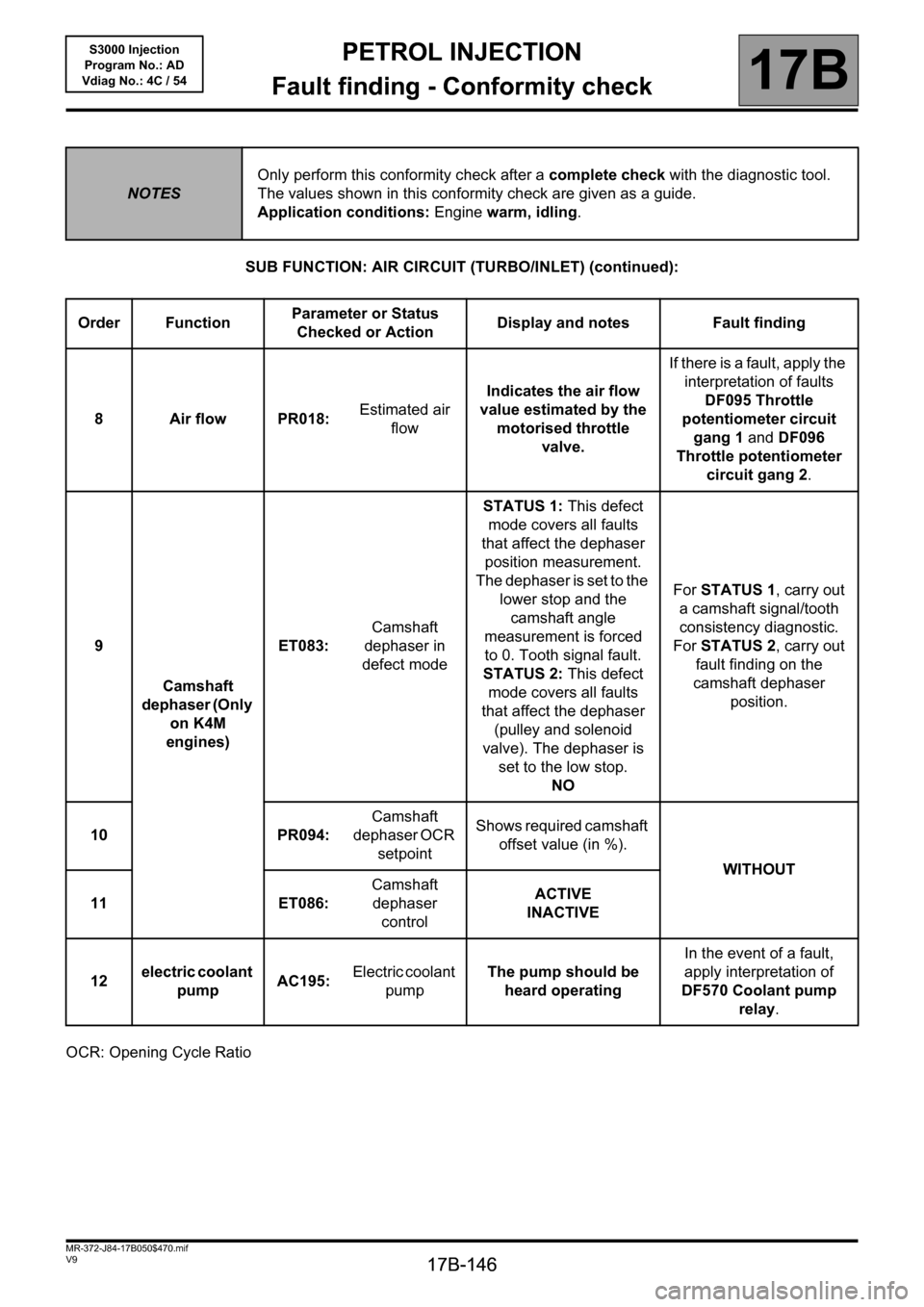

SUB FUNCTION: AIR CIRCUIT (TURBO/INLET) (continued):

OCR: Opening Cycle Ratio

NOTESOnly perform this conformity check after a complete check with the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application conditions: Engine warm, idling.

Order FunctionParameter or Status

Checked or ActionDisplay and notes Fault finding

8 Air flow PR018:Estimated air

flowIndicates the air flow

value estimated by the

motorised throttle

valve.If there is a fault, apply the

interpretation of faults

DF095 Throttle

potentiometer circuit

gang 1 and DF096

Throttle potentiometer

circuit gang 2.

9

Camshaft

dephaser (Only

on K4M

engines)ET083:Camshaft

dephaser in

defect modeSTATUS 1: This defect

mode covers all faults

that affect the dephaser

position measurement.

The dephaser is set to the

lower stop and the

camshaft angle

measurement is forced

to 0. Tooth signal fault.

STATUS 2: This defect

mode covers all faults

that affect the dephaser

(pulley and solenoid

valve). The dephaser is

set to the low stop.

NOFor STATUS 1, carry out

a camshaft signal/tooth

consistency diagnostic.

For STATUS 2, carry out

fault finding on the

camshaft dephaser

position.

10 PR094:Camshaft

dephaser OCR

setpointShows required camshaft

offset value (in %).

WITHOUT

11 ET086:Camshaft

dephaser

controlACTIVE

INACTIVE

12electric coolant

pumpAC195:Electric coolant

pumpThe pump should be

heard operatingIn the event of a fault,

apply interpretation of

DF570 Coolant pump

relay.

Page 153 of 230

PETROL INJECTION

Fault finding - Conformity check

17B

17B-153

PETROL INJECTION

Fault finding - Conformity check

17B

17B-153V9 MR-372-J84-17B050$517.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

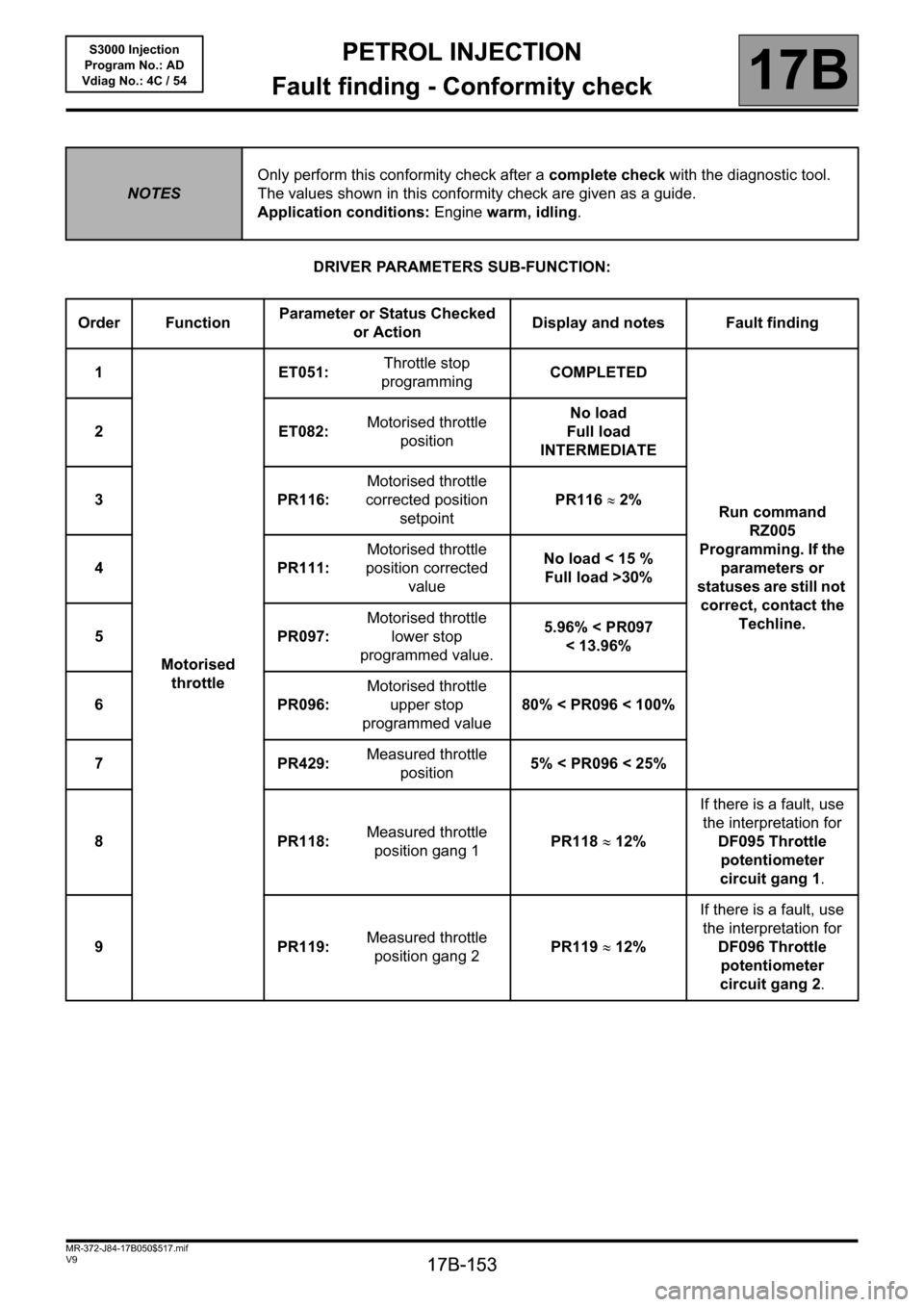

DRIVER PARAMETERS SUB-FUNCTION:

NOTESOnly perform this conformity check after a complete check with the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application conditions: Engine warm, idling.

Order FunctionParameter or Status Checked

or ActionDisplay and notes Fault finding

1

Motorised

throttleET051:Throttle stop

programmingCOMPLETED

Run command

RZ005

Programming. If the

parameters or

statuses are still not

correct, contact the

Techline. 2ET082:Motorised throttle

positionNo load

Full load

INTERMEDIATE

3 PR116:Motorised throttle

corrected position

setpointPR116≈ 2%

4 PR111:Motorised throttle

position corrected

valueNo load < 15 %

Full load >30%

5 PR097:Motorised throttle

lower stop

programmed value.5.96% < PR097

< 13.96%

6 PR096:Motorised throttle

upper stop

programmed value80%

position5% < PR096 < 25%

8 PR118:Measured throttle

position gang 1PR118≈ 12%If there is a fault, use

the interpretation for

DF095 Throttle

potentiometer

circuit gang 1.

9 PR119:Measured throttle

position gang 2PR119≈ 12%If there is a fault, use

the interpretation for

DF096 Throttle

potentiometer

circuit gang 2.