ECU RENAULT SCENIC 2010 J95 / 3.G Petrol Injection S3000 Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2010, Model line: SCENIC, Model: RENAULT SCENIC 2010 J95 / 3.GPages: 230, PDF Size: 0.92 MB

Page 3 of 230

PETROL INJECTION

Fault finding - Introduction

17B

17B-3

PETROL INJECTION

Fault finding - Introduction

17B

17B-3V9 MR-372-J84-17B050$047.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

Faults

Faults are displayed as present or stored (they appeared in a certain context and have since disappeared, or they

are still present but cannot be diagnosed in the current context).

The present or stored status of faults should be taken into consideration when the diagnostic tool is used after the

+ after ignition feed is switched on (without acting on the system components).

For a present fault, apply the procedure described in the Interpretation of faults section.

For a stored fault, note the faults displayed and apply the instructions in the Notes section.

If the fault is confirmed when the instructions are applied, the fault is present. Deal with the fault.

If the fault is not confirmed, check:

– the electrical lines which correspond to the fault,

– the connectors for these lines (for oxidation, bent pins, etc.),

– the resistance of the component detected as faulty,

– the condition of the wires (melted or split insulation, wear).

Conformity check

The aim of the conformity check is to check data that does not produce a fault on the diagnostic tool when the data

is inconsistent. Therefore, this stage is used to:

– perform fault finding on faults that do not have a fault display, and which may correspond to a customer complaint.

– check that the system is operating correctly and that there is no risk of a fault recurring after repair.

This section gives the fault finding procedures for statuses and parameters and the conditions for checking them.

If a status is not behaving normally or a parameter is outside the permitted tolerance values, consult the

corresponding fault finding page.

Customer complaints - Fault finding chart

If the test with the diagnostic tool is OK but the customer complaint is still present, the fault should be processed by

Customer complaints.

A summary of the overall procedure to follow is provided on the

following page in the form of a flow chart

Page 6 of 230

PETROL INJECTION

Fault finding - Introduction

17B

17B-6

PETROL INJECTION

Fault finding - Introduction

17B

17B-6V9 MR-372-J84-17B050$047.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

5. FAULT FINDING LOG

You will always be asked for this log:

– when requesting technical assistance from Techline,

– for approval requests when replacing parts with mandatory approval, and to be enclosed when returning monitored

parts on request. The log is needed for warranty reimbursement, and enables better analysis of the parts removed.

6. SAFETY INSTRUCTIONS

Safety rules must be observed during any work on a component to prevent any damage or injury:

– check the battery voltage to avoid incorrect operation of computer functions,

– use the proper tools.

7. FAULT FINDING

Stored faults are managed the same way for all sensors and actuators.

A stored fault is cleared after 128 recurrence-free starts. IMPORTANT!IMPORTANT

Any fault on a complex system requires thorough fault finding with the appropriate tools. The

FAULT FINDING LOG, which should be completed during the fault finding procedure, ensures a

record is kept of the procedure carried out. It is an essential document when consulting the

manufacturer.

IT IS THEREFORE MANDATORY TO FILL OUT A FAULT FINDING LOG EACH TIME FAULT FINDING IS

CARRIED OUT.

Page 8 of 230

PETROL INJECTION

Fault finding - System operation

17B

17B - 8

PETROL INJECTION

Fault finding - System operation

17B

17B - 8V9 MR-372-J84-17B050$094.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

2. Role of components, operating strategy

Engine immobiliser

The Verlog 4 type immobiliser function is managed by the UCH computer and the engine management computer.

Before any starting request, the engine management computer is protected.

When a starting request is made, the injection computer and the UCH exchange authentication data via the multiplex

network; this determines whether the engine start is authorised.

After more than 5 consecutive failed authentication attempts, the engine management computer goes into protection

(antiscanning) mode and no longer tries to authenticate the UCH computer. It only exits this mode when the

following sequence of operations occurs:

– the ignition is left on for at least 20 seconds,

– the message is switched off,

– the injection computer self-supply cuts out when it should (the time varies according to engine temperature).

After this, only one authentication attempt is allowed. If this fails again, repeat the sequence of operations described

above.

If the engine management computer still fails to unlock, contact the Techline.

Impact detected

If an impact has been stored by the injection computer, switch off the ignition for 10 seconds, then switch it back on

so that the engine can be started. Clear the faults.

Torque management

The torque structure is the system for managing engine torque. It is necessary for some functions such as the

electronic stability program (ESP) and the automatic gearbox.

Each inter-system (ESP and automatic gearbox) sends a request for torque via the multiplex network to the injection

computer. It arbitrates between the inter-system torque requests and the driver's request (pedal or cruise control/

speed limiter). The result of the arbitration gives the torque setpoint. The torque structure uses the torque setpoint to

calculate the throttle position setpoint, the advance and, if there is turbocharging, the turbocharger valve setpoint

(wastegate) for engines fitted with a turbocharger. WARNING

Disconnect the injection computer when carrying out any welding work on the vehicle.

Page 12 of 230

PETROL INJECTION

Fault finding - System operation

17B

17B - 12

PETROL INJECTION

Fault finding - System operation

17B

17B - 12V9 MR-372-J84-17B050$094.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

A vehicle is fitted with an upstream sensor if the configuration reading LC003 Upstream oxygen sensor is WITH.

For the upstream sensor to be operational very rapidly, it is heated. Sensor heating ET052 Upstream O

2 sensor

heating is only ACTIVE when the engine is running. It is disabled above 84 mph (140 km/h) or with the engine

under load.

The downstream sensor is also used for richness regulation via the double loop program. The way it works is to

characterise the condition of the upstream sensor and to compensate for any upstream sensor dynamic richness

drift.

The vehicle is fitted with a downstream sensor if the configuration reading LC004 Downstream oxygen sensor is

WITH.

For the double loop ET056 Double richness loop to be ACTIVE, the vehicle must be driven with the engine warm

for approximately 1 minute 30 seconds in the absence of no load conditions.

The downstream sensor is also heated. The command is not immediate when the engine is started.

ET053 Downstream O

2 sensor heating is ACTIVE after a time that depends on the latest coolant temperature with

the engine running and in the absence of no load conditions. The heating of the downstream sensor is deactivated

under 84 mph (140 km/h) or when the engine is under load.

There are several types of control depending on the sensor type:

●BOSCH LSH25/NTK 6L (6Ω)/DELPHI AFS128 (3 wires): Continuous control,

●BOSCH LSF 4.7 (known as PLANAR): Each time the engine is started, control is first executed by means

of an OCR (opening cycle ratio) type signal of 20 Hz in frequency for approximately 20 seconds then it

becomes continuous,

●BOSCH NTK 6L (3.3Ω): each time the engine is started, the control is continuous first for 15 seconds then

executed by an OCR (Opening Cycle Ratio) type signal with a 20 Hz frequency.

Management of turbocharging pressure (F4R Turbo only)

The turbocharging pressure is adjusted via the position of the pressure regulation valve (wastegate).

Principle

This pressure regulation valve, connected via a rod to the wastegate diaphragm, is operated by the injection

computer via a solenoid valve. This solenoid valve is normally open and is fitted to the inlet pipe between the air filter

and turbocharger inlet.

At rest (open position), this solenoid valve connects the turbocharger outlet (turbocharging pressure) and the

pressure regulation valve control diaphragm.

The turbocharging pressure affects the diaphragm directly, the pressure regulation valve (wastegate) opens and the

maximum possible pressure is approximately 1,350 mbar - 1,400 mbar, irrespective of the engine speed (minimum

turbocharging for the engine).

When the solenoid valve is controlled, the turbocharging pressure signal (taken at the turbocharger outlet) is

diverted to the compressor inlet. As a result, the diaphragm is not subject to turbocharging pressure, the pressure

regulation valve (wastegate) closes back to a position imposed by the regulation system.

Page 14 of 230

PETROL INJECTION

Fault finding - System operation

17B

17B - 14

PETROL INJECTION

Fault finding - System operation

17B

17B - 14V9 MR-372-J84-17B050$094.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

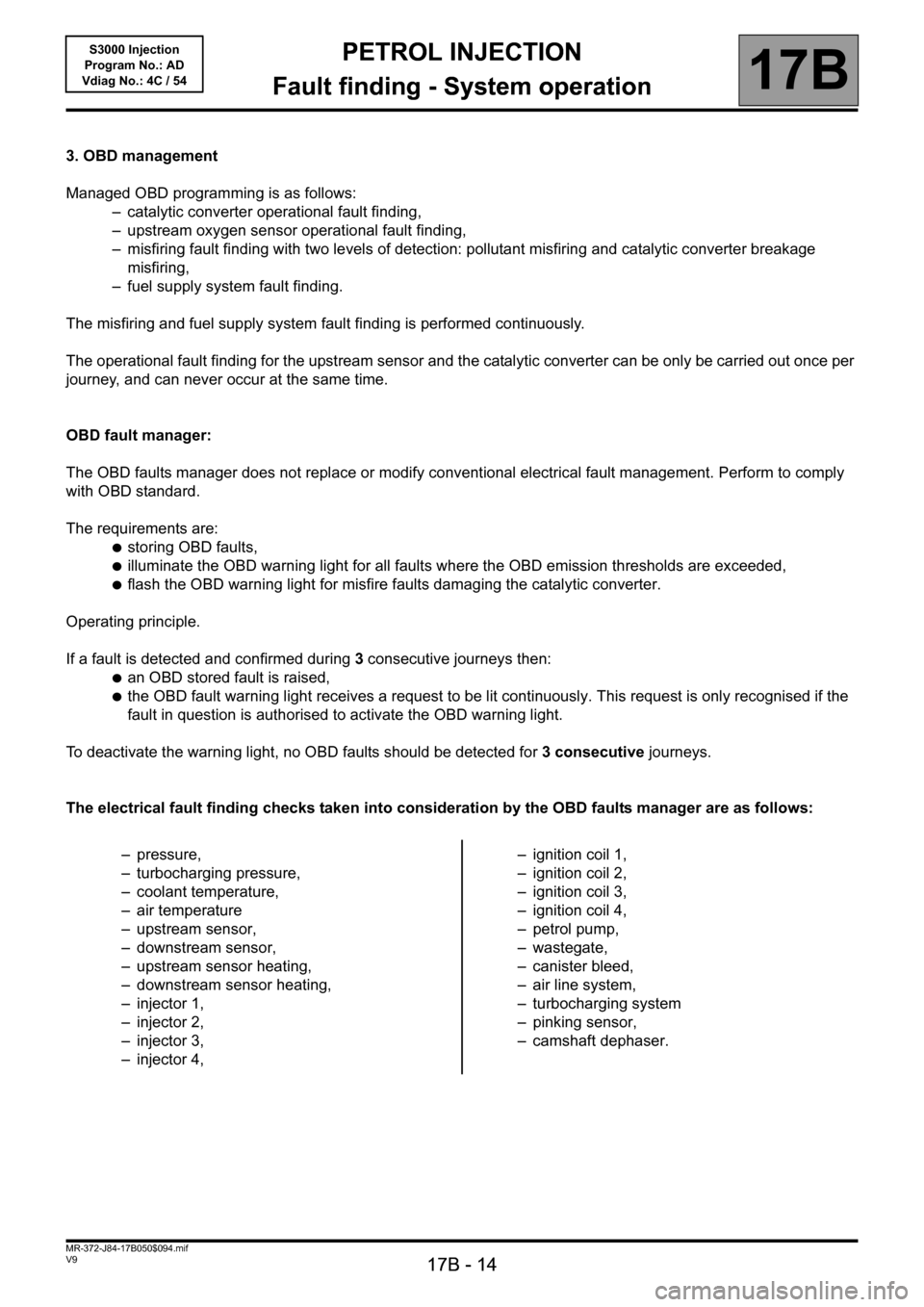

3. OBD management

Managed OBD programming is as follows:

– catalytic converter operational fault finding,

– upstream oxygen sensor operational fault finding,

– misfiring fault finding with two levels of detection: pollutant misfiring and catalytic converter breakage

misfiring,

– fuel supply system fault finding.

The misfiring and fuel supply system fault finding is performed continuously.

The operational fault finding for the upstream sensor and the catalytic converter can be only be carried out once per

journey, and can never occur at the same time.

OBD fault manager:

The OBD faults manager does not replace or modify conventional electrical fault management. Perform to comply

with OBD standard.

The requirements are:

●storing OBD faults,

●illuminate the OBD warning light for all faults where the OBD emission thresholds are exceeded,

●flash the OBD warning light for misfire faults damaging the catalytic converter.

Operating principle.

If a fault is detected and confirmed during 3 consecutive journeys then:

●an OBD stored fault is raised,

●the OBD fault warning light receives a request to be lit continuously. This request is only recognised if the

fault in question is authorised to activate the OBD warning light.

To deactivate the warning light, no OBD faults should be detected for 3 consecutive journeys.

The electrical fault finding checks taken into consideration by the OBD faults manager are as follows:

– pressure,

– turbocharging pressure,

– coolant temperature,

– air temperature

– upstream sensor,

– downstream sensor,

– upstream sensor heating,

– downstream sensor heating,

–injector1,

–injector2,

–injector3,

–injector4,– ignition coil 1,

– ignition coil 2,

– ignition coil 3,

– ignition coil 4,

– petrol pump,

– wastegate,

– canister bleed,

– air line system,

– turbocharging system

– pinking sensor,

– camshaft dephaser.

Page 15 of 230

PETROL INJECTION

Fault finding - System operation

17B

17B - 15

PETROL INJECTION

Fault finding - System operation

17B

17B - 15V9 MR-372-J84-17B050$094.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

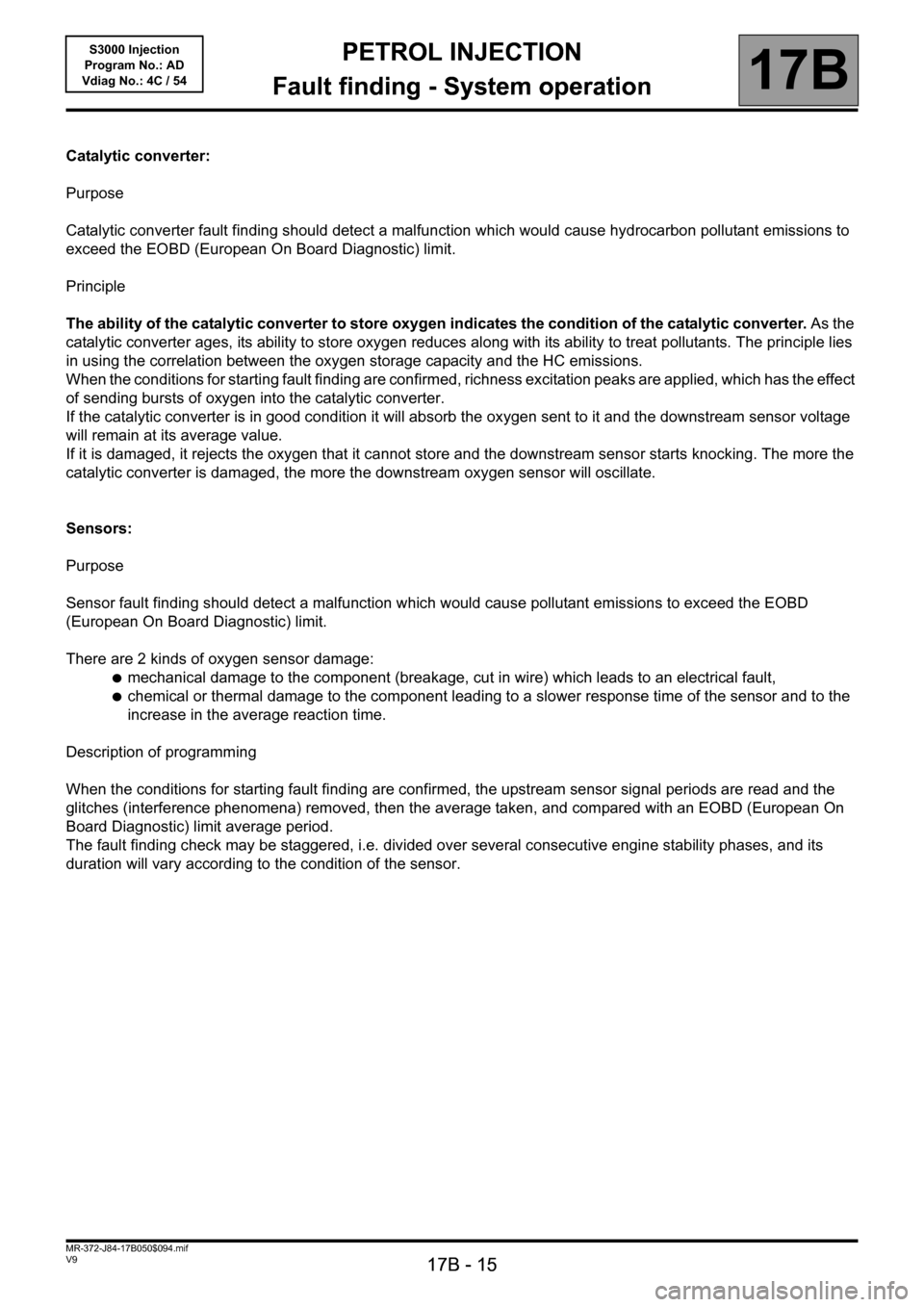

Catalytic converter:

Purpose

Catalytic converter fault finding should detect a malfunction which would cause hydrocarbon pollutant emissions to

exceed the EOBD (European On Board Diagnostic) limit.

Principle

The ability of the catalytic converter to store oxygen indicates the condition of the catalytic converter. As the

catalytic converter ages, its ability to store oxygen reduces along with its ability to treat pollutants. The principle lies

in using the correlation between the oxygen storage capacity and the HC emissions.

When the conditions for starting fault finding are confirmed, richness excitation peaks are applied, which has the effect

of sending bursts of oxygen into the catalytic converter.

If the catalytic converter is in good condition it will absorb the oxygen sent to it and the downstream sensor voltage

will remain at its average value.

If it is damaged, it rejects the oxygen that it cannot store and the downstream sensor starts knocking. The more the

catalytic converter is damaged, the more the downstream oxygen sensor will oscillate.

Sensors:

Purpose

Sensor fault finding should detect a malfunction which would cause pollutant emissions to exceed the EOBD

(European On Board Diagnostic) limit.

There are 2 kinds of oxygen sensor damage:

●mechanical damage to the component (breakage, cut in wire) which leads to an electrical fault,

●chemical or thermal damage to the component leading to a slower response time of the sensor and to the

increase in the average reaction time.

Description of programming

When the conditions for starting fault finding are confirmed, the upstream sensor signal periods are read and the

glitches (interference phenomena) removed, then the average taken, and compared with an EOBD (European On

Board Diagnostic) limit average period.

The fault finding check may be staggered, i.e. divided over several consecutive engine stability phases, and its

duration will vary according to the condition of the sensor.

Page 27 of 230

PETROL INJECTION

Fault finding - Replacement of components

17B

17B-27

PETROL INJECTION

Fault finding - Replacement of components

17B

17B-27V9 MR-372-J84-17B050$188.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54PETROL INJECTION

Fault finding - Replacement of components

2. REPLACING OR REMOVING THE TDC SENSOR

When replacing or removing the TDC sensor, program the flywheel target (see17B, Petrol injection,

Configuration and programming).

3. REPLACING THE MOTORISED THROTTLE VALVE

When replacing the throttle valve, the throttle stops are automatically programmed.

–PR058 Air temperature between 0°C and 105°C,

– wait for the end of power latch for the programming to be stored in the computer memory.

Check the programming using status ET051 Throttle stop programming is DONE.

When replacing the throttle valve, reinitialise the programming using command RZ005 Programming. IMPORTANT

– The injection computer retains the immobiliser code for life,

– the system has no security code,

– it is forbidden to perform tests with computers borrowed from the Parts Department or from another vehicle which

must then be returned. These computers are hard-coded.

IMPORTANT

Never drive the vehicle without having programmed the throttle stops.

Page 175 of 230

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 175

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 175V9 MR-372-J84-17B050$611.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

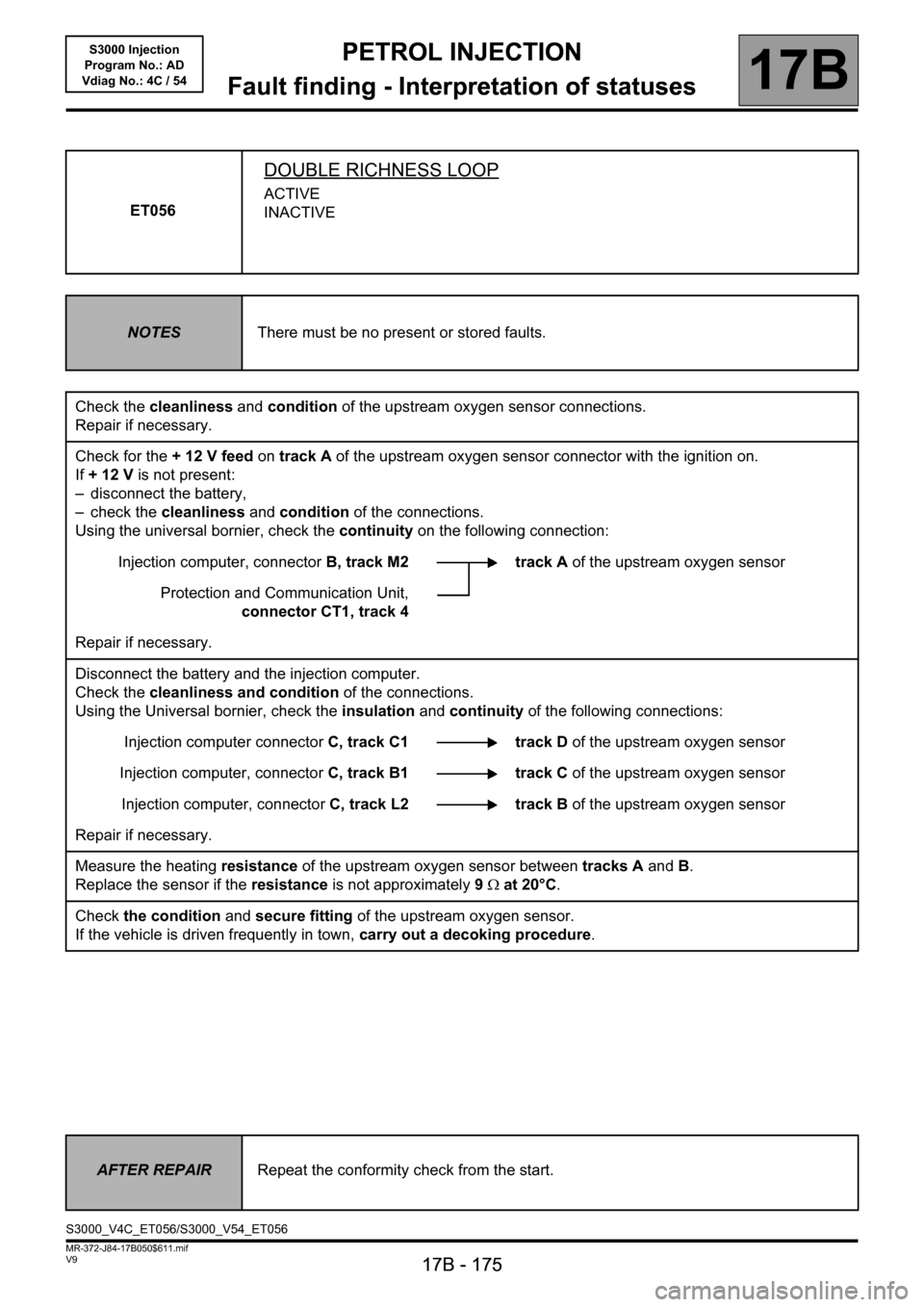

ET056

DOUBLE RICHNESS LOOP

ACTIVE

INACTIVE

NOTESThere must be no present or stored faults.

Check the cleanliness and condition of the upstream oxygen sensor connections.

Repair if necessary.

Check for the + 12 V feed on track A of the upstream oxygen sensor connector with the ignition on.

If +12V is not present:

– disconnect the battery,

– check the cleanliness and condition of the connections.

Using the universal bornier, check the continuity on the following connection:

Injection computer, connectorB, track M2 track A of the upstream oxygen sensor

Protection and Communication Unit,

connector CT1, track 4

Repair if necessary.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Using the Universal bornier, check the insulation and continuity of the following connections:

Injection computer connectorC, track C1 track D of the upstream oxygen sensor

Injection computer, connectorC, track B1 track C of the upstream oxygen sensor

Injection computer, connectorC, track L2 track B of the upstream oxygen sensor

Repair if necessary.

Measure the heating resistance of the upstream oxygen sensor between tracks A and B.

Replace the sensor if the resistance is not approximately 9Ω at 20°C.

Check the condition and secure fitting of the upstream oxygen sensor.

If the vehicle is driven frequently in town, carry out a decoking procedure.

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_ET056/S3000_V54_ET056

Page 176 of 230

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 176

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 176V9 MR-372-J84-17B050$611.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

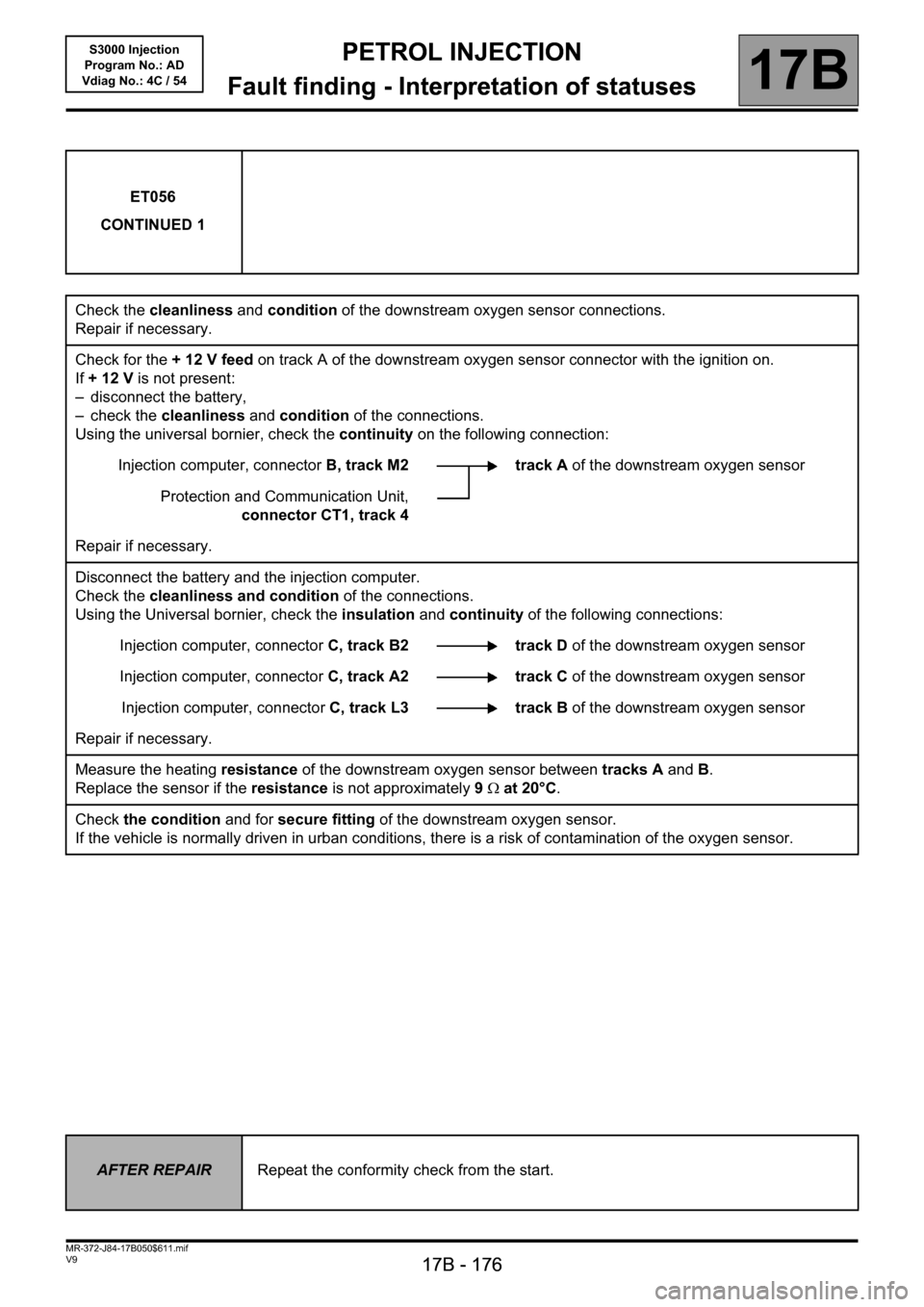

ET056

CONTINUED 1

Check the cleanliness and condition of the downstream oxygen sensor connections.

Repair if necessary.

Check for the + 12 V feed on track A of the downstream oxygen sensor connector with the ignition on.

If +12V is not present:

– disconnect the battery,

– check the cleanliness and condition of the connections.

Using the universal bornier, check the continuity on the following connection:

Injection computer, connectorB, track M2 track A of the downstream oxygen sensor

Protection and Communication Unit,

connector CT1, track 4

Repair if necessary.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Using the Universal bornier, check the insulation and continuity of the following connections:

Injection computer, connectorC, track B2 track D of the downstream oxygen sensor

Injection computer, connectorC, track A2 track C of the downstream oxygen sensor

Injection computer, connectorC, track L3 track B of the downstream oxygen sensor

Repair if necessary.

Measure the heating resistance of the downstream oxygen sensor between tracks A and B.

Replace the sensor if the resistance is not approximately 9Ω at 20°C.

Check the condition and for secure fitting of the downstream oxygen sensor.

If the vehicle is normally driven in urban conditions, there is a risk of contamination of the oxygen sensor.

AFTER REPAIRRepeat the conformity check from the start.