clutch RENAULT SCENIC 2010 J95 / 3.G Petrol Injection S3000 Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2010, Model line: SCENIC, Model: RENAULT SCENIC 2010 J95 / 3.GPages: 230, PDF Size: 0.92 MB

Page 7 of 230

PETROL INJECTION

Fault finding - System operation

17B

17B - 7

PETROL INJECTION

Fault finding - System operation

17B

17B - 7V9 MR-372-J84-17B050$094.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54PETROL INJECTION

Fault finding - System operation

1. SYSTEM OPERATION

Composition

The injection system consists of the:

– accelerator potentiometer,

– clutch pedal switch,

– TDC sensor,

– atmospheric pressure sensor,

– air temperature sensor,

– coolant temperature sensor,

– upstream oxygen sensor,

– downstream oxygen sensor,

– cruise control switch,

– steering column switch,

– cruise control on/off switch,

– fuel vapour absorber,

– injection computer,

– motorised throttle valve,

– 4 injectors,

– 4 pencil coils,

– pinking sensor,

– camshaft dephaser solenoid valve (non-LPG K4M only),

– camshaft position sensor (non-LPG K4M only),

– turbocharging pressure sensor (F4R turbo only)

– electric coolant pump (F4R turbo only),

– wastegate solenoid valve (only on F4R Turbo),

– turbocharging solenoid valve (only on F4R-Turbo)

Computer

128 track SAGEM type S3000 FLASH EEPROM computer controlling injection and ignition.

Multipoint injection in sequential mode.

Connections to the other computers:

– air conditioning,

– UCH,

– protection and switching unit (UPC)

– Automatic Gearbox Electronic Control Unit (AUTO).

– airbag,

– ABS/ESP,

– instrument panel.

MR-372-J84-17B050$094.mif

Page 21 of 230

PETROL INJECTION

17B

17B - 21

17B

17B - 21V9 MR-372-J84-17B050$141.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54PETROL INJECTION

Fault finding - Allocation of computer tracks

Connector (A), 32 tracks:

Track Description

A1 Not used

A2 Cruise control on/off button logical input

A3 CAN L1 passenger compartment multiplex connection

A4 CAN H1 passenger compartment multiplex connection

B1 Not used

B2 Not used

B3 Not used

B4 OBD diagnostic line K

C1 Not used

C2 Not used

C3 Speed limiter on/off button logical input

C4 + Clutch switch signal

D1 + after ignition feed via UPC

D2 Cruise control signal analogue input

D3 Cruise control signal earth

D4 Not used

E1 Not used

E2 Not used

E3 Not used

E4 Brake pedal normally closed switch no. 1 signal

F1 Not used

F2 + 5 V supply, accelerator pedal potentiometer gang 2

F3 Accelerator pedal potentiometer signal, gang 2

F4 Accelerator pedal potentiometer earth, gang 2

G1 Not used

G2 + 5 V supply, accelerator pedal potentiometer gang 1

G3 Not used

G4 Not used

H1 Not used

H2 Accelerator pedal potentiometer signal, gang 1

H3 Accelerator pedal potentiometer earth, gang 1

H4 Not used

MR-372-J84-17B050$141.mif

Page 29 of 230

PETROL INJECTION

Fault finding - Configurations and programming17B

17B - 29

17B

17B - 29V9 MR-372-J84-17B050$235.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

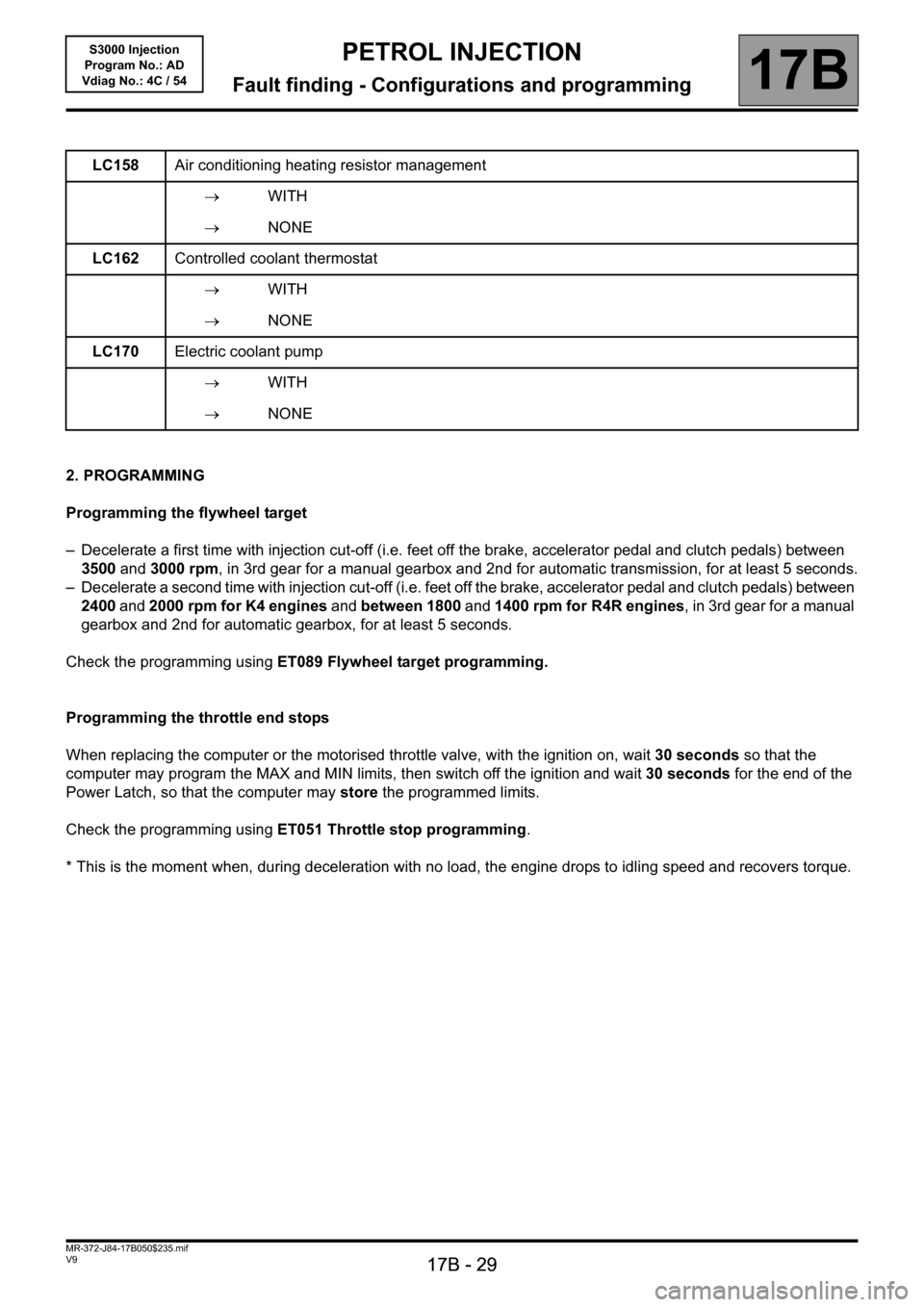

2. PROGRAMMING

Programming the flywheel target

– Decelerate a first time with injection cut-off (i.e. feet off the brake, accelerator pedal and clutch pedals) between

3500 and 3000 rpm, in 3rd gear for a manual gearbox and 2nd for automatic transmission, for at least 5 seconds.

– Decelerate a second time with injection cut-off (i.e. feet off the brake, accelerator pedal and clutch pedals) between

2400 and 2000 rpm for K4 engines and between 1800 and 1400 rpm for R4R engines, in 3rd gear for a manual

gearbox and 2nd for automatic gearbox, for at least 5 seconds.

Check the programming using ET089 Flywheel target programming.

Programming the throttle end stops

When replacing the computer or the motorised throttle valve, with the ignition on, wait 30 seconds so that the

computer may program the MAX and MIN limits, then switch off the ignition and wait 30 seconds for the end of the

Power Latch, so that the computer may store the programmed limits.

Check the programming using ET051 Throttle stop programming.

* This is the moment when, during deceleration with no load, the engine drops to idling speed and recovers torque. LC158Air conditioning heating resistor management

→WITH

→NONE

LC162Controlled coolant thermostat

→WITH

→NONE

LC170Electric coolant pump

→WITH

→NONE

Page 32 of 230

PETROL INJECTION

Fault finding - Fault summary table

17B

17B-32

PETROL INJECTION

Fault finding - Fault summary table

17B

17B-32V9 MR-372-J84-17B050$282.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

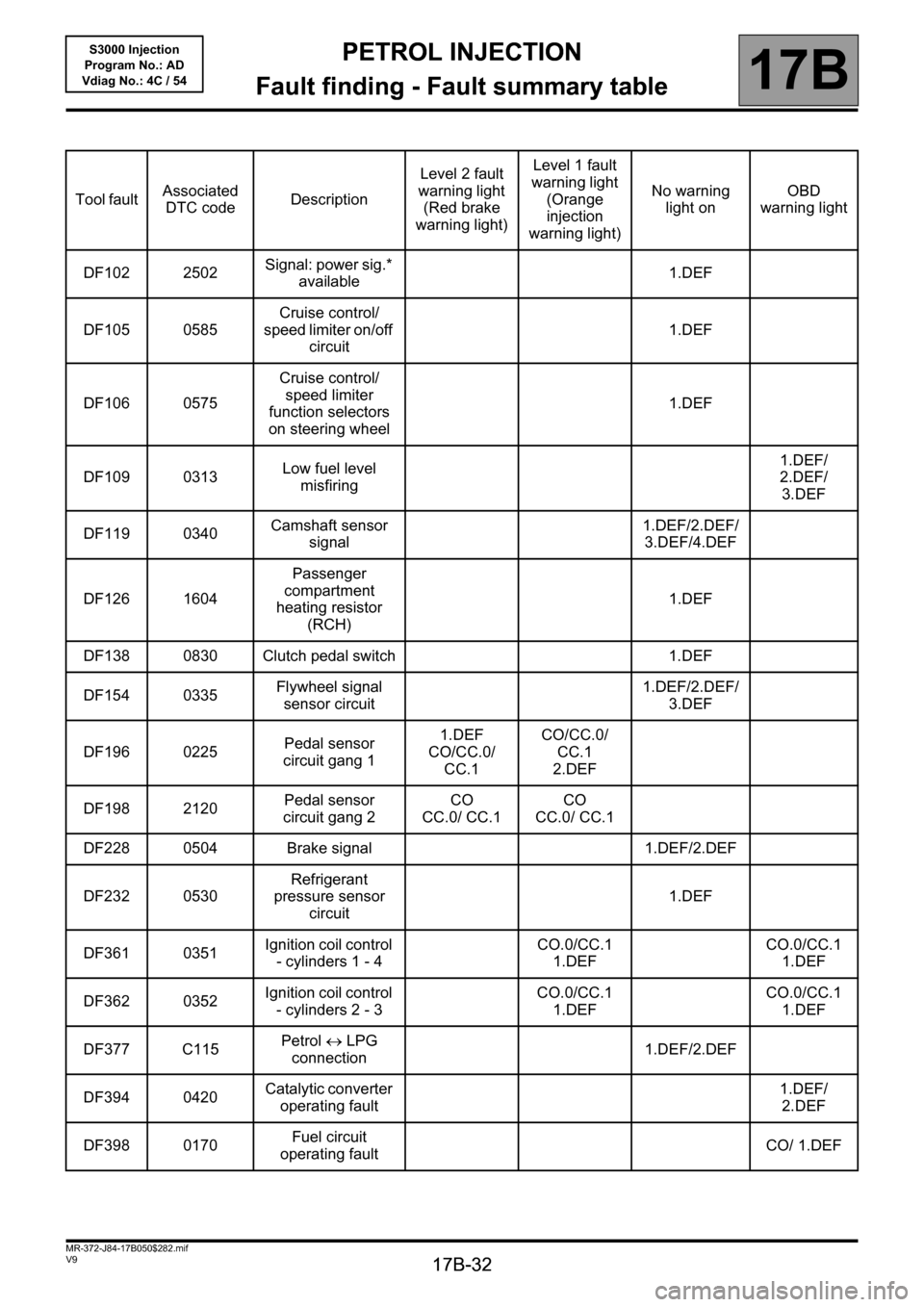

Tool faultAssociated

DTC codeDescriptionLevel 2 fault

warning light

(Red brake

warning light)Level 1 fault

warning light

(Orange

injection

warning light)No warning

light onOBD

warning light

DF102 2502Signal: power sig.*

available1.DEF

DF105 0585Cruise control/

speed limiter on/off

circuit1.DEF

DF106 0575Cruise control/

speed limiter

function selectors

on steering wheel1.DEF

DF109 0313Low fuel level

misfiring1.DEF/

2.DEF/

3.DEF

DF119 0340Camshaft sensor

signal1.DEF/2.DEF/

3.DEF/4.DEF

DF126 1604Passenger

compartment

heating resistor

(RCH)1.DEF

DF138 0830 Clutch pedal switch 1.DEF

DF154 0335Flywheel signal

sensor circuit1.DEF/2.DEF/

3.DEF

DF196 0225Pedal sensor

circuit gang 11.DEF

CO/CC.0/

CC.1CO/CC.0/

CC.1

2.DEF

DF198 2120Pedal sensor

circuit gang 2CO

CC.0/ CC.1CO

CC.0/ CC.1

DF228 0504 Brake signal 1.DEF/2.DEF

DF232 0530Refrigerant

pressure sensor

circuit1.DEF

DF361 0351Ignition coil control

- cylinders 1 - 4CO.0/CC.1

1.DEFCO.0/CC.1

1.DEF

DF362 0352Ignition coil control

- cylinders 2 - 3CO.0/CC.1

1.DEFCO.0/CC.1

1.DEF

DF377 C115Petrol↔ LPG

connection1.DEF/2.DEF

DF394 0420Catalytic converter

operating fault1.DEF/

2.DEF

DF398 0170Fuel circuit

operating faultCO/ 1.DEF

Page 86 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-86

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-86V9 MR-372-J84-17B050$376.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

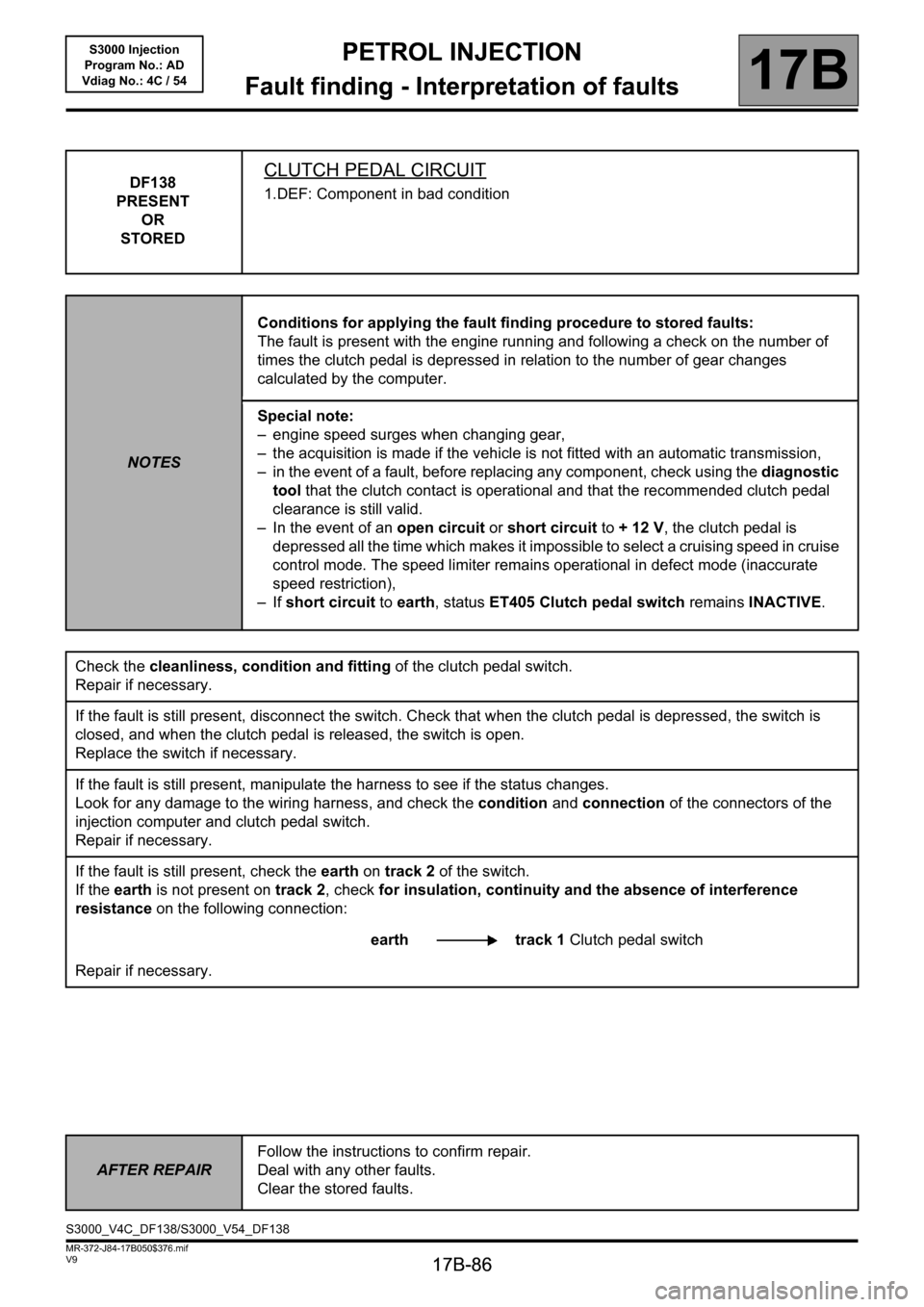

DF138

PRESENT

OR

STOREDCLUTCH PEDAL CIRCUIT

1.DEF: Component in bad condition

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is present with the engine running and following a check on the number of

times the clutch pedal is depressed in relation to the number of gear changes

calculated by the computer.

Special note:

– engine speed surges when changing gear,

– the acquisition is made if the vehicle is not fitted with an automatic transmission,

– in the event of a fault, before replacing any component, check using the diagnostic

tool that the clutch contact is operational and that the recommended clutch pedal

clearance is still valid.

– In the event of an open circuit or short circuit to + 12 V, the clutch pedal is

depressed all the time which makes it impossible to select a cruising speed in cruise

control mode. The speed limiter remains operational in defect mode (inaccurate

speed restriction),

–If short circuit to earth, status ET405 Clutch pedal switch remains INACTIVE.

Check the cleanliness, condition and fitting of the clutch pedal switch.

Repair if necessary.

If the fault is still present, disconnect the switch. Check that when the clutch pedal is depressed, the switch is

closed, and when the clutch pedal is released, the switch is open.

Replace the switch if necessary.

If the fault is still present, manipulate the harness to see if the status changes.

Look for any damage to the wiring harness, and check the condition and connection of the connectors of the

injection computer and clutch pedal switch.

Repair if necessary.

If the fault is still present, check the earth on track 2 of the switch.

If the earth is not present on track 2, check for insulation, continuity and the absence of interference

resistance on the following connection:

earth track 1 Clutch pedal switch

Repair if necessary.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF138/S3000_V54_DF138

Page 87 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-87

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-87V9 MR-372-J84-17B050$376.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

DF138

CONTINUED

If the fault is still present, check for insulation, continuity and the absence of interference resistance between

the following connection:

Injection computer, connectorA, track C4 track 2 Clutch pedal switch

Repair if necessary.

If the fault is still present, deal with the other faults then proceed to the conformity check.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

Page 88 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-88

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-88V9 MR-372-J84-17B050$376.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

DF154

PRESENT

OR

STOREDFLYWHEEL SIGNAL SENSOR CIRCUIT

1.DEF: Abnormal voltage

2.DEF: Tooth lost

3.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

If faults DF154, DF119 Camshaft sensor circuit and DF080 Camshaft dephaser

circuit are present, ignore DF080 and deal with the other 2 faults first.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after the starter motor has been running for 10 seconds

or at an engine speed above 600 rpm.

Special note:

–the OBD warning light is lit,

– In the event of flywheel signal loss, the injection and ignition are cut off: the vehicle

stalls and cannot be restarted.

1.DEF

NOTESNone.

Check the cleanliness, condition and the fitting of the flywheel.

Repair if necessary.

If the flywheel has been replaced or removed, the flywheel target has to be reinitialised, then reprogrammed.

Programming reinitialisation:

Use command RZ005: Programming.

Carrying out the flywheel target programming:

– Decelerate a first time with injection cut-off (i.e. feet off the brake, accelerator pedal and clutch pedals) between

3500 and 3000 rpm, in 3rd gear for a manual gearbox and 2nd for automatic gearbox, for at least 5 seconds.

– Decelerate a second time with injection cut-off (i.e. brake, accelerator and clutch pedals released) between

2400and 2000 rpm for K4 engines and between 1800 and

1400 rpm for F4R engines, in 3rd gear for a manual gearbox and 2nd for an automatic gearbox, for at least

5 seconds.

After the operation, check that status ET089 Flywheel target programming is COMPLETED.

(*This is the moment when, during deceleration with no load, the engine drops to idle speed and recovers torque).

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF154/S3000_V54_DF154

Page 89 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-89

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-89V9 MR-372-J84-17B050$376.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

DF154

CONTINUED

2.DEF

NOTESNone.

Check that the engine speed sensor is correctly fitted and positioned (see MR 364 or 370 Mechanics, 17B,

Petrol injection, engine speed and position sensor).

Check the cleanliness and condition of the engine speed sensor.

Repair if necessary.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Use the "Universal bornier" to check the insulation and continuity of the following connections:

Computer, connector B, track E4 track 2 or B of the engine speed sensor

Computer, connector B, track F3 track 1 or A of the engine speed sensor

Repair if necessary.

Check the resistance of the engine speed sensor between tracks 1 and 2:

Replace the engine speed sensor if the resistance is not between 235 ± 60Ω at 20°C.

If the engine speed sensor has been replaced, the flywheel target has to be reinitialised, then reprogrammed.

Programming reinitialisation:

Use command RZ005: Programming.

Carrying out the flywheel target programming:

– Decelerate a first time with injection cut-off (i.e. feet off the brake, accelerator pedal and clutch pedals) between

3500 and 3000 rpm, in 3rd gear for a manual gearbox and 2nd for automatic gearbox, for at least 5 seconds.

– Decelerate a second time with injection cut-off (i.e. brake, accelerator and clutch pedals released) between

2400and 2000 rpm for K4 engines and between 1800 and

1400 rpm for F4R engines, in 3rd gear for a manual gearbox and 2nd for an automatic gearbox, for at least

5 seconds.

After the operation, check that status ET089 Flywheel target programming is COMPLETED.

(*This is the moment when, during deceleration with no load, the engine drops to idle speed and recovers torque).

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

Page 106 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-106

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-106V9 MR-372-J84-17B050$423.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

DF457

PRESENT

OR

STOREDFLYWHEEL TARGET

1.DEF: Component in bad condition

2.DEF: Non-compliance with emission control standards

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is declared present with the engine running.

Special note:

–OBD warning light illuminated.

Check the cleanliness and condition of the engine flywheel.

Repair or replace the engine flywheel if necessary.

If the flywheel has been replaced or removed, the flywheel ring has to be reinitialised, then reprogrammed.

Reinitialise programming:

Use command RZ005: Programming.

Carrying out the flywheel target programming:

– Decelerate a first time with injection cut-off (i.e. feet off the brake, accelerator pedal and clutch pedals) between

3500 and 3000 rpm, in 3rd gear for a manual gearbox and 2nd for automatic gearbox, for at least 5 seconds.

– Decelerate a second time with injection cut-off (i.e. brake, accelerator and clutch pedals released) between

2400and 2000 rpm for K4 engines and between 1800 and

1400 rpm for F4R engines, in 3rd gear for a manual gearbox and 2nd for an automatic gearbox, for at least

5 seconds.

After the operation, check that status ET089 Flywheel target programming is COMPLETED.

(*This is the moment when, during deceleration with no load, the engine drops to idle speed and recovers torque).

If the fault is still present, contact the Techline.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF457/S3000_V54_DF457

Page 119 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-119

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-119V9 MR-372-J84-17B050$423.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

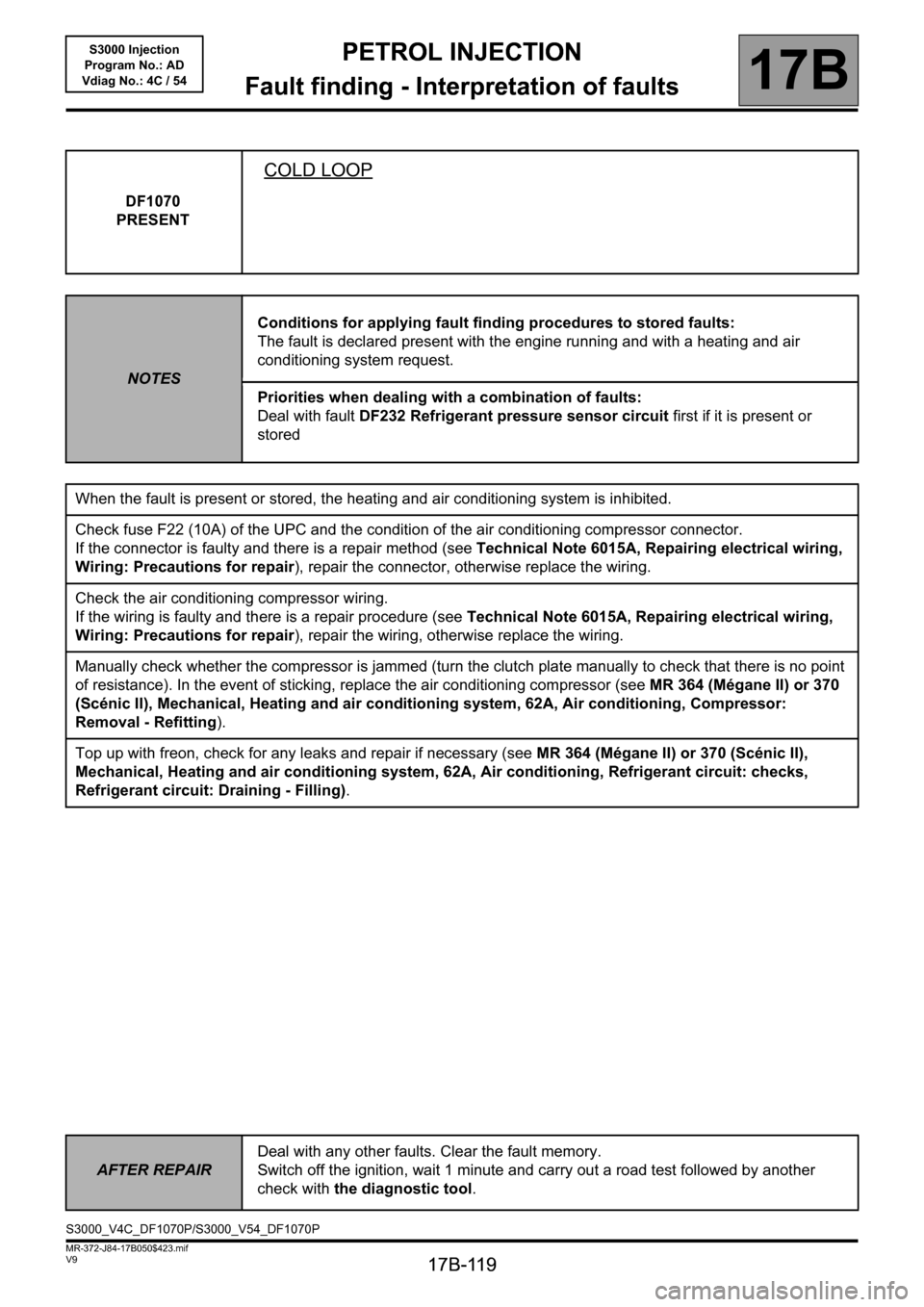

DF1070

PRESENT

COLD LOOP

NOTESConditions for applying fault finding procedures to stored faults:

The fault is declared present with the engine running and with a heating and air

conditioning system request.

Priorities when dealing with a combination of faults:

Deal with fault DF232 Refrigerant pressure sensor circuit first if it is present or

stored

When the fault is present or stored, the heating and air conditioning system is inhibited.

Check fuse F22 (10A) of the UPC and the condition of the air conditioning compressor connector.

If the connector is faulty and there is a repair method (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the air conditioning compressor wiring.

If the wiring is faulty and there is a repair procedure (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

Manually check whether the compressor is jammed (turn the clutch plate manually to check that there is no point

of resistance). In the event of sticking, replace the air conditioning compressor (see MR 364 (Mégane II) or 370

(Scénic II), Mechanical, Heating and air conditioning system, 62A, Air conditioning, Compressor:

Removal - Refitting).

Top up with freon, check for any leaks and repair if necessary (see MR 364 (Mégane II) or 370 (Scénic II),

Mechanical, Heating and air conditioning system, 62A, Air conditioning, Refrigerant circuit: checks,

Refrigerant circuit: Draining - Filling).

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition, wait 1 minute and carry out a road test followed by another

check with the diagnostic tool.

S3000_V4C_DF1070P/S3000_V54_DF1070P