fuse RENAULT SCENIC 2010 J95 / 3.G Petrol Injection S3000 Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2010, Model line: SCENIC, Model: RENAULT SCENIC 2010 J95 / 3.GPages: 230, PDF Size: 0.92 MB

Page 4 of 230

PETROL INJECTION

Fault finding - Introduction

17B-4

17B

PETROL INJECTION

Fault finding - Introduction

17B-4

17B

V9 MR-372-J84-17B050$047.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

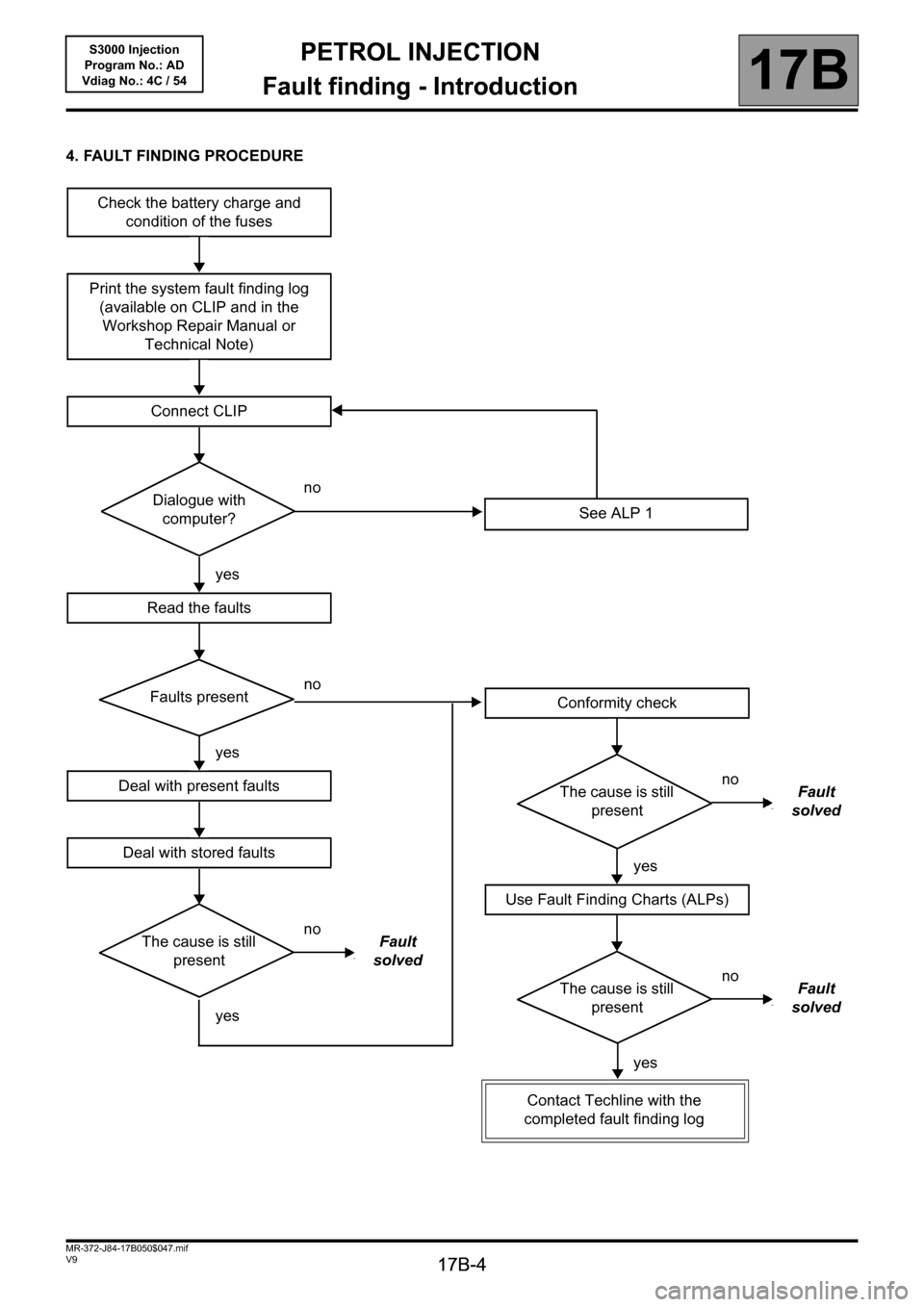

4. FAULT FINDING PROCEDURE

Check the battery charge and

condition of the fuses

Print the system fault finding log

(available on CLIP and in the

Workshop Repair Manual or

Technical Note)

Connect CLIP

no

Dialogue with

computer?

yes

Read the faults

no

Faults present

yes

Deal with present faults

Deal with stored faults

no

The cause is still

presentFault

solved

yes

See ALP 1

Conformity check

no

The cause is still

presentFault

solved

yes

Use Fault Finding Charts (ALPs)

no

The cause is still

presentFault

solved

yes

Contact Techline with the

completed fault finding log

Page 5 of 230

PETROL INJECTION

Fault finding - Introduction

17B

17B-5

PETROL INJECTION

Fault finding - Introduction

17B

17B-5V9 MR-372-J84-17B050$047.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

4. FAULT FINDING PROCEDURE (continued)

Wiring check:

Fault finding problems:

Disconnecting the connectors and/or manipulating the wiring may temporarily remove the cause of a fault.

Electrical measurements of the voltage, resistance and insulation are generally correct, especially if the fault is not

present when the analysis is made (stored fault).

Visual inspection:

Look for damage under the bonnet and in the passenger compartment.

Carefully check the fuses, insulation and wiring routing.

Look for signs of oxidation.

Tactile inspection:

While manipulating the wiring, use the diagnostic tool to note any change in fault status from stored to present.

Check that the connectors are correctly tightened, apply light pressure to the connectors, twist the wiring harness.

If there is a change in status, try to locate the source of the fault.

Inspection of each component:

Disconnect the connectors and check the appearance of the clips and tabs, as well as their crimping (no crimping on

the insulating section).

Make sure that the clips and tabs are properly locked in the sockets.

Make sure no clips or tabs have been dislodged during connection.

Check the clip contact pressure using an appropriate model of tab.

Resistance check:

Check the continuity of entire lines, then section by section.

Look for a short circuit to earth, to + 12 V or with another wire.

If a fault is detected, repair or replace the wiring harness.

Page 65 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-65

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-65V9 MR-372-J84-17B050$376.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

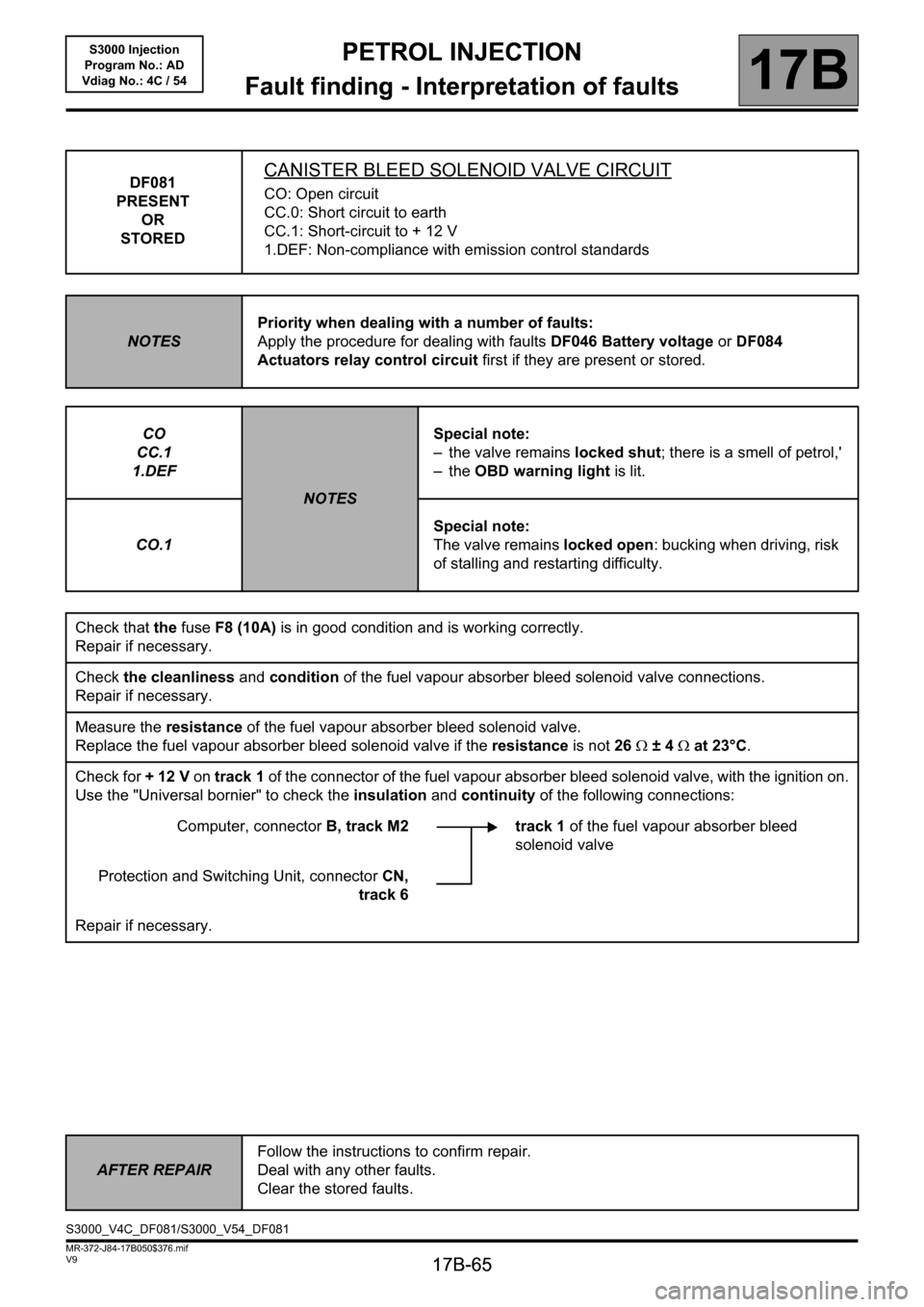

DF081

PRESENT

OR

STOREDCANISTER BLEED SOLENOID VALVE CIRCUIT

CO: Open circuit

CC.0: Short circuit to earth

CC.1: Short-circuit to + 12 V

1.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

Apply the procedure for dealing with faults DF046 Battery voltage or DF084

Actuators relay control circuit first if they are present or stored.

CO

CC.1

1.DEF

NOTESSpecial note:

– the valve remains locked shut; there is a smell of petrol,'

–the OBD warning light is lit.

CO.1Special note:

The valve remains locked open: bucking when driving, risk

of stalling and restarting difficulty.

Check that the fuseF8 (10A) is in good condition and is working correctly.

Repair if necessary.

Check the cleanliness and condition of the fuel vapour absorber bleed solenoid valve connections.

Repair if necessary.

Measure the resistance of the fuel vapour absorber bleed solenoid valve.

Replace the fuel vapour absorber bleed solenoid valve if the resistance is not 26Ω ±4Ω at 23°C.

Check for + 12 V on track 1 of the connector of the fuel vapour absorber bleed solenoid valve, with the ignition on.

Use the "Universal bornier" to check the insulation and continuity of the following connections:

Computer, connectorB, track M2 track 1 of the fuel vapour absorber bleed

solenoid valve

Protection and Switching Unit, connectorCN,

track 6

Repair if necessary.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF081/S3000_V54_DF081

Page 119 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-119

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-119V9 MR-372-J84-17B050$423.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

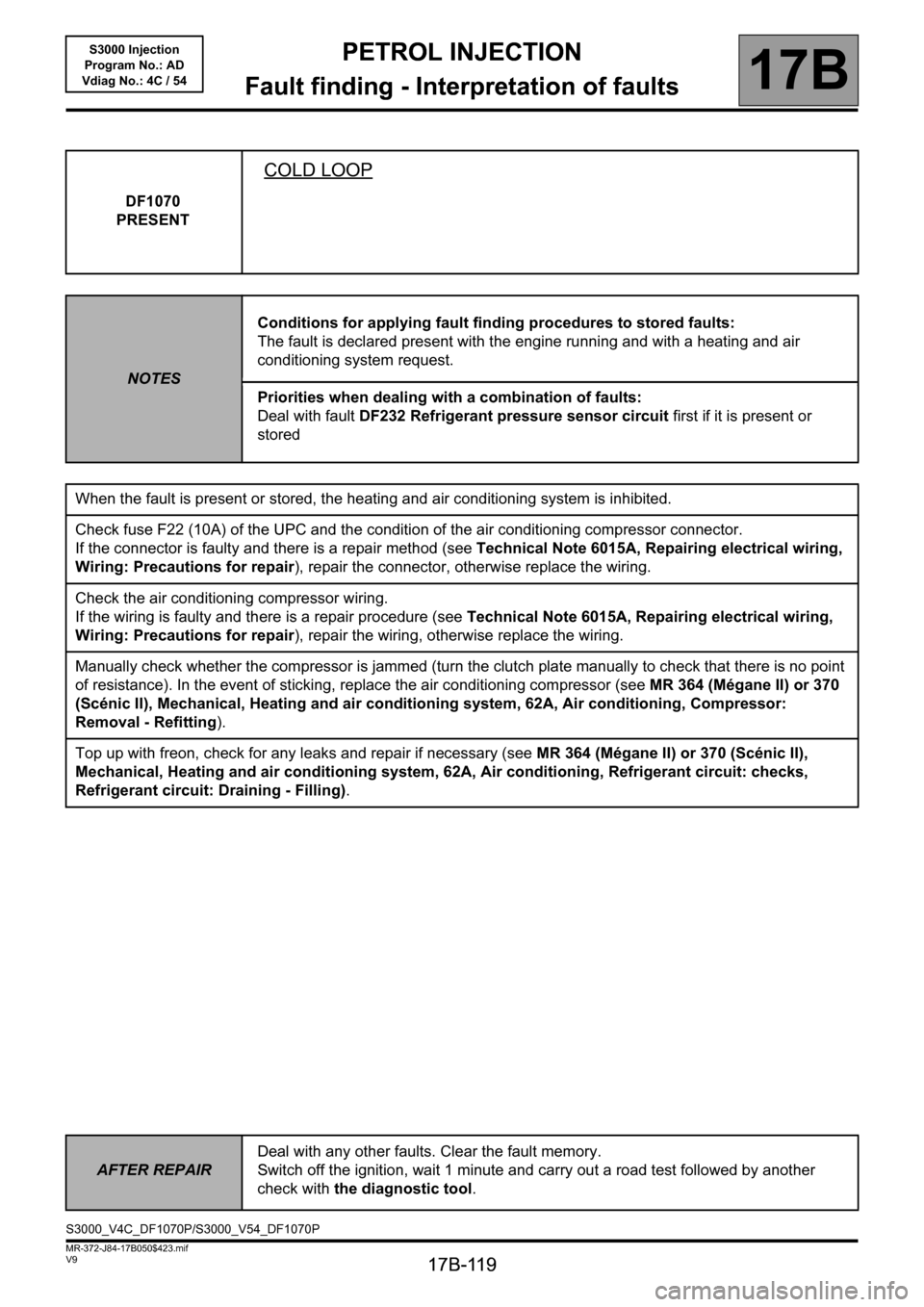

DF1070

PRESENT

COLD LOOP

NOTESConditions for applying fault finding procedures to stored faults:

The fault is declared present with the engine running and with a heating and air

conditioning system request.

Priorities when dealing with a combination of faults:

Deal with fault DF232 Refrigerant pressure sensor circuit first if it is present or

stored

When the fault is present or stored, the heating and air conditioning system is inhibited.

Check fuse F22 (10A) of the UPC and the condition of the air conditioning compressor connector.

If the connector is faulty and there is a repair method (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the air conditioning compressor wiring.

If the wiring is faulty and there is a repair procedure (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

Manually check whether the compressor is jammed (turn the clutch plate manually to check that there is no point

of resistance). In the event of sticking, replace the air conditioning compressor (see MR 364 (Mégane II) or 370

(Scénic II), Mechanical, Heating and air conditioning system, 62A, Air conditioning, Compressor:

Removal - Refitting).

Top up with freon, check for any leaks and repair if necessary (see MR 364 (Mégane II) or 370 (Scénic II),

Mechanical, Heating and air conditioning system, 62A, Air conditioning, Refrigerant circuit: checks,

Refrigerant circuit: Draining - Filling).

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition, wait 1 minute and carry out a road test followed by another

check with the diagnostic tool.

S3000_V4C_DF1070P/S3000_V54_DF1070P

Page 160 of 230

PETROL INJECTION

Fault finding - Conformity check

17B

17B-160

PETROL INJECTION

Fault finding - Conformity check

17B

17B-160V9 MR-372-J84-17B050$517.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

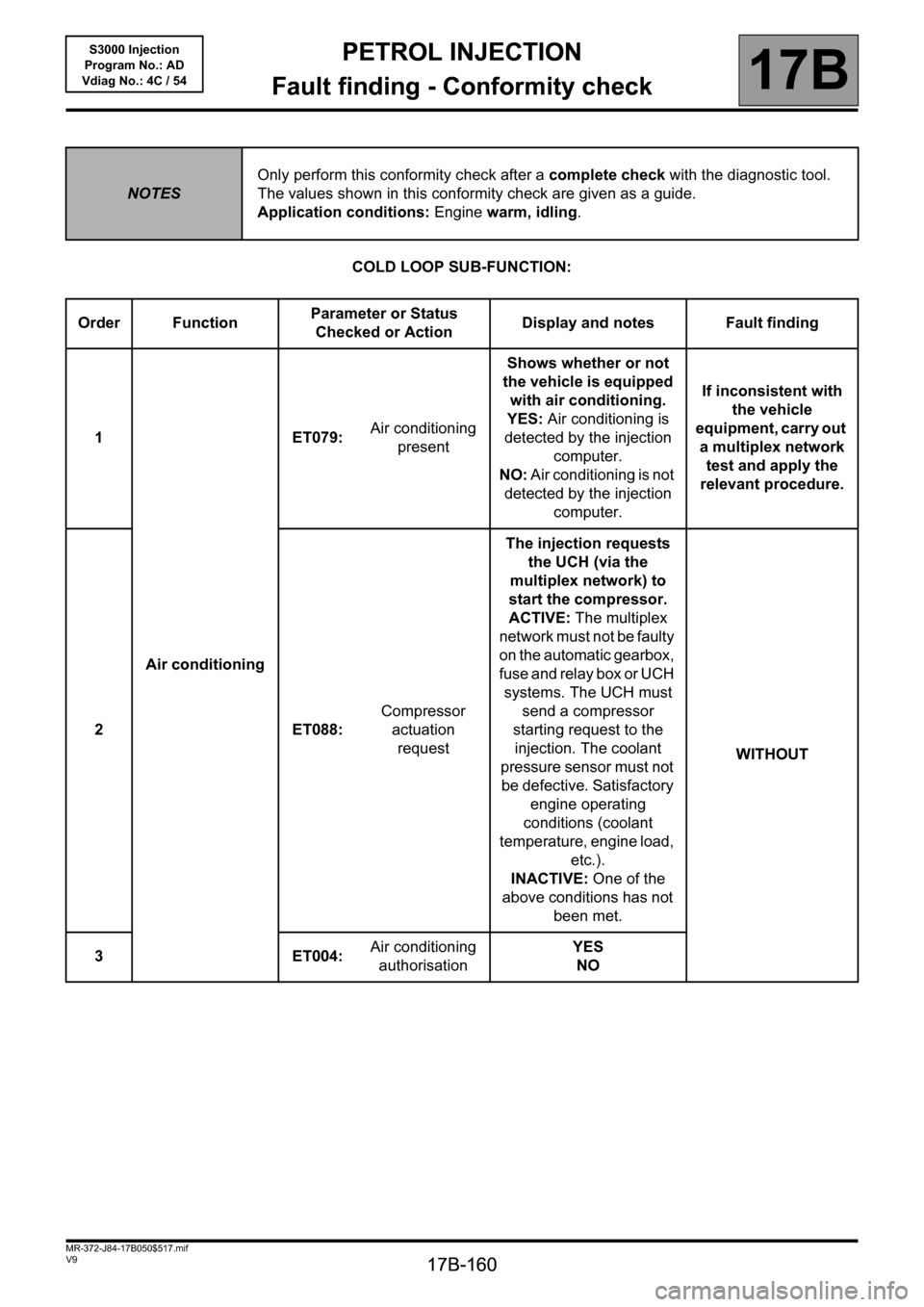

COLD LOOP SUB-FUNCTION:

NOTESOnly perform this conformity check after a complete check with the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application conditions: Engine warm, idling.

Order FunctionParameter or Status

Checked or ActionDisplay and notes Fault finding

1

Air conditioningET079:Air conditioning

presentShows whether or not

the vehicle is equipped

with air conditioning.

YES: Air conditioning is

detected by the injection

computer.

NO: Air conditioning is not

detected by the injection

computer.If inconsistent with

the vehicle

equipment, carry out

a multiplex network

test and apply the

relevant procedure.

2 ET088:Compressor

actuation

requestThe injection requests

the UCH (via the

multiplex network) to

start the compressor.

ACTIVE: The multiplex

network must not be faulty

on the automatic gearbox,

fuse and relay box or UCH

systems. The UCH must

send a compressor

starting request to the

injection. The coolant

pressure sensor must not

be defective. Satisfactory

engine operating

conditions (coolant

temperature, engine load,

etc.).

INACTIVE: One of the

above conditions has not

been met.WITHOUT

3 ET004:Air conditioning

authorisationYES

NO

Page 182 of 230

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 182

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 182V9 MR-372-J84-17B050$611.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

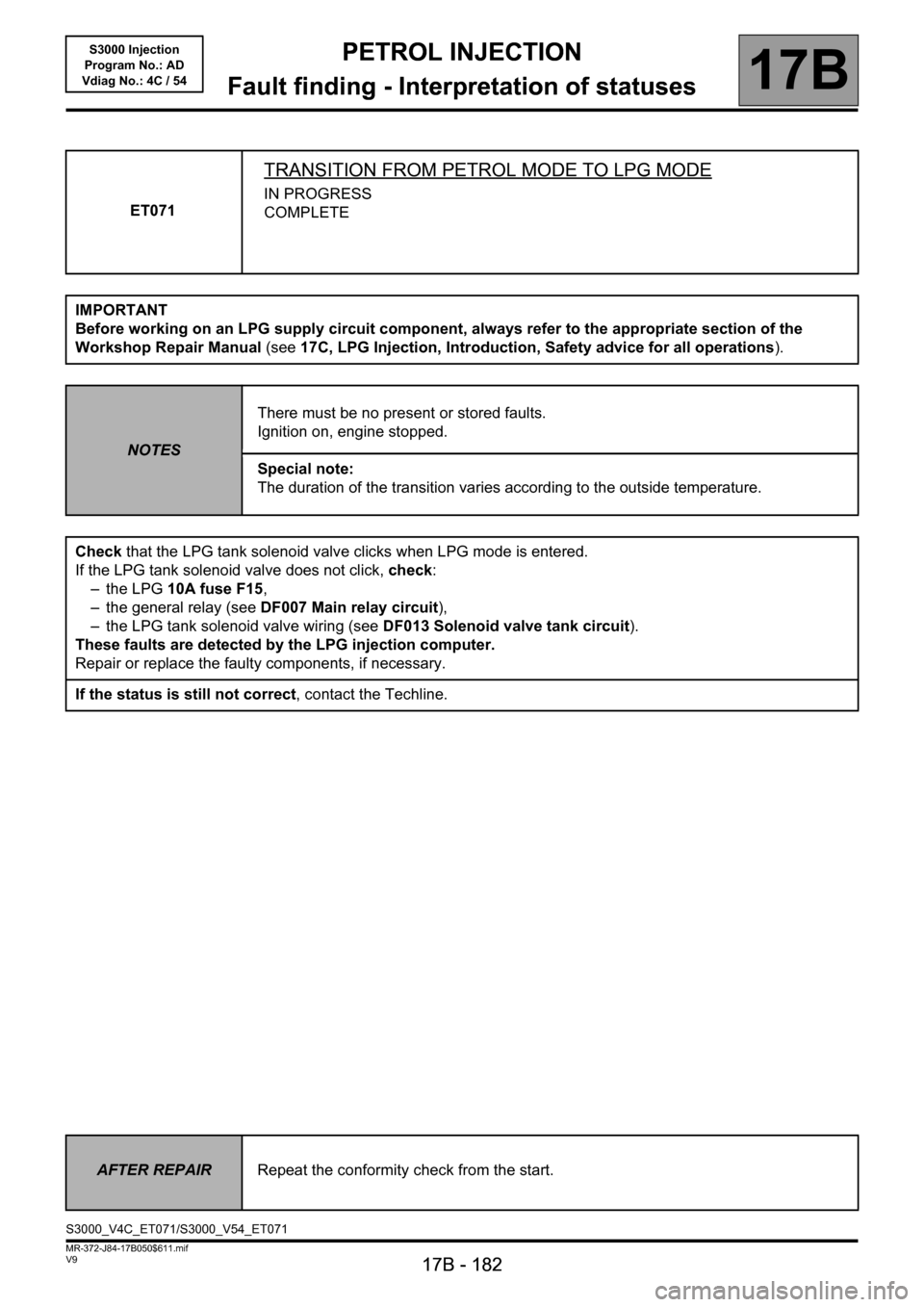

ET071

TRANSITION FROM PETROL MODE TO LPG MODE

IN PROGRESS

COMPLETE

IMPORTANT

Before working on an LPG supply circuit component, always refer to the appropriate section of the

Workshop Repair Manual (see17C, LPG Injection, Introduction, Safety advice for all operations).

NOTESThere must be no present or stored faults.

Ignition on, engine stopped.

Special note:

The duration of the transition varies according to the outside temperature.

Check that the LPG tank solenoid valve clicks when LPG mode is entered.

If the LPG tank solenoid valve does not click, check:

– the LPG 10A fuse F15,

– the general relay (see DF007 Main relay circuit),

– the LPG tank solenoid valve wiring (see DF013 Solenoid valve tank circuit).

These faults are detected by the LPG injection computer.

Repair or replace the faulty components, if necessary.

If the status is still not correct, contact the Techline.

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_ET071/S3000_V54_ET071

Page 201 of 230

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 201

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 201V9 MR-372-J84-17B050$611.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

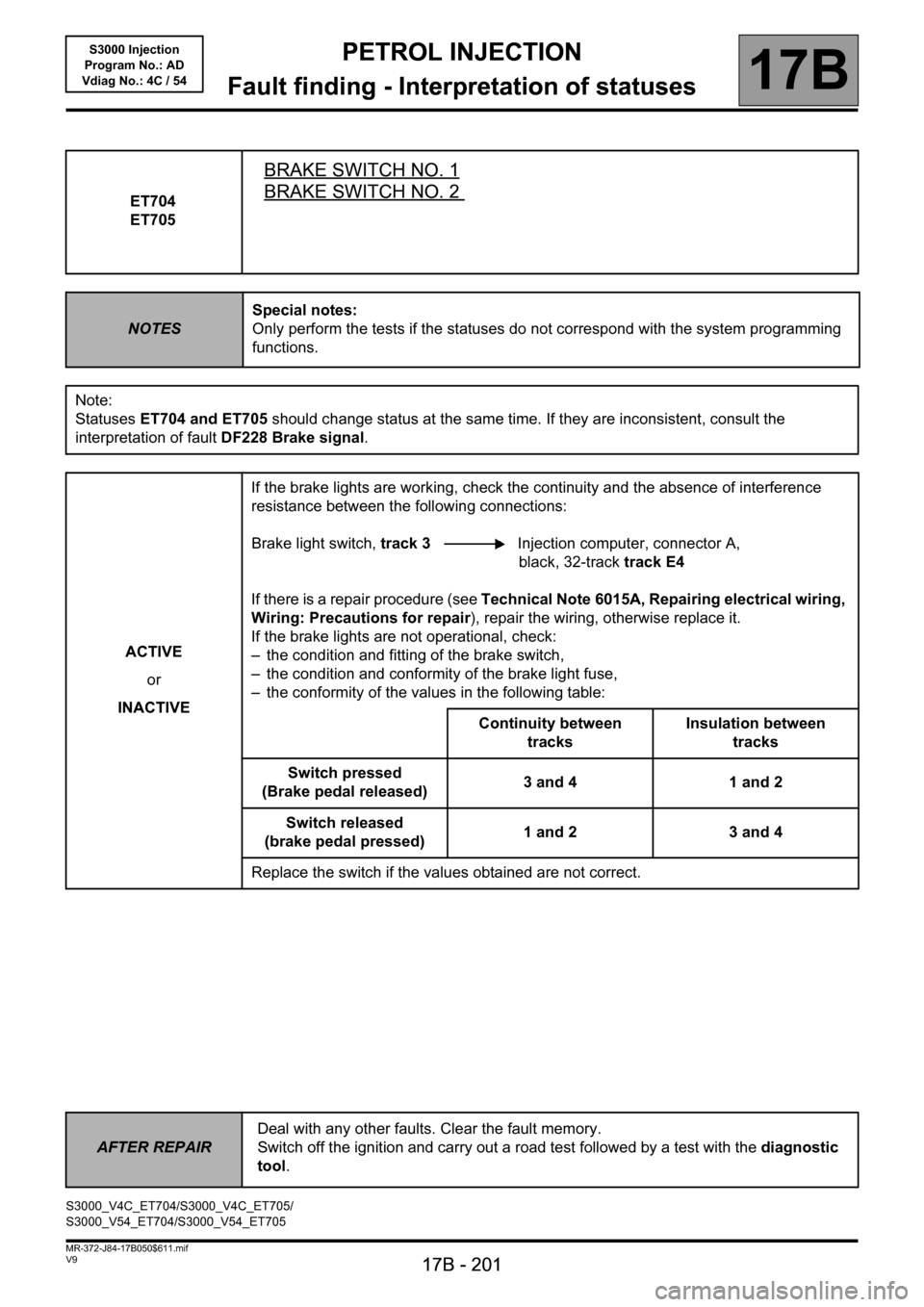

ET704

ET705

BRAKE SWITCH NO. 1

BRAKE SWITCH NO. 2

NOTESSpecial notes:

Only perform the tests if the statuses do not correspond with the system programming

functions.

Note:

Statuses ET704 and ET705 should change status at the same time. If they are inconsistent, consult the

interpretation of fault DF228 Brake signal.

ACTIVE

or

INACTIVEIf the brake lights are working, check the continuity and the absence of interference

resistance between the following connections:

Brake light switch, track 3 Injection computer, connector A,

black, 32-track track E4

If there is a repair procedure (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the brake lights are not operational, check:

– the condition and fitting of the brake switch,

– the condition and conformity of the brake light fuse,

– the conformity of the values in the following table:

Continuity between

tracksInsulation between

tracks

Switch pressed

(Brake pedal released)3 and 4 1 and 2

Switch released

(brake pedal pressed)1 and 2 3 and 4

Replace the switch if the values obtained are not correct.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

S3000_V4C_ET704/S3000_V4C_ET705/

S3000_V54_ET704/S3000_V54_ET705

Page 225 of 230

PETROL INJECTION

Fault finding - Fault Finding Chart

17B

17B-225

PETROL INJECTION

Fault finding - Fault Finding Chart

17B

17B-225V9 MR-372-J84-17B050$940.mif

S3000 Injection

Program No.: AD

Vdiag No.:4C / 54PETROL INJECTION

Fault finding - Fault Finding Chart

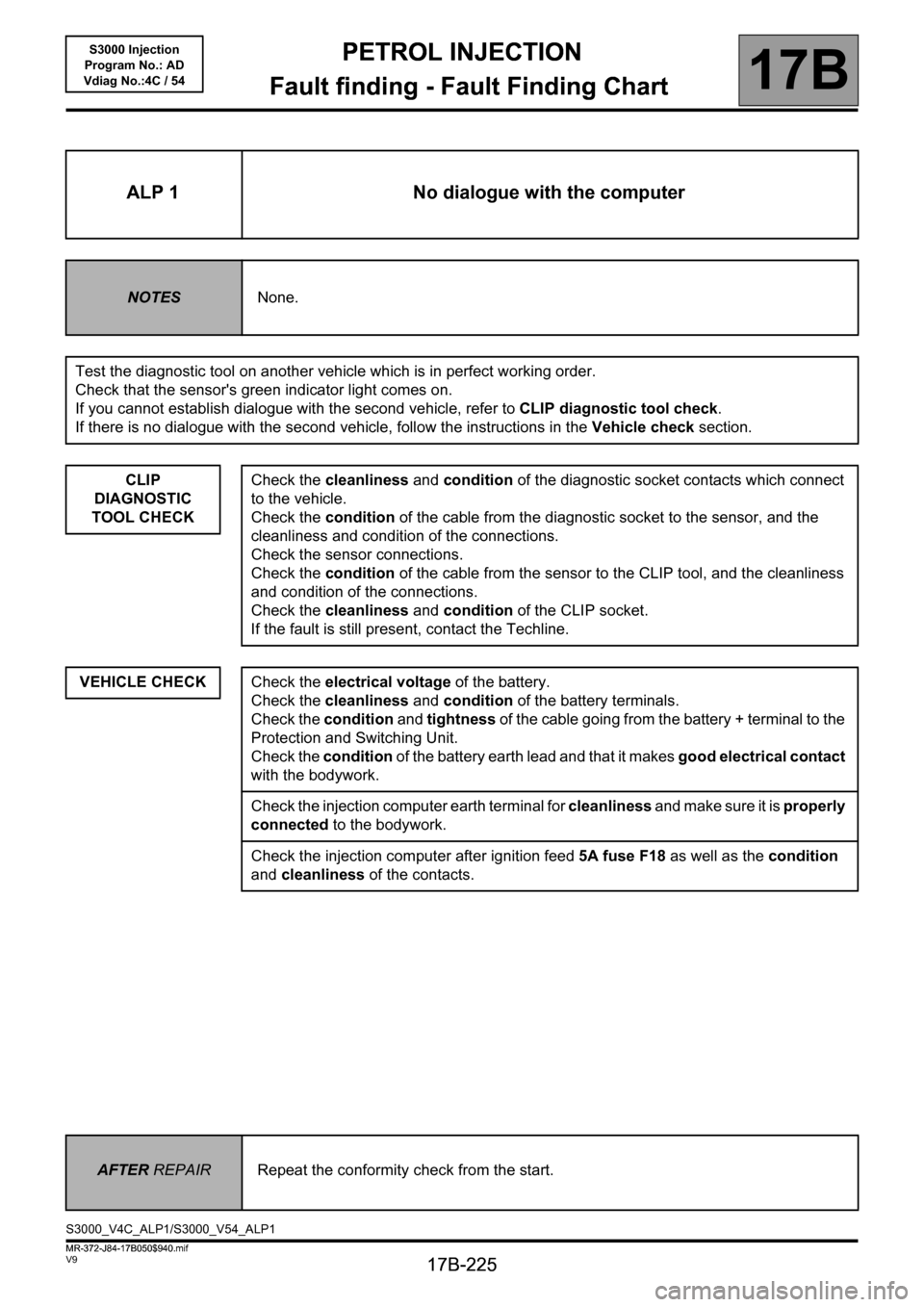

ALP 1 No dialogue with the computer

NOTESNone.

Test the diagnostic tool on another vehicle which is in perfect working order.

Check that the sensor's green indicator light comes on.

If you cannot establish dialogue with the second vehicle, refer to CLIP diagnostic tool check.

If there is no dialogue with the second vehicle, follow the instructions in the Vehicle check section.

CLIP

DIAGNOSTIC

TOOL CHECK

VEHICLE CHECK

Check the cleanliness and condition of the diagnostic socket contacts which connect

to the vehicle.

Check the condition of the cable from the diagnostic socket to the sensor, and the

cleanliness and condition of the connections.

Check the sensor connections.

Check the condition of the cable from the sensor to the CLIP tool, and the cleanliness

and condition of the connections.

Check the cleanliness and condition of the CLIP socket.

If the fault is still present, contact the Techline.

Check the electrical voltage of the battery.

Check the cleanliness and condition of the battery terminals.

Check the condition and tightness of the cable going from the battery + terminal to the

Protection and Switching Unit.

Check the condition of the battery earth lead and that it makes good electrical contact

with the bodywork.

Check the injection computer earth terminal for cleanliness and make sure it is properly

connected to the bodywork.

Check the injection computer after ignition feed 5A fuse F18 as well as the condition

and cleanliness of the contacts.

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_ALP1/S3000_V54_ALP1

MR-372-J84-17B050$940.mif

Page 227 of 230

PETROL INJECTION

Fault finding - Fault Finding Chart

17B

17B-227

PETROL INJECTION

Fault finding - Fault Finding Chart

17B

17B-227V9 MR-372-J84-17B050$940.mif

S3000 Injection

Program No.: AD

Vdiag No.:4C / 54

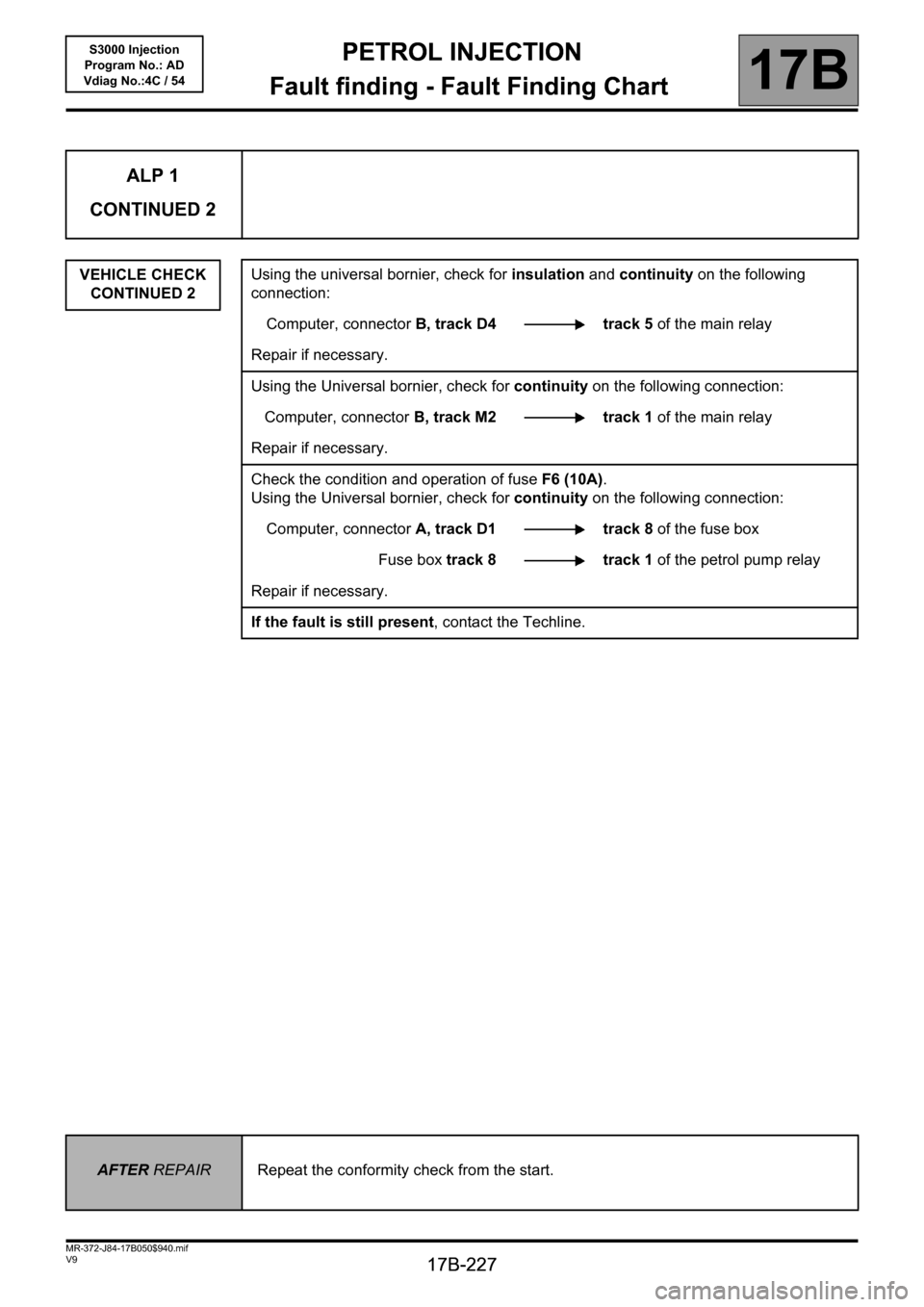

ALP 1

CONTINUED 2

VEHICLE CHECK

CONTINUED 2Using the universal bornier, check for insulation and continuity on the following

connection:

Computer, connectorB, track D4 track 5 of the main relay

Repair if necessary.

Using the Universal bornier, check for continuity on the following connection:

Computer, connectorB, track M2 track 1 of the main relay

Repair if necessary.

Check the condition and operation of fuse F6 (10A).

Using the Universal bornier, check for continuity on the following connection:

Computer, connector A, track D1 track 8 of the fuse box

Fuse box track8 track1 of the petrol pump relay

Repair if necessary.

If the fault is still present, contact the Techline.

AFTER REPAIRRepeat the conformity check from the start.