air RENAULT SCENIC 2012 J95 / 3.G Engine And Peripherals EDC16CP33 User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2012, Model line: SCENIC, Model: RENAULT SCENIC 2012 J95 / 3.GPages: 510, PDF Size: 2.98 MB

Page 13 of 510

13B-13V12 MR-372-J84-13B300$030.mif

DIESEL INJECTION

Fault finding – System operation13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Fuel surplus from the pump, injector return rail or rail is collected in a low pressure "octopus manifold" and is then

sent to the fuel filter, providing that the fuel is cold (recirculation), and then to the tank.

The system can inject diesel fuel into the engine at a pressure of up to 1600 bar. Before each operation, check that

the injector rail is depressurised and that the fuel temperature is not too high.

You must respect the cleanliness guidelines and safety advice specified in this document for any work on the high

pressure injection system.

Removal of the internal parts of the pump and injectors is prohibited. Only the fuel pressure regulator (or actuator)

on the high pressure pump (MPROP), the fuel pressure regulator (or actuator) on the injector rail (DRV) or the diesel

temperature sensor can be replaced.

For safety reasons, it is strictly prohibited to undo a high pressure pipe union when the engine is running.

It is not possible to remove the pressure sensor from the fuel rail because this may cause circuit contamination

faults. If the pressure sensor fails, replace the pressure sensor, the rail and the high pressure pipes.

Some vehicles have a presence sensor mounted in the filter for detecting water in the diesel. If there is water in

the diesel fuel, the orange "Injection and pre-post heating" warning light will come on.

Supplying + 12 V directly to any component in the system is prohibited.

Ultrasonic decoking and cleaning are prohibited.

Never start the engine unless the battery is connected correctly.

Disconnect the injection computer when carrying out any welding work on the vehicle.

b. The connections between the vehicle's various computers are multiplexed.

The electronic system fitted in this vehicle is multiplexed.

This enables dialogue between the various vehicle computers. As a result:

– the fault warning lights on the instrument panel are lit by the multiplex network,

– vehicle faults are displayed by the multiplex network,

– the vehicle speed sensor on the gearbox is not needed.

The vehicle speed signal on the instrument panel is sent by the ABS computer via the multiplex network. The vehicle

speed signal is mainly used by the injection computer, the airbag computer and the automatic transmission

computer (if the vehicle is fitted with this).WARNING:

The engine must not operate with:

– Diesel fuel containing more than 10% diester,

– petrol, even in tiny quantities.

Note:

For the M9R 724 (Vdiag 5C and 58):

The engine is limited to 3000 rpm if the vehicle is stationary or if the vehicle speed is less than 4 mph (7 km/h)

and if the engine is warm.

Page 14 of 510

13B-14V12 MR-372-J84-13B300$030.mif

DIESEL INJECTION

Fault finding – System operation13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

c. Functions hosted:

Air conditioning management assistance:

For vehicles with air conditioning, the EDC16CP33 system provides the option of deactivating the air conditioning

via the UCH, under certain conditions of use:

– when requested by the driver,

– when starting the engine,

– if the engine overheats (in order to reduce the power the engine has to supply),

– when the engine speed is kept at a very high level (to protect the compressor),

– during transition phases (e.g. under heavy acceleration when overtaking, anti-stalling and moving off strategies).

These conditions are only taken into account when they do not occur repeatedly, in order to prevent system

instabilities (erratic deactivations),

– when certain faults appear.

I - Cold loop air conditioning management:

The air conditioning is the cold loop type and its management shared between several computers.

The injection computer is responsible for:

– authorising requests for cold air depending on the engine coolant temperature and the engine speed,

– calculating the power absorbed by the compressor from the refrigerant pressure.

–requesting fan assembly actuation (Mégane II ph2 and Scénic II ph2) and controlling fan assembly actuation

(Laguna II, Vel Satis ph2 and Espace IV ph2), according to the vehicle speed, the refrigerant pressure and the

engine coolant temperature.

The driver requests the air conditioning to be switched on by means of the ventilation selector coupled to a switch.

The cold air request is authorised or denied depending on the pressure measured. If this pressure is outside the

operating limits, the cold loop program is not activated.

The air conditioning system is authorised by the injection computer 2 to 8 seconds after the engine is started.

Management of the thermoplungers:

To improve cold starting, the vehicle is fitted with thermoplungers. These thermoplungers are managed and

controlled by the injection computer, according to the operating phases, primarily to accelerate the increase in

engine coolant temperature.

The maximum number of thermoplungers that can be actuated is four and their actuation depends mainly on the

coolant temperature and the air temperature.

See configuration reading LC056 Thermoplungers: WITH or WITHOUT.

When necessary, they are actuated by the injection system only during particle filter regeneration by means

of a special unit.

The maximum number of thermoplungers that can be managed is four and their activation depends mainly on the

coolant temperature (< 15°C) and air temperature (< 5°C).

Page 16 of 510

13B-16V12 MR-372-J84-13B300$030.mif

DIESEL INJECTION

Fault finding – System operation13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

III - Management of the damper valve

The damper valve is now responsible for two functions:

– Damping: when the engine is switched off, the flap closes in order to block the passage of air towards the cylinders.

The aim of this is to stop the engine as quickly as possible and to reduce instabilities when the engine is switched

off.

– "Valving" function depending on the engine operation: the damper valve closes by a few % to create a "venturi"

effect at the EGR valve passage section.

The aim of this is to accelerate the air flow of EGR gases and to reduce the emission of pollutants.

IV - Exhaust gas recirculation management

The EGR (Exhaust Gas Recirculation) system involves removing exhaust gases and reintroducing them into the

inlet.

This system plays a major role in reducing diesel engine emissions. The EGR system is cooled by a gas - water

exchanger, as on most Euro IV engines. This cooler has a dual position bypass valve, which allows the gas to be

cooled or not depending on the emission control requirements. The bypass circuit is inside the cooler (not visible

from the outside). The valve control rod is visible from the outside.

The exhaust gases are collected in the exhaust manifold (before the turbocharger), then directed to the EGR cooler

and the EGR valve. The EGR valve connects the air circuit between the damper valve and the inlet manifold; the

EGR valve is positioned next to the damper valve.

The EGR valve is activated every time the engine stops by performing 10opening/closing cycles. This programming

activates the EGR valve in order to prevent it from clogging. The program is no longer active if there are any system

faults.

The EGR system does not operate below 5°C (air flowmeter temperature).

– The controlled EGR cooler bypass

The EGR cooler bypass is controlled by an all-or-nothing solenoid valve, connected on one side to the vacuum

pump, and on the other side to the bypass control diaphragm. It is actuated according to the coolant temperature

and the engine operating status. Gases flow into the EGR section of the cooler unless the engine is cold, in which

case they flow through the bypass valve. There is also a regular actuation function for the bypass valve to prevent it

from clogging.

– EGR valve

The EGR valve is supplied by direct current and connected to a potentiometer copying the position of the valve.

The opening of the valve is actuated (H bridge) by a positive command 0 to 100%.

The valve is controlled using a double regulation loop.

The first loop (fastest) is a position loop. It brings the valve to the desired position by a loop connection using the

signal from the position sensor.

The second loop is slower and is an air flow loop. At a given operating point, the air flow setpoint is attained by

adjusting the quantity of exhaust gas flowing through the EGR valve and the flow of fresh air passing through the

damper valve. At a total constant flow, the more exhaust gas recirculation, the less fresh air there is and vice versa.

The air flow is measured by the flowmeter and the setpoint is attained using both the EGR valve position setpoint

and the damper valve position setpoint.

Page 18 of 510

13B-18V12 MR-372-J84-13B300$030.mif

DIESEL INJECTION

Fault finding – System operation13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

VI - Pre-postheating actuation

Pre/postheating control involves actuating the heater plugs and the preheating indicator light on the instrument

panel (multiplex signal).

The heater plugs are actuated by a static relay.

After the ignition is switched on, a preheating delay is activated. The length of time that the warning light is lit

depends on the coolant temperature, air temperature, atmospheric pressure and battery voltage. When the coolant

temperature is below a certain threshold, a postheating function can be used to improve the combustion stability,

and consequently engine operation (reducing unburnt particles and pollutant emissions). Postheating can last up

to5 minutes.

IMPORTANT:

There are two types of heater plug: SLOW and FAST:

SLOW plugs are identified by a black ring.

FAST plugs are identified by a white ring.

The heater plugs fitted on the vehicle must be replaced with plugs of the same type; otherwise there is

a risk of the heater plugs deteriorating which could lead to engine destruction.

Only Vdiag 20, 24, 38 and 74:

when replacing heater plugs with plugs which differ from those currently fitted on the vehicle (replacement of

SLOW plugs with FAST plugs), the computer must be configured (see Replacement of components, Replacing

heater plugs) by running command SC036 Reinitialise programming and selecting Heater plugs if this choice

is available, then following the procedure.

Page 19 of 510

13B-19V12 MR-372-J84-13B300$030.mif

DIESEL INJECTION

Fault finding – System operation13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Warning light management:

Instrument panel display

The computer displays certain information on the instrument panel relating to engine operation. This concerns five

functions:

– the pre-postheating warning light,

– the coolant temperature warning light,

–the level 1 fault warning light (non-critical fault),

–the level 2 fault warning light (emergency stop),

–the EOBD (European On Board Diagnostic) warning light,

These six functions are represented by 3 warning lights and/or messages displayed by the on-board computer.

Orange pre-post heating/non-critical fault SERVICE warning light (severity 1)

This light is used both as an in-operation indicator light and as a system fault indicator:

– Continuously lit with + after ignition feed:

Indicates preheating of the spark plugs.

– Continuously lit with the Check injection message:

Indicates a level 1 fault (involving operation of the injection system in defect mode).

The driver should have the repairs carried out as soon as possible.

Temperature / red emergency STOP warning light (level 2)

This indicator light is used both as an in-operation indicator light and as a system fault warning light. It lights up for

3 seconds after the ignition is switched on (automatic test procedure managed by the instrument panel):

– Continuously lit:

Indicates engine overheating (the driver is free to choose whether or not to stop the vehicle).

– Continuously lit with the faulty injection message:

Indicates a level 2 fault (In this case, the injection is automatically cut after a few seconds).

The driver should carry out repairs as soon as possible.

ORANGE Excessive pollution EOBD warning light

Symbolised by an engine, it lights up for approximately 3 seconds when the ignition is switched on.

This warning light comes on if the system has one or more EOBD faults.

This warning light is used to alert the driver to injection faults that could lead to excessive pollution, or if the EOBD

system (European On Board Diagnostic) has been deactivated.

The injection computer requests illumination of the EOBD warning light for a present fault only after three

consecutive driving cycles.

The 3 second visual inspection when the ignition is switched on (automatic test procedure managed by the

instrument panel) is carried out by the injection computer.

Special particle filter ORANGE warning light or warning message (depending on instrument panel)

Only for Vdiag: 18, 1C, 54, 20, 58, 5C, 24, 26 and 60.

This warning light or message is used to warn the driver that the particle filter is loaded with particles, (see the soot

weight thresholds for illumination of the warning light for fault DF312 Speed request) due to driving conditions which

were not suitable for regeneration to take place. The driver must then drive as soon as possible at an average speed

of 48 mph (80 km/h) subject to the road conditions and authorised speed limits, until the warning light goes out.

Page 20 of 510

13B-20V12 MR-372-J84-13B300$030.mif

DIESEL INJECTION

Fault finding – System operation13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

EOBD management (European On Board Diagnostic):

The EOBD system enables the detection of any faults relating to the vehicle emission control system

(EOBD EURO IV emission control standards exceeded).

This system should be active for the entire life of the vehicle.

1. Conditions for an EOBD fault appearing

An EOBD fault will be detected after 3 driving cycles.

It allows the driver to know whether the vehicle has a fault directly linked to the emission control system.

2. System faults displayed by the EOBD

Only a few faults are indicated by the EOBD system:

– DF002 Air temperature sensor circuit.

– DF004 Turbocharging pressure sensor circuit.

– DF011 Sensor feed voltage no. 1.

– DF012 Sensor feed voltage no. 2.

– DF013 Sensor feed voltage no. 3.

– DF026 Cylinder 1 injector control circuit.

– DF027 Cylinder 2 injector control circuit.

– DF028 Cylinder 3 injector control circuit.

– DF029 Cylinder 4 injector control circuit.

– DF054 Turbocharging solenoid valve control circuit.

– DF056 Air flow sensor circuit.

– DF107 Computer memory.

– DF200 Atmospheric pressure sensor.

– DF209 EGR position sensor circuit.

– DF272 EGR valve control circuit.

– DF569 Turbocharging circuit.

Some repair operations require programming to ensure that certain engine components function correctly.

Follow the programming procedures (see Replacement of components), if replacing the exhaust gas

recirculation valve or an injector.

3. Conditions for clearing an EOBD fault

An EOBD fault is cleared in several phases.

The fault present in the diagnostic tool will only be stored (following repair) after the vehicle has been driven

3times.

The EOBD warning light will only go out after these 3 driving cycles.

The instrument panel warning light coming on does not automatically mean that the system has a fault.

In order for the EOBD fault and display parameters to be cleared from the computer, the system must go

through 40 engine heating cycles.

An engine heating cycle is a driving cycle during which:

– the engine coolant temperature reaches at least 71.1°C,

– the engine coolant temperature varies by 22.2°C in relation to the engine starting temperature.

If one of these conditions is not fulfilled, the EOBD fault will still be present or stored in the injection

computer.

Page 21 of 510

13B-21V12 MR-372-J84-13B300$040.mif

13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

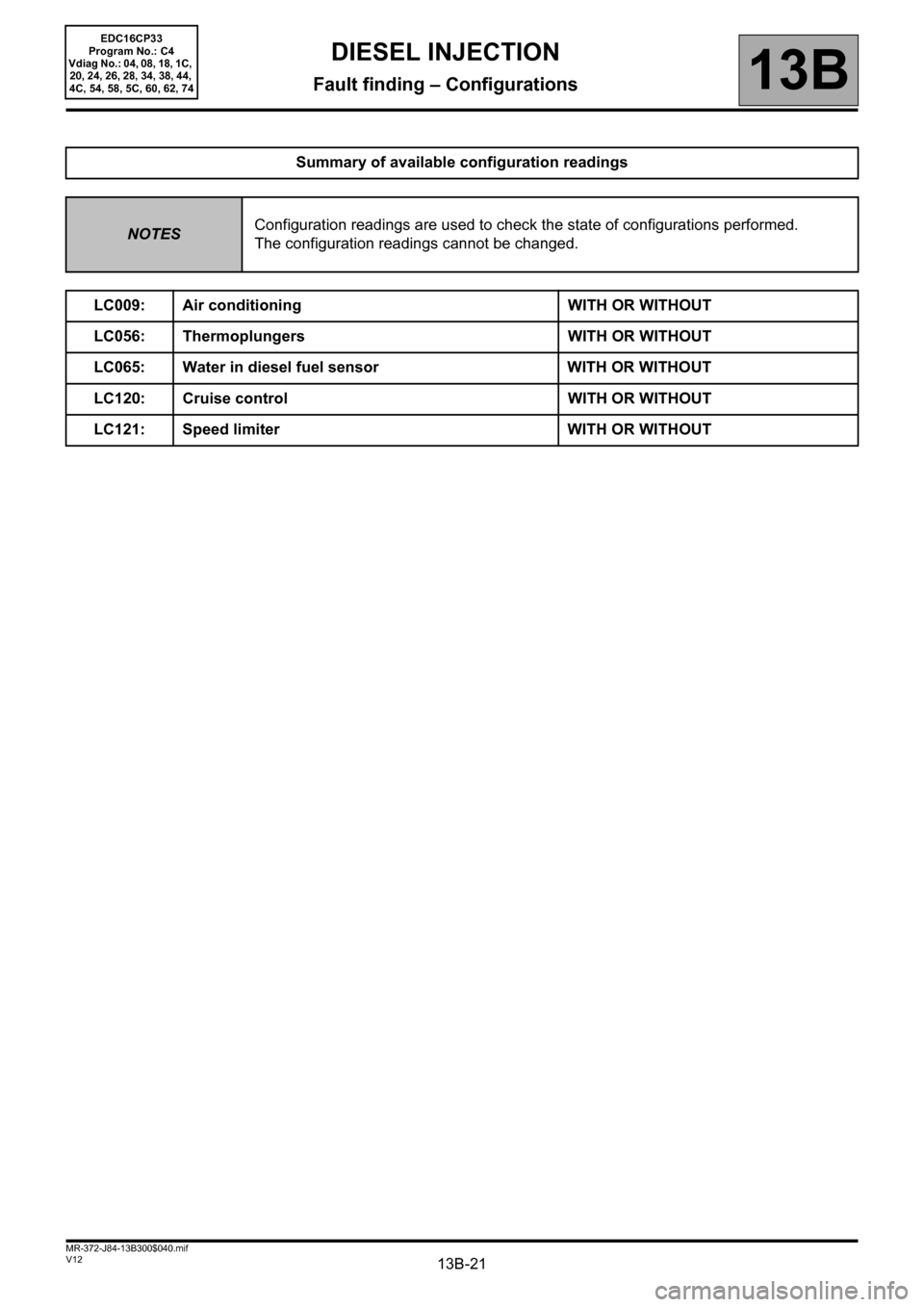

Summary of available configuration readings

NOTESConfiguration readings are used to check the state of configurations performed.

The configuration readings cannot be changed.

LC009: Air conditioning WITH OR WITHOUT

LC056: Thermoplungers WITH OR WITHOUT

LC065: Water in diesel fuel sensor WITH OR WITHOUT

LC120: Cruise control WITH OR WITHOUT

LC121: Speed limiter WITH OR WITHOUT

DIESEL INJECTION

Fault finding – Configurations

Page 22 of 510

13B-22V12 MR-372-J84-13B300$050.mif

13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

COMPUTER REPLACEMENT OR REPROGRAMMING

Two operations must be performed when replacing or reprogramming the computer:

SC003 Save computer data and SC001 Enter saved data.

–Run SC003 before replacing or reprogramming the computer. This enables certain data to be saved in the

diagnostic tool so that the new computer* can be reconfigured like the old one. The saved data includes: injector

codes, EGR programming, specific data for particle filter operation and vehicle options.

–Run SC001 after replacing or reprogramming the computer. It enables you to rewrite the data (saved by

command SC003) to the new computer*.

Only Vdiag 20, 24, 38 and 74:

–Run SC036 Reinitialise programming and select Heater plugs (see Interpretation of commands); this will allow

you to configure the correct type of heater plugs fitted on the vehicle, if necessary.

If you cannot establish dialogue with the computer being replaced: you will not be able to save anything. After

replacing the computer:

– Write the IMA codes for each injector manually by reading the code on each injector; run command SC002 Enter

injector codes.

– Check the exhaust pipe for leaks or blockage. Repair if necessary.

– Perform an After-Sales regeneration, follow the procedure for command SC017 Particle filter regeneration (see

Interpretation of commands).

– It is essential to change the engine oil and oil filter.

– Enter the data specific to particle filter operation by running SC036 Reinitialise programming and selecting after

replacing injection computer with no save option.

– Enter the VIN into the computer, use command VP010 Enter VIN.

–Only for Vdiag 20, 24, 38 and 74: Configure the type of heater plugs fitted on the vehicle by running SC036

Reinitialise programming and selecting Heater plugs (see Interpretation of commands).

Exhaust gas recirculation valve data is programmed automatically the 1st time the new computer is turned on*.

* New computer or reprogrammed computer.

IMA*: Individual injector correctionOperations to be carried out before the injection computer is reprogrammed:

Before reprogramming the injection computer, move the main cruise control/speed limiter switch to the rest

position. The information about the cruise control or the speed limiter displayed on the instrument panel

disappears.

Otherwise, if the main switch remains in the cruise control or speed limiter position during and after reprogramming,

the cruise control/speed limiter function will not be operational.

The procedure for resetting the function is as follows:

Vehicle ignition on.

• Position the cruise control/speed limiter switch in the rest position (the computer detects the rest position at that

moment).

• Position the cruise control/speed limiter switch in the Cruise control position to activate the cruise control

function.

• Position the cruise control/speed limiter switch in the Speed limiter position to activate the speed limiter function.

DIESEL INJECTION

Fault finding – Replacement of components

Page 28 of 510

13B-28V12 MR-372-J84-13B300$060.mif

13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

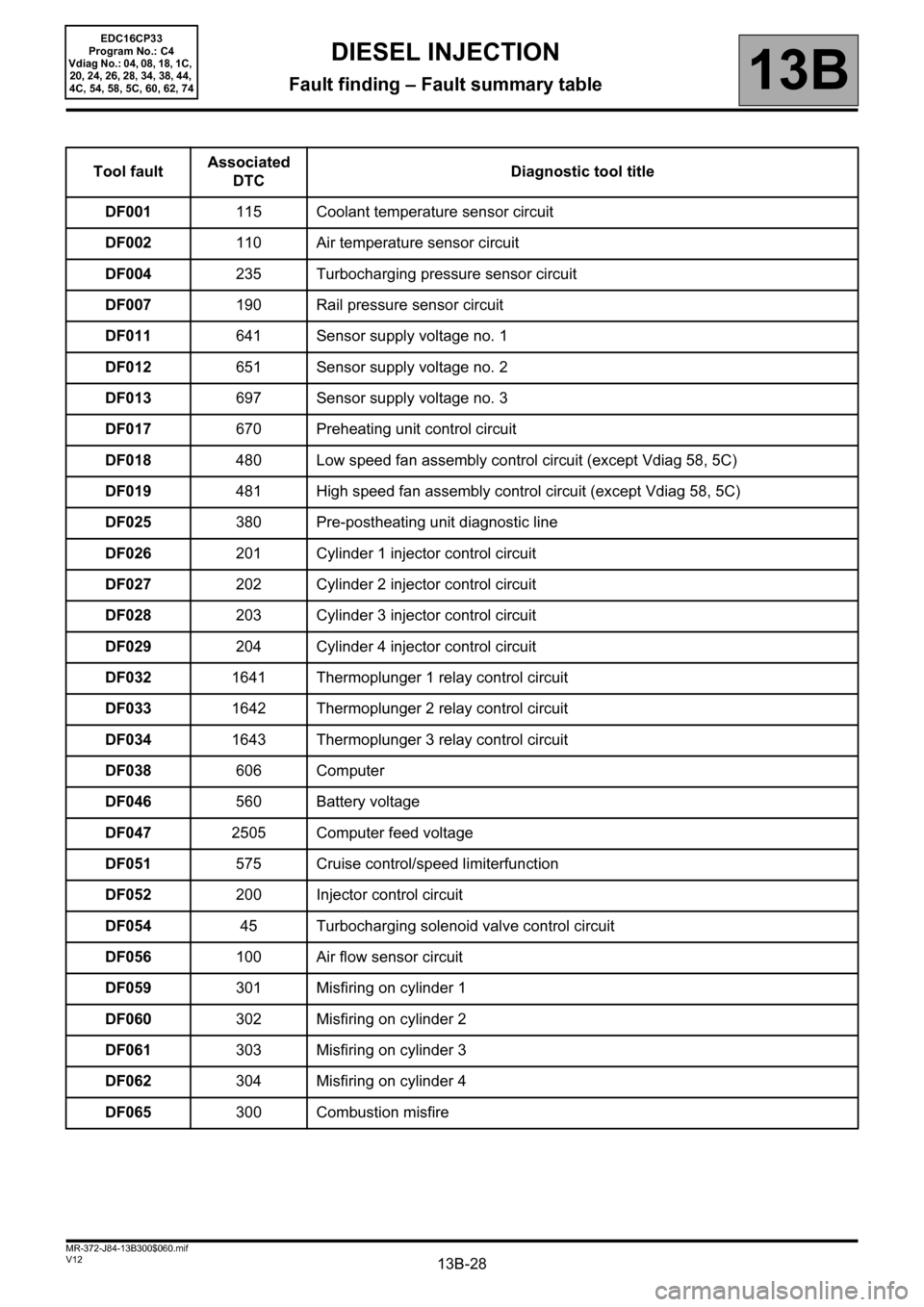

Tool faultAssociated

DTCDiagnostic tool title

DF001115 Coolant temperature sensor circuit

DF002110 Air temperature sensor circuit

DF004235 Turbocharging pressure sensor circuit

DF007190 Rail pressure sensor circuit

DF011641 Sensor supply voltage no. 1

DF012651 Sensor supply voltage no. 2

DF013697 Sensor supply voltage no. 3

DF017670 Preheating unit control circuit

DF018480 Low speed fan assembly control circuit (except Vdiag 58, 5C)

DF019481 High speed fan assembly control circuit (except Vdiag 58, 5C)

DF025380 Pre-postheating unit diagnostic line

DF026201 Cylinder 1 injector control circuit

DF027202 Cylinder 2 injector control circuit

DF028203 Cylinder 3 injector control circuit

DF029204 Cylinder 4 injector control circuit

DF0321641 Thermoplunger 1 relay control circuit

DF0331642 Thermoplunger 2 relay control circuit

DF0341643 Thermoplunger 3 relay control circuit

DF038606 Computer

DF046560 Battery voltage

DF0472505 Computer feed voltage

DF051575 Cruise control/speed limiterfunction

DF052200 Injector control circuit

DF05445 Turbocharging solenoid valve control circuit

DF056100 Air flow sensor circuit

DF059301 Misfiring on cylinder 1

DF060302 Misfiring on cylinder 2

DF061303 Misfiring on cylinder 3

DF062304 Misfiring on cylinder 4

DF065300 Combustion misfire

DIESEL INJECTION

Fault finding – Fault summary table

Page 30 of 510

13B-30V12 MR-372-J84-13B300$060.mif

DIESEL INJECTION

Fault finding – Fault summary table13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

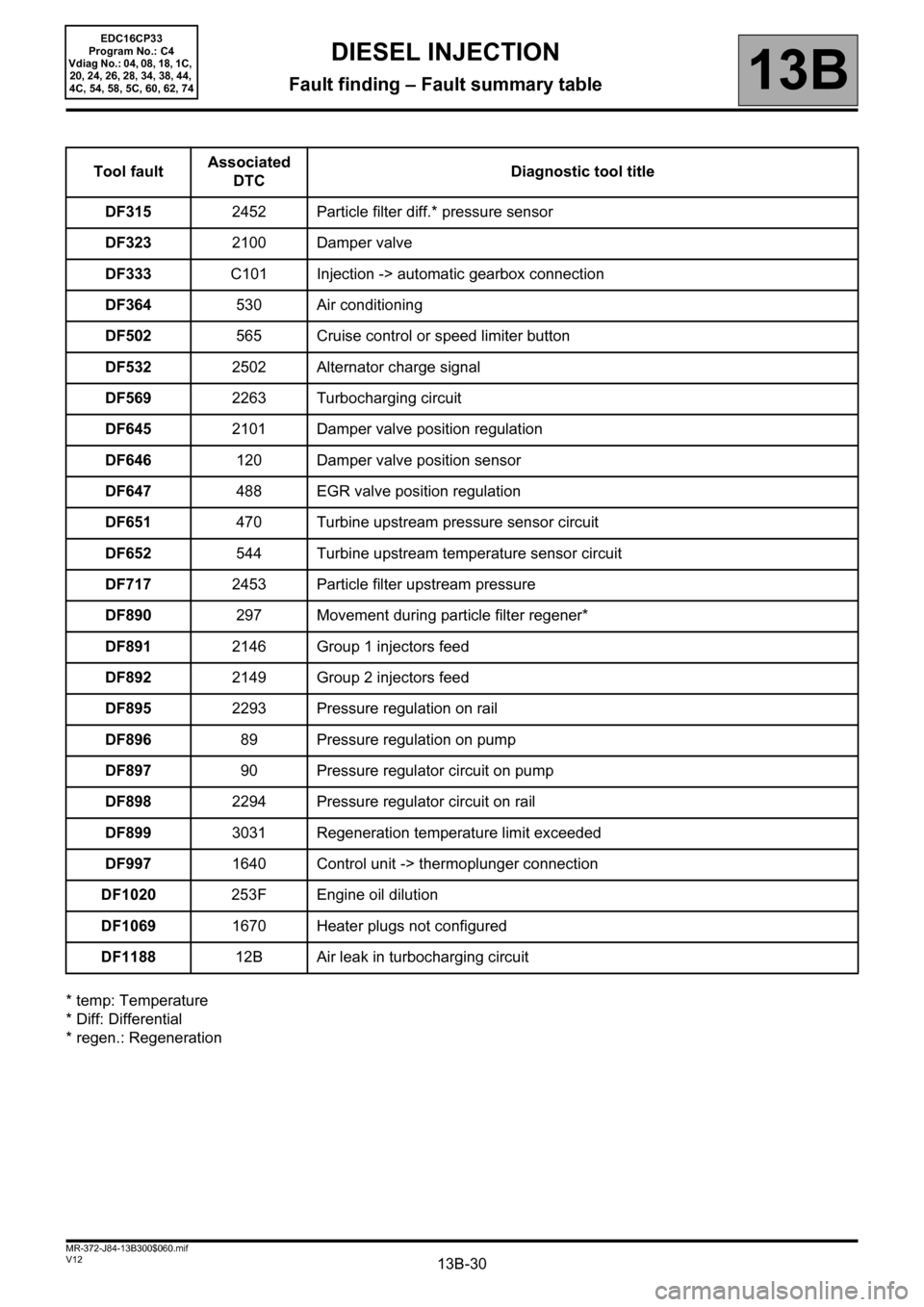

* temp: Temperature

* Diff: Differential

* regen.: RegenerationTool faultAssociated

DTCDiagnostic tool title

DF3152452 Particle filter diff.* pressure sensor

DF3232100 Damper valve

DF333C101 Injection -> automatic gearbox connection

DF364530 Air conditioning

DF502565 Cruise control or speed limiter button

DF5322502 Alternator charge signal

DF5692263 Turbocharging circuit

DF6452101 Damper valve position regulation

DF646120 Damper valve position sensor

DF647488 EGR valve position regulation

DF651470 Turbine upstream pressure sensor circuit

DF652544 Turbine upstream temperature sensor circuit

DF7172453 Particle filter upstream pressure

DF890297 Movement during particle filter regener*

DF8912146 Group 1 injectors feed

DF8922149 Group 2 injectors feed

DF8952293 Pressure regulation on rail

DF89689 Pressure regulation on pump

DF89790 Pressure regulator circuit on pump

DF8982294 Pressure regulator circuit on rail

DF8993031 Regeneration temperature limit exceeded

DF9971640 Control unit -> thermoplunger connection

DF1020253F Engine oil dilution

DF10691670 Heater plugs not configured

DF118812B Air leak in turbocharging circuit