Air condition RENAULT SCENIC 2012 J95 / 3.G Engine And Peripherals EDC16CP33 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2012, Model line: SCENIC, Model: RENAULT SCENIC 2012 J95 / 3.GPages: 510, PDF Size: 2.98 MB

Page 3 of 510

13B-3V12 MR-372-J84-13B300$010.mif

DIESEL INJECTION

Fault finding – Introduction13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Faults

Faults are declared present or stored (depending on whether they appeared in a certain context and have

disappeared since, or whether they remain present but are not diagnosed within the current context).

The present or stored status of faults should be taken into consideration when the diagnostic tool is switched on

following + after ignition feed is activated (no system components active).

For a present fault, apply the procedure described in the Interpretation of faults section.

For a stored fault, note the faults displayed and apply the Notes section.

If the fault is confirmed when the instructions are applied, the fault is present. Deal with the fault.

If the fault is not confirmed, check:

– the electrical lines which correspond to the fault,

– the connectors on these lines (corrosion, bent pins, etc.),

– the resistance of the faulty component,

– the condition of the wires (melted or cut insulation, wear).

Conformity check

The purpose of the conformity check is to check data that does not produce a fault on the diagnostic tool if the data

is inconsistent. Therefore, this stage is used to:

– carry out fault finding on faults that do not have a fault display, and which may correspond to a customer complaint.

– check that the system is operating correctly and that there is no risk of a fault recurring after repair.

The conformity check is a fault finding procedure carried out using the interpretation of statuses and parameters.

If a status does not function normally or a parameter is outside the permitted tolerance values, consult the

corresponding fault finding pages (see interpretation of statuses and parameters).

Customer complaints - Fault finding chart

If the test with the diagnostic tool is correct but the customer complaint is still present, the fault should be dealt with

by customer complaints. WARNING:

Deal first with instrument panel faults (eg. "Particle filter" warning light).

Then carry out scheduled maintenance on the vehicle.

A synopsis of the general procedure to follow is provided on the following page in the form of a flow chart.

Page 6 of 510

13B-6V12 MR-372-J84-13B300$010.mif

DIESEL INJECTION

Fault finding – Introduction13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

4.2 Connector check

1. Visual inspection of the connection:

– Check that the connector is connected correctly and that the male and female parts of the connection are correctly

coupled.

2. Visual inspection of the area around the connection:

– Check the condition of the mounting (pin, strap, adhesive tape, etc.) if the connectors are attached to the vehicle.

– Check that there is no damage to the wiring trim (sheath, foam, adhesive tape, etc.) near the wiring.

– Check that there is no damage to the electrical wires at the connector outputs, in particular on the insulating material

(wear, cuts, burns, etc.).

Disconnect the connector to continue the checks.

3. Visual inspection of the plastic casing:

– Check that there is no mechanical damage (casing crushed, cracked, broken, etc.), in particular to the fragile

components (lever, lock, terminal locations, etc.).

– Check that there is no heat damage (casing melted, blackened, deformed, etc.).

– Check that there are is no dirt (grease, mud, liquid, etc.).

4. visual inspection of the metal contacts:

(The female contact is called CLIP. The male contact is called TAB).

– Check that there are no bent contacts (the contact is not inserted correctly and can come out of the back of the

connector). The spring contact of the connector when the wire is pulled slightly.

– Check that there is no damage (tabs bent, clips open too wide, blackened or melted, etc.).

– Check that there is no oxidation on the metal contacts.

Visual inspection of the sealing:

(Only for watertight connectors)

– Check for the seal on the connection (between the 2 parts of the connection).

– Check the seal at the back of the connectors:

– For unit joints (1 for each wire), check that the unit joints are present on each electrical wire and that they are

correctly positioned in the opening (level with the housing). Check that plugs are present on openings which are

not used.

– For a grommet seal (one seal which covers the entire internal surface of the connector), check that the seal is

present.

– For gel seals, check for gel in all of the openings without removing the excess or any protruding sections

(it does not matter if there is gel on the contacts).

– For hotmelt sealing (heat-shrink sleeve with adhesive), check that the sleeve has shrunk correctly on the back

of the connectors and electrical wires, and that the hardened adhesive is evident from the wire ends.

– Check that there is no damage to any of the seals (cuts, burns, significant deformation, etc.).

If a fault is detected, consult Technical Note 6015A, Repairing electrical wiring. Note:

Carry out each requested check visually. Do not remove a connector if it is not required.

Note:

The check is carried out on the 2 parts of the connection. There may be 2 types of connections:

– Connector/Connector.

– Connector/Device.

Page 8 of 510

13B-8V12 MR-372-J84-13B300$020.mif

13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

I - HAZARDS ASSOCIATED WITH CONTAMINATION

The high pressure direct injection system is highly sensitive to contamination. The risks caused by the introduction of

contamination are:

– damage to or destruction of the high pressure injection system,

– a component seizing up,

– a component losing its sealing.

All After-Sales operations must be performed under very clean conditions. This means that no impurities

(particles a few microns in size) should have penetrated the system during dismantling.

The cleanliness guidelines must be applied from the filter through to the injectors.

What are the sources of contamination?

– metal or plastic swarf,

– paint,

–fibres:

– from cardboard,

– from brushes,

– from paper,

– from clothing,

– from cloths,

– foreign bodies such as hair,

– the ambient atmosphere

–etc.

IMPORTANT:

Cleaning the engine using a high pressure washer is prohibited because of the risk of damaging connections.

In addition, moisture may collect in the connectors and create faults in the electrical connections.

DIESEL INJECTION

Fault finding – Cleanliness guidelines

Page 9 of 510

13B-9V12 MR-372-J84-13B300$020.mif

DIESEL INJECTION

Fault finding – Cleanliness guidelines13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

II - INSTRUCTIONS TO BE FOLLOWED PRIOR TO ALL OPERATIONS

Check that you have plugs for the unions to be opened (set of plugs available from the Parts Department). The plugs

are single-use only. After use, they must be discarded (once used they are soiled and cleaning is not sufficient to

make them reusable). Unused plugs must be discarded.

Check that you have hermetically resealable plastic bags for storing removed parts. Parts stored in this way will be

less susceptible to the risk of contamination. The bags are to be used once only, and discarded after use.

Use lint-free cleaning cloths (cloth part reference 77 11 211 707). Using normal cloth or paper is prohibited. They are

not lint-free and could contaminate the fuel circuit. A lint-free cloth should only be used once.

Use fresh cleaning agent for each operation (used cleaning agent is contaminated). Pour it into a clean receptacle.

For each operation, use a clean brush in good condition (the brush must not shed its bristles).

Use a brush and cleaning agent to clean the unions to be opened.

Blow compressed air over the cleaned parts (tools, workbench, the parts, unions and injection system zones).

Check that no bristles are left.

Wash your hands before and during the operation if necessary.

When wearing leather protective gloves cover them with latex gloves to prevent contamination. IMPORTANT:

Before carrying out any work on the high pressure injection system, protect:

– the accessories and timing belts,

– the electrical accessories, (starter, alternator, electric power-assisted steering pump),

– the flywheel surface, to prevent any diesel from running onto the clutch friction plate,

– timing chain.

Page 12 of 510

13B-12V12 MR-372-J84-13B300$030.mif

DIESEL INJECTION

Fault finding – System operation13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

a. The computer:

Determines the injection pressure value necessary for the correct operation of the engine; the pressure can reach

1600 bar in the rail and it must be constantly regulated.

Checks that the pressure value is correct by analysing the value transmitted by the pressure sensor located on

the rail.

Determines the injection duration required to deliver the right quantity of diesel fuel and the moment when injection

should start. Controls each injector electrically and individually after determining these two values.

The quantity of fuel injected is determined by:

– Engine speed (Crankshaft + Cam for synchronisation).

– Accelerator pedal.

– Turbocharging pressure.

– Coolant temperature,

– Inlet air temperature.

–Air flow

– Pressure in the rail.

– Vehicle speed.

The computer manages:

– idling regulation,

– exhaust gas flow reinjection to the inlet,

– fuel supply check (advance, flow and rail pressure),

– the fan assembly control,

– the air conditioning (cold loop function),

– cruise control/speed limiter function,

– pre-post heating control,

– indicator lights control via the multiplex network,

– the operation of the catalysed particle filter,

– turbocharging pressure.

The high pressure pump is supplied at low pressure by an integrated low pressure pump (transfer pump).

It supplies the rail, the pressure in which is regulated by:

–the pressure regulator on the rail (DRV) for starting phases, starting the engine when cold (increase in

temperature to heat the diesel circuit) and when throttling-off,

–the pressure regulator on the pump (MPROP) for all other phases (90% of cases).

As natural leaks in piezoelectric injectors are very low, opening the pressure regulator (DRV) is the only quick

method of dumping the rail pressure and it prevents overpressure when injection is restarted.

The pressure regulator on the pump (MPROP) enables the high pressure pump to supply just the exact quantity

of diesel fuel required to maintain the rail pressure. This component minimises the heat generated and improves

engine output.

Note:

Each piezoelectric injector is connected to the return rail. The injector return rail is kept pressurised by a

mechanical valve at the end of the return rail with a 10 bar calibration (by comparison, solenoid injectors used to

return directly into the common fuel return circuit). This feature is linked to the operation of piezoelectric injectors.

Page 14 of 510

13B-14V12 MR-372-J84-13B300$030.mif

DIESEL INJECTION

Fault finding – System operation13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

c. Functions hosted:

Air conditioning management assistance:

For vehicles with air conditioning, the EDC16CP33 system provides the option of deactivating the air conditioning

via the UCH, under certain conditions of use:

– when requested by the driver,

– when starting the engine,

– if the engine overheats (in order to reduce the power the engine has to supply),

– when the engine speed is kept at a very high level (to protect the compressor),

– during transition phases (e.g. under heavy acceleration when overtaking, anti-stalling and moving off strategies).

These conditions are only taken into account when they do not occur repeatedly, in order to prevent system

instabilities (erratic deactivations),

– when certain faults appear.

I - Cold loop air conditioning management:

The air conditioning is the cold loop type and its management shared between several computers.

The injection computer is responsible for:

– authorising requests for cold air depending on the engine coolant temperature and the engine speed,

– calculating the power absorbed by the compressor from the refrigerant pressure.

–requesting fan assembly actuation (Mégane II ph2 and Scénic II ph2) and controlling fan assembly actuation

(Laguna II, Vel Satis ph2 and Espace IV ph2), according to the vehicle speed, the refrigerant pressure and the

engine coolant temperature.

The driver requests the air conditioning to be switched on by means of the ventilation selector coupled to a switch.

The cold air request is authorised or denied depending on the pressure measured. If this pressure is outside the

operating limits, the cold loop program is not activated.

The air conditioning system is authorised by the injection computer 2 to 8 seconds after the engine is started.

Management of the thermoplungers:

To improve cold starting, the vehicle is fitted with thermoplungers. These thermoplungers are managed and

controlled by the injection computer, according to the operating phases, primarily to accelerate the increase in

engine coolant temperature.

The maximum number of thermoplungers that can be actuated is four and their actuation depends mainly on the

coolant temperature and the air temperature.

See configuration reading LC056 Thermoplungers: WITH or WITHOUT.

When necessary, they are actuated by the injection system only during particle filter regeneration by means

of a special unit.

The maximum number of thermoplungers that can be managed is four and their activation depends mainly on the

coolant temperature (< 15°C) and air temperature (< 5°C).

Page 19 of 510

13B-19V12 MR-372-J84-13B300$030.mif

DIESEL INJECTION

Fault finding – System operation13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Warning light management:

Instrument panel display

The computer displays certain information on the instrument panel relating to engine operation. This concerns five

functions:

– the pre-postheating warning light,

– the coolant temperature warning light,

–the level 1 fault warning light (non-critical fault),

–the level 2 fault warning light (emergency stop),

–the EOBD (European On Board Diagnostic) warning light,

These six functions are represented by 3 warning lights and/or messages displayed by the on-board computer.

Orange pre-post heating/non-critical fault SERVICE warning light (severity 1)

This light is used both as an in-operation indicator light and as a system fault indicator:

– Continuously lit with + after ignition feed:

Indicates preheating of the spark plugs.

– Continuously lit with the Check injection message:

Indicates a level 1 fault (involving operation of the injection system in defect mode).

The driver should have the repairs carried out as soon as possible.

Temperature / red emergency STOP warning light (level 2)

This indicator light is used both as an in-operation indicator light and as a system fault warning light. It lights up for

3 seconds after the ignition is switched on (automatic test procedure managed by the instrument panel):

– Continuously lit:

Indicates engine overheating (the driver is free to choose whether or not to stop the vehicle).

– Continuously lit with the faulty injection message:

Indicates a level 2 fault (In this case, the injection is automatically cut after a few seconds).

The driver should carry out repairs as soon as possible.

ORANGE Excessive pollution EOBD warning light

Symbolised by an engine, it lights up for approximately 3 seconds when the ignition is switched on.

This warning light comes on if the system has one or more EOBD faults.

This warning light is used to alert the driver to injection faults that could lead to excessive pollution, or if the EOBD

system (European On Board Diagnostic) has been deactivated.

The injection computer requests illumination of the EOBD warning light for a present fault only after three

consecutive driving cycles.

The 3 second visual inspection when the ignition is switched on (automatic test procedure managed by the

instrument panel) is carried out by the injection computer.

Special particle filter ORANGE warning light or warning message (depending on instrument panel)

Only for Vdiag: 18, 1C, 54, 20, 58, 5C, 24, 26 and 60.

This warning light or message is used to warn the driver that the particle filter is loaded with particles, (see the soot

weight thresholds for illumination of the warning light for fault DF312 Speed request) due to driving conditions which

were not suitable for regeneration to take place. The driver must then drive as soon as possible at an average speed

of 48 mph (80 km/h) subject to the road conditions and authorised speed limits, until the warning light goes out.

Page 20 of 510

13B-20V12 MR-372-J84-13B300$030.mif

DIESEL INJECTION

Fault finding – System operation13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

EOBD management (European On Board Diagnostic):

The EOBD system enables the detection of any faults relating to the vehicle emission control system

(EOBD EURO IV emission control standards exceeded).

This system should be active for the entire life of the vehicle.

1. Conditions for an EOBD fault appearing

An EOBD fault will be detected after 3 driving cycles.

It allows the driver to know whether the vehicle has a fault directly linked to the emission control system.

2. System faults displayed by the EOBD

Only a few faults are indicated by the EOBD system:

– DF002 Air temperature sensor circuit.

– DF004 Turbocharging pressure sensor circuit.

– DF011 Sensor feed voltage no. 1.

– DF012 Sensor feed voltage no. 2.

– DF013 Sensor feed voltage no. 3.

– DF026 Cylinder 1 injector control circuit.

– DF027 Cylinder 2 injector control circuit.

– DF028 Cylinder 3 injector control circuit.

– DF029 Cylinder 4 injector control circuit.

– DF054 Turbocharging solenoid valve control circuit.

– DF056 Air flow sensor circuit.

– DF107 Computer memory.

– DF200 Atmospheric pressure sensor.

– DF209 EGR position sensor circuit.

– DF272 EGR valve control circuit.

– DF569 Turbocharging circuit.

Some repair operations require programming to ensure that certain engine components function correctly.

Follow the programming procedures (see Replacement of components), if replacing the exhaust gas

recirculation valve or an injector.

3. Conditions for clearing an EOBD fault

An EOBD fault is cleared in several phases.

The fault present in the diagnostic tool will only be stored (following repair) after the vehicle has been driven

3times.

The EOBD warning light will only go out after these 3 driving cycles.

The instrument panel warning light coming on does not automatically mean that the system has a fault.

In order for the EOBD fault and display parameters to be cleared from the computer, the system must go

through 40 engine heating cycles.

An engine heating cycle is a driving cycle during which:

– the engine coolant temperature reaches at least 71.1°C,

– the engine coolant temperature varies by 22.2°C in relation to the engine starting temperature.

If one of these conditions is not fulfilled, the EOBD fault will still be present or stored in the injection

computer.

Page 21 of 510

13B-21V12 MR-372-J84-13B300$040.mif

13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

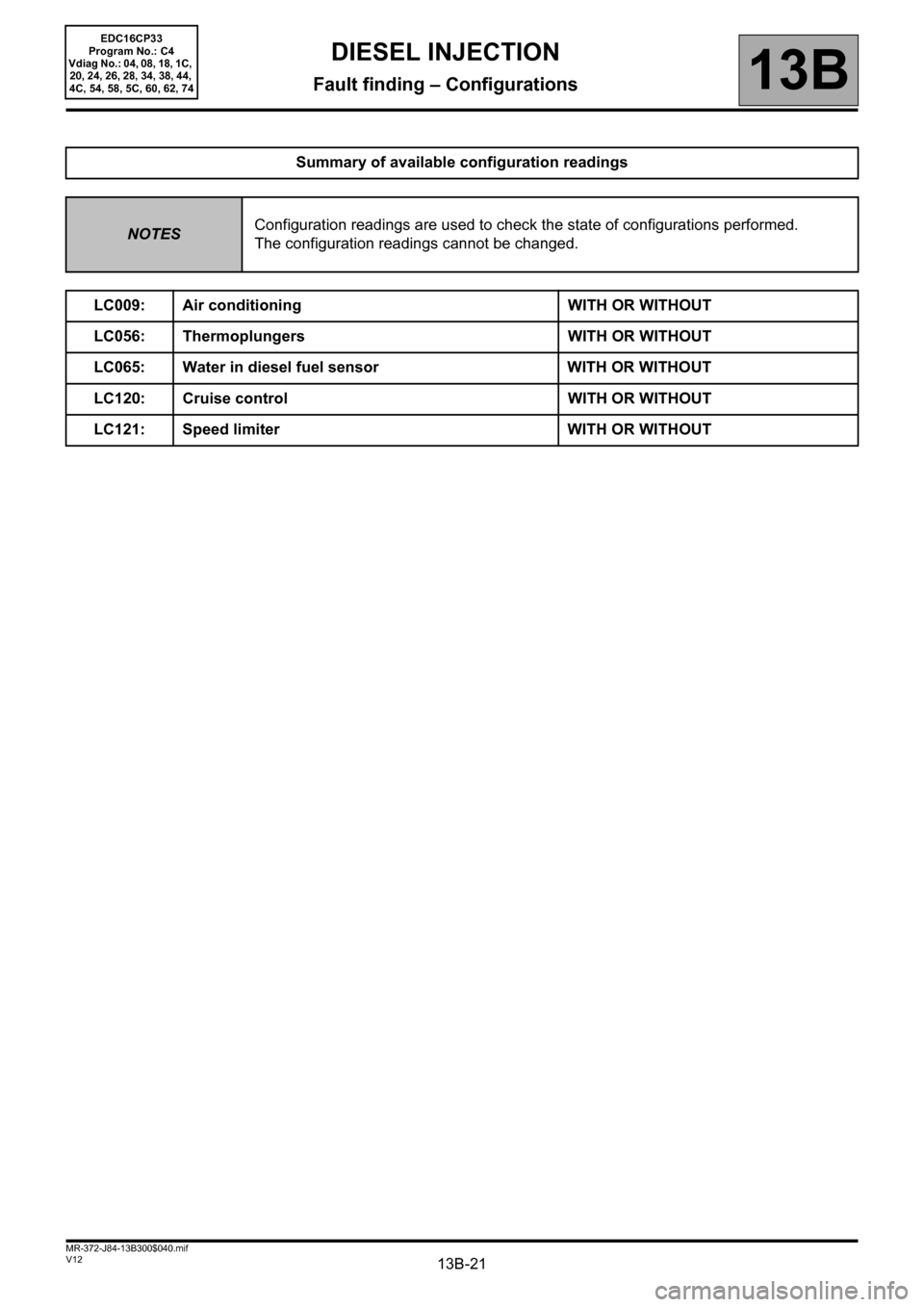

Summary of available configuration readings

NOTESConfiguration readings are used to check the state of configurations performed.

The configuration readings cannot be changed.

LC009: Air conditioning WITH OR WITHOUT

LC056: Thermoplungers WITH OR WITHOUT

LC065: Water in diesel fuel sensor WITH OR WITHOUT

LC120: Cruise control WITH OR WITHOUT

LC121: Speed limiter WITH OR WITHOUT

DIESEL INJECTION

Fault finding – Configurations

Page 30 of 510

13B-30V12 MR-372-J84-13B300$060.mif

DIESEL INJECTION

Fault finding – Fault summary table13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

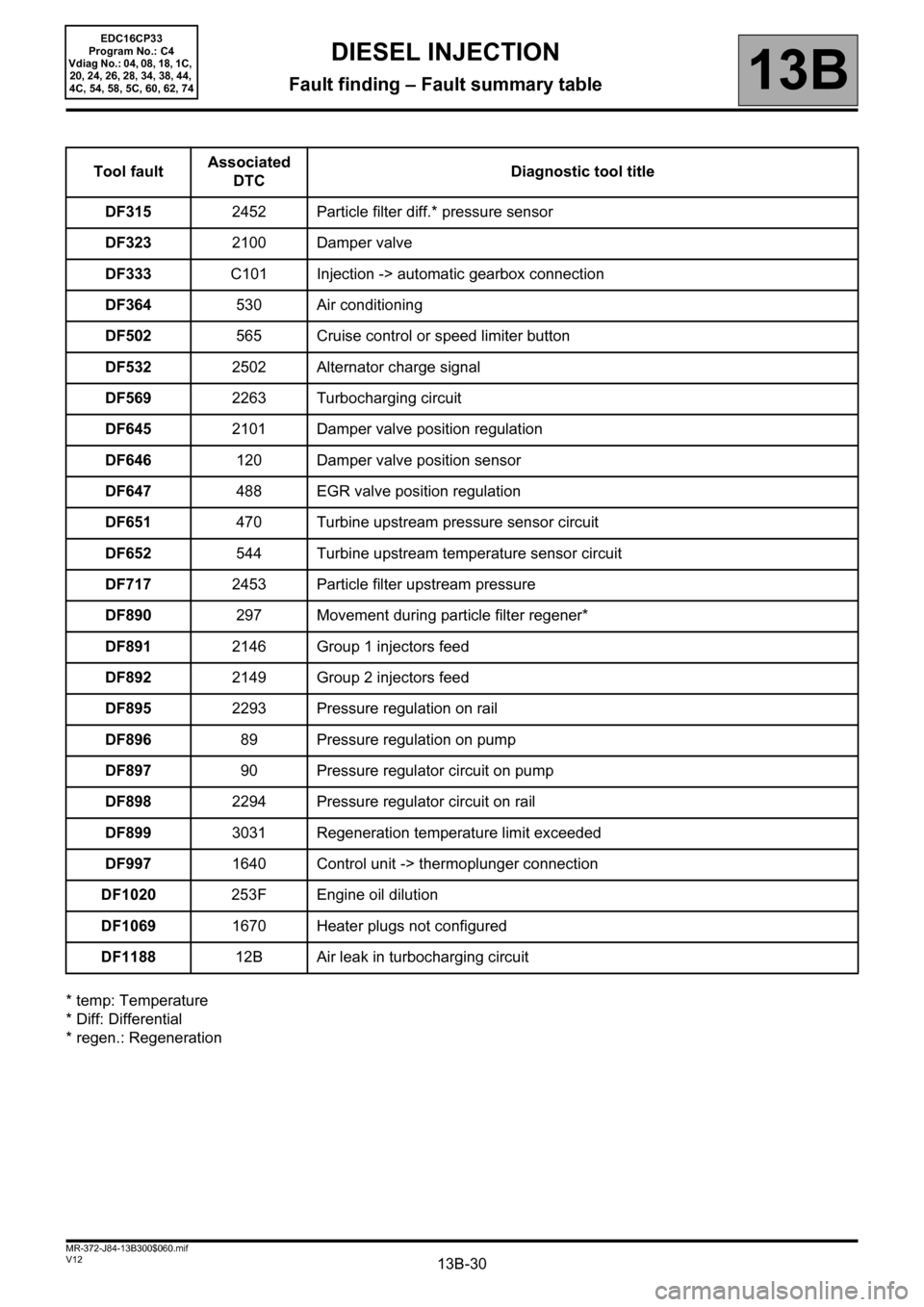

* temp: Temperature

* Diff: Differential

* regen.: RegenerationTool faultAssociated

DTCDiagnostic tool title

DF3152452 Particle filter diff.* pressure sensor

DF3232100 Damper valve

DF333C101 Injection -> automatic gearbox connection

DF364530 Air conditioning

DF502565 Cruise control or speed limiter button

DF5322502 Alternator charge signal

DF5692263 Turbocharging circuit

DF6452101 Damper valve position regulation

DF646120 Damper valve position sensor

DF647488 EGR valve position regulation

DF651470 Turbine upstream pressure sensor circuit

DF652544 Turbine upstream temperature sensor circuit

DF7172453 Particle filter upstream pressure

DF890297 Movement during particle filter regener*

DF8912146 Group 1 injectors feed

DF8922149 Group 2 injectors feed

DF8952293 Pressure regulation on rail

DF89689 Pressure regulation on pump

DF89790 Pressure regulator circuit on pump

DF8982294 Pressure regulator circuit on rail

DF8993031 Regeneration temperature limit exceeded

DF9971640 Control unit -> thermoplunger connection

DF1020253F Engine oil dilution

DF10691670 Heater plugs not configured

DF118812B Air leak in turbocharging circuit