bulb RENAULT SCENIC 2012 J95 / 3.G Engine And Peripherals EDC16CP33 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2012, Model line: SCENIC, Model: RENAULT SCENIC 2012 J95 / 3.GPages: 510, PDF Size: 2.98 MB

Page 11 of 510

13B-11V12 MR-372-J84-13B300$030.mif

13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

System outline

The high pressure injection system is designed to deliver a precise quantity of diesel fuel to the engine at a set

moment.

It is fitted with a BOSCH computer, type EDC16CP33.

The system comprises:

– a priming bulb,

– a diesel filter,

– a high pressure pump,

– a fuel pressure regulator (or actuator) on the high pressure pump (MPROP),

– a fuel pressure regulator (or actuator) mounted on the injector rail (DRV),

– an injector rail,

– a fuel pressure sensor,

– four piezoelectric injectors,

– a diesel temperature sensor,

– a coolant temperature sensor,

– an upstream air temperature sensor,

– a cylinder reference sensor,

– an engine speed sensor,

– a turbocharger pressure sensor,

– an exhaust gas recirculation valve,

– a recycled gas cooling solenoid valve,

– an accelerator pedal potentiometer,

– an atmospheric pressure sensor integrated into the injection computer,

– a flow sensor,

– a turbocharging limiter solenoid valve,

– a damper valve,

– a particle filter,

– a turbo upstream temperature sensor,

– a turbo upstream pressure sensor,

– a particle filter differential pressure sensor,

– a particle filter upstream temperature sensor,

– a particle filter downstream temperature sensor,

– an electric coolant pump (turbocharger),

– four thermoplungers.

The common rail direct high pressure injection system works sequentially (based on the petrol engine

multipoint injection).

This system uses piezoelectric injectors which enable a more precise injection since opening and closing times

are shorter compared to conventional solenoid injectors.

This injection system reduces operating noise, reduces the volume of pollutant gases and particles and produces

high engine torque at low engine speeds thanks to a pre-injection procedure.

The high pressure pump generates the high pressure and transmits it to the injector rail. The actuator located on

the pump controls the quantity of diesel supplied, according to the demand determined by the computer.

The rail supplies each injector through a steel pipe. The actuator located on the injector rail controls the pressure

of diesel fuel in the rail according to the demand determined by the computer.

DIESEL INJECTION

Fault finding – System operation

Page 481 of 510

13B-481

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V12 MR-372-J84-13B300$170.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

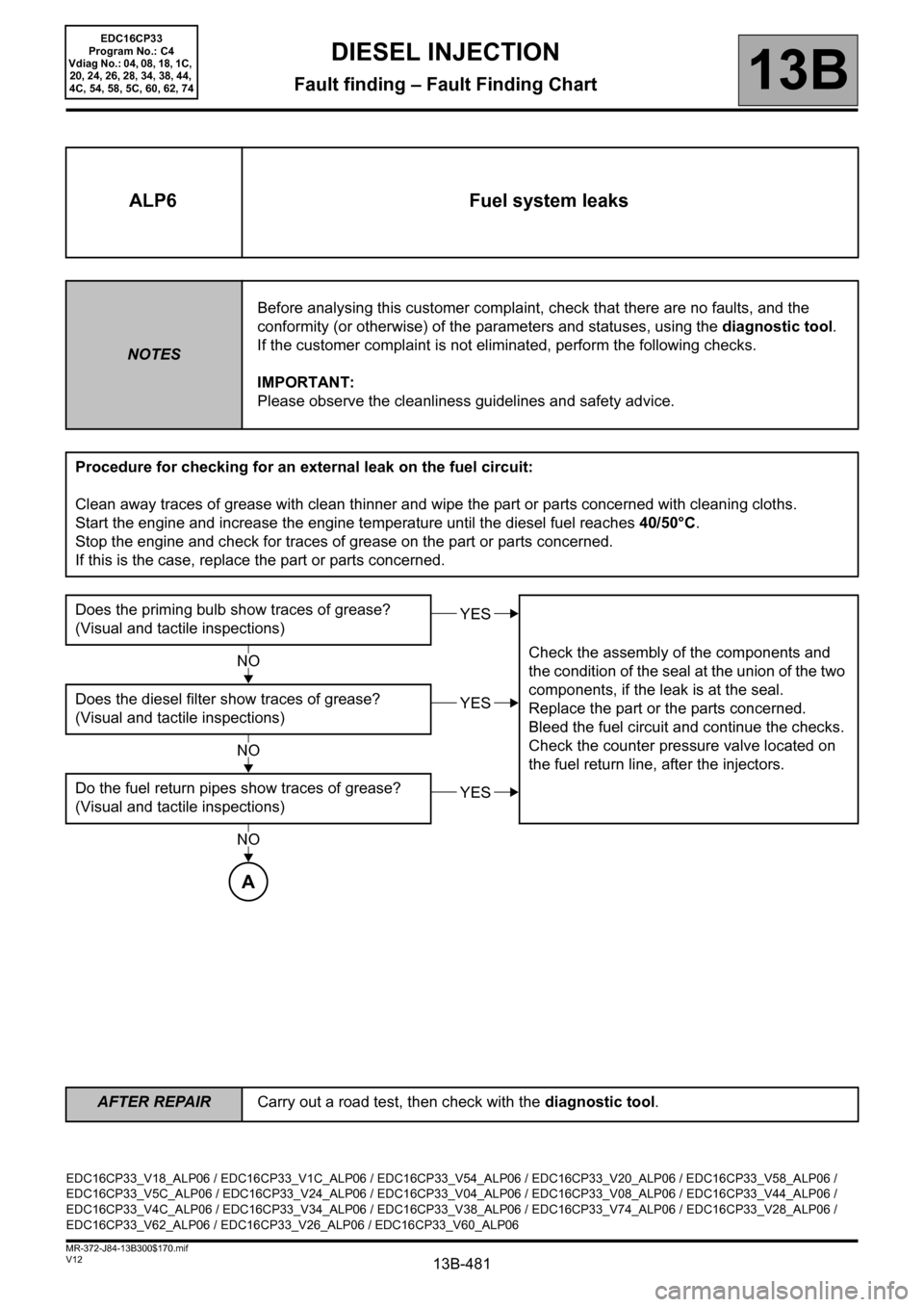

ALP6 Fuel system leaks

NOTESBefore analysing this customer complaint, check that there are no faults, and the

conformity (or otherwise) of the parameters and statuses, using the diagnostic tool.

If the customer complaint is not eliminated, perform the following checks.

IMPORTANT:

Please observe the cleanliness guidelines and safety advice.

Procedure for checking for an external leak on the fuel circuit:

Clean away traces of grease with clean thinner and wipe the part or parts concerned with cleaning cloths.

Start the engine and increase the engine temperature until the diesel fuel reaches 40/50°C.

Stop the engine and check for traces of grease on the part or parts concerned.

If this is the case, replace the part or parts concerned.

Does the priming bulb show traces of grease?

(Visual and tactile inspections)

Check the assembly of the components and

the condition of the seal at the union of the two

components, if the leak is at the seal.

Replace the part or the parts concerned.

Bleed the fuel circuit and continue the checks.

Check the counter pressure valve located on

the fuel return line, after the injectors. Does the diesel filter show traces of grease?

(Visual and tactile inspections)

Do the fuel return pipes show traces of grease?

(Visual and tactile inspections)

YES

NO

YES

NO

YES

NO

A

EDC16CP33_V18_ALP06 / EDC16CP33_V1C_ALP06 / EDC16CP33_V54_ALP06 / EDC16CP33_V20_ALP06 / EDC16CP33_V58_ALP06 /

EDC16CP33_V5C_ALP06 / EDC16CP33_V24_ALP06 / EDC16CP33_V04_ALP06 / EDC16CP33_V08_ALP06 / EDC16CP33_V44_ALP06 /

EDC16CP33_V4C_ALP06 / EDC16CP33_V34_ALP06 / EDC16CP33_V38_ALP06 / EDC16CP33_V74_ALP06 / EDC16CP33_V28_ALP06 /

EDC16CP33_V62_ALP06 / EDC16CP33_V26_ALP06 / EDC16CP33_V60_ALP06

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Page 498 of 510

13B-498V12 MR-372-J84-13B300$180.mif

DIESEL INJECTION

Fault finding – Test13B

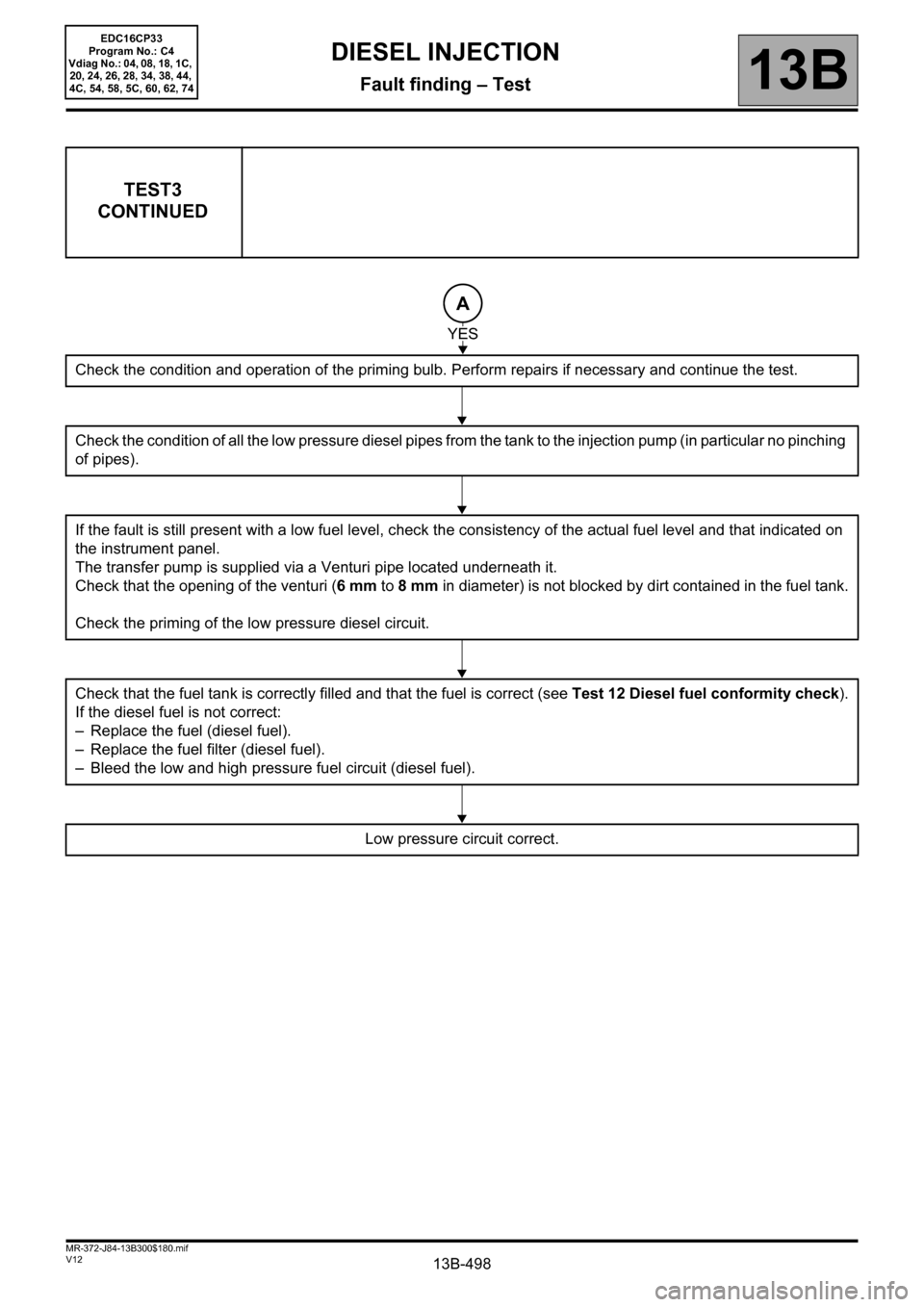

TEST3

CONTINUED

Check the condition and operation of the priming bulb. Perform repairs if necessary and continue the test.

Check the condition of all the low pressure diesel pipes from the tank to the injection pump (in particular no pinching

of pipes).

If the fault is still present with a low fuel level, check the consistency of the actual fuel level and that indicated on

the instrument panel.

The transfer pump is supplied via a Venturi pipe located underneath it.

Check that the opening of the venturi (6 mm to 8 mm in diameter) is not blocked by dirt contained in the fuel tank.

Check the priming of the low pressure diesel circuit.

Check that the fuel tank is correctly filled and that the fuel is correct (see Test 12 Diesel fuel conformity check).

If the diesel fuel is not correct:

– Replace the fuel (diesel fuel).

– Replace the fuel filter (diesel fuel).

– Bleed the low and high pressure fuel circuit (diesel fuel).

Low pressure circuit correct.

A

YES

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74