compression RENAULT SCENIC 2012 J95 / 3.G Engine And Peripherals EDC16CP33 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2012, Model line: SCENIC, Model: RENAULT SCENIC 2012 J95 / 3.GPages: 510, PDF Size: 2.98 MB

Page 432 of 510

13B-432V12 MR-372-J84-13B300$150.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

SC031

CONTINUED

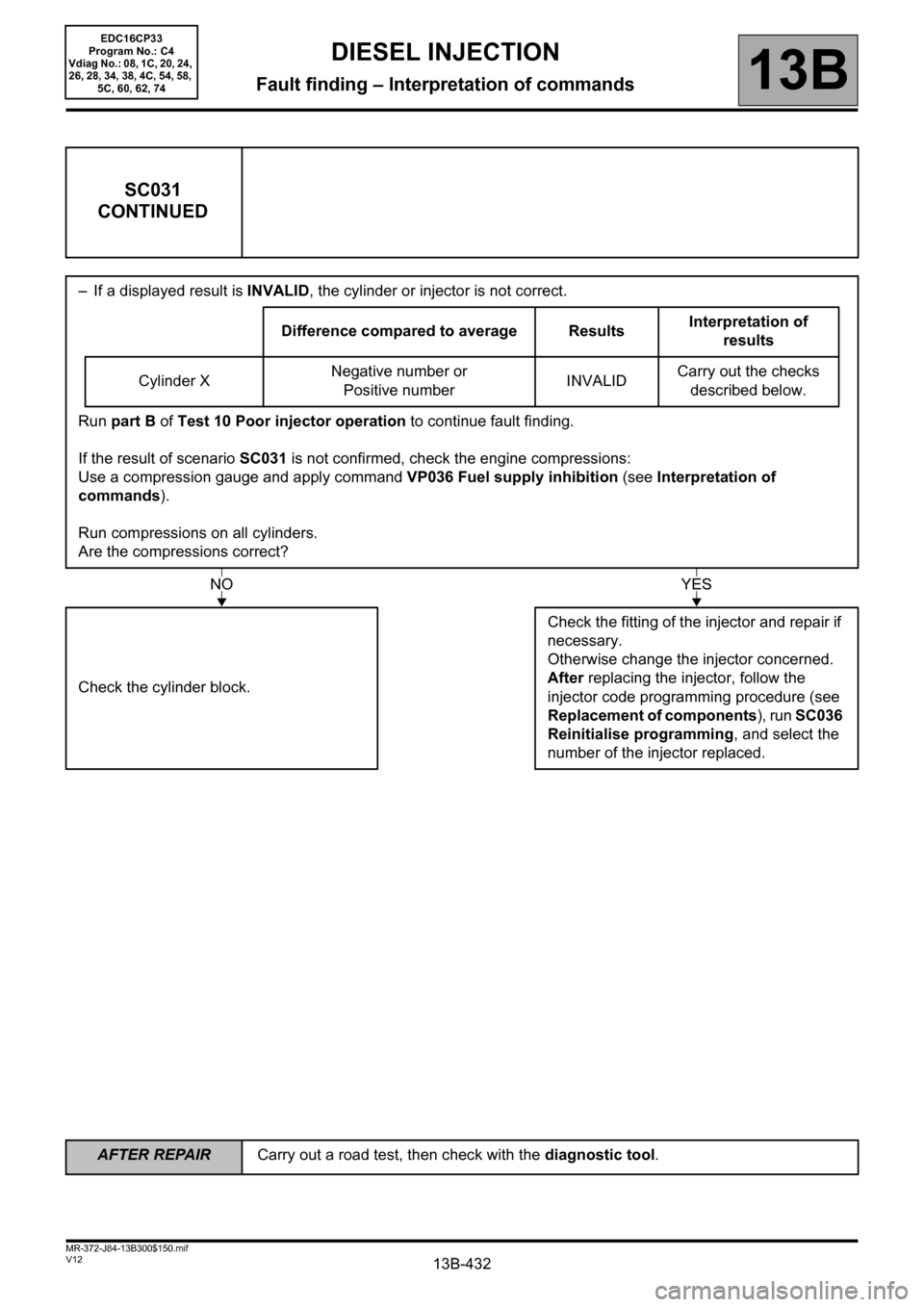

– If a displayed result is INVALID, the cylinder or injector is not correct.

Difference compared to average ResultsInterpretation of

results

Cylinder XNegative number or

Positive numberINVALIDCarry out the checks

described below.

Run part B of Test 10 Poor injector operation to continue fault finding.

If the result of scenario SC031 is not confirmed, check the engine compressions:

Use a compression gauge and apply command VP036 Fuel supply inhibition (see Interpretation of

commands).

Run compressions on all cylinders.

Are the compressions correct?

Check the cylinder block.Check the fitting of the injector and repair if

necessary.

Otherwise change the injector concerned.

After replacing the injector, follow the

injector code programming procedure (see

Replacement of components), run SC036

Reinitialise programming, and select the

number of the injector replaced.

NOYES

EDC16CP33

Program No.: C4

Vdiag No.: 08, 1C, 20, 24,

26, 28, 34, 38, 4C, 54, 58,

5C, 60, 62, 74

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

Page 462 of 510

13B-462V12 MR-372-J84-13B300$150.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

MT001

CONTINUED 3

Fault finding procedure Monitool no. 1:

– Check the fitting of the air flowmeter (direction of fitting to be observed).

– Check the tightness of the different air flowmeter clips.

– Check the + 5 V supply of connection 3KJ of component 799.

If the connection is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

– Check that there are no air leaks between the air flowmeter and the turbocharger.

– Run Test 5 Air flowmeter: check that there is no dust on the sensors.

If the checks do not reveal any non-conformity and the fault is still present, change the air flowmeter. Attach a

screen copy of the Monitool results.

Monitool no. 2 fault finding procedure:

– Measure the internal resistance of the turbocharger control solenoid valve by applying the interpretation of

DF054 Turbocharging solenoid valve control circuit.

– Check the connection of all the air hoses and the tightness of the clips.

– Check the condition of the air filter and replace it if necessary.

– Check that the exhaust pipe is not clogged, run Test 1 Exhaust pipe check.

–Apply Test 7 Variable geometry turbocharger control.

– Check that there are no leaks around the exhaust manifold.

– Check that there is no clogging obstructing the air refrigerant.

– Check that there are no air leaks on the engine (compression test).

If the checks do not reveal any non-conformity and the fault is still present, replace the turbocharger. Attach a

screen copy of the Monitool results.

EDC16CP33

Program No.: C4

Vdiag No.: 04, 44

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

Page 468 of 510

13B-468V12 MR-372-J84-13B300$150.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

VP036INHIBIT FUEL SUPPLY

NOTESThis command enables you to disable the supply to the injectors.

This command is carried out with the engine switched off, and ignition on.

This command allows the injectors to be locked, so that starting is not possible.

Command VP036 allows the engine compressions to be checked in complete safety without disconnecting the

connectors of the injectors or the TDC sensor.

Procedure to follow (cylinder no. 1 is located on the timing end):

– Remove all of the heater plugs, connect the compression gauge with the M9R flexible end piece, part no.

MOT 1772, to a cylinder.

– Position the gear lever in neutral (manual gearbox) or to position P (automatic/sequential gearbox).

– Depress the brake pedal and keep it in this position throughout the test.

– Activate command VP036.

– Attempt to start the vehicle (within 10 seconds of activating command VP036).

If the vehicle does not start, check the cylinder compressions.

Start the procedure again on another cylinder.

WARNING:

Keep the brake pedal depressed for the length of the test.

This command is inhibited automatically after 10 seconds.

EDC16CP33_V18_VP036 / EDC16CP33_V1C_VP036 / EDC16CP33_V54_VP036 / EDC16CP33_V20_VP036 / EDC16CP33_V58_VP036 /

EDC16CP33_V5C_VP036 / EDC16CP33_V24_VP036 / EDC16CP33_V04_VP036 / EDC16CP33_V08_VP036 / EDC16CP33_V44_VP036 /

EDC16CP33_V4C_VP036 / EDC16CP33_V34_VP036 / EDC16CP33_V38_VP036 / EDC16CP33_V74_VP036 / EDC16CP33_V28_VP036 /

EDC16CP33_V62_VP036 / EDC16CP33_V26_VP036 / EDC16CP33_V60_VP036

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

Page 479 of 510

13B-479

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V12 MR-372-J84-13B300$170.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

ALP4

CONTINUED 3

Check:

– That the diesel filter is not clogged.

– That there are no leaks on the high and low pressure diesel circuits: run Test 3 Low pressure circuit check.

–Test the high pressure fuel circuit:

Run scenario SC035 High pressure fuel circuit fault finding (see Interpretation of commands).

Continue by checking the following:

– The connection of the oil vapour rebreathing circuit.

– The pump pressure regulator (MPROP), (jamming - sticking); apply the interpretation of command AC226 Pump

pressure regulator.

– The rail pressure regulator (DRV), (jamming - sticking); apply the interpretation of command AC225 Rail

pressure regulator.

– Check the engine timing (and the position of the high pressure pump sprocket).

– Check the engine compressions: use a compression gauge, M9R hose end piece, part no. Mot. 1772 and apply

command VP036 Fuel supply inhibition (see Interpretation of commands).

If the fault is still present, contact the techline.

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Page 490 of 510

13B-490

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V12 MR-372-J84-13B300$170.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

IMA*: Individual injector correction

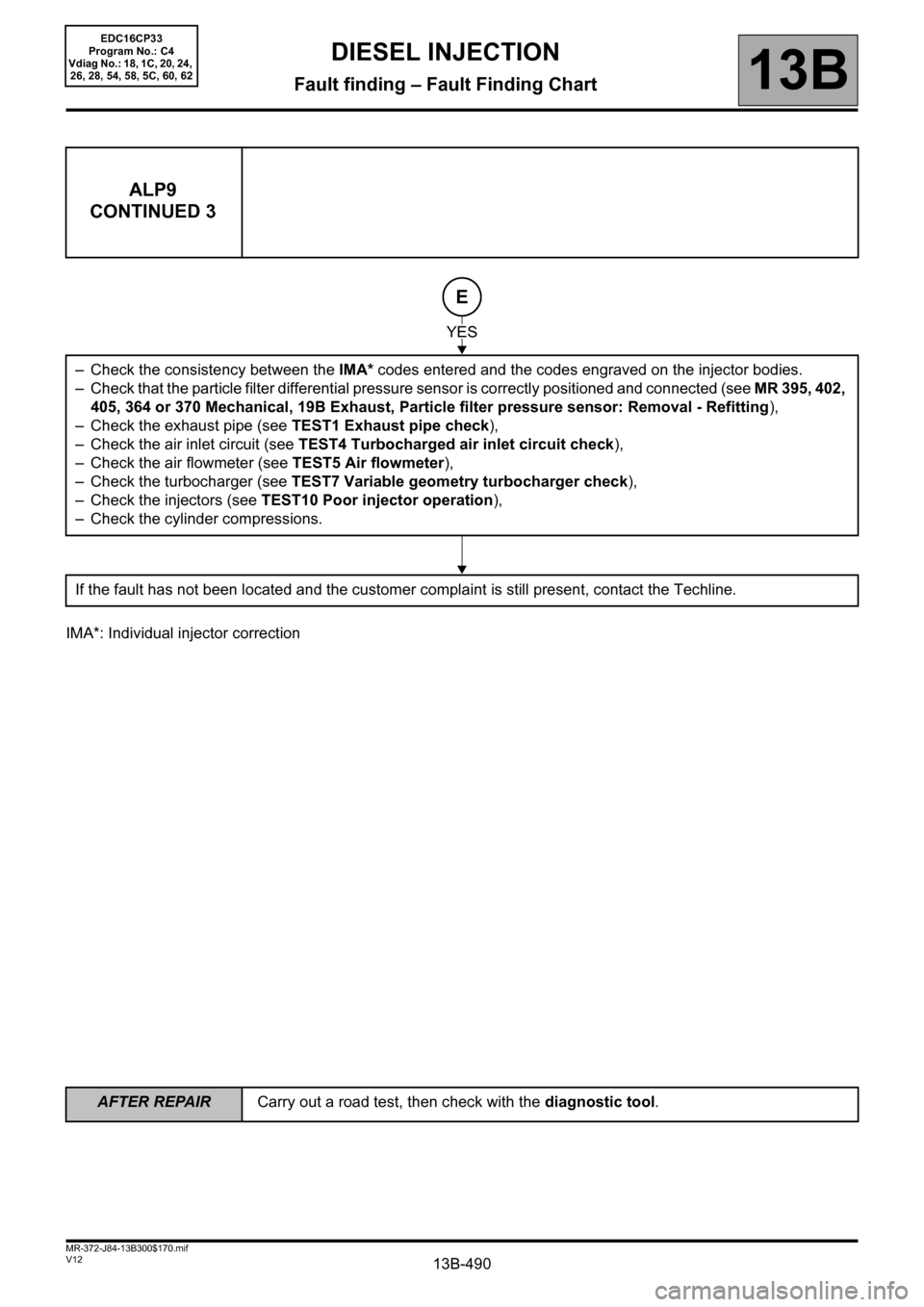

ALP9

CONTINUED 3

– Check the consistency between the IMA* codes entered and the codes engraved on the injector bodies.

– Check that the particle filter differential pressure sensor is correctly positioned and connected (see MR 395, 402,

405, 364 or 370 Mechanical, 19B Exhaust, Particle filter pressure sensor: Removal - Refitting),

– Check the exhaust pipe (see TEST1 Exhaust pipe check),

– Check the air inlet circuit (see TEST4 Turbocharged air inlet circuit check),

– Check the air flowmeter (see TEST5 Air flowmeter),

– Check the turbocharger (see TEST7 Variable geometry turbocharger check),

– Check the injectors (see TEST10 Poor injector operation),

– Check the cylinder compressions.

If the fault has not been located and the customer complaint is still present, contact the Techline.

YES

E

EDC16CP33

Program No.: C4

Vdiag No.: 18, 1C, 20, 24,

26, 28, 54, 58, 5C, 60, 62

Page 495 of 510

13B-495V12 MR-372-J84-13B300$180.mif

DIESEL INJECTION

Fault finding – Test13B

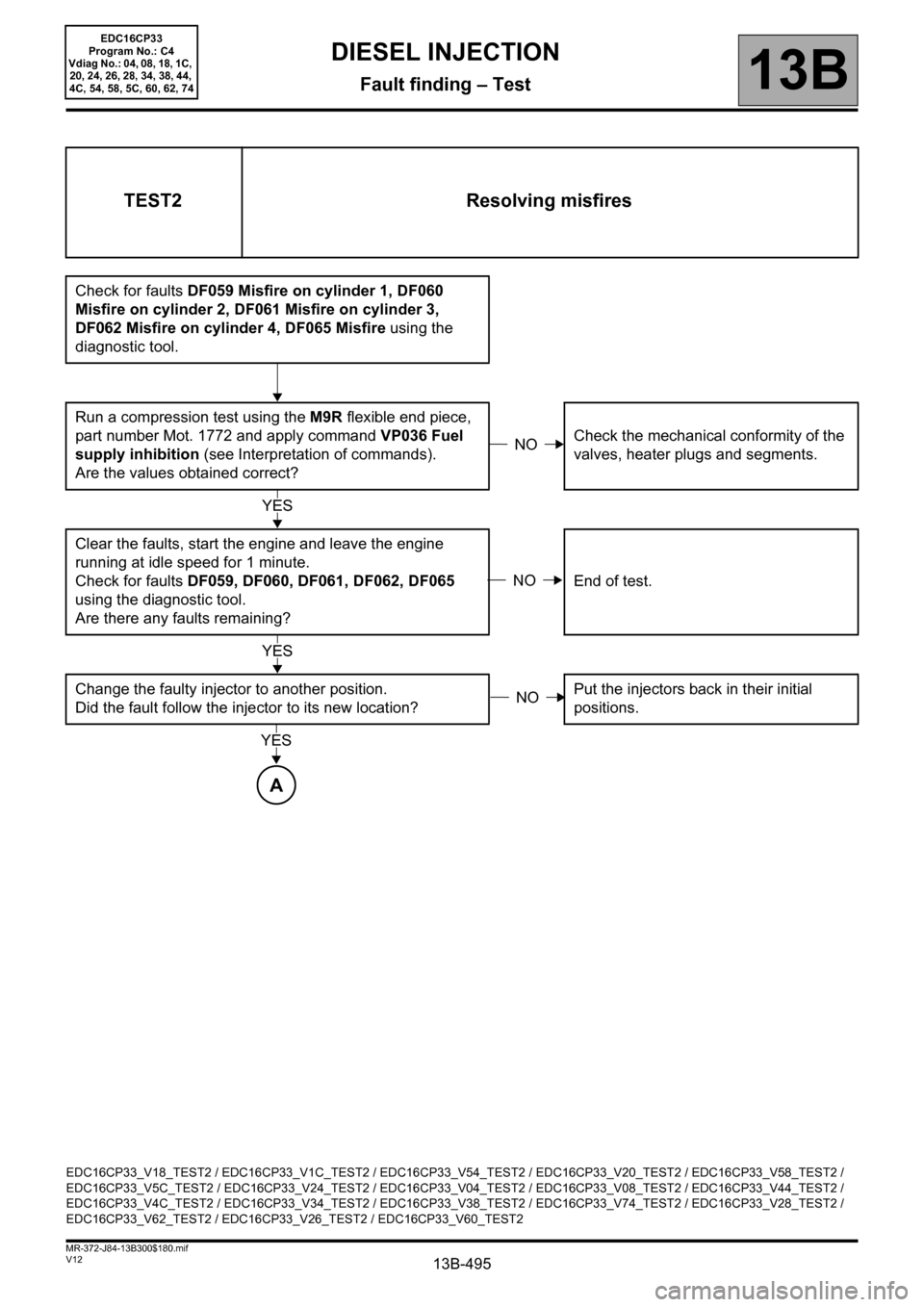

TEST2 Resolving misfires

Check for faults DF059 Misfire on cylinder 1, DF060

Misfire on cylinder 2, DF061 Misfire on cylinder 3,

DF062 Misfire on cylinder 4, DF065 Misfire using the

diagnostic tool.

Run a compression test using the M9R flexible end piece,

part number Mot. 1772 and apply command VP036 Fuel

supply inhibition (see Interpretation of commands).

Are the values obtained correct?Check the mechanical conformity of the

valves, heater plugs and segments.

Clear the faults, start the engine and leave the engine

running at idle speed for 1 minute.

Check for faults DF059, DF060, DF061, DF062, DF065

using the diagnostic tool.

Are there any faults remaining?End of test.

Change the faulty injector to another position.

Did the fault follow the injector to its new location?Put the injectors back in their initial

positions.

NO

YES

NO

YES

NO

YES

A

EDC16CP33_V18_TEST2 / EDC16CP33_V1C_TEST2 / EDC16CP33_V54_TEST2 / EDC16CP33_V20_TEST2 / EDC16CP33_V58_TEST2 /

EDC16CP33_V5C_TEST2 / EDC16CP33_V24_TEST2 / EDC16CP33_V04_TEST2 / EDC16CP33_V08_TEST2 / EDC16CP33_V44_TEST2 /

EDC16CP33_V4C_TEST2 / EDC16CP33_V34_TEST2 / EDC16CP33_V38_TEST2 / EDC16CP33_V74_TEST2 / EDC16CP33_V28_TEST2 /

EDC16CP33_V62_TEST2 / EDC16CP33_V26_TEST2 / EDC16CP33_V60_TEST2

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Page 503 of 510

13B-503V12 MR-372-J84-13B300$180.mif

DIESEL INJECTION

Fault finding – Test13B

IMA*: Individual injector correction

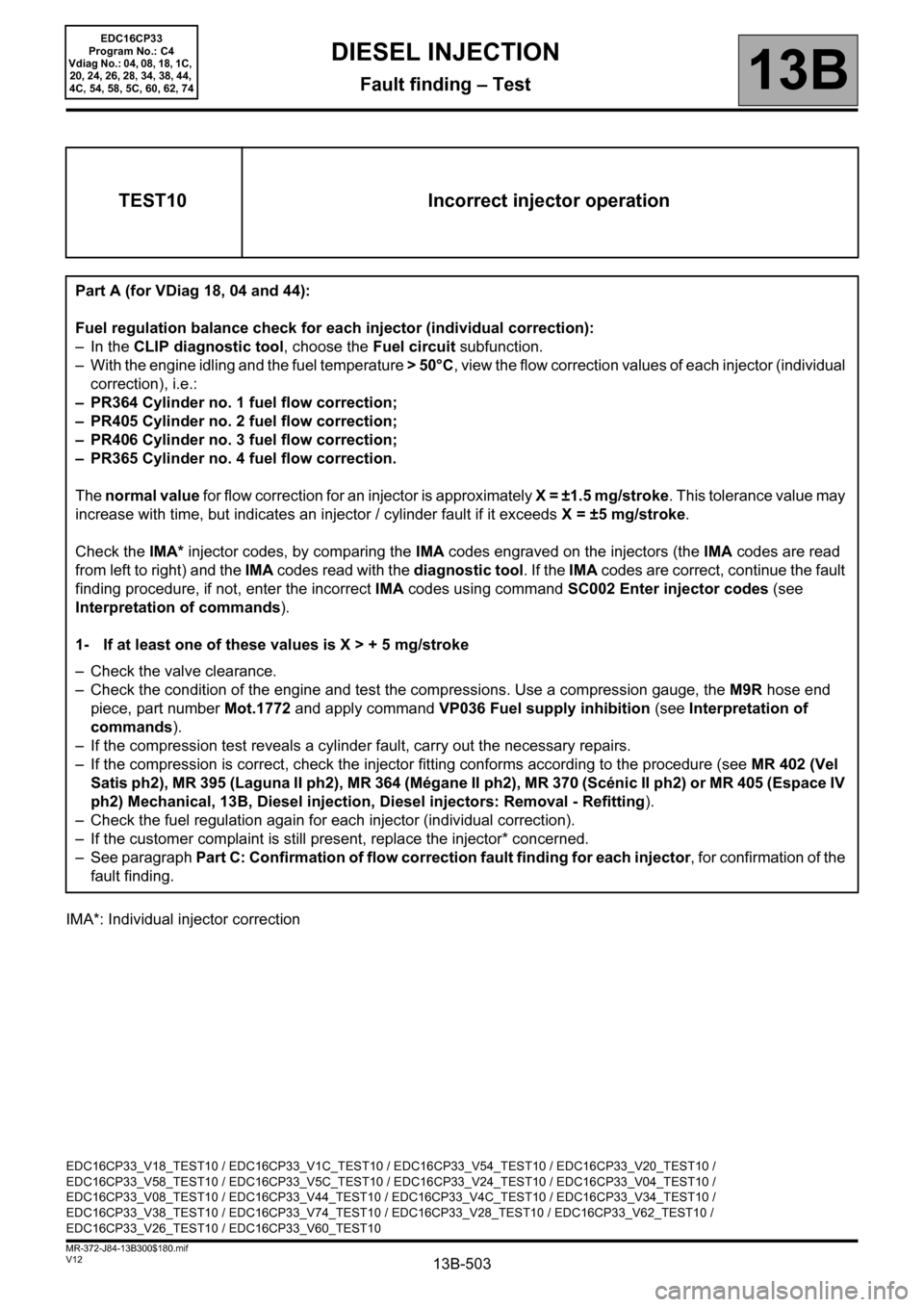

TEST10 Incorrect injector operation

Part A (for VDiag 18, 04 and 44):

Fuel regulation balance check for each injector (individual correction):

– In the CLIP diagnostic tool, choose the Fuel circuit subfunction.

– With the engine idling and the fuel temperature > 50°C, view the flow correction values of each injector (individual

correction), i.e.:

– PR364 Cylinder no. 1 fuel flow correction;

– PR405 Cylinder no. 2 fuel flow correction;

– PR406 Cylinder no. 3 fuel flow correction;

– PR365 Cylinder no. 4 fuel flow correction.

The normal value for flow correction for an injector is approximately X = ±1.5 mg/stroke. This tolerance value may

increase with time, but indicates an injector / cylinder fault if it exceeds X = ±5 mg/stroke.

Check the IMA* injector codes, by comparing the IMA codes engraved on the injectors (the IMA codes are read

from left to right) and the IMA codes read with the diagnostic tool. If the IMA codes are correct, continue the fault

finding procedure, if not, enter the incorrect IMA codes using command SC002 Enter injector codes (see

Interpretation of commands).

1- If at least one of these values is X > + 5 mg/stroke

– Check the valve clearance.

– Check the condition of the engine and test the compressions. Use a compression gauge, the M9R hose end

piece, part number Mot.1772 and apply command VP036 Fuel supply inhibition (see Interpretation of

commands).

– If the compression test reveals a cylinder fault, carry out the necessary repairs.

– If the compression is correct, check the injector fitting conforms according to the procedure (see MR 402 (Vel

Satis ph2), MR 395 (Laguna II ph2), MR 364 (Mégane II ph2), MR 370 (Scénic II ph2) or MR 405 (Espace IV

ph2) Mechanical, 13B, Diesel injection, Diesel injectors: Removal - Refitting).

– Check the fuel regulation again for each injector (individual correction).

– If the customer complaint is still present, replace the injector* concerned.

– See paragraph Part C: Confirmation of flow correction fault finding for each injector, for confirmation of the

fault finding.

EDC16CP33_V18_TEST10 / EDC16CP33_V1C_TEST10 / EDC16CP33_V54_TEST10 / EDC16CP33_V20_TEST10 /

EDC16CP33_V58_TEST10 / EDC16CP33_V5C_TEST10 / EDC16CP33_V24_TEST10 / EDC16CP33_V04_TEST10 /

EDC16CP33_V08_TEST10 / EDC16CP33_V44_TEST10 / EDC16CP33_V4C_TEST10 / EDC16CP33_V34_TEST10 /

EDC16CP33_V38_TEST10 / EDC16CP33_V74_TEST10 / EDC16CP33_V28_TEST10 / EDC16CP33_V62_TEST10 /

EDC16CP33_V26_TEST10 / EDC16CP33_V60_TEST10

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Page 505 of 510

13B-505V12 MR-372-J84-13B300$180.mif

DIESEL INJECTION

Fault finding – Test13B

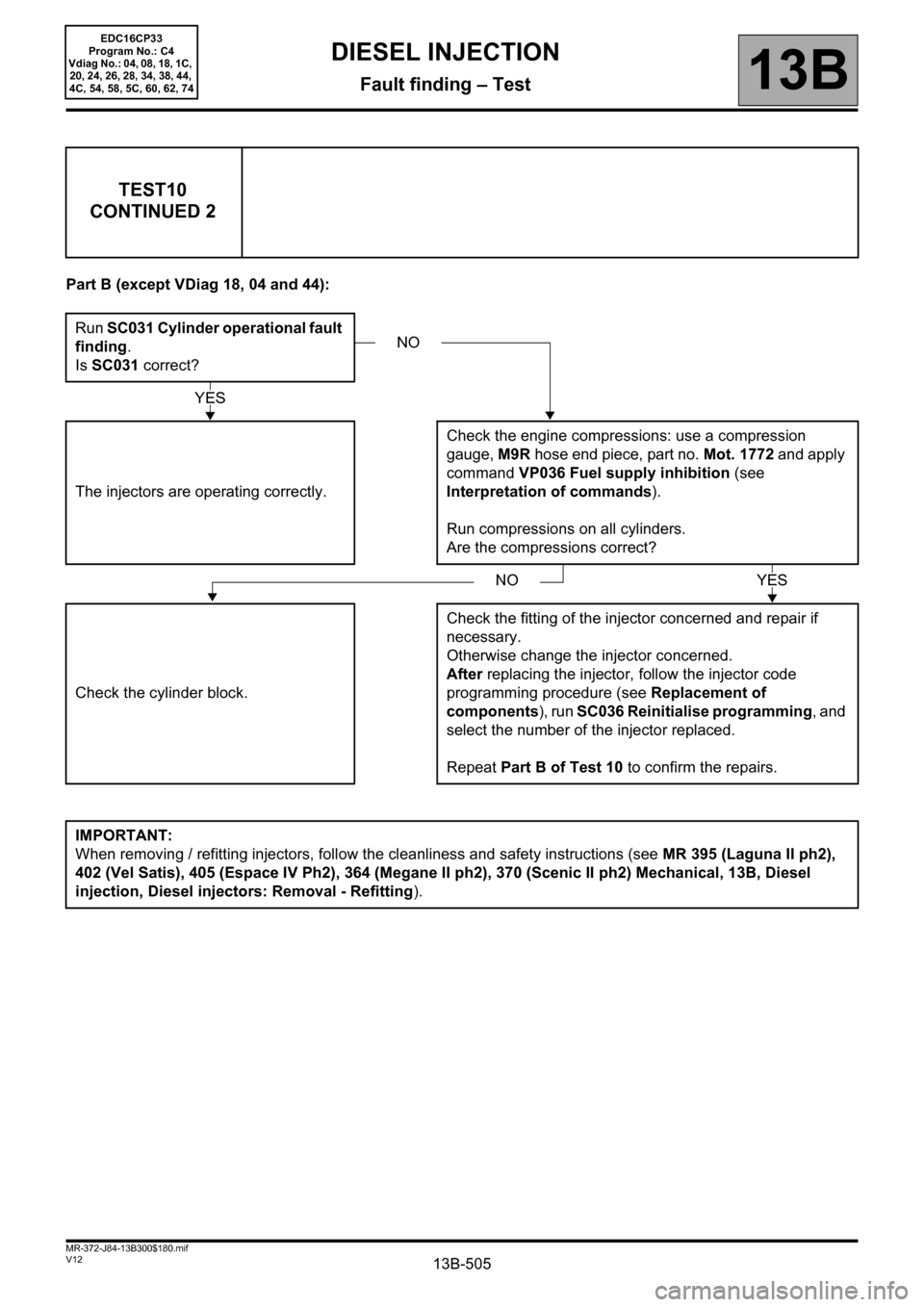

Part B (except VDiag 18, 04 and 44):

TEST10

CONTINUED 2

Run SC031 Cylinder operational fault

finding.

Is SC031 correct?

The injectors are operating correctly.Check the engine compressions: use a compression

gauge, M9R hose end piece, part no. Mot. 1772 and apply

command VP036 Fuel supply inhibition (see

Interpretation of commands).

Run compressions on all cylinders.

Are the compressions correct?

Check the cylinder block.Check the fitting of the injector concerned and repair if

necessary.

Otherwise change the injector concerned.

After replacing the injector, follow the injector code

programming procedure (see Replacement of

components), run SC036 Reinitialise programming, and

select the number of the injector replaced.

Repeat Part B of Test 10 to confirm the repairs.

IMPORTANT:

When removing / refitting injectors, follow the cleanliness and safety instructions (see MR 395 (Laguna II ph2),

402 (Vel Satis), 405 (Espace IV Ph2), 364 (Megane II ph2), 370 (Scenic II ph2) Mechanical, 13B, Diesel

injection, Diesel injectors: Removal - Refitting).NO

YES

YESNO

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Page 506 of 510

13B-506V12 MR-372-J84-13B300$180.mif

DIESEL INJECTION

Fault finding – Test13B

TEST10

CONTINUED 3

Part C:

Confirmation of flow correction fault finding for each injector (individual correction):

Clear the faults and run a test with the engine at idle speed and the fuel temperature > 50°C, check that no faults

appear on the diagnostic tool and that the correction values do not reach X = ± 5 mg/stroke to confirm the repair.

– If one or more cylinders have flow correction values for an injector which exceed X = ± 5 mg/stroke, follow the

fault finding procedure described in Part A: Fuel regulation balance check for each injector (individual) of

Test 10.

– Otherwise, follow the fault finding procedure described in Part D of Test 10.

Part D:

Injector nozzle sealing check:

Check the level and condition of the engine oil:

– If there is contamination from the diesel fuel, the leaking injector nozzle will be "greasy".

– Disconnect the preheating relay.

– Ensure that this is not caused by rising engine oil by checking the engine compression values.

– Check the condition of the heater plug: this must not be wet. If it is, change the defective injector.

– If the engine compression values are correct: locate the faulty injector by looking at the condition of the cylinders

and the pistons through the heater plug wells (greasy cylinder, overheating, signs of damage, etc.).

– If the cylinder - piston examination is not conclusive, remove the injectors and change the one with the greasy

nozzle.

– If the fault finding checks do not enable the engine to be repaired, contact the Techline.

After replacing the injector, follow the injector code programming procedure (see Replacement of components),

run SC036 Reinitialise programming, and select the number of the injector replaced.

Note:

Before replacing an injector, check for the sealing washer and its conformity (see Fault finding chart ALP4 Poor

performance).

IMPORTANT:

When removing / refitting injectors, follow the cleanliness and safety instructions (see MR 395 (Laguna II ph2),

402 (Vel Satis), 405 (Espace IV Ph2), 364 (Megane II ph2), 370 (Scenic II ph2) Mechanical, 13B, Diesel

injection, Diesel injectors: Removal - Refitting).

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74