brake RENAULT TRAFIC 2018 Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2018, Model line: TRAFIC, Model: RENAULT TRAFIC 2018Pages: 298, PDF Size: 8.05 MB

Page 207 of 298

3.43

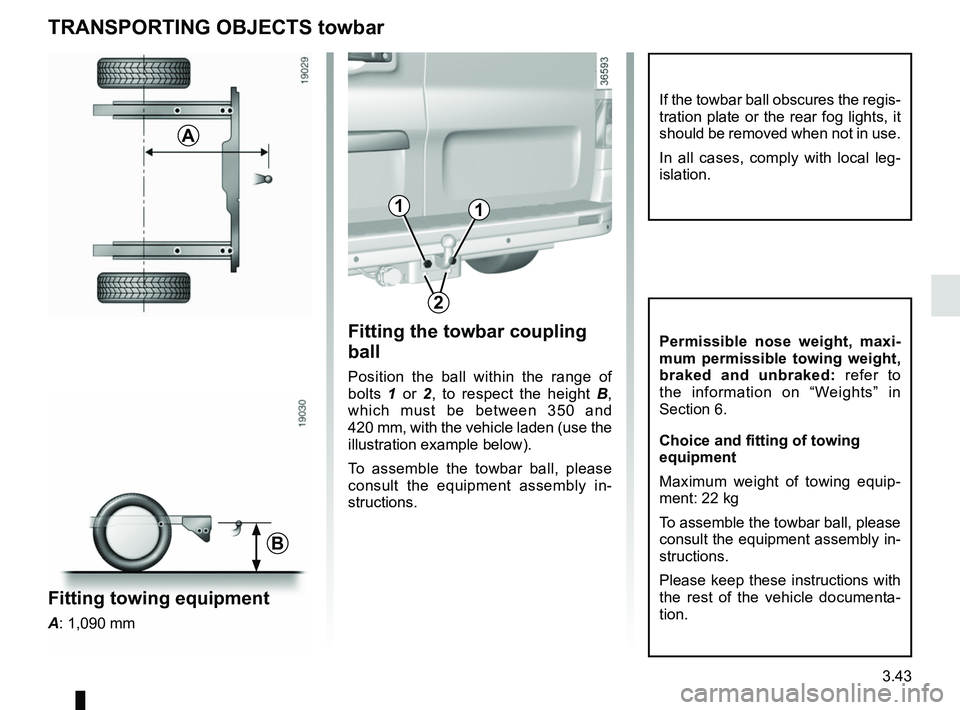

TRANSPORTING OBJECTS towbar

Fitting the towbar coupling

ball

Position the ball within the range of

bolts 1 or 2 , to respect the height B,

which must be between 350 and

420 mm, with the vehicle laden (use the

illustration example below).

To assemble the towbar ball, please

consult the equipment assembly in-

structions.

A

If the towbar ball obscures the regis-

tration plate or the rear fog lights, it

should be removed when not in use.

In all cases, comply with local leg-

islation.

Permissible nose weight, maxi-

mum permissible towing weight,

braked and unbraked: refer to

the information on “Weights” in

Section 6.

Choice and fitting of towing

equipment

Maximum weight of towing equip-

ment: 22 kg

To assemble the towbar ball, please

consult the equipment assembly in-

structions.

Please keep these instructions with

the rest of the vehicle documenta-

tion.

2

B

11

Fitting towing equipment

A: 1,090 mm

Page 209 of 298

4.1

Section 4: Maintenance

Bonnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.2

Engine oil level: general information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . 4.4

Engine oil level: topping up/filling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . 4.5

Oil change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.6

Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.7engine coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . . . . . . . . . 4.7

brake fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.8

windscreen washer reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . 4.9

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.9

Tyre pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.10

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.12

Bodywork maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . 4.14

Interior trim maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . 4.17

Page 216 of 298

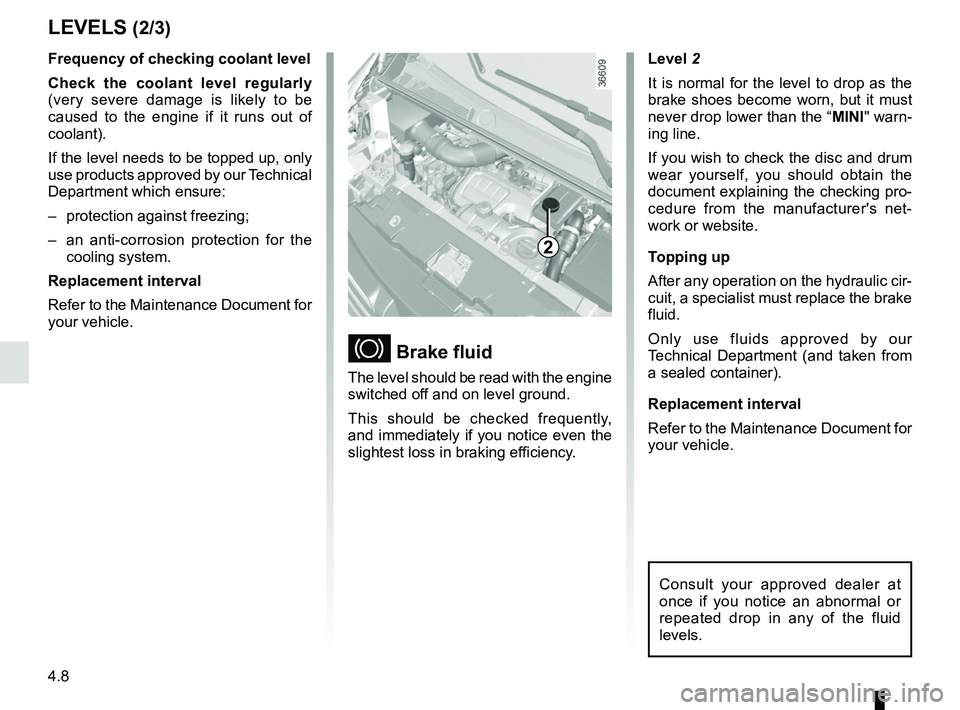

4.8

Level 2

It is normal for the level to drop as the

brake shoes become worn, but it must

never drop lower than the “MINI" warn-

ing line.

If you wish to check the disc and drum

wear yourself, you should obtain the

document explaining the checking pro-

cedure from the manufacturer's net-

work or website.

Topping up

After any operation on the hydraulic cir-

cuit, a specialist must replace the brake

fluid.

Only use fluids approved by our

Technical Department (and taken from

a sealed container).

Replacement interval

Refer to the Maintenance Document for

your vehicle.

Brake fluid

The level should be read with the engine

switched off and on level ground.

This should be checked frequently,

and immediately if you notice even the

slightest loss in braking efficiency.

LEVELS (2/3)

2

Consult your approved dealer at

once if you notice an abnormal or

repeated drop in any of the fluid

levels.

Frequency of checking coolant level

Check the coolant level regularly

(very severe damage is likely to be

caused to the engine if it runs out of

coolant).

If the level needs to be topped up, only

use products approved by our Technical

Department which ensure:

– protection against freezing;

– an anti-corrosion protection for the cooling system.

Replacement interval

Refer to the Maintenance Document for

your vehicle.

Page 231 of 298

5.5

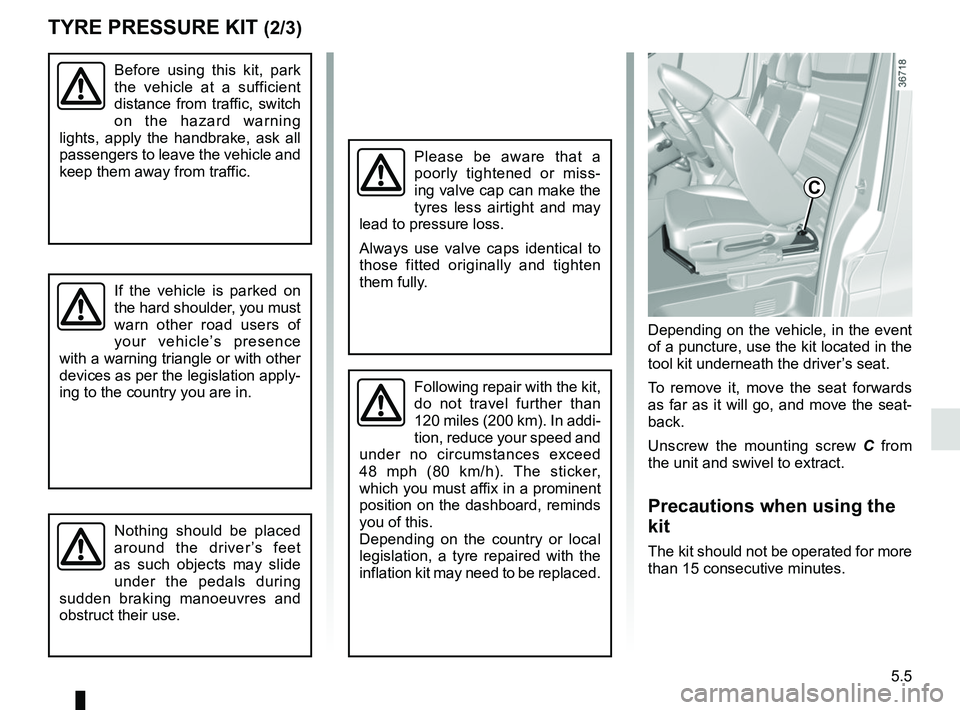

TYRE PRESSURE KIT (2/3)

Before using this kit, park

the vehicle at a sufficient

distance from traffic, switch

on the hazard warning

lights, apply the handbrake, ask all

passengers to leave the vehicle and

keep them away from traffic.

Nothing should be placed

around the driver’s feet

as such objects may slide

under the pedals during

sudden braking manoeuvres and

obstruct their use.

Please be aware that a

poorly tightened or miss-

ing valve cap can make the

tyres less airtight and may

lead to pressure loss.

Always use valve caps identical to

those fitted originally and tighten

them fully.

If the vehicle is parked on

the hard shoulder, you must

warn other road users of

your vehicle’s presence

with a warning triangle or with other

devices as per the legislation apply-

ing to the country you are in.

Following repair with the kit,

do not travel further than

120 miles (200 km). In addi-

tion, reduce your speed and

under no circumstances exceed

48 mph (80 km/h). The sticker,

which you must affix in a prominent

position on the dashboard, reminds

you of this.

Depending on the country or local

legislation, a tyre repaired with the

inflation kit may need to be replaced.

Depending on the vehicle, in the event

of a puncture, use the kit located in the

tool kit underneath the driver’s seat.

To remove it, move the seat forwards

as far as it will go, and move the seat-

back.

Unscrew the mounting screw C from

the unit and swivel to extract.

Precautions when using the

kit

The kit should not be operated for more

than 15 consecutive minutes.

C

Page 232 of 298

5.6

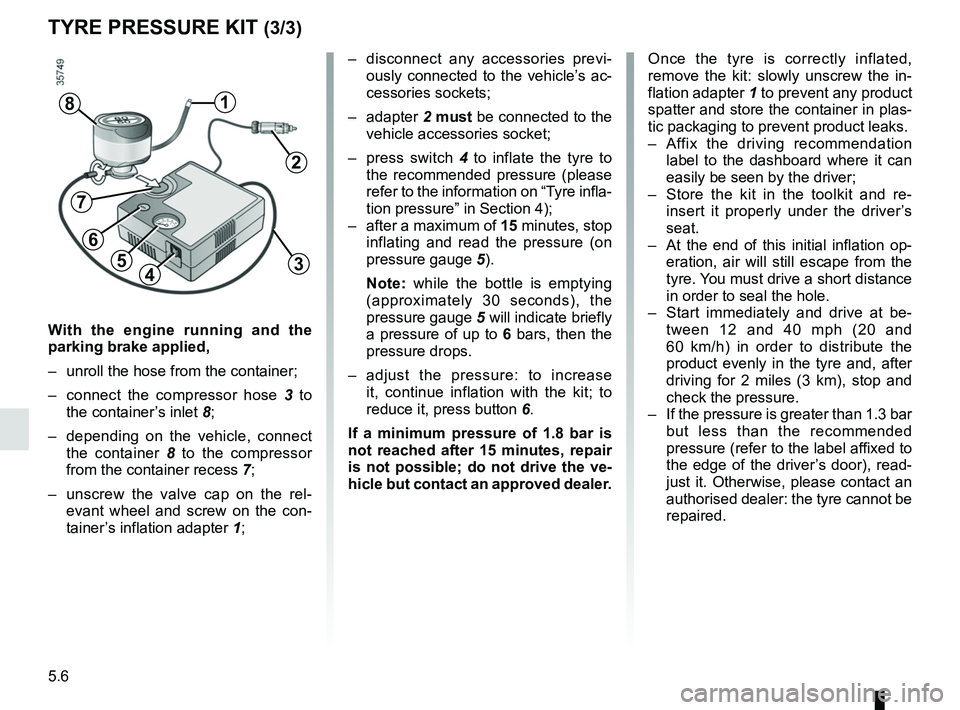

With the engine running and the

parking brake applied,

– unroll the hose from the container;

– connect the compressor hose 3 to

the container’s inlet 8;

– depending on the vehicle, connect the container 8 to the compressor

from the container recess 7;

– unscrew the valve cap on the rel- evant wheel and screw on the con-

tainer’s inflation adapter 1;

45

1

TYRE PRESSURE KIT (3/3)

Once the tyre is correctly inflated,

remove the kit: slowly unscrew the in-

flation adapter 1 to prevent any product

spatter and store the container in plas-

tic packaging to prevent product leaks.

– Affix the driving recommendation label to the dashboard where it can

easily be seen by the driver;

– Store the kit in the toolkit and re- insert it properly under the driver’s

seat.

– At the end of this initial inflation op- eration, air will still escape from the

tyre. You must drive a short distance

in order to seal the hole.

– Start immediately and drive at be- tween 12 and 40 mph (20 and

60 km/h) in order to distribute the

product evenly in the tyre and, after

driving for 2 miles (3 km), stop and

check the pressure.

– If the pressure is greater than 1.3 bar but less than the recommended

pressure (refer to the label affixed to

the edge of the driver’s door), read-

just it. Otherwise, please contact an

authorised dealer: the tyre cannot be

repaired.

8

– disconnect any accessories previ-ously connected to the vehicle’s ac-

cessories sockets;

– adapter 2 must be connected to the

vehicle accessories socket;

– press switch 4 to inflate the tyre to

the recommended pressure (please

refer to the information on “Tyre infla-

tion pressure” in Section 4);

– after a maximum of 15 minutes, stop inflating and read the pressure (on

pressure gauge 5).

Note: while the bottle is emptying

(approximately 30 seconds), the

pressure gauge 5 will indicate briefly

a pressure of up to 6 bars, then the

pressure drops.

– adjust the pressure: to increase it, continue inflation with the kit; to

reduce it, press button 6.

If a minimum pressure of 1.8 bar is

not reached after 15 minutes, repair

is not possible; do not drive the ve-

hicle but contact an approved dealer.

2

3

7

6

Page 235 of 298

5.9

CHANGING A WHEEL (1/2)

Switch on the hazard warn-

ing lights.

Keep the vehicle away from

traffic and on a level surface

where it will not slip.

Apply the hand brake and engage a

gear (first or reverse, or P for auto-

matic transmissions).

Ask all the passengers to leave the

vehicle and keep them away from

traffic.

If the vehicle is parked on

the hard shoulder, you must

warn other road users of

your vehicle’s presence

with a warning triangle or with other

devices as per the legislation apply-

ing to the country you are in.

If you have a puncture, re-

place the wheel as soon as

possible.

A tyre which has been punc-

tured should always be inspected

(and repaired, where possible) by a

specialist.

Do not leave the tools un-

secured inside the vehicle

as they may come loose

under braking. After use,

check that all the tools are correctly

clipped into the tool kit, then position

it correctly in its housing: there is a

risk of injury.

The jack is designed for wheel

changing purposes only. Under no

circumstances should it be used for

carrying out repairs underneath the

vehicle or to gain access to the un-

derside of the vehicle.

Page 243 of 298

5.17

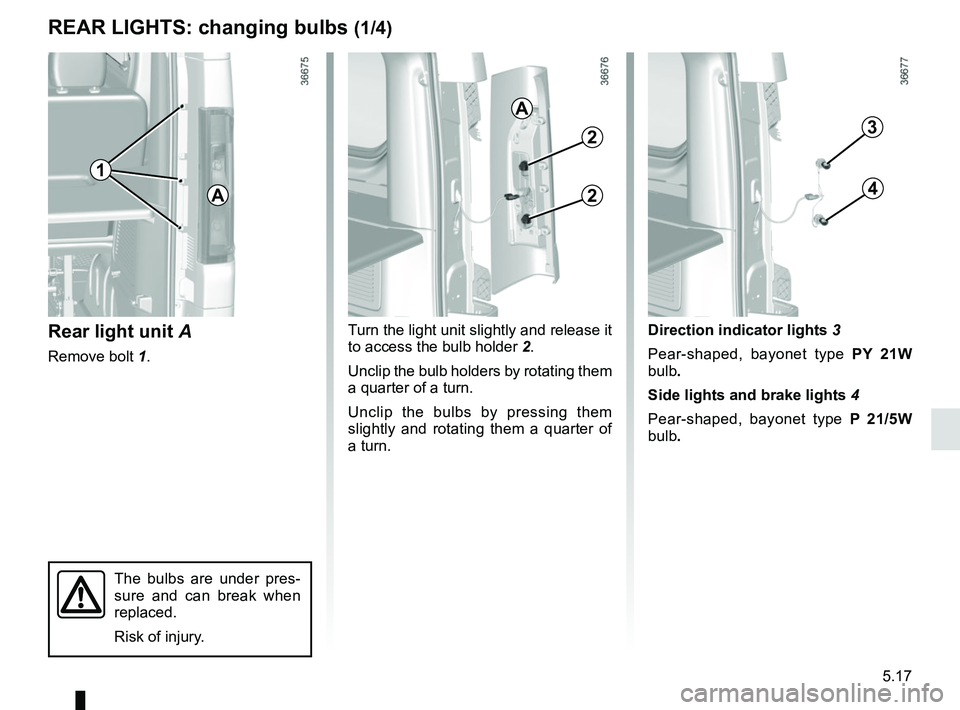

REAR LIGHTS: changing bulbs (1/4)

Rear light unit A

Remove bolt 1.

Turn the light unit slightly and release it

to access the bulb holder 2.

Unclip the bulb holders by rotating them

a quarter of a turn.

Unclip the bulbs by pressing them

slightly and rotating them a quarter of

a turn.

The bulbs are under pres-

sure and can break when

replaced.

Risk of injury.

A

A

2

2

1

3

4

Direction indicator lights 3

Pear-shaped, bayonet type PY 21W

bulb .

Side lights and brake lights 4

Pear-shaped, bayonet type P 21/5W

bulb .

Page 245 of 298

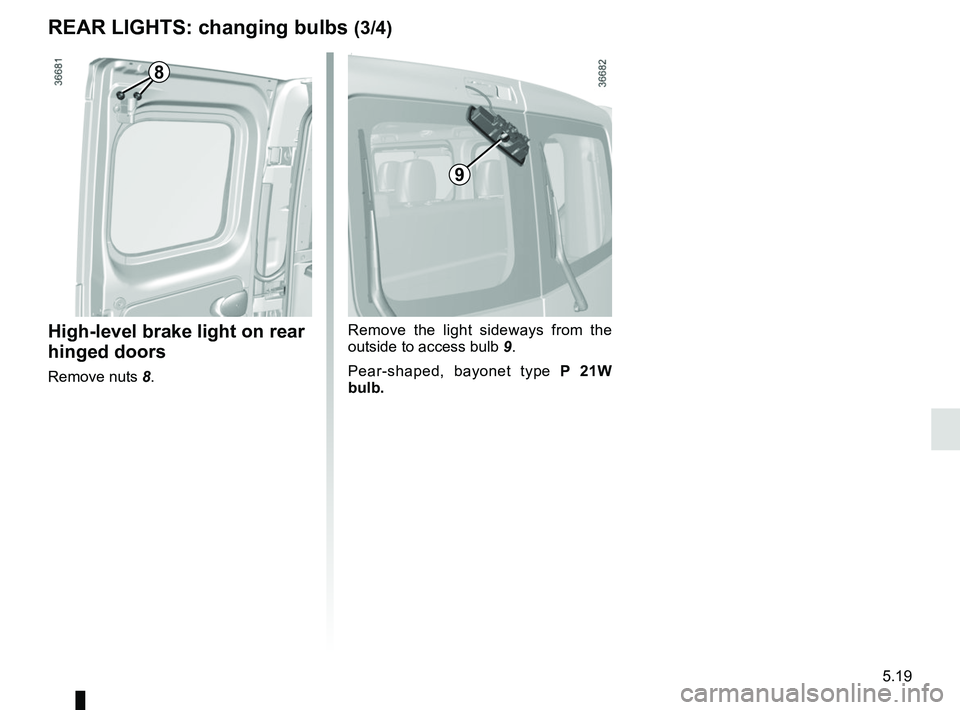

5.19

REAR LIGHTS: changing bulbs (3/4)

High-level brake light on rear

hinged doors

Remove nuts 8.Remove the light sideways from the

outside to access bulb

9.

Pear-shaped, bayonet type P 21W

bulb.

9

8

Page 246 of 298

5.20

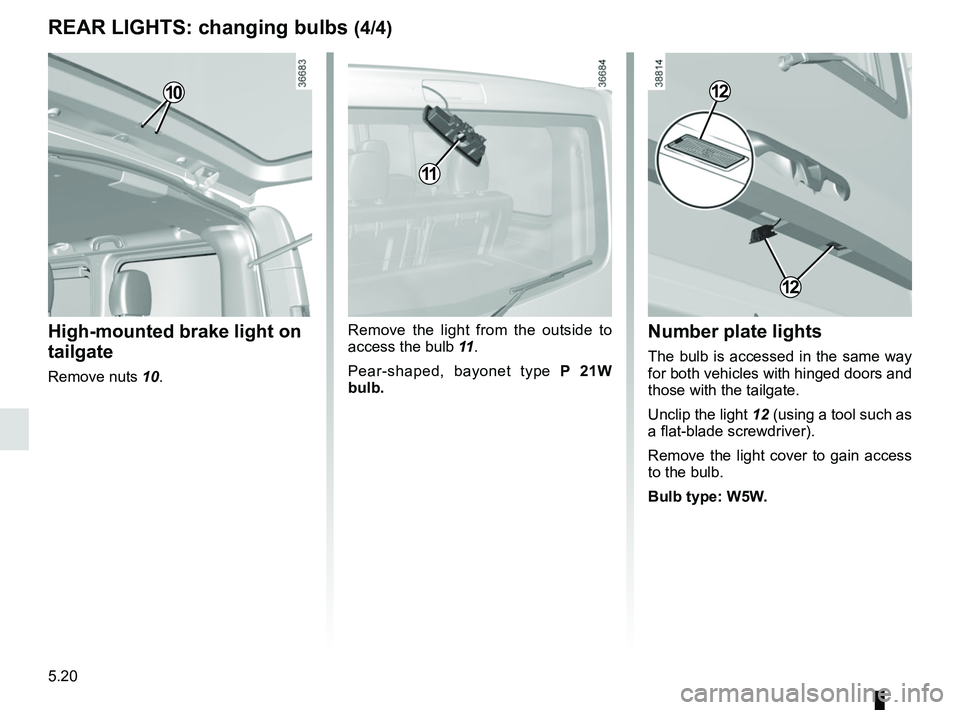

REAR LIGHTS: changing bulbs (4/4)

High-mounted brake light on

tailgate

Remove nuts 10.

Remove the light from the outside to

access the bulb 11.

Pear-shaped, bayonet type P 21W

bulb.Number plate lights

The bulb is accessed in the same way

for both vehicles with hinged doors and

those with the tailgate.

Unclip the light 12 (using a tool such as

a flat-blade screwdriver).

Remove the light cover to gain access

to the bulb.

Bulb type: W5W.

11

10

12

12

Page 255 of 298

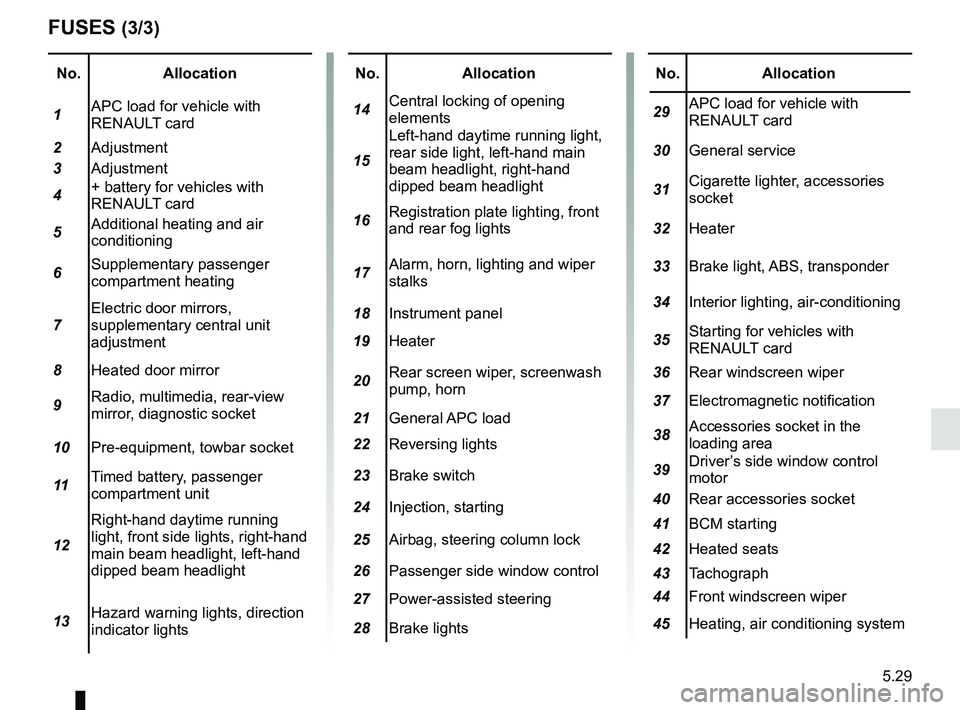

5.29

No.Allocation

1 APC load for vehicle with

RENAULT card

2 Adjustment

3 Adjustment

4 + battery for vehicles with

RENAULT card

5 Additional heating and air

conditioning

6 Supplementary passenger

compartment heating

7 Electric door mirrors,

supplementary central unit

adjustment

8 Heated door mirror

9 Radio, multimedia, rear-view

mirror, diagnostic socket

10 Pre-equipment, towbar socket

11 Timed battery, passenger

compartment unit

12 Right-hand daytime running

light, front side lights, right-hand

main beam headlight, left-hand

dipped beam headlight

13 Hazard warning lights, direction

indicator lights

FUSES (3/3)

No.

Allocation

14 Central locking of opening

elements

15 Left-hand daytime running light,

rear side light, left-hand main

beam headlight, right-hand

dipped beam headlight

16 Registration plate lighting, front

and rear fog lights

17 Alarm, horn, lighting and wiper

stalks

18 Instrument panel

19 Heater

20 Rear screen wiper, screenwash

pump, horn

21 General APC load

22 Reversing lights

23 Brake switch

24 Injection, starting

25 Airbag, steering column lock

26 Passenger side window control

27 Power-assisted steering

28 Brake lightsNo. Allocation

29 APC load for vehicle with

RENAULT card

30 General service

31 Cigarette lighter, accessories

socket

32 Heater

33 Brake light, ABS, transponder

34 Interior lighting, air-conditioning

35 Starting for vehicles with

RENAULT card

36 Rear windscreen wiper

37 Electromagnetic notification

38 Accessories socket in the

loading area

39 Driver’s side window control

motor

40 Rear accessories socket

41 BCM starting

42 Heated seats

43 Tachograph

44 Front windscreen wiper

45 Heating, air conditioning system