check engine RENAULT TRAFIC 2018 Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2018, Model line: TRAFIC, Model: RENAULT TRAFIC 2018Pages: 298, PDF Size: 8.05 MB

Page 176 of 298

3.12

Operating faults

As a general rule, contact your ap-

proved dealer in the event of an oper-

ating fault.

– Reduction in de-icing, demisting or air conditioning performance.

This may be caused by the passen-

ger compartment filter cartridge be-

coming clogged.

– No cold air is being produced .

Check that the controls are set cor-

rectly and that the fuses are sound.

Otherwise, switch off the system.

Presence of water under the

vehicle

After prolonged use of the air condi-

tioning system, it is normal for water

to be present under the vehicle. This is

caused by condensation.

AIR CONDITIONING: information and operating instructions (1/2)

Do not add anything to the

vehicle’s ventilation circuit

(for example, to remove

bad odours).

There is a risk of damage or of

fire.

Do not open the refriger-

ant fluid circuit. The fluid

may damage eyes or skin.

Fuel consumption

You will normally notice an increase in

fuel consumption (especially in town)

when the air conditioning is operating.

For vehicles fitted with air conditioning

with no automatic mode, switch off the

system when it is not required.

Advice for reducing consumption

and helping to preserve the

environment

Drive with the air vents open and the

windows closed. If the vehicle has been

parked in the sun, open the doors for a

few moments to let the hot air escape

before starting the engine.

MaintenanceRefer to the Maintenance Document

for your vehicle for the inspection fre-

quency.

Advice on use

In some situations (air conditioning off,

air recirculation activated, ventilation

speed at zero or low etc.), you may

notice that condensation starts to form

on the windows and windscreen.

If there is condensation, use the “Clear

View” function to remove it, then use

the air conditioning in automatic mode

to stop it forming again.

Use the air conditioning system reg-

ularly, even in cold weather, running

it at least once a month for approxi-

mately 5 minutes.

Vehicles equipped with

modeECO

Once activated, ECO mode may

reduce air conditioning perform-

ance. Please refer to the informa-

tion on “Driving advice, Eco-driving”

in Section 2.

Page 206 of 298

3.42

While driving with the right

rear hinged door open,

always secure transported

loads. The left-hand door,

which remains shut, should not be

used to hold transported loads in

place. Using the right rear hinged

door open while driving should only

be done in exceptional cases.

In any event, please refer to local

legislation. Risk of loads falling on

the road surface.

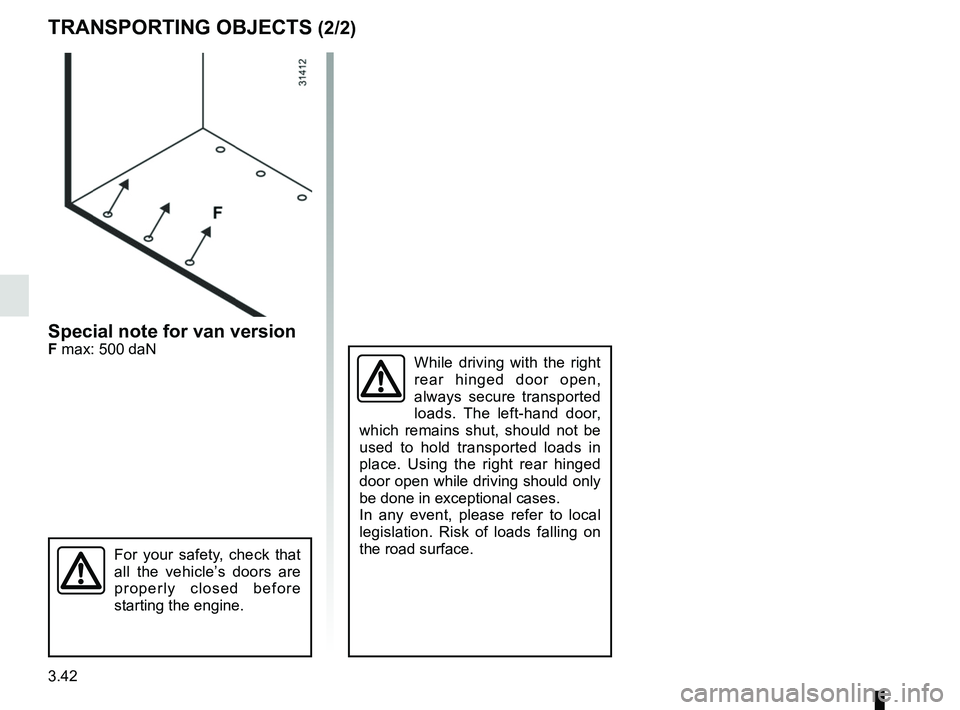

Special note for van versionF max: 500 daN

TRANSPORTING OBJECTS (2/2)

For your safety, check that

all the vehicle’s doors are

properly closed before

starting the engine.

Page 210 of 298

4.2

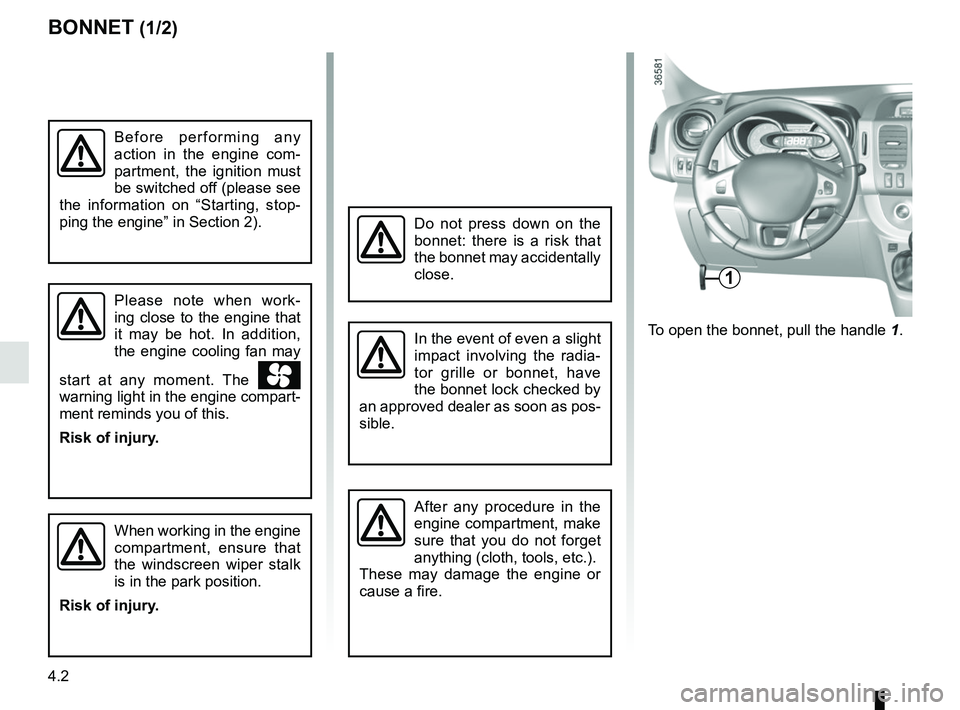

To open the bonnet, pull the handle 1.

BONNET (1/2)

1

Please note when work-

ing close to the engine that

it may be hot. In addition,

the engine cooling fan may

start at any moment. The

warning light in the engine compart-

ment reminds you of this.

Risk of injury.

Do not press down on the

bonnet: there is a risk that

the bonnet may accidentally

close.

When working in the engine

compartment, ensure that

the windscreen wiper stalk

is in the park position.

Risk of injury.

In the event of even a slight

impact involving the radia-

tor grille or bonnet, have

the bonnet lock checked by

an approved dealer as soon as pos-

sible.

After any procedure in the

engine compartment, make

sure that you do not forget

anything (cloth, tools, etc.).

These may damage the engine or

cause a fire.

Before performing any

action in the engine com-

partment, the ignition must

be switched off (please see

the information on “Starting, stop-

ping the engine” in Section 2).

Page 211 of 298

4.3

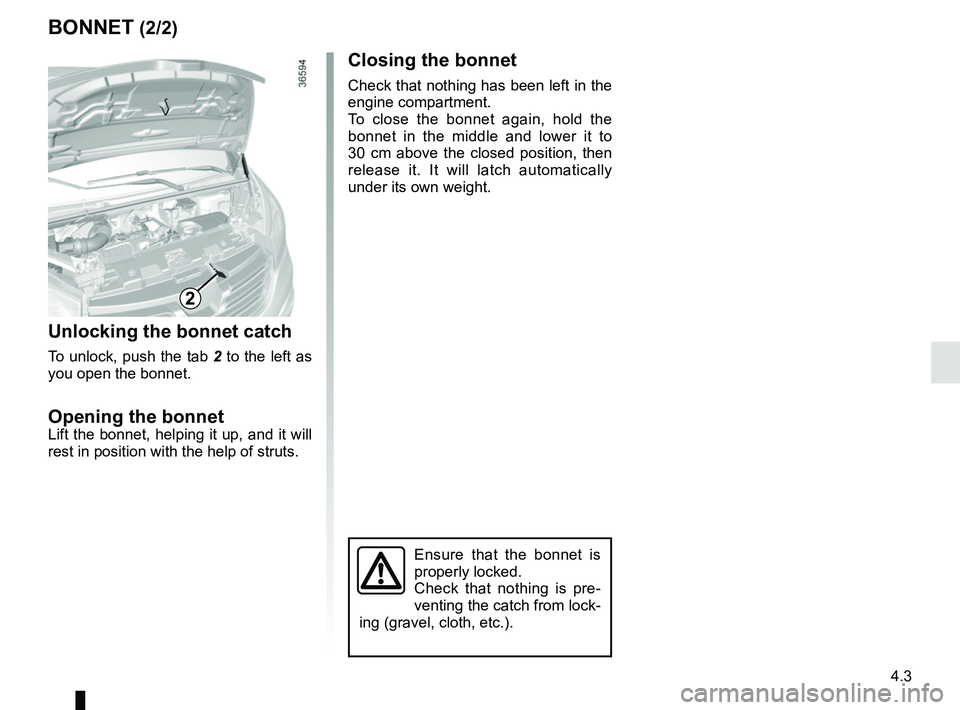

Closing the bonnet

Check that nothing has been left in the

engine compartment.

To close the bonnet again, hold the

bonnet in the middle and lower it to

30 cm above the closed position, then

release it. It will latch automatically

under its own weight.

BONNET (2/2)

2

Unlocking the bonnet catch

To unlock, push the tab 2 to the left as

you open the bonnet.

Opening the bonnetLift the bonnet, helping it up, and it will

rest in position with the help of struts.

Ensure that the bonnet is

properly locked.

Check that nothing is pre-

venting the catch from lock-

ing (gravel, cloth, etc.).

Page 212 of 298

4.4

It is normal for an engine to use oil for

lubrication and cooling of moving parts

and it is normal to top up the level be-

tween oil changes.

However, contact your approved

Dealer if more than 0.5 litres is being

consumed every 600 miles (1,000 km)

after the running in period.

Oil change frequency: check the oil

level from time to time and certainly

before any long journey to avoid the

risk of damaging your engine.

ENGINE OIL LEVEL: general information

Exceeding the maximum

engine oil level

Under no circumstances

should maximum filling

level B be exceeded: this could

damage the engine and the cata-

lytic converter.

If the level exceeds the maximum

level, do not start your vehicle and

contact an authorised dealer.

In order to prevent splashback, it is

recommended that a funnel be used

when topping up/filling with oil.

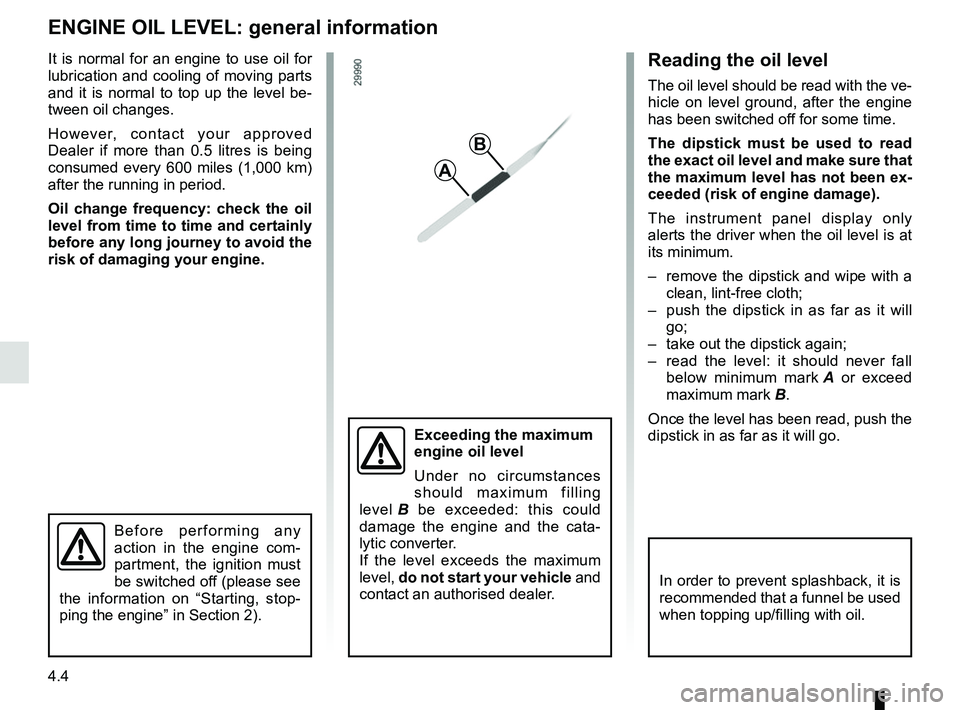

Reading the oil level

The oil level should be read with the ve-

hicle on level ground, after the engine

has been switched off for some time.

The dipstick must be used to read

the exact oil level and make sure that

the maximum level has not been ex-

ceeded (risk of engine damage).

The instrument panel display only

alerts the driver when the oil level is at

its minimum.

– remove the dipstick and wipe with a clean, lint-free cloth;

– push the dipstick in as far as it will go;

– take out the dipstick again;

– read the level: it should never fall below minimum mark A or exceed

maximum mark B.

Once the level has been read, push the

dipstick in as far as it will go.

A

B

Before performing any

action in the engine com-

partment, the ignition must

be switched off (please see

the information on “Starting, stop-

ping the engine” in Section 2).

Page 214 of 298

4.6

ENGINE OIL LEVEL: topping up, filling (2/2) OIL CHANGE

Oil change

Service interval: refer to the

Maintenance Service Booklet for your

vehicle.

Oil change capacity

Please refer to the maintenance docu-

ment for your vehicle, or contact an au-

thorised dealer.

Always check the engine oil level using

the dipstick, as explained previously (it

should never fall below the minimum

level, or be over the maximum level on

the dipstick).

Engine oil grade

Refer to the Maintenance Service

Booklet for your vehicle.

Consult your approved dealer at

once if you notice an abnormal or

repeated drop in any of the fluid

levels.

1

2

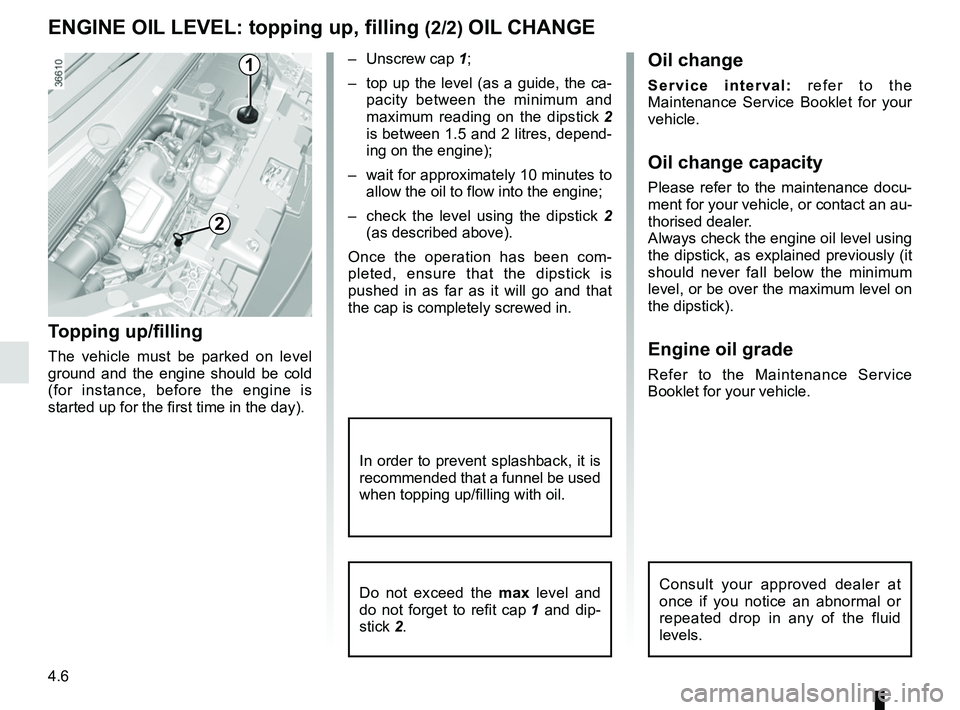

Topping up/filling

The vehicle must be parked on level

ground and the engine should be cold

(for instance, before the engine is

started up for the first time in the day).– Unscrew cap

1;

– top up the level (as a guide, the ca- pacity between the minimum and

maximum reading on the dipstick 2

is between 1.5 and 2 litres, depend-

ing on the engine);

– wait for approximately 10 minutes to allow the oil to flow into the engine;

– check the level using the dipstick 2

(as described above).

Once the operation has been com-

pleted, ensure that the dipstick is

pushed in as far as it will go and that

the cap is completely screwed in.

In order to prevent splashback, it is

recommended that a funnel be used

when topping up/filling with oil.

Do not exceed the max level and

do not forget to refit cap 1 and dip-

stick 2.

Page 216 of 298

4.8

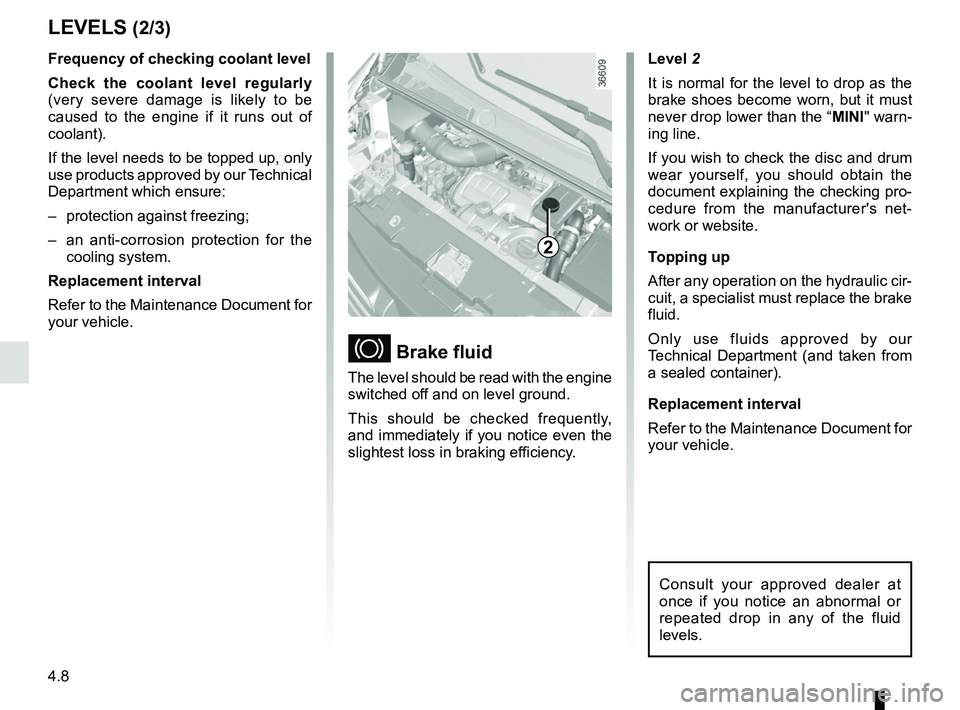

Level 2

It is normal for the level to drop as the

brake shoes become worn, but it must

never drop lower than the “MINI" warn-

ing line.

If you wish to check the disc and drum

wear yourself, you should obtain the

document explaining the checking pro-

cedure from the manufacturer's net-

work or website.

Topping up

After any operation on the hydraulic cir-

cuit, a specialist must replace the brake

fluid.

Only use fluids approved by our

Technical Department (and taken from

a sealed container).

Replacement interval

Refer to the Maintenance Document for

your vehicle.

Brake fluid

The level should be read with the engine

switched off and on level ground.

This should be checked frequently,

and immediately if you notice even the

slightest loss in braking efficiency.

LEVELS (2/3)

2

Consult your approved dealer at

once if you notice an abnormal or

repeated drop in any of the fluid

levels.

Frequency of checking coolant level

Check the coolant level regularly

(very severe damage is likely to be

caused to the engine if it runs out of

coolant).

If the level needs to be topped up, only

use products approved by our Technical

Department which ensure:

– protection against freezing;

– an anti-corrosion protection for the cooling system.

Replacement interval

Refer to the Maintenance Document for

your vehicle.

Page 232 of 298

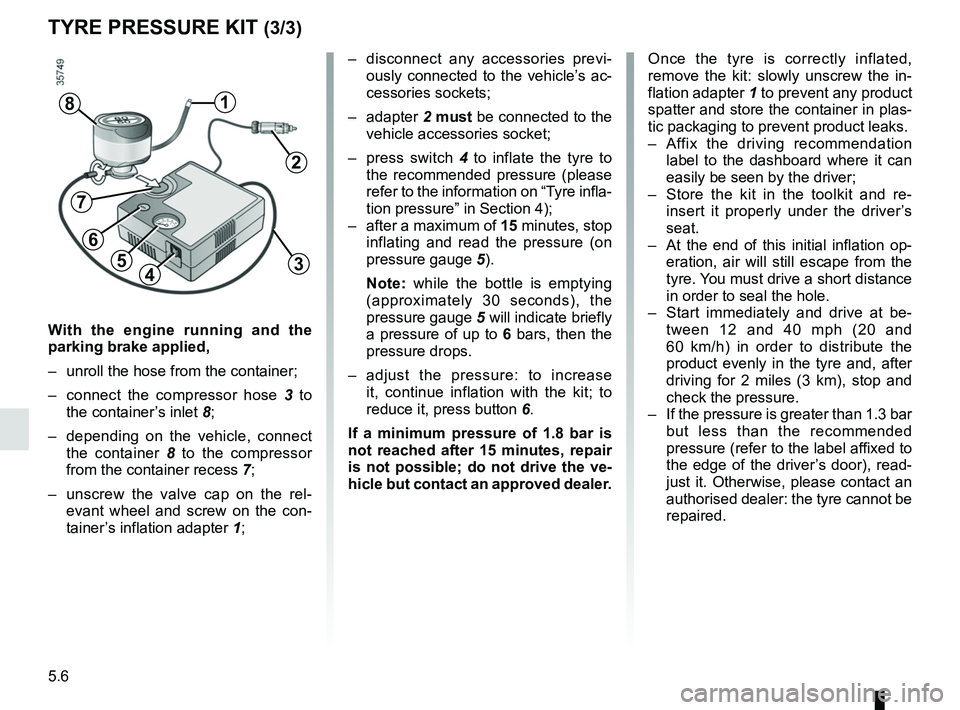

5.6

With the engine running and the

parking brake applied,

– unroll the hose from the container;

– connect the compressor hose 3 to

the container’s inlet 8;

– depending on the vehicle, connect the container 8 to the compressor

from the container recess 7;

– unscrew the valve cap on the rel- evant wheel and screw on the con-

tainer’s inflation adapter 1;

45

1

TYRE PRESSURE KIT (3/3)

Once the tyre is correctly inflated,

remove the kit: slowly unscrew the in-

flation adapter 1 to prevent any product

spatter and store the container in plas-

tic packaging to prevent product leaks.

– Affix the driving recommendation label to the dashboard where it can

easily be seen by the driver;

– Store the kit in the toolkit and re- insert it properly under the driver’s

seat.

– At the end of this initial inflation op- eration, air will still escape from the

tyre. You must drive a short distance

in order to seal the hole.

– Start immediately and drive at be- tween 12 and 40 mph (20 and

60 km/h) in order to distribute the

product evenly in the tyre and, after

driving for 2 miles (3 km), stop and

check the pressure.

– If the pressure is greater than 1.3 bar but less than the recommended

pressure (refer to the label affixed to

the edge of the driver’s door), read-

just it. Otherwise, please contact an

authorised dealer: the tyre cannot be

repaired.

8

– disconnect any accessories previ-ously connected to the vehicle’s ac-

cessories sockets;

– adapter 2 must be connected to the

vehicle accessories socket;

– press switch 4 to inflate the tyre to

the recommended pressure (please

refer to the information on “Tyre infla-

tion pressure” in Section 4);

– after a maximum of 15 minutes, stop inflating and read the pressure (on

pressure gauge 5).

Note: while the bottle is emptying

(approximately 30 seconds), the

pressure gauge 5 will indicate briefly

a pressure of up to 6 bars, then the

pressure drops.

– adjust the pressure: to increase it, continue inflation with the kit; to

reduce it, press button 6.

If a minimum pressure of 1.8 bar is

not reached after 15 minutes, repair

is not possible; do not drive the ve-

hicle but contact an approved dealer.

2

3

7

6

Page 252 of 298

5.26

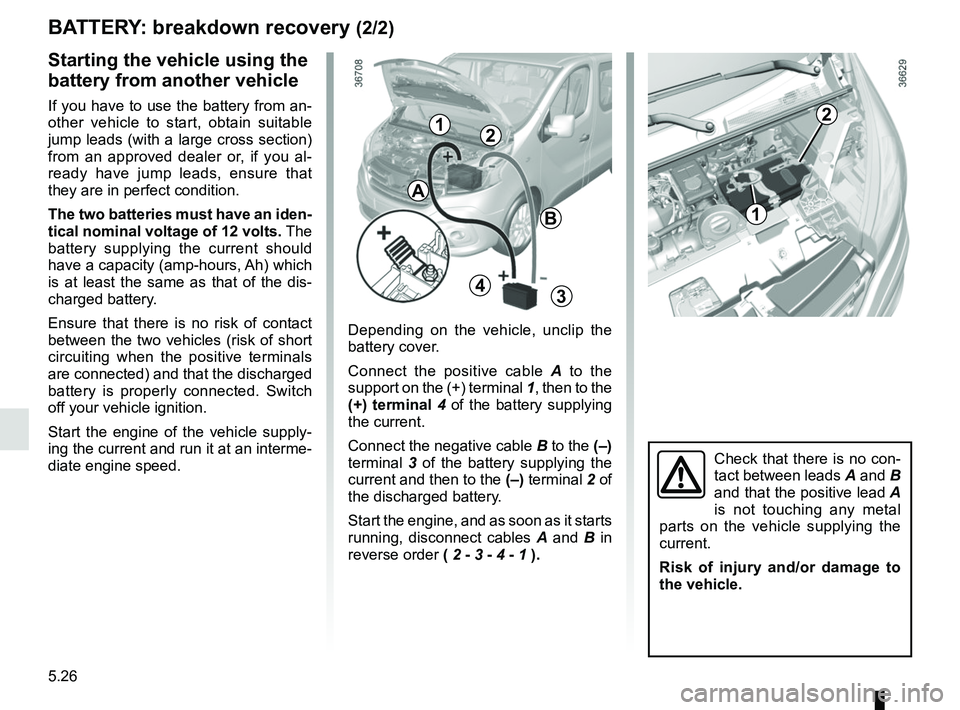

BATTERY: breakdown recovery (2/2)

Depending on the vehicle, unclip the

battery cover.

Connect the positive cable A to the

support on the (+) terminal 1, then to the

(+) terminal 4 of the battery supplying

the current.

Connect the negative cable B to the (–)

terminal 3 of the battery supplying the

current and then to the (–) terminal 2 of

the discharged battery.

Start the engine, and as soon as it starts

running, disconnect cables A and B in

reverse order ( 2 - 3 - 4 - 1 ).

Starting the vehicle using the

battery from another vehicle

If you have to use the battery from an-

other vehicle to start, obtain suitable

jump leads (with a large cross section)

from an approved dealer or, if you al-

ready have jump leads, ensure that

they are in perfect condition.

The two batteries must have an iden-

tical nominal voltage of 12 volts. The

battery supplying the current should

have a capacity (amp-hours, Ah) which

is at least the same as that of the dis-

charged battery.

Ensure that there is no risk of contact

between the two vehicles (risk of short

circuiting when the positive terminals

are connected) and that the discharged

battery is properly connected. Switch

off your vehicle ignition.

Start the engine of the vehicle supply-

ing the current and run it at an interme-

diate engine speed.

Check that there is no con-

tact between leads A and B

and that the positive lead A

is not touching any metal

parts on the vehicle supplying the

current.

Risk of injury and/or damage to

the vehicle.

212

4

A

B

3

1

Page 257 of 298

5.31

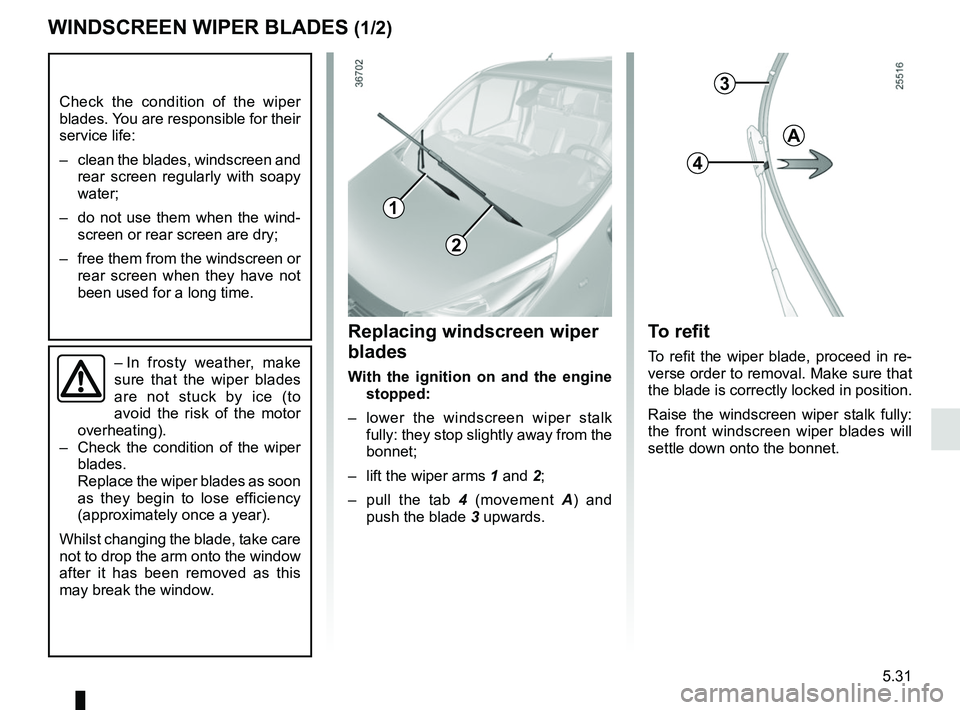

WINDSCREEN WIPER BLADES (1/2)

– In frosty weather, make

sure that the wiper blades

are not stuck by ice (to

avoid the risk of the motor

overheating).

– Check the condition of the wiper

blades.

Replace the wiper blades as soon

as they begin to lose efficiency

(approximately once a year).

Whilst changing the blade, take care

not to drop the arm onto the window

after it has been removed as this

may break the window.

Check the condition of the wiper

blades. You are responsible for their

service life:

– clean the blades, windscreen and rear screen regularly with soapy

water;

– do not use them when the wind- screen or rear screen are dry;

– free them from the windscreen or rear screen when they have not

been used for a long time.

To refit

To refit the wiper blade, proceed in re-

verse order to removal. Make sure that

the blade is correctly locked in position.

Raise the windscreen wiper stalk fully:

the front windscreen wiper blades will

settle down onto the bonnet.

Replacing windscreen wiper

blades

With the ignition on and the engine stopped:

– lower the windscreen wiper stalk fully: they stop slightly away from the

bonnet;

– lift the wiper arms 1 and 2;

– pull the tab 4 (movement A) and

push the blade 3 upwards.

3

4

A

1

2