turbocharging RENAULT TWINGO 2009 2.G Electrical Equipment - Petrol Injection User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 348

Page 67 of 348

17B-67V7 MR-413-X44-17B000$131.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

Vdiag 54 only

DF054

PRESENT

OR

STOREDTURBOCHARGING SOLENOID VALVE CONTROL CIRCUITCO: Open circuit

CC.0: Short circuit to earth

CC.1: Short circuit to + 12 V

1.DEF: EOBD

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is declared present after the ignition is switched on or after the engine has

been running at an engine speed above 600 rpm.

Special notes:

–OBD warning light illuminated.

–Throttle valve defect mode type 6.

Use the Wiring Diagrams Technical Note for NEW TWINGO, E33, CLIO III, or

MODUS.

Check the cleanliness, condition, and fitting of the turbocharging solenoid valve (component code 436).

If the connector is faulty and there is a repair method (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

If the fault is still present, manipulate the wiring harness in order to note a change in fault status (present

→

stored).

Check the condition of the engine management computer connector (component code 120).

Look for possible damage to the wiring harness.

If the connector is faulty and there is a repair method (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check for +12 V on connection 3AHN of the turbocharger solenoid valve, component code 436.

If +12 V is not present, check the insulation, continuity, and the absence of interference resistance on

connection:

●3AHN between components 120 and 436.

If the connection is faulty and if there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

SIM32_V54_DF054

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition, wait 1 minute and carry out a road test followed by a check with

the diagnostic tool.

Page 68 of 348

17B-68V7 MR-413-X44-17B000$131.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

DF054

CONTINUED

If the fault is still present, disconnect the battery and the injection computer.

Check the insulation, continuity, and the absence of interference resistance on connection:

●3AT between components 120 and 436.

If the connection is faulty and if there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, measure the resistance of the turbocharging solenoid valve between connections 3AHN

and 3AT.

If the resistance of the turbocharger solenoid valve is not between:

●21.8 Ω < X < 24.2 Ω at 23˚C, replace the solenoid valve.

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition, wait 1 minute and carry out a road test followed by a check with

the diagnostic tool.

Page 154 of 348

17B-154V7 MR-413-X44-17B000$133.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

Only Vdiag 54

DF569

PRESENT

OR

STOREDTURBOCHARGING CIRCUIT

1.DEF: Signal outside lower limit

2.DEF: Signal outside upper limit

3.DEF: OBD

NOTESConditions for applying the fault finding procedure to stored faults

The fault is declared present with the engine running.

Special note:

Defect mode 4: speed limited to less than 66 mph (110 km/h) in 5th and 6

th and the

accelerator pedal feels spongy.

Defect mode 5: the ESP and Cruise control - Speed limiter are deactivated.

Defect mode 6: the wastegate is not controlled and opens freely.

The engine runs without turbocharging, like a naturally aspirated engine.

Use the Wiring Diagrams Technical Note for NEW TWINGO, E33, CLIO III, or

MODUS.

Check the connection of the turbocharging ducts.

Check the condition of the connector of the turbocharger pressure sensor (component code 1071), of the

wastegate solenoid valve (component code 436), and of the engine management computer (component

code 120).

If the connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Use the universal bornier to check the insulation and continuity of the following connections:

●3AHN between components 436 and 120,

●3AT between components 436 and 120,

●3LN between components 1071 and 120,

●3LP between components 1071 and 120,

●3LQ between components 1071 and 120.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, contact the Techline.

SIM32_V54_DF569

AFTER REPAIRFollow the instructions to confirm repair:

–If the fault is present, continue to deal with the fault.

–If the fault is stored, ignore it.

Deal with any other faults.

Clear the stored faults.

Page 245 of 348

17B-245V7 MR-413-X44-17B000$152.mif

PETROL INJECTION

Fault finding – Interpretation of statuses17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

ET567DEFECT MODE TYPE 4

STATUS

DEFINITIONACTIVE: This status indicates that defect mode type 4 is active.

INACTIVE: This status indicates that defect mode type 4 is inactive.

NOTESThere must be no present or stored faults.

This type groups together faults affecting the motorised throttle valve monitoring system, the pedal and the

turbocharging circuit for which there is a backup operating mode that is viable for the system.

The associated defect mode is a limitation of the throttle opening according to the engine speed. This is expressed

by limiting the speed to less than 66 mph (110 km/h) in 5

th and 6th and the accelerator pedal feels "soft".

SIM32_V44_ET567/SIM32_V4C_ET567/SIM32_V50_ET567/SIM32_V54_ET567

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

Page 246 of 348

17B-246V7 MR-413-X44-17B000$152.mif

PETROL INJECTION

Fault finding – Interpretation of statuses17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

ET568TYPE 5 DEFECT MODE

STATUS

DEFINITIONACTIVE: This status indicates that defect mode type 5 is active.

INACTIVE: This status indicates that defect mode type 5 is inactive.

NOTESThere must be no present or stored faults.

This type groups together faults affecting the pressure, the throttle valve control by the torque structure and the

turbocharging pressure.

Its effect is to go into pedal feedback mode instead of the permanent torque structure. The ESP and cruise control/

speed limiter systems are deactivated. The automatic or sequential gearbox goes into safe mode. The engine

management no longer accepts requests from the gearbox, and sends torque values by default to the multiplex

network.

SIM32_V44_ET568/SIM32_V4C_ET568/SIM32_V50_ET568/SIM32_V54_ET568

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

Page 247 of 348

17B-247V7 MR-413-X44-17B000$152.mif

PETROL INJECTION

Fault finding – Interpretation of statuses17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

ET569DEFECT MODE TYPE

6

STATUS

DEFINITIONACTIVE: This status indicates that defect mode type 6 is active.

INACTIVE: This status indicates that defect mode type 6 is inactive.

NOTESThere must be no present or stored faults.

This type groups the faults affecting the wastegate control in turbocharged vehicles.

Defect mode enables the engine to operate as a naturally aspirated engine.

The wastegate is no longer controlled and opens freely. The vehicle operates without turbocharging: loss of

turbocharger effectiveness (brisk engine performance, acceleration, recovery, etc.); operation as a naturally

aspirated engine.

Entry into type 1 to 5 defect mode always leads to the application of type 6 in turbocharged versions.

SIM32_V44_ET569/SIM32_V4C_ET569/SIM32_V50_ET569/SIM32_V54_ET569

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

Page 263 of 348

17B-263V7 MR-413-X44-17B000$160.mif

17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

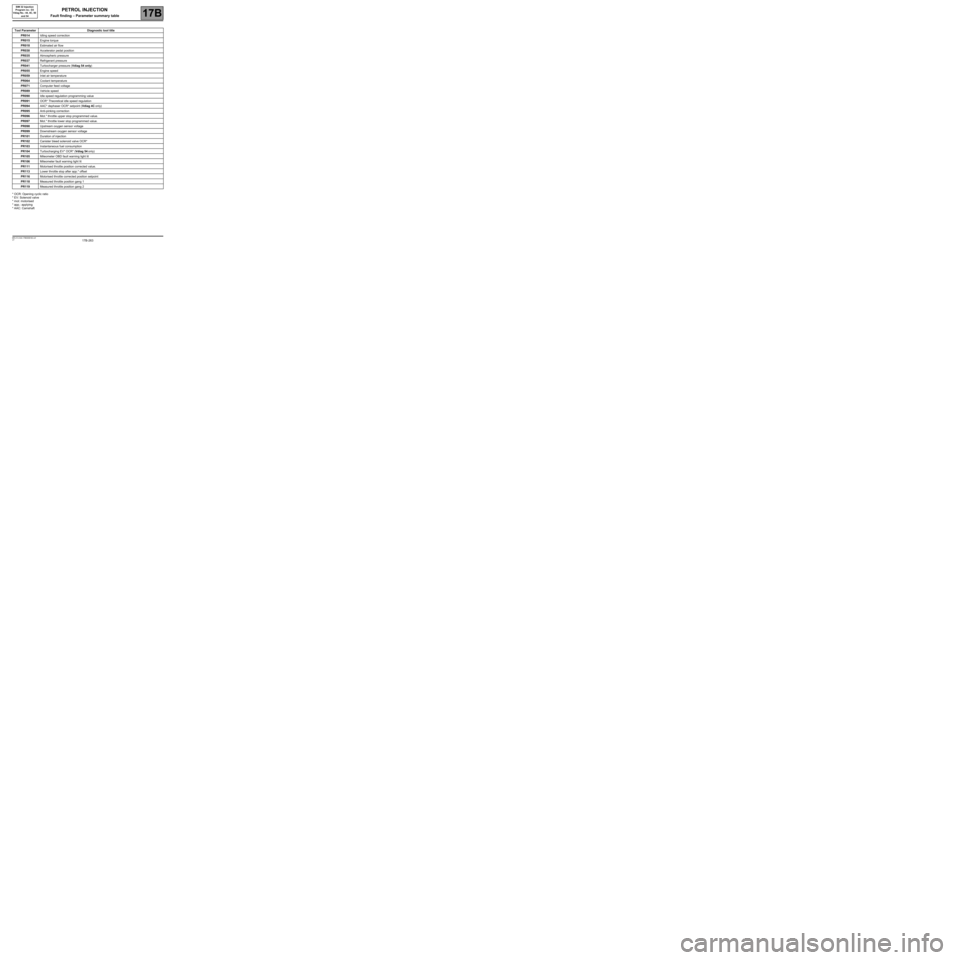

* OCR: Opening cyclic ratio

* EV: Solenoid valve

* mot: motorised

* app.: applying

* AAC: Camshaft

Tool ParameterDiagnostic tool title

PR014Idling speed correction

PR015Engine torque

PR018Estimated air flow

PR030Accelerator pedal position

PR035Atmospheric pressure

PR037Refrigerant pressure

PR041Turbocharger pressure (Vdiag 54 only)

PR055Engine speed

PR059Inlet air temperature

PR064Coolant temperature

PR071Computer feed voltage

PR089Vehicle speed

PR090Idle speed regulation programming value

PR091OCR* Theoretical idle speed regulation

PR094AAC* dephaser OCR* setpoint (Vdiag 4C only)

PR095Anti-pinking correction

PR096Mot.* throttle upper stop programmed value.

PR097Mot.* throttle lower stop programmed value.

PR098Upstream oxygen sensor voltage

PR099Downstream oxygen sensor voltage

PR101Duration of injection

PR102Canister bleed solenoid valve OCR*

PR103Instantaneous fuel consumption

PR104Turbocharging EV* OCR* (Vdiag 54 only)

PR105Mileometer OBD fault warning light lit

PR106Mileometer fault warning light lit

PR111Motorised throttle position corrected value.

PR113Lower throttle stop after app.* offset

PR116Motorised throttle corrected position setpoint

PR118Measured throttle position gang 1

PR119Measured throttle position gang 2

PETROL INJECTION

Fault finding – Parameter summary table

Page 270 of 348

17B-270V7 MR-413-X44-17B000$171.mif

PETROL INJECTION

Fault finding – Interpretation of parameters17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

PR035ATMOSPHERIC PRESSURE

PARAMETER

DEFINITIONThis parameter indicates the atmospheric pressure in bar. The sensor is integrated in

the computer.

NOTESSpecial notes:

Only perform these tests if the parameters do not correspond with the system operation

programming.

Use the Wiring Diagrams Technical Note for NEW TWINGO, E33, CLIO III

or MODUS.

Conformity check with engine stopped and ignition on, or engine running, and engine coolant

temperature > 80˚C

The atmospheric pressure value is:

PR035 ≈ 1 bar +/- 0.20 bar

In the event of a fault, consult the interpretation of DF004 Turbocharging pressure sensor circuit.

Check the cleanliness and condition of the atmospheric pressure sensor and its connections (component

code 147) and the engine management computer (component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

On the atmospheric pressure sensor, component code 147, check the resistance between connections 3LG

and 3CK.

If the resistance is not X 50 kΩ, replace the sensor.

SIM32_V44_PR035/SIM32_V4C_PR035/SIM32_V50_PR035/SIM32_V54_PR035

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

Page 273 of 348

17B-273V7 MR-413-X44-17B000$171.mif

PETROL INJECTION

Fault finding – Interpretation of parameters17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

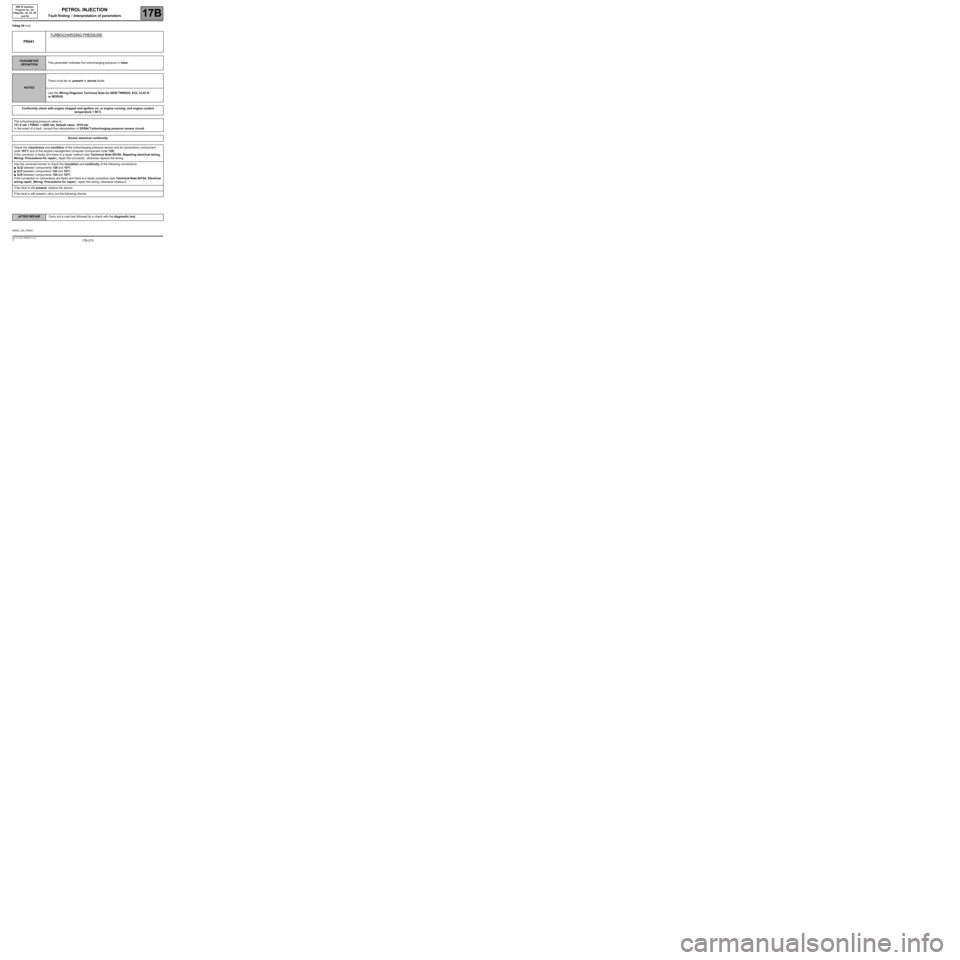

Vdiag 54 only

PR041TURBOCHARGING PRESSURE

PARAMETER

DEFINITIONThis parameter indicates the turbocharging pressure in mbar.

NOTESThere must be no present or stored faults.

Use the Wiring Diagrams Technical Note for NEW TWINGO, E33, CLIO III

or MODUS.

Conformity check with engine stopped and ignition on, or engine running, and engine coolant

temperature > 80˚C

The turbocharging pressure value is:

121.5 mb < PR041 < 2200 mb, Default value: 1016 mb.

In the event of a fault, consult the interpretation of DF004 Turbocharging pressure sensor circuit.

Sensor electrical conformity

Check the cleanliness and condition of the turbocharging pressure sensor and its connections (component

code 1071) and of the engine management computer (component code 120).

If the connector is faulty and there is a repair method (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Use the universal bornier to check the insulation and continuity of the following connections:

●3LQ between components 120 and 1071,

●3LP between components 120 and 1071,

●3LN between components 120 and 1071.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, replace the sensor.

If the fault is still present, carry out the following checks:

SIM32_V54_PR041

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

Page 274 of 348

17B-274V7 MR-413-X44-17B000$171.mif

PETROL INJECTION

Fault finding – Interpretation of parameters17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

PR041

CONTINUED

–Check the cleanliness of the air filter.

–Replace the filter if necessary.

–Check that the air inlet circuit is not blocked.

The turbocharging system must be perfectly sealed, from the exhaust manifold to the turbocharger, from the

turbocharger to the heat exchanger and from the heat exchanger to the throttle valve.

Check that there are no air leaks:

–around the turbocharger pressure sensor,

–around the air temperature sensor.

Check absence of leaks in the wastegate capsule pressure circuit connected to the turbocharger system.

Check that the air-air heat exchanger is not clogged (presence of oil).

If there is oil in the heat exchanger, the turbocharger is certainly damaged.

Using a pressure/vacuum pump, check that the turbocharger protection and turbocharging valve capsule

diaphragms do not leak.

Check the condition the motorised throttle valve in terms of clogging.

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.