ignition RENAULT TWINGO 2009 2.G Electrical Equipment User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 241

Page 45 of 241

82A-5

ENGINE IMMOBILISER

Ignition switch: Removal - Refitting

82A

III - FINAL OPERATION.

aRefit:

-the antenna/transponder ring (see 82A, Engine

immobiliser, Transponder ring: Removal - Re-

fitting, page 82A-6) ,

-the steering column switch assembly (see 84A,

Control - Signals, Steering column switch as-

sembly: Removal - Refitting, page 84A-2) ,

-the steering wheel ( (see Steering wheel: Remo-

val - Refitting) ),

-the driver's front airbag (see 88C, Air bag and Pre-

tensioners, Driver's frontal airbag: Removal -

Refitting, page 88C-6) .

aRefit the rev counter (see 83A, Instrument panel,

Rev counter: Removal - Refitting, page 83A-3) .

aConnect the battery (see 80A, Battery, Battery: Re-

moval - Refitting, page 80A-2) .

aUnlock the airbag computer using the Diagnostic

tool (see MR 413 Fault finding, 88C, Airbags and

pretensioners, Fault finding - Replacement of

components). ENGINE REV COUNTER

Page 47 of 241

82A-7

ENGINE IMMOBILISER

Transponder ring: Removal - Refitting

82A

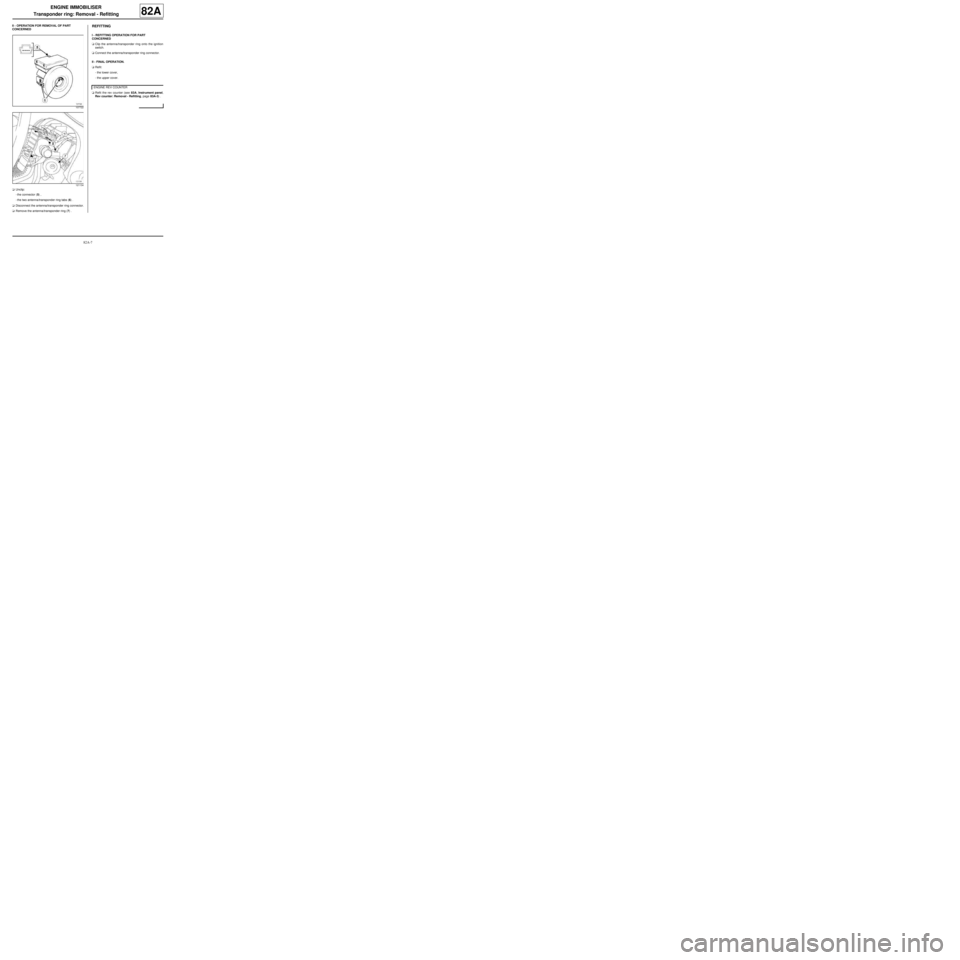

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aUnclip:

-the connector (5) ,

-the two antenna/transponder ring tabs (6) .

aDisconnect the antenna/transponder ring connector.

aRemove the antenna/transponder ring (7) .REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aClip the antenna/transponder ring onto the ignition

switch.

aConnect the antenna/transponder ring connector.

II - FINAL OPERATION.

aRefit:

-the lower cover,

-the upper cover.

aRefit the rev counter (see 83A, Instrument panel,

Rev counter: Removal - Refitting, page 83A-3) .

107722

121134

ENGINE REV COUNTER

Page 60 of 241

84A-5

CONTROL - SIGNALS

Steering column switch assembly: Removal - Refitting84A

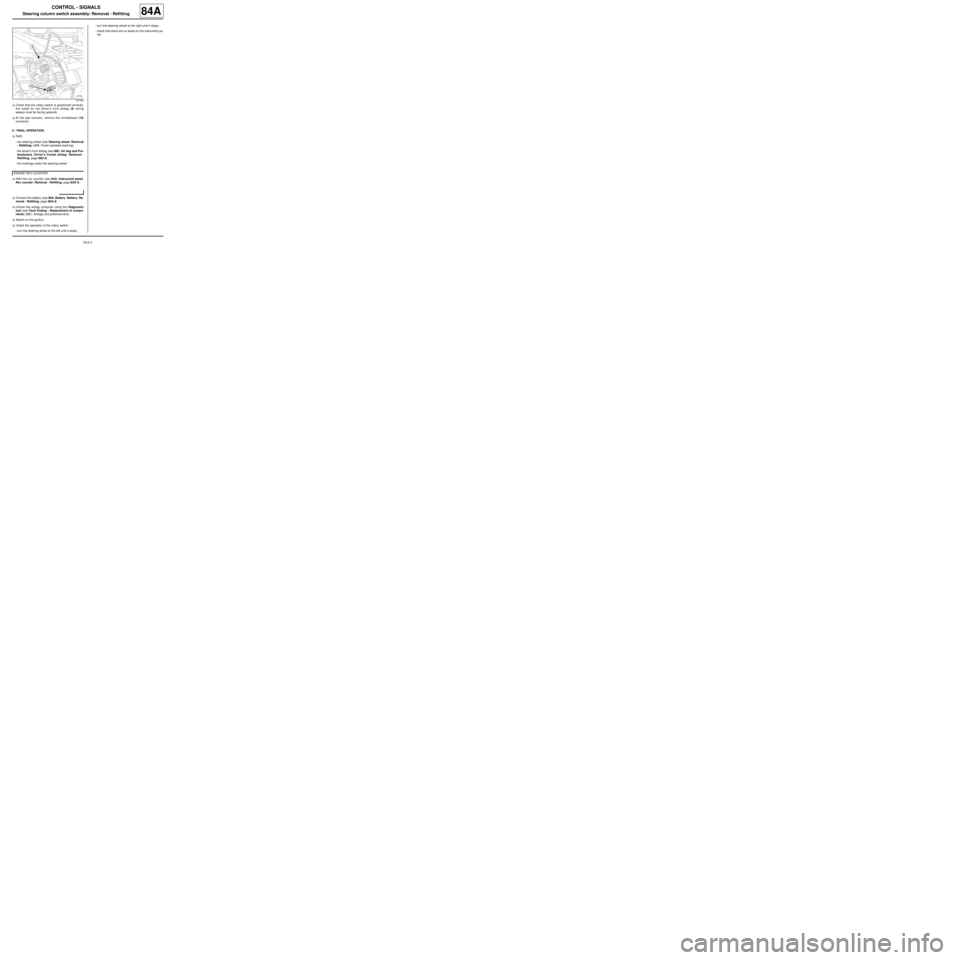

aCheck that the rotary switch is positioned correctly:

the outlet for the driver's front airbag (9) wiring

always must be facing upwards.

aAt the last moment, remove the immobilised (10)

connector.

II - FINAL OPERATION.

aRefit:

-the steering wheel (see Steering wheel: Removal

- Refitting) (36B, Power-assisted steering),

-the driver's front airbag (see 88C, Air bag and Pre-

tensioners, Driver's frontal airbag: Removal -

Refitting, page 88C-6) .

-the cowlings under the steering wheel.

aRefit the rev counter (see 83A, Instrument panel,

Rev counter: Removal - Refitting, page 83A-3) .

aConnect the battery (see 80A, Battery, Battery: Re-

moval - Refitting, page 80A-2) .

aUnlock the airbag computer using the Diagnostic

tool (see Fault finding - Replacement of compo-

nents) (88C, Airbags and pretensioners).

aSwitch on the ignition.

aCheck the operation of the rotary switch:

-turn the steering wheel to the left until it stops,-turn the steering wheel to the right until it stops,

-check that there are no faults on the instrument pa-

nel.

127766

ENGINE REV COUNTER

Page 69 of 241

84A-14

CONTROL - SIGNALS

Heated rear screen: Repair

84A

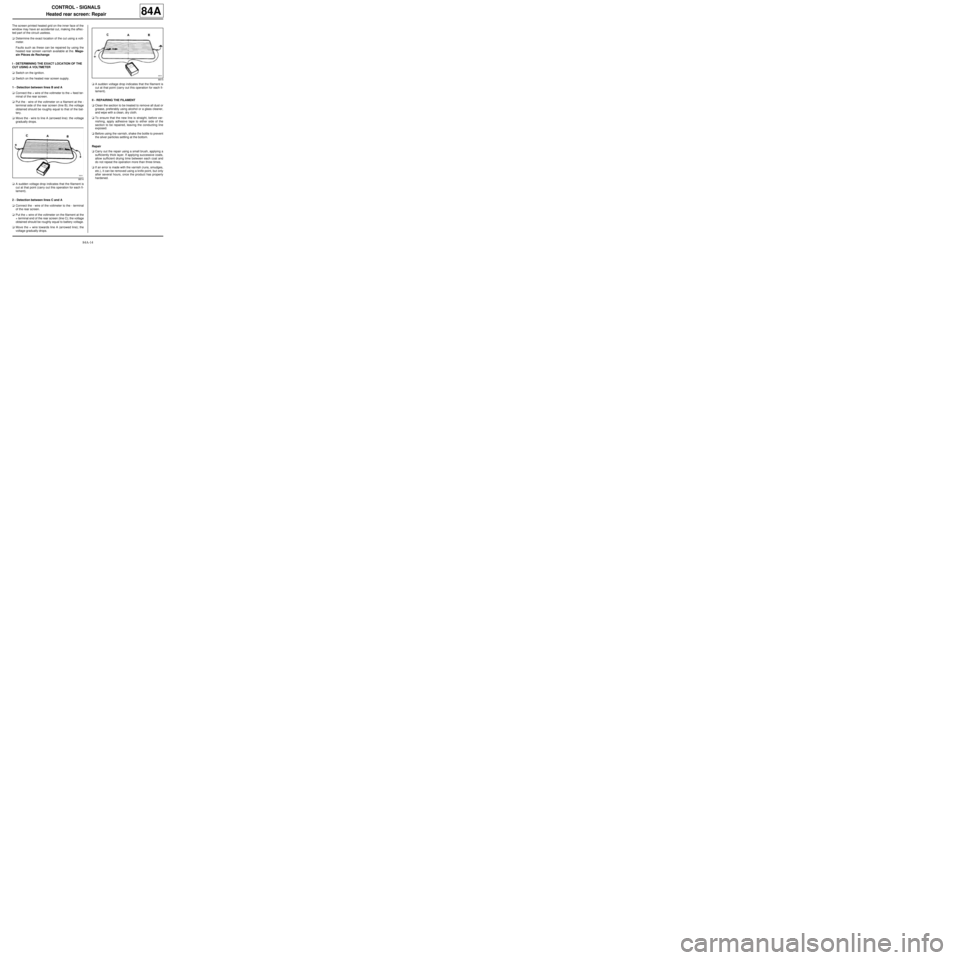

The screen printed heated grid on the inner face of the

window may have an accidental cut, making the affec-

ted part of the circuit useless.

aDetermine the exact location of the cut using a volt-

meter.

Faults such as these can be repaired by using the

heated rear screen varnish available at the. Maga-

sin Pièces de Rechange

I - DETERMINING THE EXACT LOCATION OF THE

CUT USING A VOLTMETER

aSwitch on the ignition.

aSwitch on the heated rear screen supply.

1 - Detection between lines B and A

aConnect the + wire of the voltmeter to the + feed ter-

minal of the rear screen.

aPut the - wire of the voltmeter on a filament at the -

terminal side of the rear screen (line B); the voltage

obtained should be roughly equal to that of the bat-

tery.

aMove the - wire to line A (arrowed line): the voltage

gradually drops.

aA sudden voltage drop indicates that the filament is

cut at that point (carry out this operation for each fi-

lament).

2 - Detection between lines C and A

aConnect the - wire of the voltmeter to the - terminal

of the rear screen.

aPut the + wire of the voltmeter on the filament at the

+ terminal end of the rear screen (line C); the voltage

obtained should be roughly equal to battery voltage.

aMove the + wire towards line A (arrowed line); the

voltage gradually drops.aA sudden voltage drop indicates that the filament is

cut at that point (carry out this operation for each fi-

lament).

II - REPAIRING THE FILAMENT

aClean the section to be treated to remove all dust or

grease, preferably using alcohol or a glass cleaner,

and wipe with a clean, dry cloth.

aTo ensure that the new line is straight, before var-

nishing, apply adhesive tape to either side of the

section to be repaired, leaving the conducting line

exposed.

aBefore using the varnish, shake the bottle to prevent

the silver particles settling at the bottom.

Repair

aCarry out the repair using a small brush, applying a

sufficiently thick layer. If applying successive coats,

allow sufficient drying time between each coat and

do not repeat the operation more than three times.

aIf an error is made with the varnish (runs, smudges,

etc.), it can be removed using a knife point, but only

after several hours, once the product has properly

hardened.

8814

8815

Page 75 of 241

85A-5

WIPING - WASHING

Windscreen wiper blade: Removal - Refitting

85A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aSwitch off the ignition.

II - REMOVAL OPERATION FOR PART

CONCERNED

aPress on the windscreen wiper blade clip (1) .

aExtract the windscreen wiper blade from the winds-

creen wiper arm at (2) .

REFITTING

REFITTING OPERATION FOR PART CONCERNED

aRefit the windscreen wiper blade onto the winds-

creen wiper arm.

119383

Page 76 of 241

85A-6

WIPING - WASHING

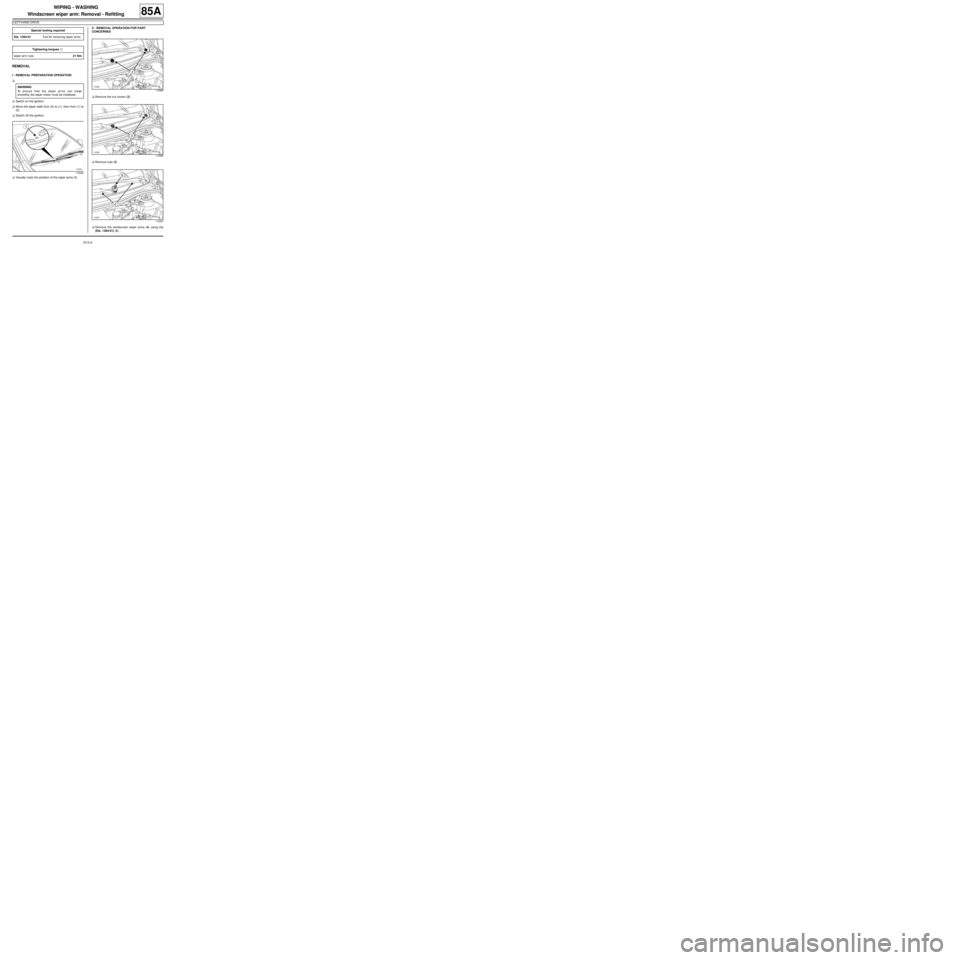

Windscreen wiper arm: Removal - Refitting

LEFT-HAND DRIVE

85A

REMOVAL

I - REMOVAL PREPARATION OPERATION

a

aSwitch on the ignition.

aMove the wiper stalk from (0) to (1), then from (1) to

(0).

aSwitch off the ignition.

aVisually mark the position of the wiper arms (1) .II - REMOVAL OPERATION FOR PART

CONCERNED

aRemove the nut covers (2) .

aRemove nuts (3) .

aRemove the windscreen wiper arms (4) using the

(Ele. 1294-01) (5) . Special tooling required

Ele. 1294-01Tool for removing wiper arms.

Tightening torquesm

wiper arm nuts21 Nm

WARNING

To ensure that the wiper arms can travel

smoothly, the wiper motor must be initialised.

119382

119385

119386

119387

Page 78 of 241

85A-8

WIPING - WASHING

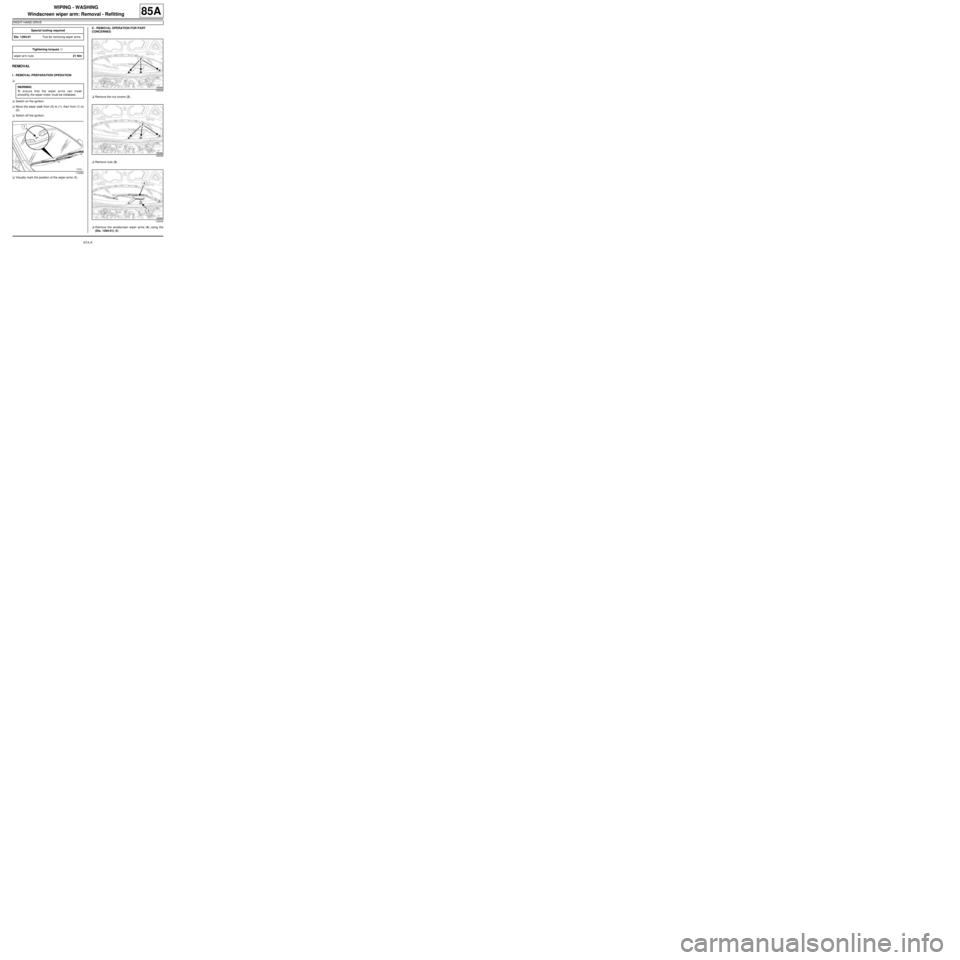

Windscreen wiper arm: Removal - Refitting

RIGHT-HAND DRIVE

85A

REMOVAL

I - REMOVAL PREPARATION OPERATION

a

aSwitch on the ignition.

aMove the wiper stalk from (0) to (1), then from (1) to

(0).

aSwitch off the ignition.

aVisually mark the position of the wiper arms (1) .II - REMOVAL OPERATION FOR PART

CONCERNED

aRemove the nut covers (2) .

aRemove nuts (3) .

aRemove the windscreen wiper arms (4) using the

(Ele. 1294-01) (5) . Special tooling required

Ele. 1294-01Tool for removing wiper arms.

Tightening torquesm

wiper arm nuts21 Nm

WARNING

To ensure that the wiper arms can travel

smoothly, the wiper motor must be initialised.

119382

125228

125229

125230

Page 79 of 241

85A-9

WIPING - WASHING

Windscreen wiper arm: Removal - Refitting

RIGHT-HAND DRIVE

85A

REFITTING

REFITTING OPERATION FOR PART CONCERNED

a

aSwitch on the ignition.

aMove the wiper stalk from (0) to (1), then from (1) to

(0).

aSwitch off the ignition.

aFit the windscreen wiper arms in the position marked

before the removal operation (1) .

aRefit the wiper arm nuts.

aTorque tighten the wiper arm nuts (21 Nm).

aRefit the wiper arm nut covers.WARNING

To ensure that the wiper arms can travel

smoothly, the wiper motor must be initialised.

119382

Page 80 of 241

85A-10

WIPING - WASHING

Windscreen wiper mechanism: Removal - Refitting

LEFT-HAND DRIVE

85A

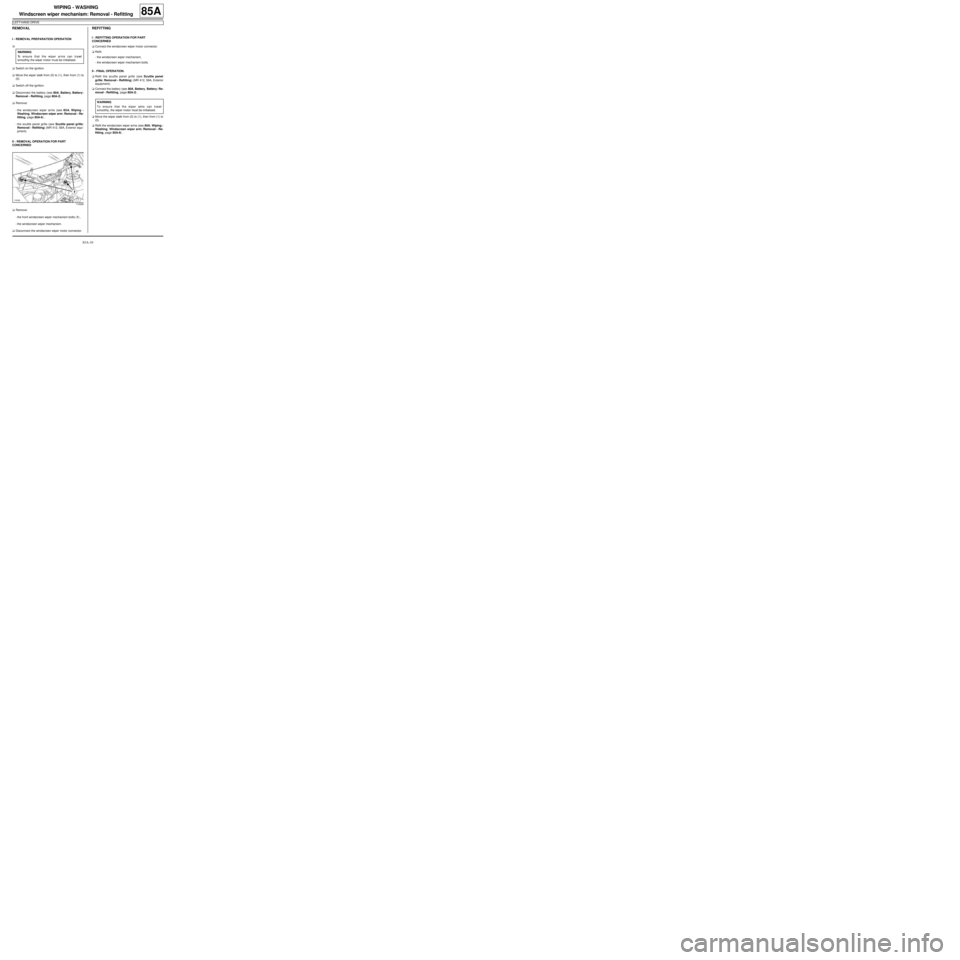

REMOVAL

I - REMOVAL PREPARATION OPERATION

a

aSwitch on the ignition.

aMove the wiper stalk from (0) to (1), then from (1) to

(0).

aSwitch off the ignition.

aDisconnect the battery (see 80A, Battery, Battery:

Removal - Refitting, page 80A-2) .

aRemove:

-the windscreen wiper arms (see 85A, Wiping -

Washing, Windscreen wiper arm: Removal - Re-

fitting, page 85A-6) ,

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (MR 412, 56A, Exterior equi-

pment).

II - REMOVAL OPERATION FOR PART

CONCERNED

aRemove:

-the front windscreen wiper mechanism bolts (1) ,

-the windscreen wiper mechanism.

aDisconnect the windscreen wiper motor connector.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aConnect the windscreen wiper motor connector.

aRefit:

-the windscreen wiper mechanism,

-the windscreen wiper mechanism bolts.

II - FINAL OPERATION.

aRefit the scuttle panel grille (see Scuttle panel

grille: Removal - Refitting) (MR 412, 56A, Exterior

equipment).

aConnect the battery (see 80A, Battery, Battery: Re-

moval - Refitting, page 80A-2) .

aMove the wiper stalk from (0) to (1), then from (1) to

(0).

aRefit the windscreen wiper arms (see 85A, Wiping -

Washing, Windscreen wiper arm: Removal - Re-

fitting, page 85A-6) . WARNING

To ensure that the wiper arms can travel

smoothly, the wiper motor must be initialised.

119389

WARNING

To ensure that the wiper arms can travel

smoothly, the wiper motor must be initialised.

Page 81 of 241

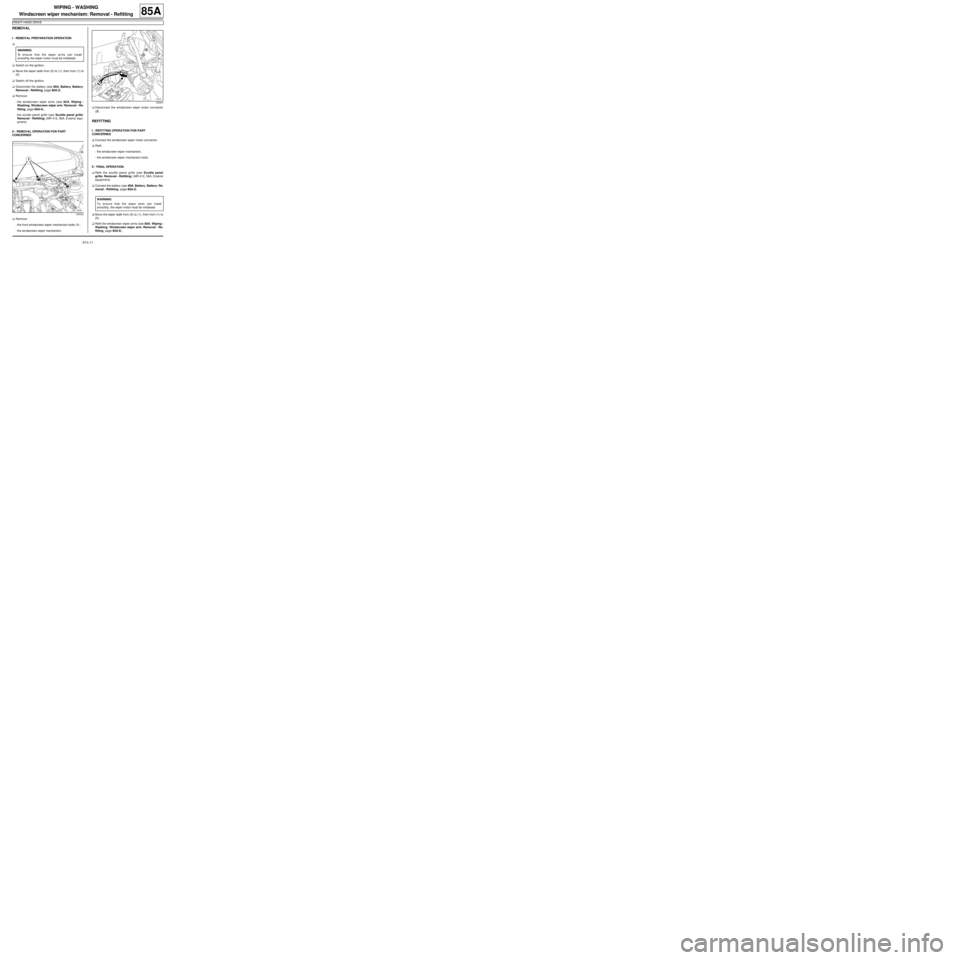

85A-11

WIPING - WASHING

Windscreen wiper mechanism: Removal - Refitting

RIGHT-HAND DRIVE

85A

REMOVAL

I - REMOVAL PREPARATION OPERATION

a

aSwitch on the ignition.

aMove the wiper stalk from (0) to (1), then from (1) to

(0).

aSwitch off the ignition.

aDisconnect the battery (see 80A, Battery, Battery:

Removal - Refitting, page 80A-2) .

aRemove:

-the windscreen wiper arms (see 85A, Wiping -

Washing, Windscreen wiper arm: Removal - Re-

fitting, page 85A-6) ,

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (MR 412, 56A, Exterior equi-

pment).

II - REMOVAL OPERATION FOR PART

CONCERNED

aRemove:

-the front windscreen wiper mechanism bolts (1) ,

-the windscreen wiper mechanism.aDisconnect the windscreen wiper motor connector

(2) .

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aConnect the windscreen wiper motor connector.

aRefit:

-the windscreen wiper mechanism,

-the windscreen wiper mechanism bolts.

II - FINAL OPERATION.

aRefit the scuttle panel grille (see Scuttle panel

grille: Removal - Refitting) (MR 412, 56A, Exterior

equipment).

aConnect the battery (see 80A, Battery, Battery: Re-

moval - Refitting, page 80A-2) .

aMove the wiper stalk from (0) to (1), then from (1) to

(0).

aRefit the windscreen wiper arms (see 85A, Wiping -

Washing, Windscreen wiper arm: Removal - Re-

fitting, page 85A-6) . WARNING

To ensure that the wiper arms can travel

smoothly, the wiper motor must be initialised.

125232

125231

WARNING

To ensure that the wiper arms can travel

smoothly, the wiper motor must be initialised.