coolant RENAULT TWINGO 2009 2.G Engine And Peripherals Repair Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 652

Page 520 of 652

19A-10

COOLING

Cooling system: Draining - Refilling

D4F or D7F or K4M or K9K

19A

2 - Filling method without special tools

a

aRemove the air filter unit (see 12A, Fuel mixture,

Air filter unit: Removal - Refitting, page 12A-13) .

aRemove the front engine cover.

aOpen the bleed screws (1) and (2) .

aFill the cooling system with engine coolant recom-

mended by the manufacturer (see Vehicle: Parts

and consumables for the repair) (04B, Consum-

ables - Products) via the expansion bottle until it

overflows.

aClose all the bleed screws as soon as the coolant

starts to flow in a continuous stream.aRefit the air filter unit (see 12A, Fuel mixture, Air fil-

ter unit: Removal - Refitting, page 12A-13) .

aRefit the engine cover.

aPressurise the system using the (Ms. 554-07) to

check that there are no leaks (see 19A, Cooling,

Engine cooling system: Check, page 19A-2) .

aRefit the expansion bottle cap.

aClean any surfaces soiled by the coolant.

IV - BLEEDING

a

aStart the engine.

aMaintain the engine speed at 2500 rpm using the

pedal press for 5 min.

aStabilise the engine speed at 2000 rpm until the fan

assembly has been activated twice.

aMaintain the engine speed at 2500 rpm, using the

pedal press for 5 minutes.

aStabilise the engine speed at 2000 rpm until the fan

assembly is activated.

aNote the coolant level in the expansion bottle after

this first activation.

aAccelerate at a minimum of 4000 rpm for several

seconds, until the level of coolant fluid in the expan-

sion bottle drops. WARNING

It is essential to open all of the bleed screws to

remove as much as air as possible in the cooling

system. Failure to perform this procedure may

prevent the cooling system from filling properly

and may damage the engine.

D4F, and 772 – K4M

K9K

120526

D4F, and 772 – K4M

K9K

WARNING

Do not open the bleed screw whilst the engine is

running; this would damage the engine.

D4F, and 772 – D7F, and 800

D4F, and 780 or 782

Page 521 of 652

19A-11

COOLING

Cooling system: Draining - Refilling

D4F or D7F or K4M or K9K

19A

aMaintain the engine speed at 1500 rpm, sharply

varying the engine speed (up to the maximum) 2 to

3 times approximately every 2 minutes until the fan

assembly starts for the second time.

aMaintain the engine speed at 3000 rpm using a ped-

al press, until the fan assembly has been activated

for a third time.

aCheck that the heating is operating correctly.

aAllow the engine to cool until the engine coolant tem-

perature is less than 50˚C.

aRemove the expansion bottle cap.

aAdjust the coolant fluid level to the "Max" mark.

aRefit the expansion bottle cap.

V - FINAL OPERATION

aRemove the coolant recovery tray.

aRefit the engine undertray. K9K

K4M

K4M

Page 522 of 652

19A-12

COOLING

Cooling radiator: Removal - Refitting

D4F or D7F, and AIR CONDITIONING

19A

PARTS AND CONSUMABLES FOR THE

REPAIR WORK

aConsumable : (see Vehicle: Parts and consuma-

bles for the repair)

-COOLANT.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift ( (see Vehicle:

Towing and lifting) ).

aRemove:

-the battery ( (see Battery: Removal - Refitting) ),

-the battery tray ( (see Battery tray: Removal - Re-

fitting) ),

-the front wheels ( (see Wheel: Removal - Refit-

ting) ), (see Front wheel arch liner: Removal -

Refitting)

-the wheel arch liners (see MR 412 Bodywork,

55A, Exterior protection, Wheel arch liners: Re-

moval-Refitting),

-the front bumper ( (see Front bumper: Removal -

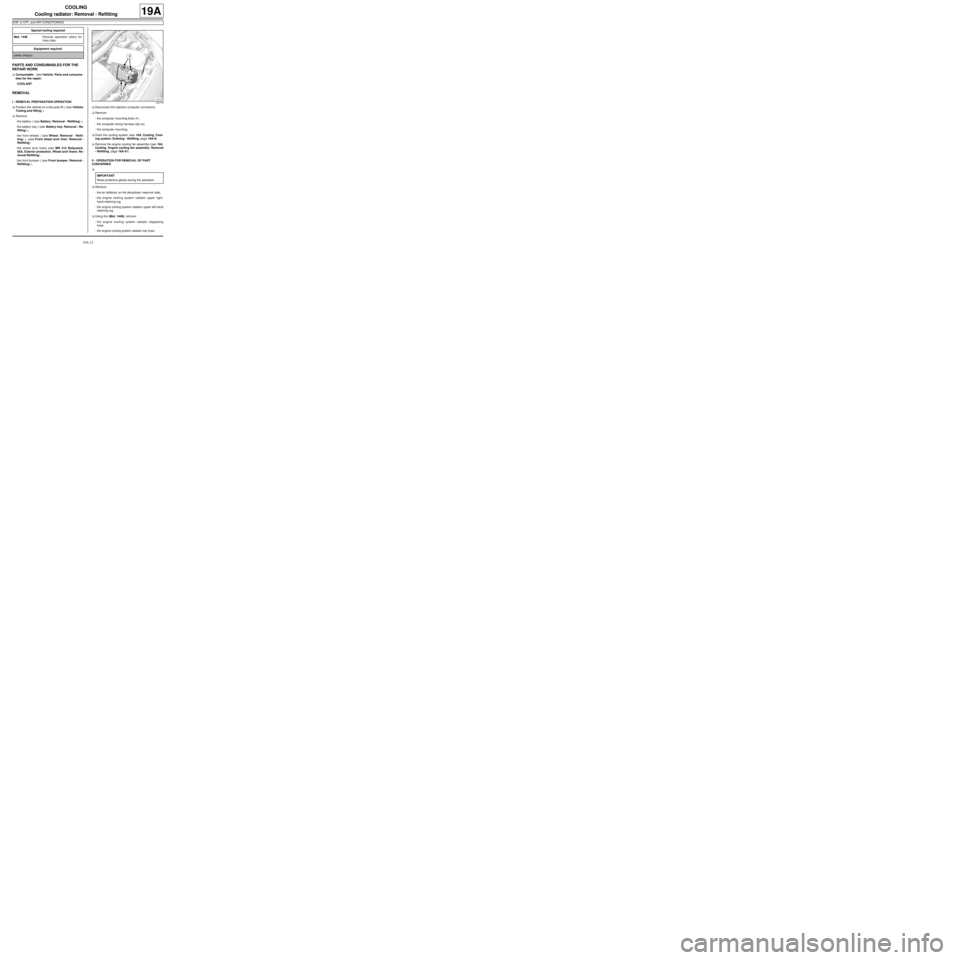

Refitting) ).aDisconnect the injection computer connectors.

aRemove:

-the computer mounting bolts (1) ,

-the computer wiring harness clip nut,

-the computer mounting.

aDrain the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) .

aRemove the engine cooling fan assembly (see 19A,

Cooling, Engine cooling fan assembly: Removal

- Refitting, page 19A-51) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

a

aRemove:

-the air deflector on the dehydrator reservoir side,

-the engine cooling system radiator upper right-

hand retaining lug,

-the engine cooling system radiator upper left-hand

retaining lug.

aUsing the (Mot. 1448), remove:

-the engine cooling system radiator degassing

hose,

-the engine cooling system radiator top hose, Special tooling required

Mot. 1448Remote operation pliers for

hose clips .

Equipment required

safety strap(s)

120779

IMPORTANT

Wear protective gloves during the operation.

Page 524 of 652

19A-14

COOLING

Cooling radiator: Removal - Refitting

K9K

19A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see ) (80A, Battery).

aDrain the refrigerant circuit using a refrigerant

charging station (see Refrigerant circuit: Drain-

ing - Filling) (62A, Air conditioning).

aRemove:

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection).

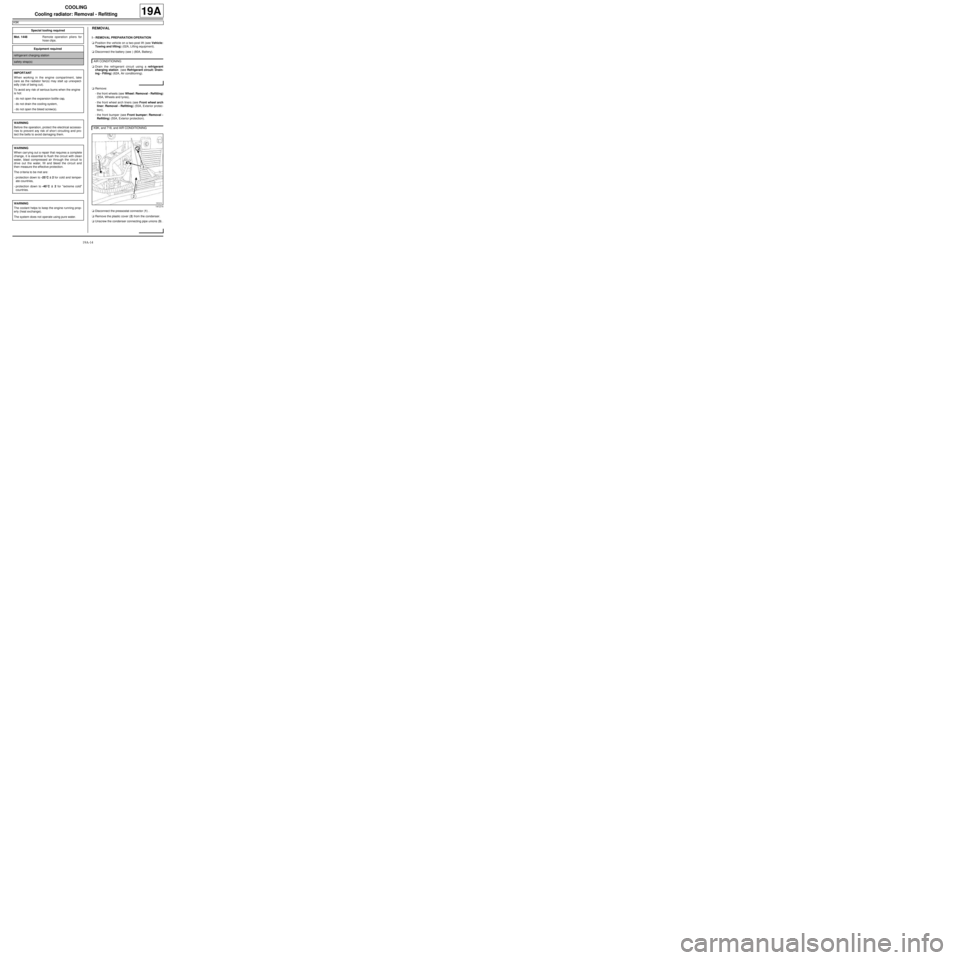

aDisconnect the pressostat connector (1) .

aRemove the plastic cover (2) from the condenser.

aUnscrew the condenser connecting pipe unions (3) . Special tooling required

Mot. 1448Remote operation pliers for

hose clips .

Equipment required

refrigerant charging station

safety strap(s)

IMPORTANT

When working in the engine compartment, take

care as the radiator fan(s) may start up unexpect-

edly (risk of being cut).

To avoid any risk of serious burns when the engine

is hot:

-do not open the expansion bottle cap,

-do not drain the cooling system,

-do not open the bleed screw(s).

WARNING

Before the operation, protect the electrical accesso-

ries to prevent any risk of shor t circuiting and pro-

tect the belts to avoid damaging them.

WARNING

When carr ying out a repair that requires a complete

change, it is essential to flush the circuit with clean

water, blast compressed air through the circuit to

drive out the water, fill and bleed the circuit and

then measure the effective protection.

The cr iteria to be met are:

-protection down to -25˚C ±± ± ±

2 for cold and temper-

ate countries,

-protection down to -40˚C ±± ± ±

2 for "extreme cold"

countries.

WARNING

The coolant helps to keep the engine running prop-

erly (heat exchange).

The system does not operate using pure water.AIR CONDITIONING

K9K, and 718, and AIR CONDITIONING

141214

Page 533 of 652

19A-23

COOLING

Cooling radiator: Removal - Refitting

K4M

19A

aPerform the following operations:

-fill the air conditioning circuit using a refrigerant

charging station (see Refrigerant circuit: Drain-

ing - Filling) (62A, Air conditioning),

-fill and bleed the coolant circuit (see 19A, Cooling,

Cooling system: Draining - Refilling, page 19A-

9) .

aRefit the engine undertray.

Page 534 of 652

19A-24

COOLING

Coolant pump: Removal - Refitting

D4F or D7F

19A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aDisconnect the battery (see ) (MR 411, 80A, Bat-

tery).

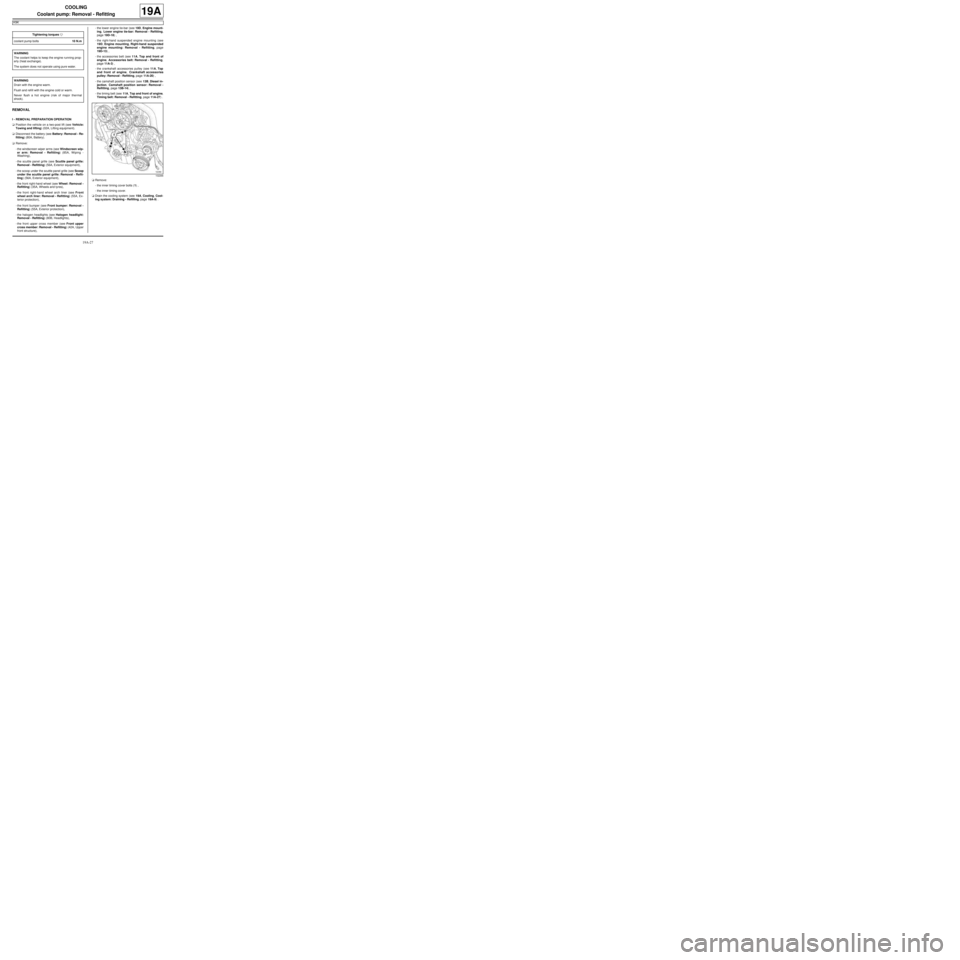

aRemove:

-the front right-hand wheel (see Wheel: Removal -

Refitting) (MR 411, 35A, Wheels and tyres),

-the front wheel arch liner (see Front wheel arch

liner: Removal - Refitting) (MR 412, 55A, Exterior

protection),

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the engine tie-bar (see 19D, Engine mounting,

Lower engine tie-bar: Removal - Refitting, page

19D-18) ,

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

-the timing belt (see 11A, Top and front of engine,

Timing belt: Removal - Refitting, page 11A-27) .

aDrain the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) .

aRemove the rigid coolant pipe bolt on the multifunc-

tion support.

aMove the rigid water pump pipe aside.aRemove the coolant pump inlet pipe (see 19A,

Cooling, Coolant pump inlet pipe: Removal - Re-

fitting, page 19A-58) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the coolant pump bolts,

-the coolant pump,

-the coolant pump seal.

aRemove the coolant pump bolts.

aMove the coolant pump 5 mm away from its bearing

face.

aPivot the coolant pump casing in the direction of the

arrows, (1) and then (2) .

aRemove:

-the coolant pump, Tightening torquesm

coolant pump bolts10 N.m

AIR CONDITIONING

D4F, and 780 or 782

STANDARD HEATING

AIR CONDITIONING

120515

Page 535 of 652

19A-25

COOLING

Coolant pump: Removal - Refitting

D4F or D7F

19A

-the coolant pump seal.

REFITTING

I - REFITTING PREPARATION OPERATION

aApply SUPER CLEANER FOR JOINT FACES (see

Vehicle: Parts and consumables for the repair)

(MR 411, 04B, Consumables - Products) to the ar-

eas to be cleaned.

aLeave for approximately ten minutes.

aRemove the residue using a wooden spatula.

aComplete the cleaning of the parts using an abrasive

pad.

aDegrease the joint faces with SURFACE CLEANER

(see Vehicle: Parts and consumables for the re-

pair) (MR 411, 04B, Consumables - Products).

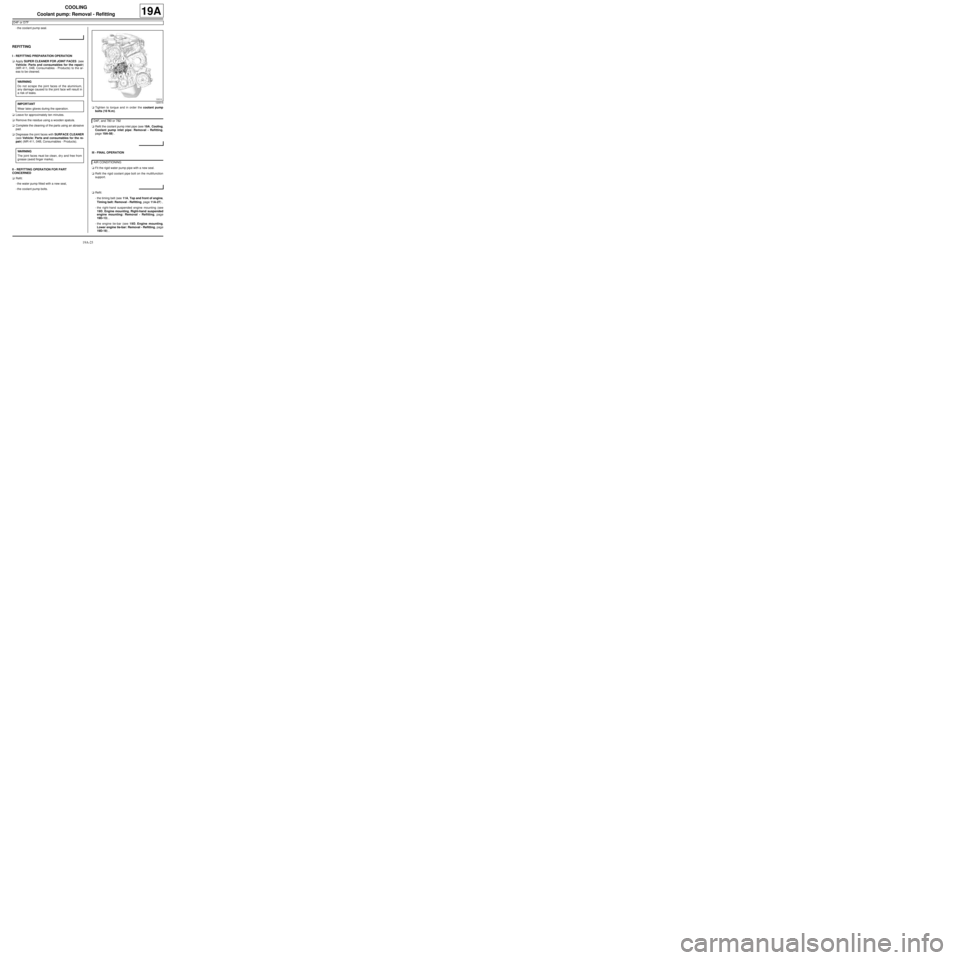

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the water pump fitted with a new seal,

-the coolant pump bolts.aTighten to torque and in order the coolant pump

bolts (10 N.m).

aRefit the coolant pump inlet pipe (see 19A, Cooling,

Coolant pump inlet pipe: Removal - Refitting,

page 19A-58) .

III - FINAL OPERATION

aFit the rigid water pump pipe with a new seal.

aRefit the rigid coolant pipe bolt on the multifunction

support.

aRefit:

-the timing belt (see 11A, Top and front of engine,

Timing belt: Removal - Refitting, page 11A-27) ,

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

-the engine tie-bar (see 19D, Engine mounting,

Lower engine tie-bar: Removal - Refitting, page

19D-18) , WARNING

Do not scrape the joint faces of the aluminium,

any damage caused to the joint face will result in

a risk of leaks.

IMPORTANT

Wear latex gloves during the operation.

WARNING

The joint faces must be clean, dr y and free from

grease (avoid finger marks).

120516

D4F, and 780 or 782

AIR CONDITIONING

Page 536 of 652

19A-26

COOLING

Coolant pump: Removal - Refitting

D4F or D7F

19A

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the front wheel arch liner (see Front wheel arch

liner: Removal - Refitting) (MR 412, 55A, Exterior

protection),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (MR 411, 35A, Wheels and tyres).

aFill and bleed the cooling system (see 19A, Cool-

ing, Cooling system: Draining - Refilling, page

19A-9) .

aConnect the battery (see ) (MR 411, 80A, Battery).

Page 537 of 652

19A-27

COOLING

Coolant pump: Removal - Refitting

K9K

19A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove:

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the halogen headlights (see Halogen headlight:

Removal - Refitting) (80B, Headlights),

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure),-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the crankshaft accessories pulley (see 11A, Top

and front of engine, Crankshaft accessories

pulley: Removal - Refitting, page 11A-20) ,

-the camshaft position sensor (see 13B, Diesel in-

jection, Camshaft position sensor: Removal -

Refitting, page 13B-14) ,

-the timing belt (see 11A, Top and front of engine,

Timing belt: Removal - Refitting, page 11A-27) .

aRemove:

-the inner timing cover bolts (1) ,

-the inner timing cover.

aDrain the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) . Tightening torquesm

coolant pump bolts10 N.m

WARNING

The coolant helps to keep the engine running prop-

erly (heat exchange).

The system does not operate using pure water.

WARNING

Drain with the engine warm.

Flush and refill with the engine cold or warm.

Never flush a hot engine (risk of major thermal

shock).

102266

Page 538 of 652

19A-28

COOLING

Coolant pump: Removal - Refitting

K9K

19A

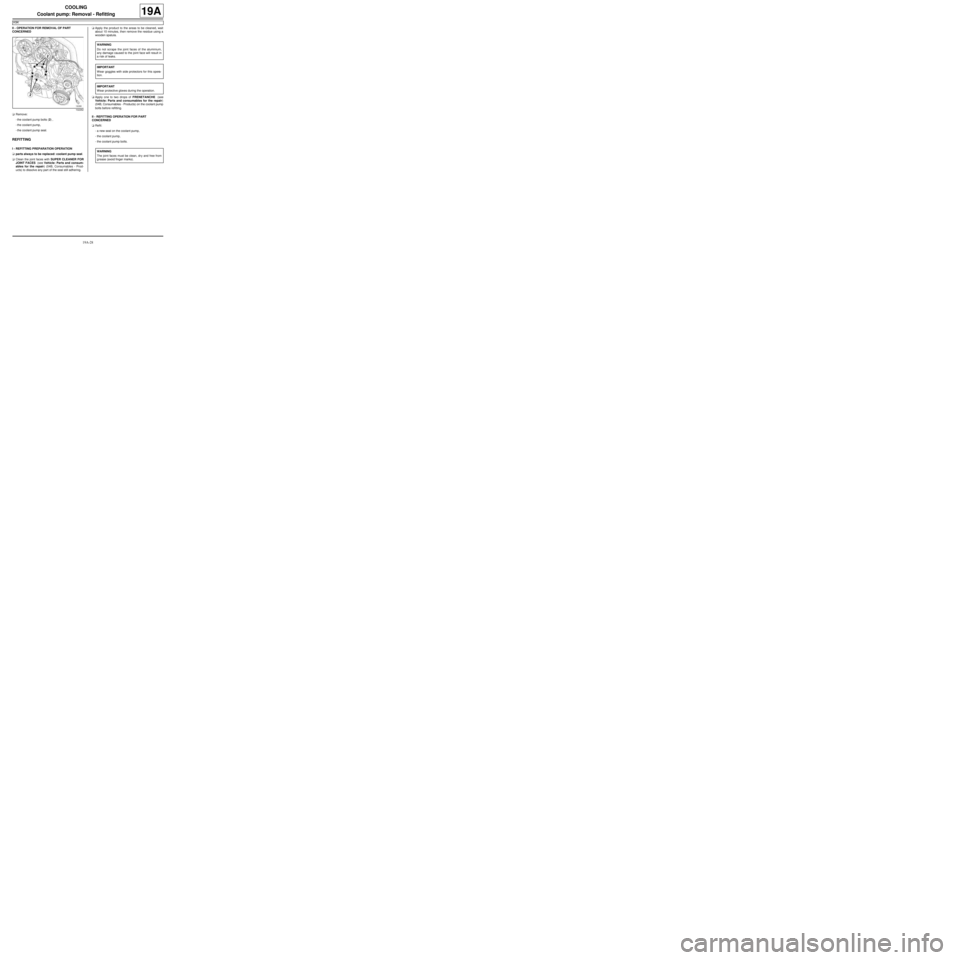

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the coolant pump bolts (2) ,

-the coolant pump,

-the coolant pump seal.

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: coolant pump seal.

aClean the joint faces with SUPER CLEANER FOR

JOINT FACES (see Vehicle: Parts and consum-

ables for the repair) (04B, Consumables - Prod-

ucts) to dissolve any part of the seal still adhering.aApply the product to the areas to be cleaned, wait

about 10 minutes, then remove the residue using a

wooden spatula.

aApply one to two drops of FRENETANCHE (see

Vehicle: Parts and consumables for the repair)

(04B, Consumables - Products) on the coolant pump

bolts before refitting.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-a new seal on the coolant pump,

-the coolant pump,

-the coolant pump bolts.

102262

WARNING

Do not scrape the joint faces of the aluminium,

any damage caused to the joint face will result in

a risk of leaks.

IMPORTANT

Wear goggles with side protectors for this opera-

tion.

IMPORTANT

Wear protective gloves during the operation.

WARNING

The joint faces must be clean, dr y and free from

grease (avoid finger marks).