sensor RENAULT TWINGO 2009 2.G Engine And Peripherals Repair Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 652

Page 255 of 652

11A-138

TOP AND FRONT OF ENGINE

Camshaft seal, timing end: Removal - Refitting

K9K

11A

PARTS AND CONSUMABLES FOR THE

REPAIR WORK

aParts always to be replaced:

-the timing end camshaft seal,

-the timing end camshaft stud,

aConsumables (see Vehicle: Parts and consuma-

bles for the repair) (MR 411, 04B, Consumables -

Products):

-SURFACE CLEANER.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (see MR 411, 02A, Lifting

equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (see MR 411, 80A, Battery).

aRemove:

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (MR 411, 85A, Wip-

ers - Washers),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (MR 412, 56A, Exterior

equipment),-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (MR 412, 56A, Exterior equipment),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (MR 411, 35A, Wheels and tyres),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (MR 412,

55A, Exterior protection),

-the front bumper (see Front bumper: Removal -

Refitting) (MR 412, 55A, Exterior protection),

-the halogen headlights (see Halogen headlight:

Removal - Refitting) (MR 411, 80B, Halogen

headlights),

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (MR 412,

42A, Upper front structure),

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the crankshaft accessories pulley (see 11A, Top

and front of engine, Crankshaft accessories

pulley: Removal - Refitting, page 11A-20) ,

-the camshaft position sensor (see 13B, Diesel in-

jection, Camshaft position sensor: Removal -

Refitting, page 13B-14) ,

-the timing belt (see 11A, Top and front of engine,

Timing belt: Removal - Refitting, page 11A-27) . Special tooling required

Mot. 1606High pressure pump pulley

support tool.

Mot. 1632Tool for fitting camshaft PTFE

seal

Mot. 799-01Timing gear wheel immobil-

iser.

Equipment required

roller-type stud removal tool

cylinder head bolt tightening gauge (angular mea-

suring type)

Tightening torquesm

camshaft hub nut30 Nm + 86˚ ±± ± ±

6˚

Page 257 of 652

11A-140

TOP AND FRONT OF ENGINE

Camshaft seal, timing end: Removal - Refitting

K9K

11A

III - FINAL OPERATION.

aRefit:

-the camshaft pulley hub,

-the camshaft pulley hub nut, locking it using the

(Mot. 799-01).

aTorque and angle tighten using a cylinder head

bolt tightening gauge (angular measuring type)

the camshaft hub nut ( 30 Nm + 86˚ ±± ± ±

6˚).

aRefit the camshaft pulley wheel.

aFit the camshaft pulley wheel bolts, without tighten-

ing them.

aRefit:

-the timing belt (see 11A, Top and front of engine,

Timing belt: Removal - Refitting, page 11A-27) ,

-the camshaft position sensor (see 13B, Diesel in-

jection, Camshaft position sensor: Removal -

Refitting, page 13B-14) ,

-the crankshaft accessories pulley (see 11A, Top

and front of engine, Crankshaft accessories

pulley: Removal - Refitting, page 11A-20) ,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (MR 412,

42A, Upper front structure),

-the halogen headlights (see Halogen headlight:

Removal - Refitting) (MR 411, 80B, Halogen

headlights),

-the front bumper (see Front bumper: Removal -

Refitting) (MR 412, 55A, Exterior protection),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (MR 412,

55A, Exterior protection),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (MR 411, 35A, Wheels and tyres),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (MR 412, 56A, Exterior equipment),-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (MR 412, 56A, Exterior

equipment),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (MR 411, 85A, Wip-

ers - Washers).

aConnect the battery (see Battery: Removal - Refit-

ting) (see MR 411, 80A, Battery).

Page 279 of 652

12A-14

FUEL MIXTURE

Air filter unit: Removal - Refitting

K9K

12A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove the front engine cover.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aUnclip:

-the air filter air inlet pipe (1) on the vehicle,

-the air filter air inlet pipe from the air filter unit.

aRemove the air filter air inlet pipe.aUnclip the air filter box harnesses.

aDisconnect the connectors:

-from the air inlet temperature sensor downstream

of the turbocharger (3) ,

-the turbocharger pressure sensor (4) ,

-from the air inlet temperature sensor upstream of

the turbocharger (5) ,

-from the EGR (6) .

aRemove the bolt (7) from the turbocharger pressure

sensor on the air filter box.

aMove aside the turbocharger pressure sensor.

aLoosen the clip at the inlet of the air filter outlet air

pipe.

aUnclip the air filter outlet air pipe from the air filter

box.

aRaise the cover of the air filter box to remove it from

its mountings.

aSlide the air filter box towards the timing end.

aRemove the air filter box.

120038

Note:

Make sure you do not break the pins (2) .

120039

Page 280 of 652

12A-15

FUEL MIXTURE

Air filter unit: Removal - Refitting

K9K

12A

REMOVAL

I - REFITTING OPERATION FOR PART

CONCERNED

aSlide the air filter box towards the gearbox side.

aCheck the condition of the air filter box mountings,

replace them if necessary.

aClip:

-the air filter box onto its mountings,

-the air filter air outlet pipe to the air filter.

aTighten the air pipe clip on the air filter outlet.

aRefit the air filter air inlet pipe on the vehicle.

aPosition the turbocharger pressure sensor on the air

filter box.

aRefit the bolt mounting the turbocharger pressure

sensor on the air filter box.

aConnect the connectors:

-of the inlet air temperature sensor,

-of the turbocharging pressure sensor,

-of the flow sensor,

-of the EGR.

aClip on the air filter box harnesses.

aClip the air filter inlet air pipe to the air filter box.

II - FINAL OPERATION.

aRefit the engine cover.Note:

Ensure that the centring lug of the box is fully

inserted in the cylinder head.

Page 282 of 652

12A-17

FUEL MIXTURE

Air filter unit: Removal - Refitting

D4F, and 780 or 782

12A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the air inlet pipe from the air filter unit (1)

.

aMove aside the air inlet pipe from the air filter unit.

aUnclip the wiring (2) from the oxygen sensor up-

stream of the air filter unit.

aRemove the bolts (3) from the air filter unit.

aLoosen the clip (4) on the air filter unit air outlet pipe

by gently moving it away from the air filter unit.

aDisconnect the air filter unit air outlet pipe from the

air filter unit.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the air filter unit.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit the air filter unit.II - FINAL OPERATION

aConnect the air filter unit air outlet pipe to the air filter

unit.

aTighten the clip of the air filter unit air outlet pipe on

the air filter unit.

aRefit the air filter unit bolts.

aClip the upstream oxygen sensor wiring onto the air

filter unit.

aRefit the air filter unit air inlet pipe.

122395

Note:

Position the air filter unit centring pin in the slot

provided for it.

Page 295 of 652

12A-30

FUEL MIXTURE

Inlet distributor: Removal - Refitting

D7F

12A

aDisconnect the spark plug high voltage wiring har-

ness (2) .

aMove aside the spark plug high voltage wiring har-

ness.

aDisconnect:

-the petrol vapour rebreather pipe from the inlet dis-

tributor (3) ,

-the non-return valve pipe on the inlet distributor (4)

,

-the air inlet pressure sensor connector (5) ,

-the air temperature sensor connector (6) ,

-the injector connector (7) ,-the fuel supply pipe intermediate union (8) ,

-the oil vapour rebreathing pipe from the inlet dis-

tributor.

aRemove the dipstick.

aRemove:

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the alternator upper bolt.

aTilt the alternator forward.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the nuts from the air inlet distributor on the

cylinder head.

121737

IMPORTANT

During this operation, be sure to:

-refrain from smoking or bringing red hot objects

close to the working area,

-be careful of fuel splashes when disconnecting

the union.

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

IMPORTANT

Wear latex gloves during the operation.

AIR CONDITIONING

121734

Page 296 of 652

12A-31

FUEL MIXTURE

Inlet distributor: Removal - Refitting

D7F

12A

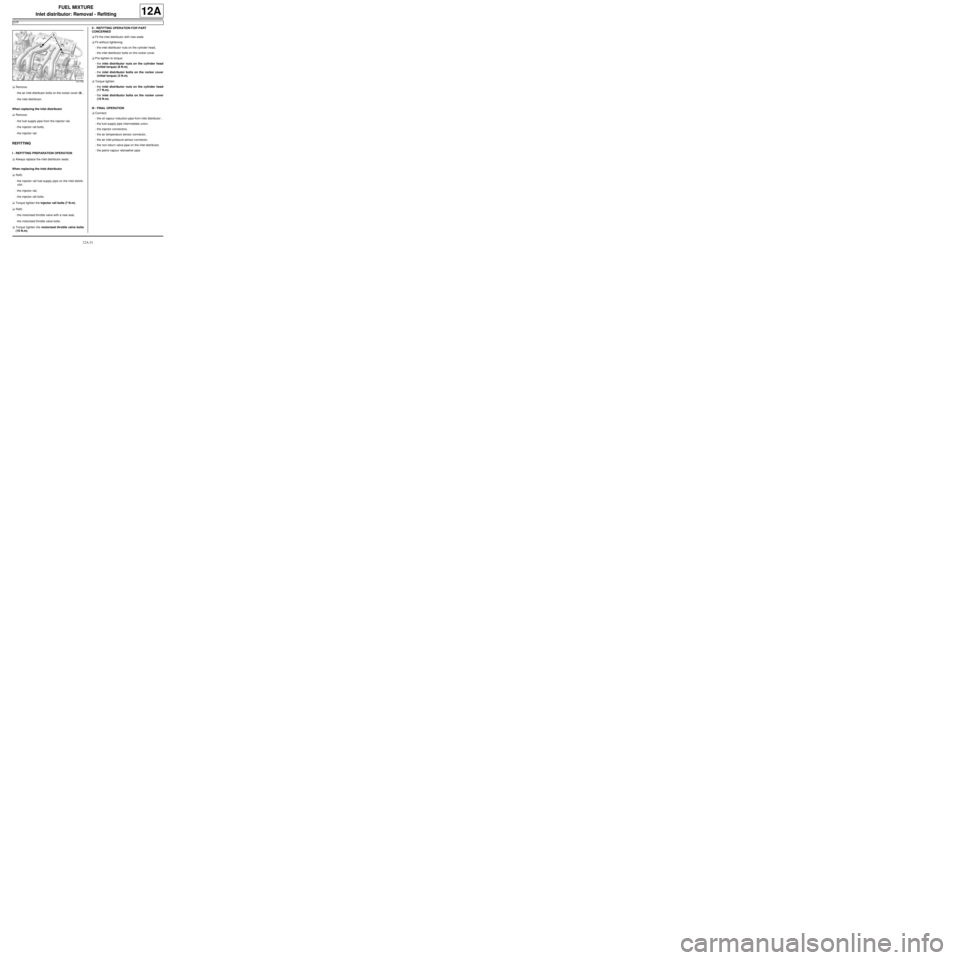

aRemove:

-the air inlet distributor bolts on the rocker cover (9) ,

-the inlet distributor.

When replacing the inlet distributor

aRemove:

-the fuel supply pipe from the injector rail,

-the injector rail bolts,

-the injector rail.

REFITTING

I - REFITTING PREPARATION OPERATION

aAlways replace the inlet distributor seals.

When replacing the inlet distributor

aRefit:

-the injector rail fuel supply pipe on the inlet distrib-

utor,

-the injector rail,

-the injector rail bolts.

aTorque tighten the injector rail bolts (7 N.m).

aRefit:

-the motorised throttle valve with a new seal,

-the motorised throttle valve bolts.

aTorque tighten the motorised throttle valve bolts

(10 N.m).II - REFITTING OPERATION FOR PART

CONCERNED

aFit the inlet distributor with new seals

aFit without tightening:

-the inlet distributor nuts on the cylinder head,

-the inlet distributor bolts on the rocker cover.

aPre-tighten to torque:

-the inlet distributor nuts on the cylinder head

(initial torque) (8 N.m),

-the inlet distributor bolts on the rocker cover

(initial torque) (3 N.m).

aTorque tighten:

-the inlet distributor nuts on the cylinder head

(17 N.m),

-the inlet distributor bolts on the rocker cover

(10 N.m).

III - FINAL OPERATION

aConnect:

-the oil vapour induction pipe from inlet distributor ,

-the fuel supply pipe intermediate union,

-the injector connectors,

-the air temperature sensor connector,

-the air inlet pressure sensor connector,

-the non-return valve pipe on the inlet distributor,

-the petrol vapour rebreather pipe.

121735

Page 299 of 652

12A-34

FUEL MIXTURE

Inlet distributor: Removal - Refitting

D4F, and 772

12A

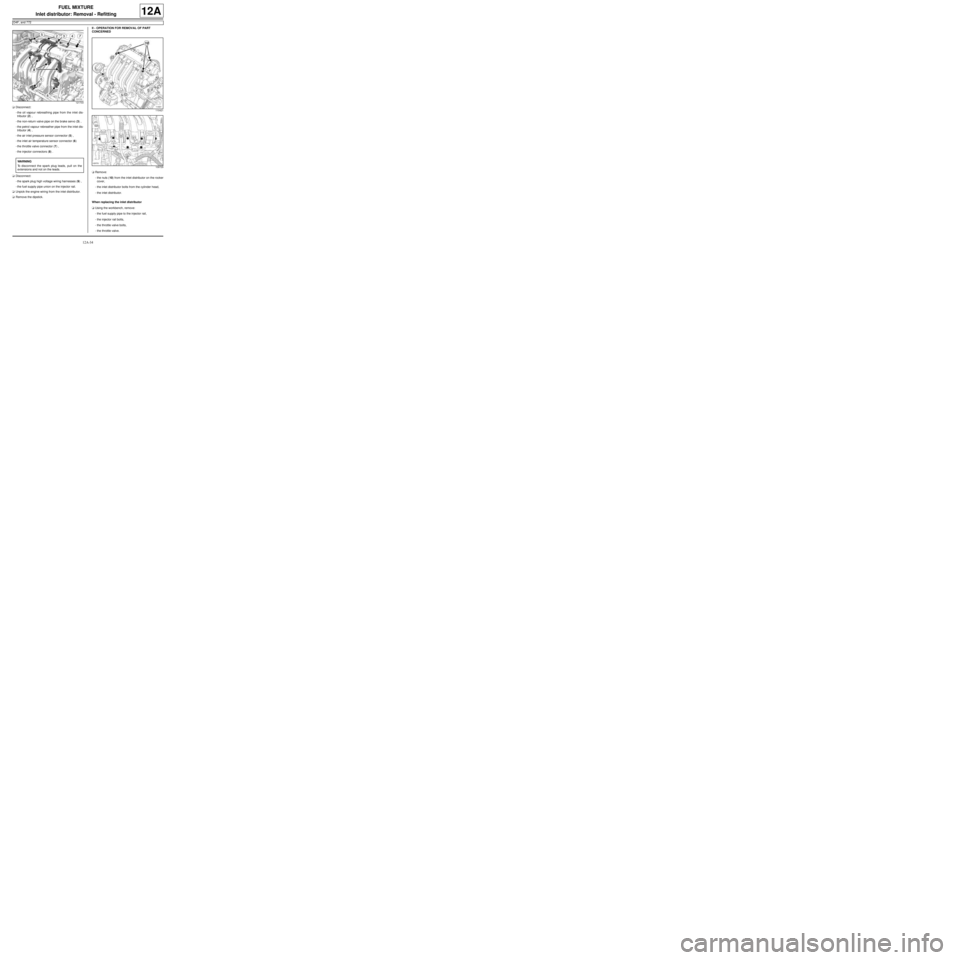

aDisconnect:

-the oil vapour rebreathing pipe from the inlet dis-

tributor (2) ,

-the non-return valve pipe on the brake servo (3) ,

-the petrol vapour rebreather pipe from the inlet dis-

tributor (4) ,

-the air inlet pressure sensor connector (5) ,

-the inlet air temperature sensor connector (6)

-the throttle valve connector (7) ,

-the injector connectors (8) .

aDisconnect:

-the spark plug high voltage wiring harnesses (9) ,

-the fuel supply pipe union on the injector rail.

aUnpick the engine wiring from the inlet distributor.

aRemove the dipstick.II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the nuts (10) from the inlet distributor on the rocker

cover,

-the inlet distributor bolts from the cylinder head,

-the inlet distributor.

When replacing the inlet distributor

aUsing the workbench, remove:

-the fuel supply pipe to the injector rail,

-the injector rail bolts,

-the throttle valve bolts,

-the throttle valve.

121733

WARNING

To disconnect the spark plug leads, pull on the

extensions and not on the leads.

110421

109729

Page 301 of 652

12A-36

FUEL MIXTURE

Inlet distributor: Removal - Refitting

D4F, and 772

12A

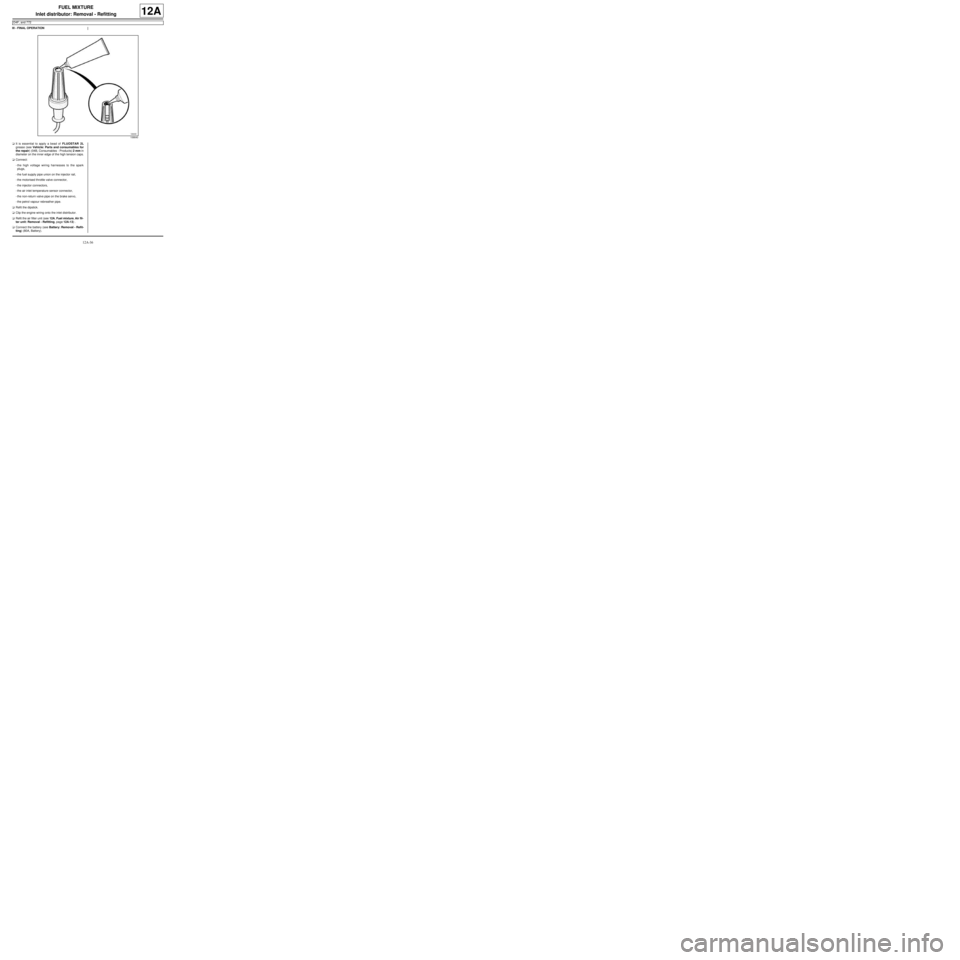

III - FINAL OPERATION

aIt is essential to apply a bead of FLUOSTAR 2L

grease (see Vehicle: Parts and consumables for

the repair) (04B, Consumables - Products) 2 mm in

diameter on the inner edge of the high tension caps.

aConnect:

-the high voltage wiring harnesses to the spark

plugs,

-the fuel supply pipe union on the injector rail,

-the motorised throttle valve connector,

-the injector connectors,

-the air inlet temperature sensor connector,

-the non-return valve pipe on the brake servo,

-the petrol vapour rebreather pipe.

aRefit the dipstick.

aClip the engine wiring onto the inlet distributor.

aRefit the air filter unit (see 12A, Fuel mixture, Air fil-

ter unit: Removal - Refitting, page 12A-13) .

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

106640

Page 302 of 652

12A-37

FUEL MIXTURE

Inlet distributor: Removal - Refitting

D4F, and 780 or 782

12A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove the throttle valve (see 12A, Fuel mixture,

Throttle valve: Removal - Refitting, page 12A-20)

.aRemove:

-the engine oil filler neck bolt (1) ,

-the engine oil filler neck in the direction of the arrow

(2) .

aDisconnect the inlet distributor pressure sensor (3) .

aRemove:

-the inlet distributor pressure sensor bolts (4) ,

-the pressure sensor. Tightening torquesm

inlet distributor bolts (ini-

tial torque)4 N.m

inlet distributor bolts12 N.m

IMPORTANT

During this oper ation, be sure to:

-refrain from smoking or bringing red hot objects

close to the working area,

-be careful of fuel splashes when disconnecting the

union.

IMPORTANT

Wear leaktight gloves (Nitrile type) for this opera-

tion.

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

IMPORTANT

Wear goggles with side protectors for this opera-

tion.

122392

122393