climate control RENAULT TWINGO 2009 2.G Heating And Air Conditioning - Heating Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 29

Page 19 of 29

61A-19

MR-413-X44-61A000$875_eng.mif

V1

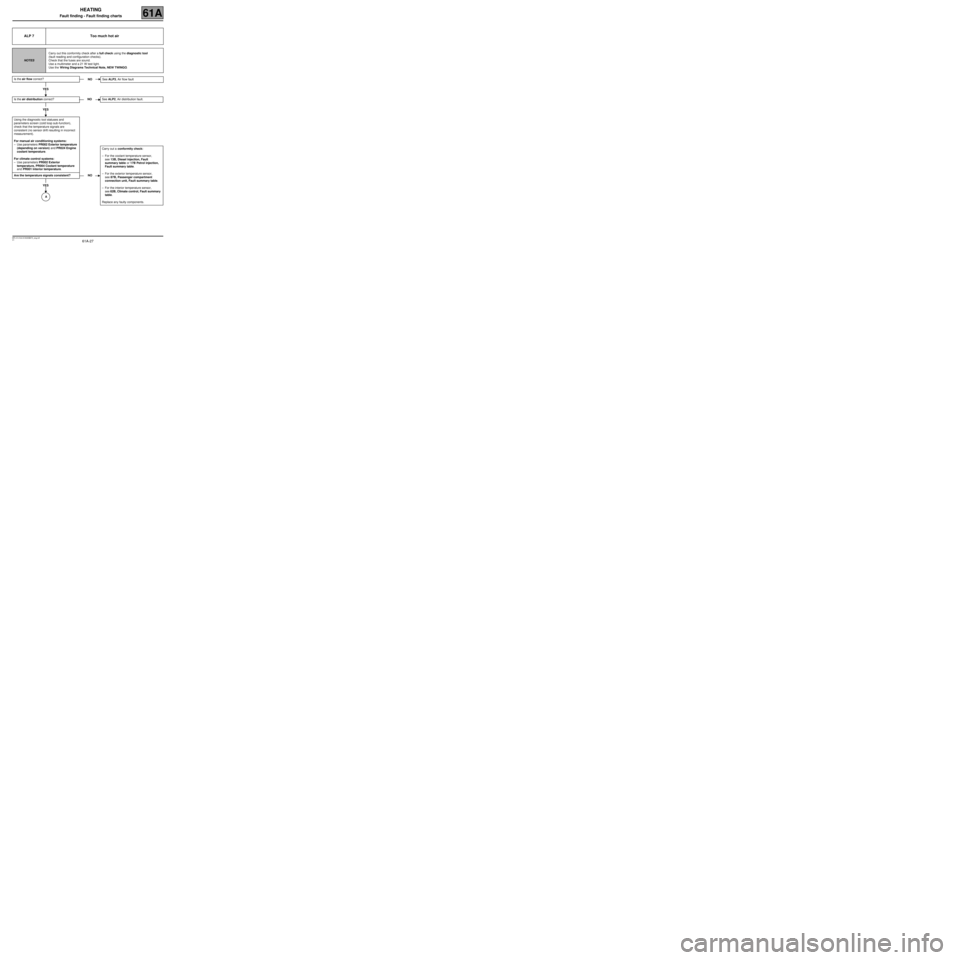

61A

HEATING

Fault finding - Fault finding charts

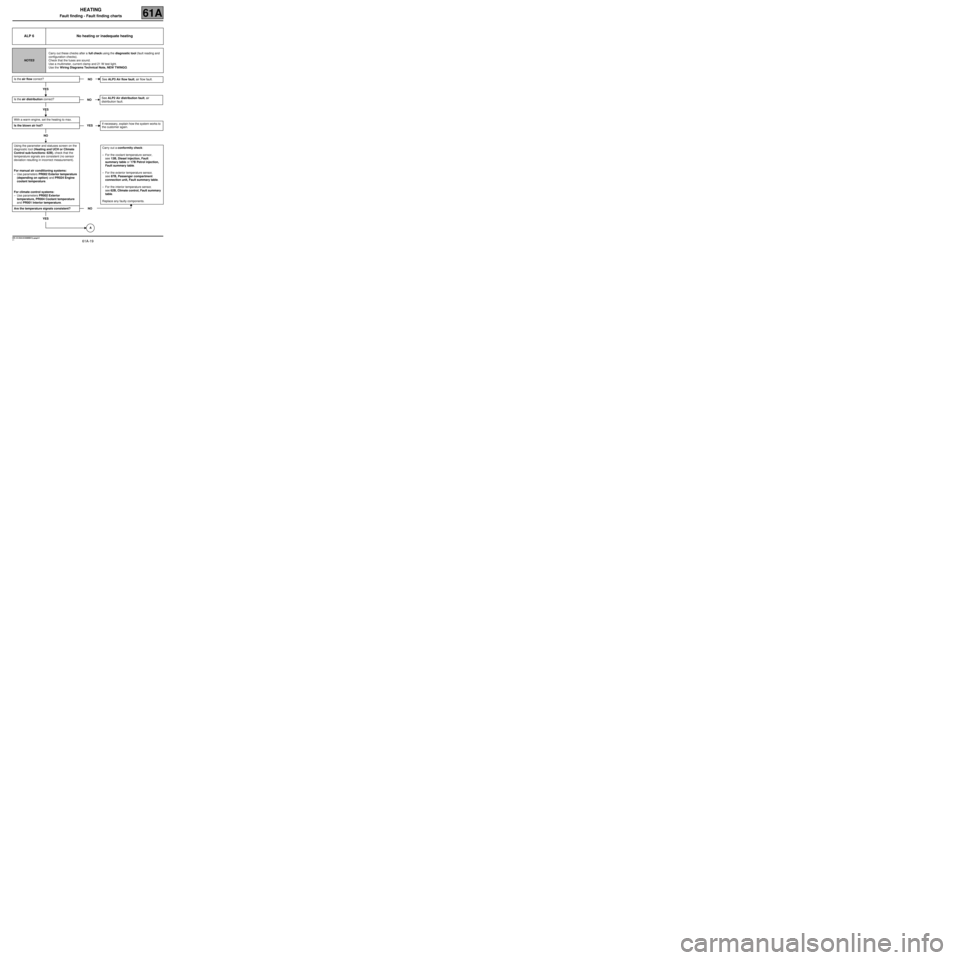

ALP 6 No heating or inadequate heating

NOTESCarry out these checks after a full check using the diagnostic tool (fault reading and

configuration checks).

Check that the fuses are sound.

Use a multimeter, current clamp and 21 W test light.

Use the Wiring Diagrams Technical Note, NEW TWINGO.

Is the air flow correct?

YES

Is the air distribution correct?

YES

With a warm engine, set the heating to max.

Is the blown air hot?

NO

Using the parameter and statuses screen on the

diagnostic tool (Heating and UCH or Climate

Control sub-functions: 62B), check that the

temperature signals are consistent (no sensor

deviation resulting in incorrect measurement).

For manual air conditioning systems:

–Use parameters PR002 Exterior temperature

(depending on option) and PR024 Engine

coolant temperature.

For climate control systems:

–Use parameters PR002 Exterior

temperature, PR004 Coolant temperature

and PR001 Interior temperature.

Are the temperature signals consistent?

YES

NOSee ALP3 Air flow fault, air flow fault.

NOSee ALP2 Air distribution fault, air

distribution fault.

YESIf necessary, explain how the system works to

the customer again.

Carry out a conformity check:

–For the coolant temperature sensor,

see 13B, Diesel injection, Fault

summary table or 17B Petrol injection,

Fault summary table.

–For the exterior temperature sensor,

see 87B, Passenger compartment

connection unit, Fault summary table.

–For the interior temperature sensor,

see 62B, Climate control, Fault summary

table.

Replace any faulty components.

NO

A

MR-413-X44-61A000$875_eng.mif

Page 20 of 29

61A-20

MR-413-X44-61A000$875_eng.mif

V1

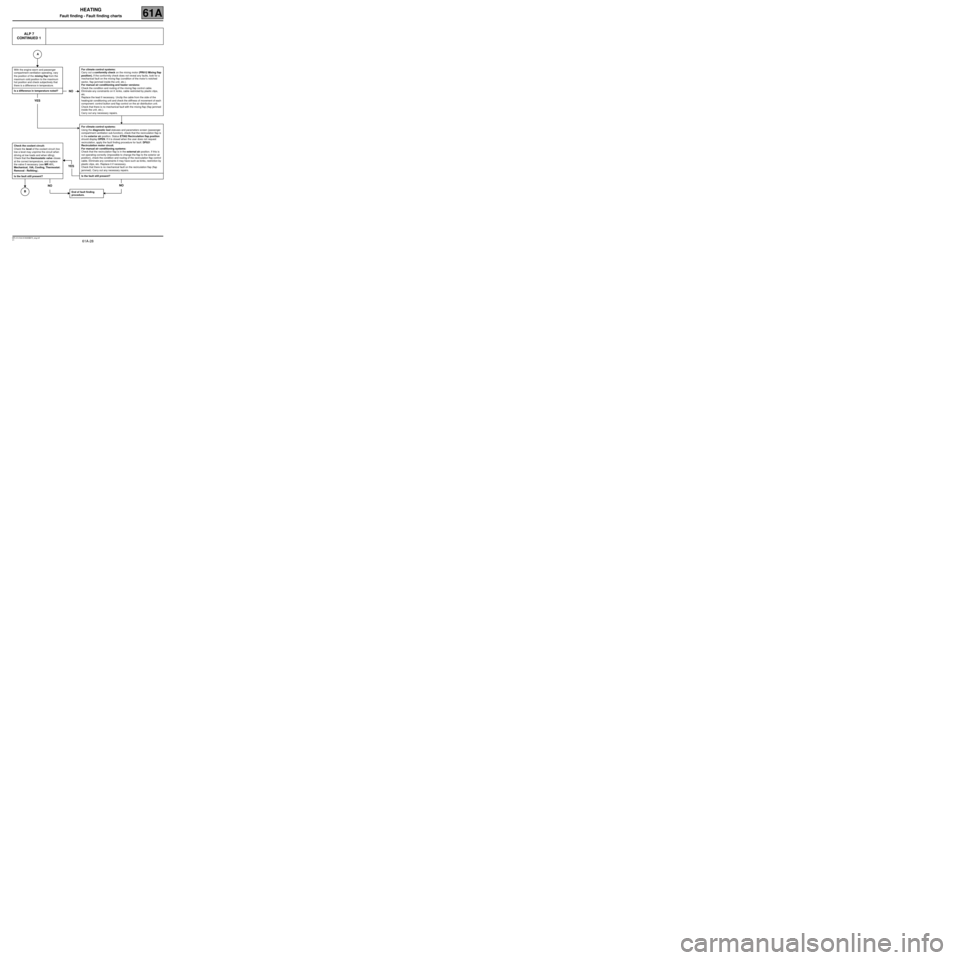

HEATING

Fault finding - Fault finding charts61A

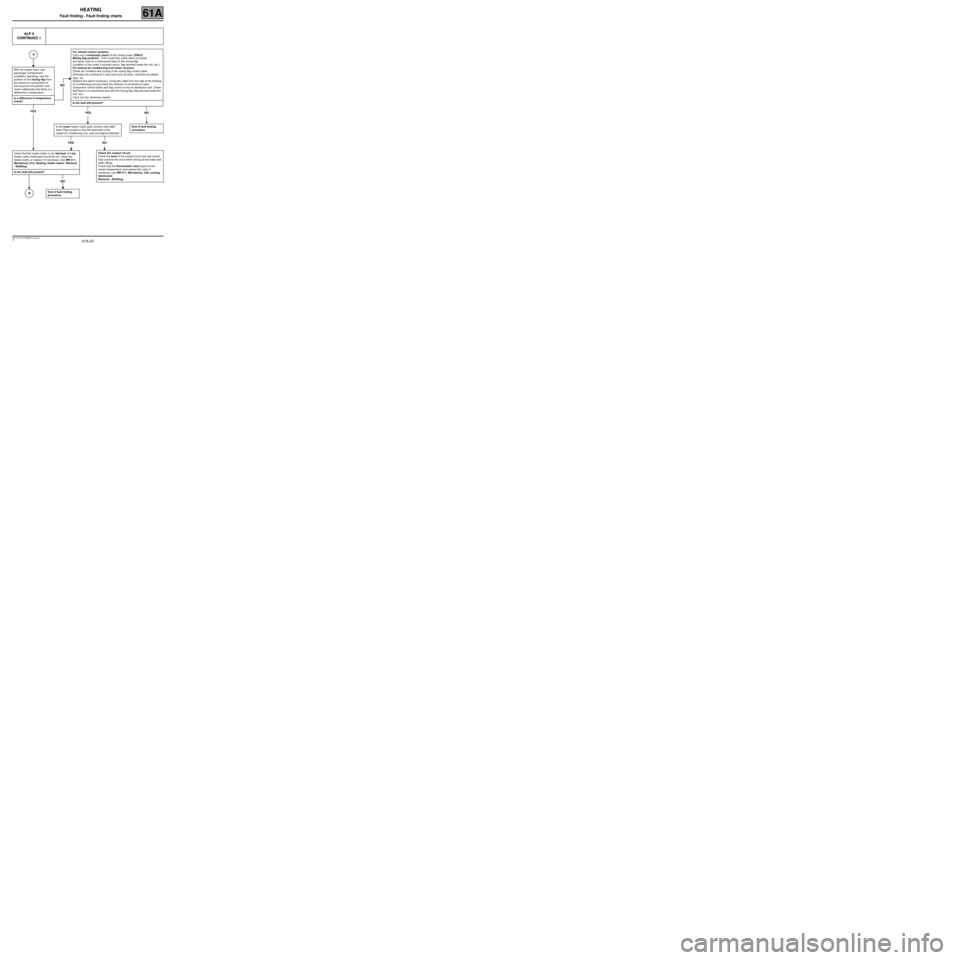

ALP 6

CONTINUED 1

With the engine warm and

passenger compartment

ventilation operating, vary the

position of the mixing flap from

the maximum cold position to

the maximum hot position and

check subjectively that there is a

dif ference in temperature.

Is a difference in temperature

noted?

YES

NO

For climate control systems:

Carry out a conformity check on the mixing motor (PR012

Mixing flap position). If the conformity check does not reveal

any faults, look for a mechanical fault on the mixing flap

(condition of the motor ’s notched sector, flap jammed inside the unit, etc.).

For manual air conditioning and heater versions:

Check the condition and routing of the mixing flap control cable.

Eliminate any constraints it may have such as kinks, restriction by plastic

clips, etc.

Replace the lead if necessary. Unclip the cable from the side of the heating/

air conditioning unit and check the stiffness of movement of each

component: control button and flap control on the air distribution unit. Check

that there is no mechanical fault with the mixing flap (flap jammed inside the

unit, etc.).

Carry out any necessary repairs.

Is the fault still present?

YES NO

Is the lower heater matrix pipe (coolant inlet) hot?

Note: Pipe located on the left-hand side of the

heater-air conditioning unit, near the engine bulkhead.

YES NO

End of fault finding

procedure.

Check that the heater matrix is not blocked: the top

heater matrix outlet pipe should be hot. Clean the

heater matrix or replace it if necessary (see MR 411,

Mechanical, 61A, Heating, Heater matrix: Removal

- Refitting).

Is the fault still present?

NO

Check the coolant circuit:

Check the level of the coolant circuit (too low a level

may unprime the circuit when driving at low loads and

when idling).

Check that the thermostatic valve opens at the

correct temperature, and replace the valve if

necessary (see MR 411, Mechanical, 19A, cooling,

thermostat:

Removal - Refitting).

End of fault finding

procedure.

A

B

Page 21 of 29

61A-21

MR-413-X44-61A000$875_eng.mif

V1

HEATING

Fault finding - Fault finding charts61A

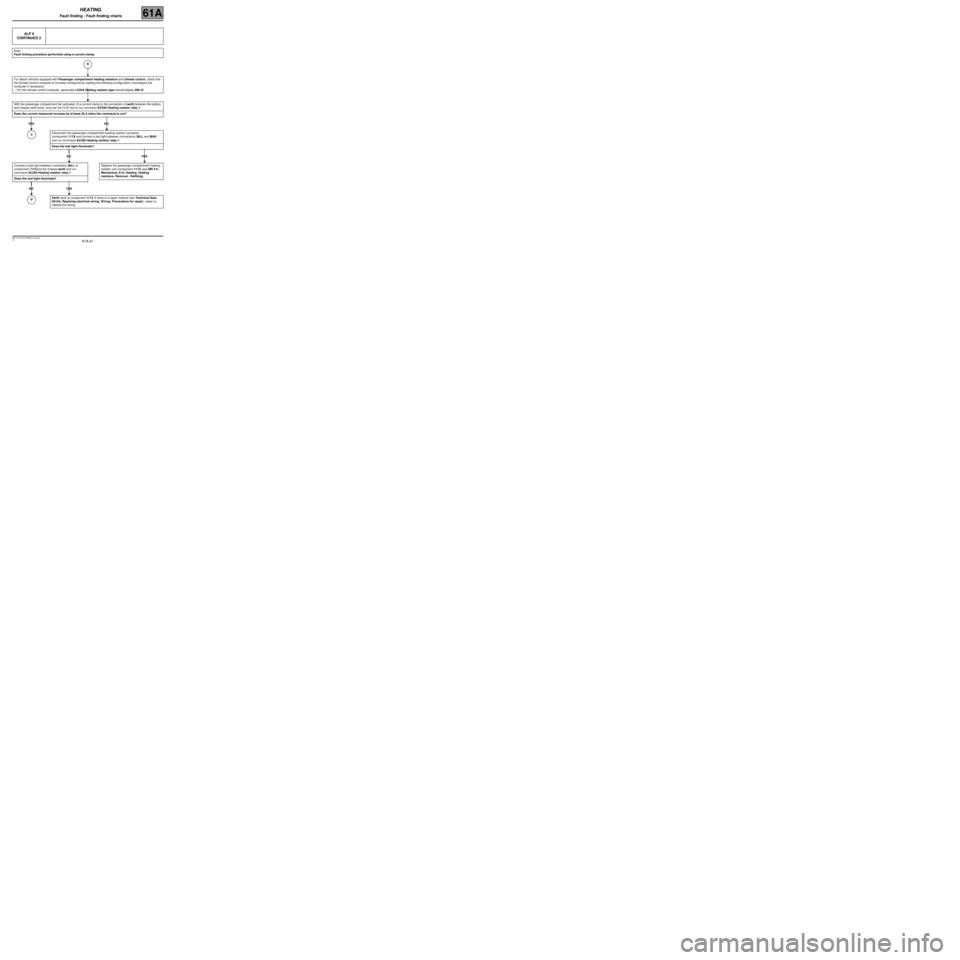

ALP 6

CONTINUED 2

Note:

Fault finding procedure performed using a current clamp.

For diesel vehicles equipped with Passenger compartment heating resistors and climate control, check that

the climate control computer is correctly configured by reading the following configuration (reconfigure the

computer if necessary):

–For the climate control computer, parameter LC044 Heating resistor type should display 900 W.

With the passenger compartment fan activated, fit a current clamp to the connection of earth between the battery

and chassis earth point, and use the CLIP tool to run command AC250 Heating resistor relay 1.

Does the current measured increase by at least 20 A when the command is run?

YES NO

Connect a test light between connection 38LL of

component 1113 and the chassis earth and run

command AC250 Heating resistor relay 1.

Does the test light illuminate?

NO YES

Disconnect the passenger compartment heating resistor connector

(component 1113) and connect a test light between connections 38LL and MAK

and run command AC250 Heating resistor relay 1.

Does the test light illuminate?

NO YES

Replace the passenger compartment heating

resistor unit (component 1113) (see MR 411,

Mechanical, 61A, Heating, Heating

resistors: Removal - Refitting).

Earth fault on component 1113. If there is a repair method (see Technical Note

6015A, Repairing electrical wiring, W iring: Precautions for repair), repair or

replace the wiring.

B

C

D

Page 24 of 29

61A-24

MR-413-X44-61A000$875_eng.mif

V1

HEATING

Fault finding - Fault finding charts61A

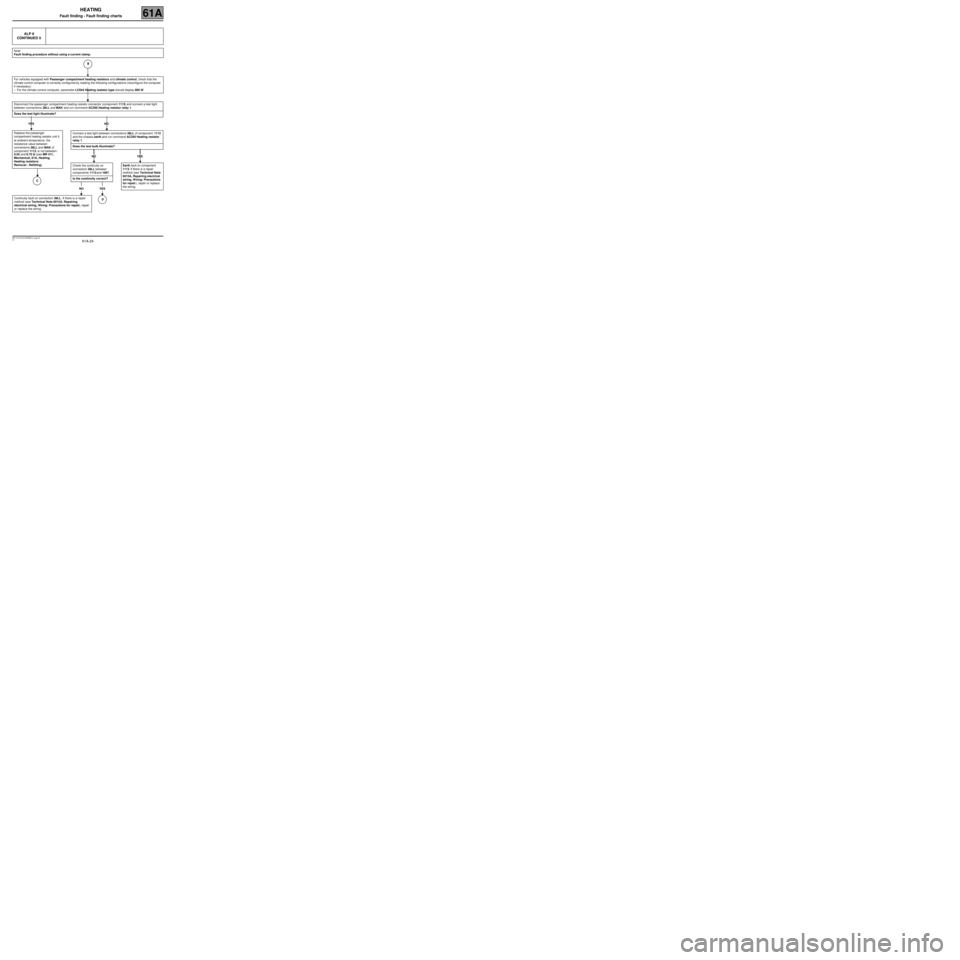

ALP 6

CONTINUED 5

Note:

Fault finding procedure without using a current clamp.

For vehicles equipped with Passenger compartment heating resistors and climate control, check that the

climate control computer is correctly configured by reading the following configurations (reconfigure the computer

if necessary):

–For the climate control computer, parameter LC044 Heating resistor type should display 900 W.

Disconnect the passenger compartment heating resistor connector (component 1113) and connect a test light

between connections 38LL and MAK and run command AC250 Heating resistor relay 1.

Does the test light illuminate?

YES NO

Replace the passenger

compartment heating resistor unit if,

at ambient temperature, the

resistance value between

connections 38LL and MAK of

component 1113, is not between:

0.55 and 0.75 ΩΩ Ω Ω

(see MR 411,

Mechanical, 61A, Heating,

Heating resistors:

Removal - Refitting).

Connect a test light between connections 38LL of component 1113

and the chassis earth and run command AC250 Heating resistor

relay 1.

Does the test bulb illuminate?

NO YES

Earth fault on component

1113. If there is a repair

method (see Technical Note

6015A, Repairing electrical

wiring, Wiring: Precautions

for repair), repair or replace

the wiring.

B

Check the continuity on

connection 38LL between

components 1113 and 1067.

Is the continuity correct?

NO YES

Continuity fault on connection 38LL. If there is a repair

method (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair

or replace the wiring.D

C

Page 27 of 29

61A-27

MR-413-X44-61A000$875_eng.mif

V1

HEATING

Fault finding - Fault finding charts61A

ALP 7 Too much hot air

NOTESCarry out this conformity check after a full check using the diagnostic tool

(fault reading and configuration checks).

Check that the fuses are sound.

Use a multimeter and a 21 W test light.

Use the Wiring Diagrams Technical Note, NEW TWINGO.

Is the air flow correct?

YES

Is the air distribution correct?

YES

Using the diagnostic tool statuses and

parameters screen (cold loop sub-function),

check that the temperature signals are

consistent (no sensor drift resulting in incorrect

measurement).

For manual air conditioning systems:

–Use parameters PR002 Exterior temperature

(depending on version) and PR024 Engine

coolant temperature.

For climate control systems:

–Use parameters PR002 Exterior

temperature, PR004 Coolant temperature

and PR001 Interior temperature.

Are the temperature signals consistent?

YES

NOSee ALP3, Air flow fault

NOSee ALP2, Air distribution fault.

NOCarry out a conformity check:

–For the coolant temperature sensor,

see 13B, Diesel injection, Fault

summary table or 17B Petrol injection,

Fault summary table.

–For the exterior temperature sensor,

see 87B, Passenger compartment

connection unit, Fault summary table.

–For the interior temperature sensor,

see 62B, Climate control, Fault summary

table.

Replace any faulty components.

A

Page 28 of 29

61A-28

MR-413-X44-61A000$875_eng.mif

V1

HEATING

Fault finding - Fault finding charts61A

ALP 7

CONTINUED 1

With the engine warm and passenger

compartment ventilation operating, vary

the position of the mixing flap from the

maximum cold position to the maximum

hot position and check subjectively that

there is a difference in temperature.

Is a difference in temperature noted?

YES

NO

For climate control systems:

Carry out a conformity check on the mixing motor (PR012 Mixing flap

position). If the conformity check does not reveal any faults, look for a

mechanical fault on the mixing flap (condition of the motor’s notched

sector, flap jammed inside the unit, etc.).

For manual air conditioning and heater versions:

Check the condition and routing of the mixing flap control cable.

Eliminate any constraints on it: kinks, cable restricted by plastic clips,

etc.

Replace the lead if necessary. Unclip the cable from the side of the

heating/air conditioning unit and check the stiffness of movement of each

component: control button and flap control on the air distribution unit.

Check that there is no mechanical fault with the mixing flap (flap jammed

inside the unit, etc.).

Carry out any necessary repairs.

YES

For climate control systems:

Using the diagnostic tool statuses and parameters screen (passenger

compartment ventilation sub-function), check that the recirculation flap is

in the exterior air position. Status ET062 Recirculation flap position

should display OPEN. If it is closed when the user does not request

recirculation, apply the fault finding procedure for fault: DF021

Recirculation motor circuit.

For manual air conditioning systems:

Check that the recirculation flap is in the external air position. If this is

not operating correctly (impossible to change the flap to the exterior air

position), check the condition and routing of the recirculation flap control

cable. Eliminate any constraints it may have such as kinks, restriction by

plastic clips, etc. Replace it if necessary.

Check that there is no mechanical fault on the recirculation flap (flap

jammed). Carry out any necessary repairs.

Is the fault still present?

NO

End of fault finding

procedure.

Check the coolant circuit:

Check the level of the coolant circuit (too

low a level may unprime the circuit when

driving at low loads and when idling).

Check that the thermostatic valve closes

at the correct temperature, and replace

the valve if necessary (see MR 411,

Mechanical, 19A, Cooling, Thermostat:

Removal - Refitting).

Is the fault still present?

NO

A

B