ABS RENAULT TWINGO 2009 2.G Heating And Air Conditioning - Manual Air Conditioning Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 63

Page 5 of 63

62C-5

MR-413-X44-62C000$091_eng.mif

V1

MANUAL AIR CONDITIONING

Fault finding - Introduction62C

4. FAULT FINDING PROCEDURE (CONTINUED)

Wiring check

Fault finding problems

Disconnecting the connectors and/or manipulating the wiring harness may temporarily remove the cause of a fault.

Electrical measurements of voltage, resistance and insulation are generally correct, especially if the fault is not

present when the analysis is made (stored fault).

Visual inspection of the connection:

●Check that the connector is connected correctly and that the male and female parts of the connection are

correctly coupled.

Visual inspection of the area around the connection:

●Check the condition of the mounting (pin, strap, adhesive tape, etc.) if the connectors are attached to the

vehicle.

●Check that there is no damage to the wiring trim (sheath, foam, adhesive tape, etc.) near the wiring.

●Check that there is no damage to the electrical wires at the connector outputs, in particular on the

insulating material (wear, cuts, burns, etc.).

Disconnect the connector to continue the checks.

Visual inspection of the plastic casing:

●Check that there is no mechanical damage (casing crushed, cracked, broken, etc.), in particular to the

fragile components (lever, lock, openings, etc.).

●Check that there is no heat damage (casing melted, darker, deformed, etc.).

●Check that there are no stains (grease, mud, liquid, etc.).

Visual inspection of the metal contacts:

(The female contact is called CLIP. The male contact is called TAB.)

●Check that there are no bent contacts (the contact is not inserted correctly and can come out of the back

of the connector). The spring contact of the connector when the wire is gently pulled.

●Check that there is no damage (folded tabs, clips open too wide, blackened or melted contact, etc.).

●Check that there is no oxidation on the metal contacts. Note:

Carry out each requested check visually. Do not remove a connector if it is not required.

Note:

Repeated connections and disconnections alter the functionality of the connectors and increase the risk of poor

electrical contact. Limit the number of connections/disconnections as much as possible.

Note:

The check is carried out on the 2 parts of the connection. There may be two types of connections:

–Connector / Connector

–Connector / Device

Page 10 of 63

62C-10

MR-413-X44-62C000$273_eng.mif

V1

MANUAL AIR CONDITIONING

Fault finding - Role of components62C

–Condenser:

The condenser is composed of flat horizontal aluminium tubes. The pipes are divided by the vanes in order to

increase the air heat exchange and therefore cool the refrigerant fluid to produce condensation.

1Condenser

2Dehydration canister

–Dehydrator reservoir:

The dehydrator reservoir is used to:

●Check the condition of the refrigerant.

●Absorb the variations in volume (expansion bottle principle).

●Filter impurities.

●Absorb moisture (water in the circuit).

–Air conditioning unit:

This unit acts as an air mixing box. It is equipped with a system of flaps which allow the air to be directed in

accordance with the requirements of the occupants whilst simultaneously allowing the temperature of the air

entering the passenger compartment to be modified by mixing hot and cold air.

–Thermostatic expansion valve: (see figure below)

This thermostatic-type expansion valve is used to check refrigerant expansion. It is located at the evaporator inlet.

–Evaporator: (see figure below)

●The evaporator is a heat exchanger which enables the air entering the passenger compartment to be cooled.

Note: Condensation of the air may occur thereby causing normal drops of water to form under the body.

1

1Expansion valve

2Evaporator

Page 11 of 63

62C-11

MR-413-X44-62C000$273_eng.mif

V1

MANUAL AIR CONDITIONING

Fault finding - Role of components62C

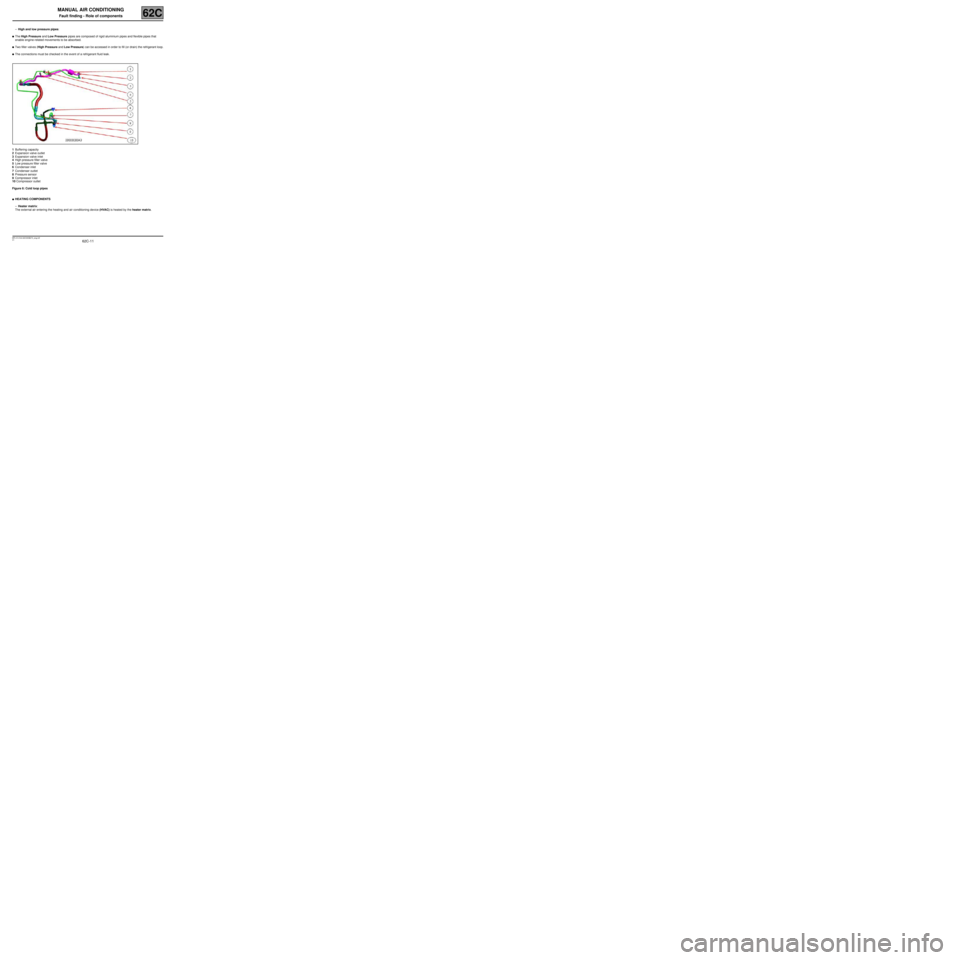

–High and low pressure pipes:

●The High Pressure and Low Pressure pipes are composed of rigid aluminium pipes and flexible pipes that

enable engine-related movements to be absorbed.

●Two filler valves (High Pressure and Low Pressure) can be accessed in order to fill (or drain) the refrigerant loop.

●The connections must be checked in the event of a refrigerant fluid leak.

1Buffering capacity

2Expansion valve outlet

3Expansion valve inlet

4High pressure filler valve

5Low pressure filler valve

6Condenser inlet

7Condenser outlet

8Pressure sensor

9Compressor inlet

10 Compressor outlet

Figure 6: Cold loop pipes

●HEATING COMPONENTS

–Heater matrix:

The external air entering the heating and air conditioning device (HVAC) is heated by the heater matrix.

Page 23 of 63

62C-23

MR-413-X44-62C000$637_eng.mif

V1

MANUAL AIR CONDITIONING

Fault finding - Conformity check62C

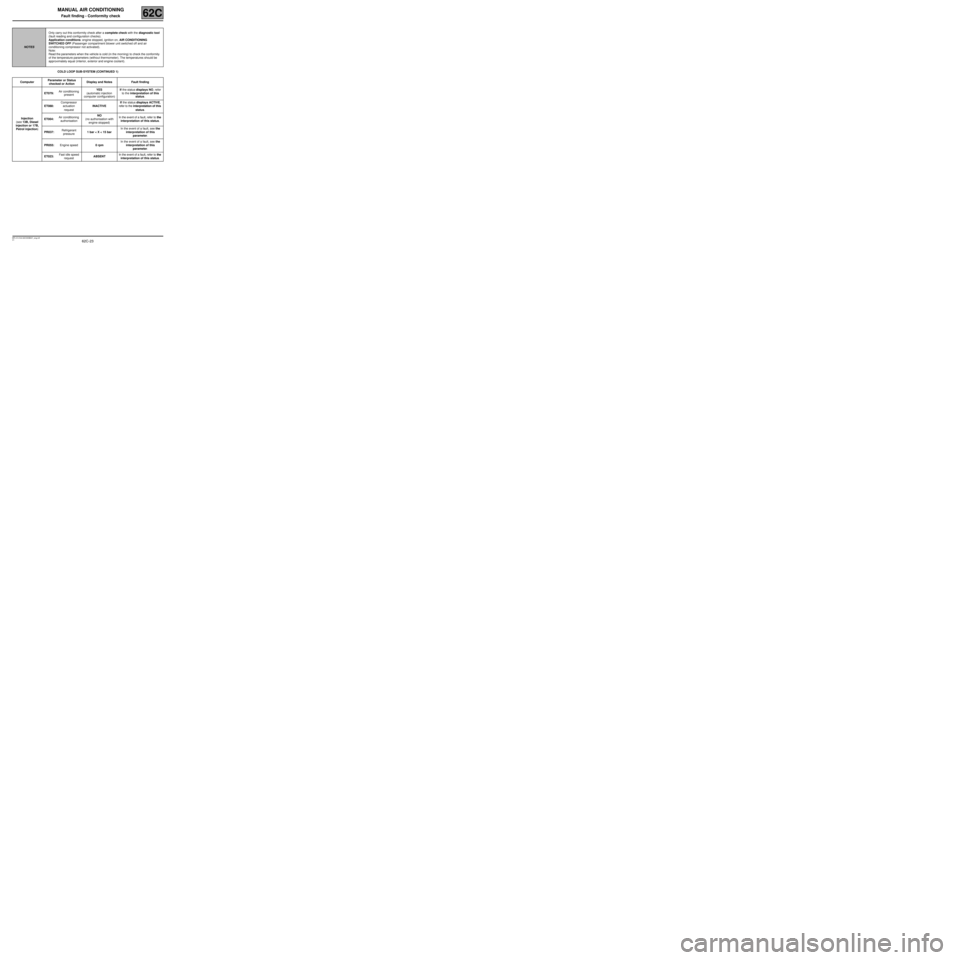

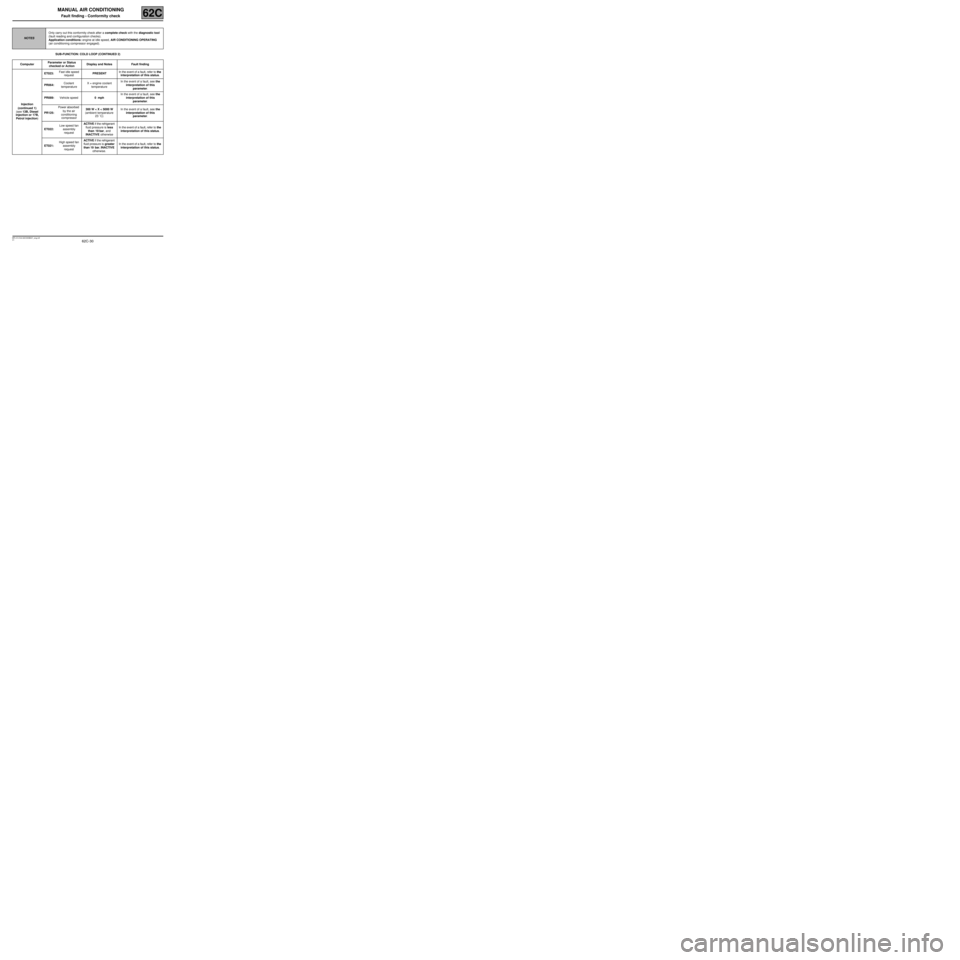

COLD LOOP SUB-SYSTEM (CONTINUED 1)

NOTESOnly carry out this conformity check after a complete check with the diagnostic tool

(fault reading and configuration checks).

Application conditions: engine stopped, ignition on, AIR CONDITIONING

SWITCHED OFF (Passenger compartment blower unit switched off and air

conditioning compressor not activated).

Note:

Read the parameters when the vehicle is cold (in the morning) to check the conformity

of the temperature parameters (without thermometer). The temperatures should be

approximately equal (interior, exterior and engine coolant).

ComputerParameter or Status

checked or ActionDisplay and Notes Fault finding

Injection

(see 13B, Diesel

injection or 17B,

Petrol injection)ET079:Air conditioning

presentYES

(automatic injection

computer configuration)If the status displays NO, refer

to the interpretation of this

status.

ET088:Compressor

actuation

requestINACTIVEIf the status displays ACTIVE,

refer to the interpretation of this

status.

ET004:Air conditioning

authorisationNO

(no authorisation with

engine stopped)In the event of a fault, refer to the

interpretation of this status.

PR037:Refrigerant

pressure 1 bar < X < 15 barIn the event of a fault, see the

interpretation of this

parameter.

PR055:Engine speed0 rpmIn the event of a fault, see the

interpretation of this

parameter.

ET023:Fast idle speed

requestABSENTIn the event of a fault, refer to the

interpretation of this status.

Page 24 of 63

62C-24

MR-413-X44-62C000$637_eng.mif

V1

MANUAL AIR CONDITIONING

Fault finding - Conformity check62C

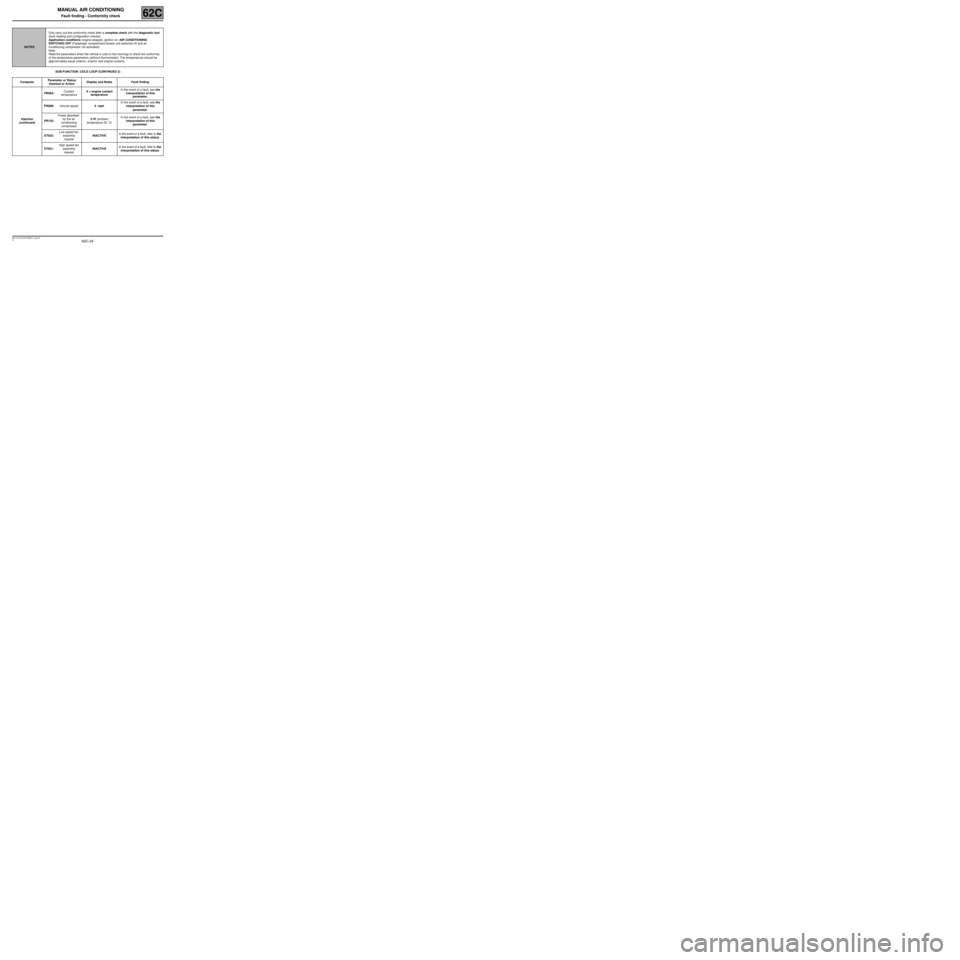

SUB-FUNCTION: COLD LOOP (CONTINUED 2)

NOTESOnly carry out this conformity check after a complete check with the diagnostic tool

(fault reading and configuration checks).

Application conditions: engine stopped, ignition on, AIR CONDITIONING

SWITCHED OFF (Passenger compartment blower unit switched off and air

conditioning compressor not activated).

Note:

Read the parameters when the vehicle is cold (in the morning) to check the conformity

of the temperature parameters (without thermometer). The temperatures should be

approximately equal (interior, exterior and engine coolant).

ComputerParameter or Status

checked or ActionDisplay and Notes Fault finding

Injection

(continued)PR064:Coolant

temperatureX = engine coolant

temperatureIn the event of a fault, see the

interpretation of this

parameter.

PR089:Vehicle speed0 mphIn the event of a fault, see the

interpretation of this

parameter.

PR125:Power absorbed

by the air

conditioning

compressor0 W (ambient

temperature 23 ˚C)In the event of a fault, see the

interpretation of this

parameter.

ET022:Low speed fan

assembly

requestINACTIVEIn the event of a fault, refer to the

interpretation of this status.

ET021:High speed fan

assembly

requestINACTIVEIn the event of a fault, refer to the

interpretation of this status.

Page 30 of 63

62C-30

MR-413-X44-62C000$637_eng.mif

V1

MANUAL AIR CONDITIONING

Fault finding - Conformity check62C

SUB-FUNCTION: COLD LOOP (CONTINUED 2)

NOTESOnly carry out this conformity check after a complete check with the diagnostic tool

(fault reading and configuration checks).

Application conditions: engine at idle speed, AIR CONDITIONING OPERATING

(air conditioning compressor engaged).

ComputerParameter or Status

checked or ActionDisplay and Notes Fault finding

Injection

(continued 1)

(see 13B, Diesel

injection or 17B,

Petrol injection)ET023:Fast idle speed

requestPRESENTIn the event of a fault, refer to the

interpretation of this status.

PR064:Coolant

temperatureX = engine coolant

temperatureIn the event of a fault, see the

interpretation of this

parameter.

PR089:Vehicle speed0 mphIn the event of a fault, see the

interpretation of this

parameter.

PR125:Power absorbed

by the air

conditioning

compressor300 W < X < 5000 W

(ambient temperature

23 ˚C)In the event of a fault, see the

interpretation of this

parameter.

ET022:Low speed fan

assembly

requestACTIVE if the refrigerant

fluid pressure is less

than 19 bar, and

INACTIVE otherwiseIn the event of a fault, refer to the

interpretation of this status.

ET021:High speed fan

assembly

requestACTIVE if the refrigerant

fluid pressure is greater

than 19 bar, INACTIVE

otherwise.In the event of a fault, refer to the

interpretation of this status.