ESP RENAULT TWINGO 2009 2.G Heating And Air Conditioning - Manual Air Conditioning Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 63

Page 3 of 63

62C-3

MR-413-X44-62C000$091_eng.mif

V1

MANUAL AIR CONDITIONING

Fault finding - Introduction62C

Faults

Faults are declared as either present or stored (depending on whether they appeared in a certain context and have

disappeared since, or whether they remain present but have not been diagnosed within the current context).

The present or stored status of faults should be taken into consideration when the diagnostic tool is switched on

after the + after ignition feed (without any system components being active).

For a present fault, apply the procedure described in the Interpretation of faults section.

For a stored fault, note the faults displayed and apply the instructions in the Notes section.

If the fault is confirmed when the instructions in the Notes section are applied, the fault is present. Deal with the fault

If the fault is not confirmed, check:

–the electrical lines which correspond to the fault,

–the connectors on these lines (corrosion, bent pins, etc.),

–the resistance of the component detected as faulty,

–the condition of the wires (melted or split insulation, wear).

Conformity check

The aim of the conformity check is to check data that does not produce a fault on the diagnostic tool because the

data is inconsistent. Therefore, this stage is used to:

–carry out fault finding on faults that do not have a fault display, and which may correspond to a customer

complaint.

–check that the system is operating correctly and that there is no risk of a fault recurring after repairs.

This section gives the fault finding procedures for statuses and parameters and the conditions for checking them.

If a status is not behaving normally or a parameter is outside the permitted tolerance values, consult the

corresponding fault finding page.

Special notes regarding conformity checks for the air conditioning system:

The air conditioning system conformity check is divided into four parts. The parts relate to the four sub-functions of

the air conditioning system: heating, cold loop, user selection and passenger compartment ventilation. The statuses

and parameters related to these sub-functions are listed with their respective computers.

Special notes: The air conditioning control panel does not control electrical components (other than the passenger

compartment fan assembly) and it cannot support fault finding.

Customer complaints - Fault finding chart

If the test with the diagnostic tool is OK but the customer complaint is still present, the fault should be processed by

customer complaint. Note:

The interpretation of statuses, parameters and commands is also split into several sections. Everything controlled

by the air conditioning control panel is explained in the two Air conditioning sections (62B and 62C). On the

other hand, signals from other computers are explained in the fault finding sections for these computers (see

conformity check).

A summary of the overall procedure to follow is provided on the following page in the

form of a flow chart.

Page 5 of 63

62C-5

MR-413-X44-62C000$091_eng.mif

V1

MANUAL AIR CONDITIONING

Fault finding - Introduction62C

4. FAULT FINDING PROCEDURE (CONTINUED)

Wiring check

Fault finding problems

Disconnecting the connectors and/or manipulating the wiring harness may temporarily remove the cause of a fault.

Electrical measurements of voltage, resistance and insulation are generally correct, especially if the fault is not

present when the analysis is made (stored fault).

Visual inspection of the connection:

●Check that the connector is connected correctly and that the male and female parts of the connection are

correctly coupled.

Visual inspection of the area around the connection:

●Check the condition of the mounting (pin, strap, adhesive tape, etc.) if the connectors are attached to the

vehicle.

●Check that there is no damage to the wiring trim (sheath, foam, adhesive tape, etc.) near the wiring.

●Check that there is no damage to the electrical wires at the connector outputs, in particular on the

insulating material (wear, cuts, burns, etc.).

Disconnect the connector to continue the checks.

Visual inspection of the plastic casing:

●Check that there is no mechanical damage (casing crushed, cracked, broken, etc.), in particular to the

fragile components (lever, lock, openings, etc.).

●Check that there is no heat damage (casing melted, darker, deformed, etc.).

●Check that there are no stains (grease, mud, liquid, etc.).

Visual inspection of the metal contacts:

(The female contact is called CLIP. The male contact is called TAB.)

●Check that there are no bent contacts (the contact is not inserted correctly and can come out of the back

of the connector). The spring contact of the connector when the wire is gently pulled.

●Check that there is no damage (folded tabs, clips open too wide, blackened or melted contact, etc.).

●Check that there is no oxidation on the metal contacts. Note:

Carry out each requested check visually. Do not remove a connector if it is not required.

Note:

Repeated connections and disconnections alter the functionality of the connectors and increase the risk of poor

electrical contact. Limit the number of connections/disconnections as much as possible.

Note:

The check is carried out on the 2 parts of the connection. There may be two types of connections:

–Connector / Connector

–Connector / Device

Page 35 of 63

62C-35

MR-413-X44-62C000$728_eng.mif

V1

62C

MANUAL AIR CONDITIONING

Fault finding - Customer complaints

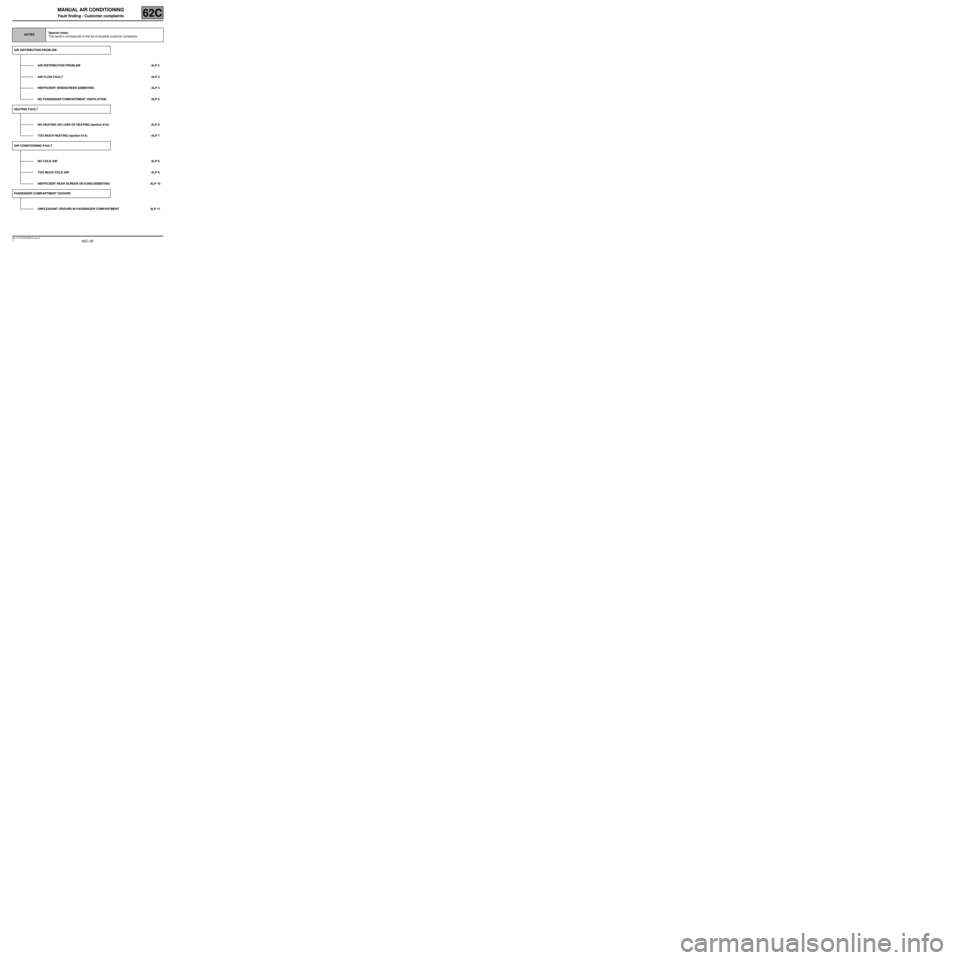

NOTESSpecial notes:

This section corresponds to the list of possible customer complaints.

AIR DISTRIBUTION PROBLEM

AIR DISTRIBUTION PROBLEM ALP 2

AIR FLOW FAULT ALP 3

INEFFICIENT WINDSCREEN DEMISTING ALP 4

NO PASSENGER COMPARTMENT VENTILATION ALP 5

HEATING FAULT

NO HEATING OR LOSS OF HEATING (section 61A) ALP 6

TOO MUCH HEATING (section 61A) ALP 7

AIR CONDITIONING FAULT

NO COLD AIR ALP 8

TOO MUCH COLD AIR ALP 9

INEFFICIENT REAR SCREEN DE-ICING/DEMISTING ALP 10

PASSENGER COMPARTMENT ODOURS

UNPLEASANT ODOURS IN PASSENGER COMPARTMENT ALP 11

MR-413-X44-62C000$728_eng.mif

Page 58 of 63

62C-58

MR-413-X44-62C000$910_eng.mif

V1

MANUAL AIR CONDITIONING

Fault finding - Fault finding charts62C

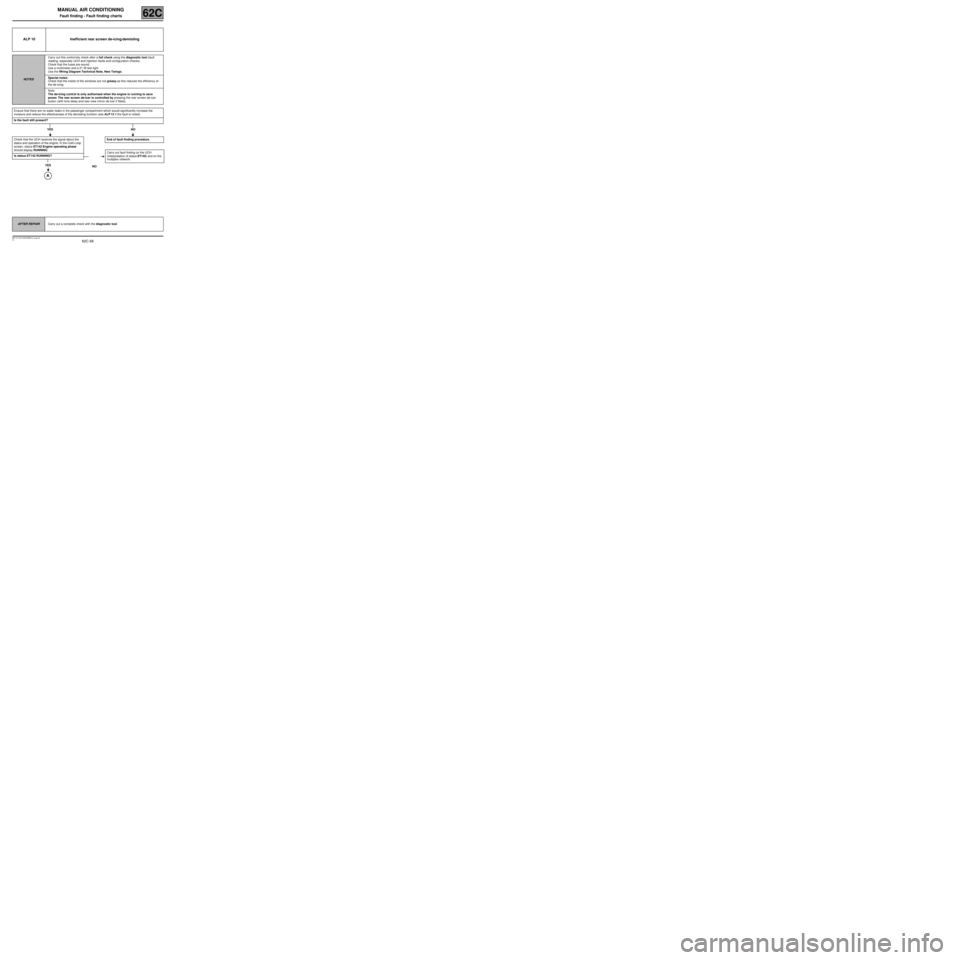

ALP 10 Inefficient rear screen de-icing/demisting

NOTESCarry out this conformity check after a full check using the diagnostic tool (fault

reading, especially UCH and injection faults and configuration checks).

Check that the fuses are sound.

Use a multimeter and a 21 W test light.

Use the Wiring Diagram Technical Note, New Twingo.

Special notes:

Check that the inside of the windows are not greasy as this reduces the efficiency of

the de-icing.

Note:

The de-icing control is only authorised when the engine is running to save

power. The rear screen de-icer is controlled by pressing the rear screen de-icer

button (with time delay and rear-view mirror de-icer if fitted).

Ensure that there are no water leaks in the passenger compartment which would significantly increase the

moisture and reduce the effectiveness of the demisting function (see ALP 12 if the fault is noted).

Is the fault still present?

YES NO

Check that the UCH receives the signal about the

status and operation of the engine. In the Cold Loop

screen, status ET142 Engine operating phase

should display RUNNING.

Is status ET142 RUNNING?

YES

End of fault finding procedure.

NOCarry out fault finding on the UCH

(interpretation of status ET142) and on the

multiplex network.

AFTER REPAIRCarry out a complete check with the diagnostic tool.