battery RENAULT TWINGO 2009 2.G Sequential Transmission Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 138

Page 7 of 138

21B-7

MR-413-X44-21B000$118.mif

V2

21B

SEQUENTIAL GEARBOX

Fault finding - Fault finding log

5. FAULT FINDING LOG

You will always be asked for this log:

●when requesting technical assistance from Techline,

●for approval requests when replacing parts for which approval is mandatory,

●to be attached to monitored parts for which reimbursement is requested. The log is needed for warranty

reimbursement, and enables better analysis of the parts removed.

6. SAFETY INSTRUCTIONS

Safety rules must be observed during any work on a component to prevent any damage or injury:

Make sure the battery is properly charged to avoid damaging the computers if there is a low charge.

Use the appropriate tools. IMPORTANTIMPORTANT

Any fault on a complex system requires thorough fault finding with the appropriate tools. The

FAULT FINDING LOG, which should be completed during the procedure, enables you to keep

track of the procedure which is carried out. It is an essential document when consulting the

manufacturer.

IT IS THEREFORE MANDATORY TO FILL OUT A FAULT FINDING LOG EACH TIME FAULT FINDING

IS CARRIED OUT.

Vdiag No: 04

MR-413-X44-21B000$118.mif

Page 22 of 138

21B-22

MR-413-X44-21B000$354.mif

V2

21B

SEQUENTIAL GEARBOX

Fault finding - Fault summary table

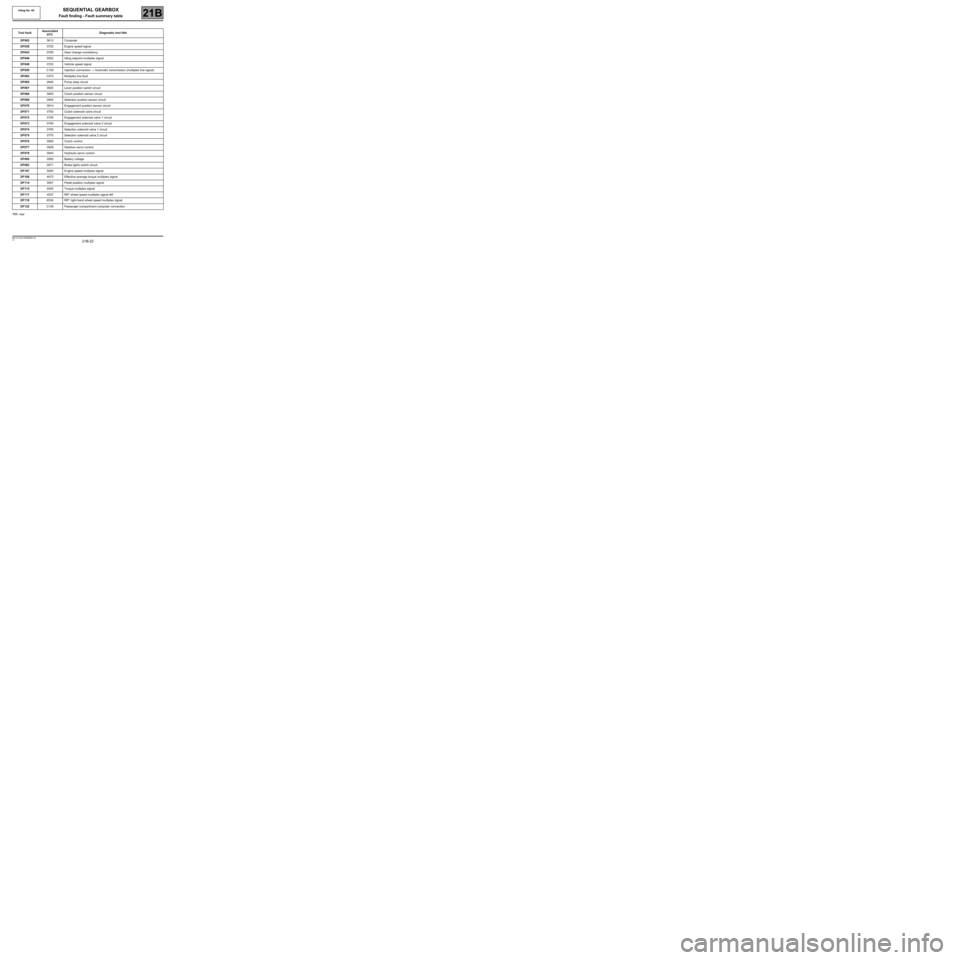

*RR: rearTool faultAssociated

DTCDiagnostic tool title

DF0020613 Computer

DF0390725 Engine speed signal

DF0430785 Gear change consistency

DF0465002 Idling setpoint multiplex signal

DF0480720 Vehicle speed signal

DF059C100 Injection connection → Automatic transmission (multiplex line signal)

DF062C073 Multiplex line fault

DF0650945 Pump relay circuit

DF0670820 Lever position switch circuit

DF0680805 Clutch position sensor circuit

DF0690904 Selection position sensor circuit

DF0700914 Engagement position sensor circuit

DF0710750 Clutch solenoid valve circuit

DF0720755 Engagement solenoid valve 1 circuit

DF0730760 Engagement solenoid valve 2 circuit

DF0740765 Selection solenoid valve 1 circuit

DF0750770 Selection solenoid valve 2 circuit

DF0760900 Clutch control

DF0770928 Gearbox servo control

DF0780944 Hydraulic servo control

DF0800560 Battery voltage

DF0820571 Brake lights switch circuit

DF1075000 Engine speed multiplex signal

DF1084073 Effective average torque multiplex signal

DF1145007 Pedal position multiplex signal

DF1155005 Torque multiplex signal

DF1174037 RR* wheel speed multiplex signal left

DF118403A RR* right-hand wheel speed multiplex signal

DF122C140 Passenger compartment computer connection

Vdiag No: 04

MR-413-X44-21B000$354.mif

Page 45 of 138

21B-45

MR-413-X44-21B000$413.mif

V2

SEQUENTIAL GEARBOX

Fault finding - Interpretation of faults

Vdiag No.: 04

21B

DF080

PRESENT

OR

STOREDBATTERY VOLTAGE

1.DEF: Battery undervoltage

NOTESSpecial notes:

–Fault warning light comes on.

Use the Wiring Diagrams Technical Note for New TWINGO.

Check that the sequential gearbox supply fuse is correctly positioned and in good condition in the passenger

compartment fuse box.

Measure the battery voltage and check the charging circuit (see Technical Note 6014A, Charging circuit

check).

Repair if necessary.

Ensure that the battery and its connections are in good condition (condition and tightness of the terminals).

Check the engine earths on the vehicle.

Repair if necessary.

Check the connection and condition of the connectors of components 1016 and 119.

If the connectors are faulty and if there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, W iring: Precautions for repair), repair the connectors; otherwise, replace the wiring.

Check the continuity and insulation of the connections between:

●Connection code BP39,

●Connection code AP4,

between components 119 and 1016.

●The two connections N between component 119 and the chassis earths MC-12A and MC-12B.

If the connection(s) are faulty and there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, W iring: Precautions for repair), repair the wiring, otherwise replace it.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

BVRJH1_V04_DF080

Page 107 of 138

21B -107

MR-413-X44-21B000$767.mif

V2

SEQUENTIAL GEARBOX

Fault finding - Interpretation of parameters

Vdiag No: 04

21B

PR008

COMPUTER SUPPLY VOLTAGE

PARAMETER

DEFINITIONThis parameter indicates the sequential gearbox computer supply voltage value

expressed in V.

NOTESUse the Wiring Diagrams Technical Note for New TWINGO.

Engine stopped, ignition on

PR008 ≈ 12 V

The computer supply voltage value must be close to the battery voltage.

Electrical check of the component

Check that the sequential gearbox supply fuse is correctly positioned and in good condition in the engine

compartment connection unit.

Check the engine earths on the vehicle are in good condition.

Repair if necessary.

Measure the battery voltage and check the charge circuit (see Technical Note 6014A, Charge circuit check).

Check the connection and condition of the connections of component 119.

If the connectors are faulty and if there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, W iring: Precautions for repair), repair the connectors; otherwise, replace the wiring.

Check the continuity and insulation of the following connections:

●Connection code BP39,

●Connection code AP4,

between components 1016 and 119.

●Connection code N (2 connections) between earths MC-12A and MC-12B and component 119.

If the connection(s) are faulty and there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, W iring: Precautions for repair), repair the wiring, otherwise replace it.

AFTER REPAIRCarry out another fault finding check on the system.

Deal with any other faults.

Clear the stored faults.

BVRJH1_V04_PR008

Page 126 of 138

21B -126

MR-413-X44-21B000$944.mif

V2

21B

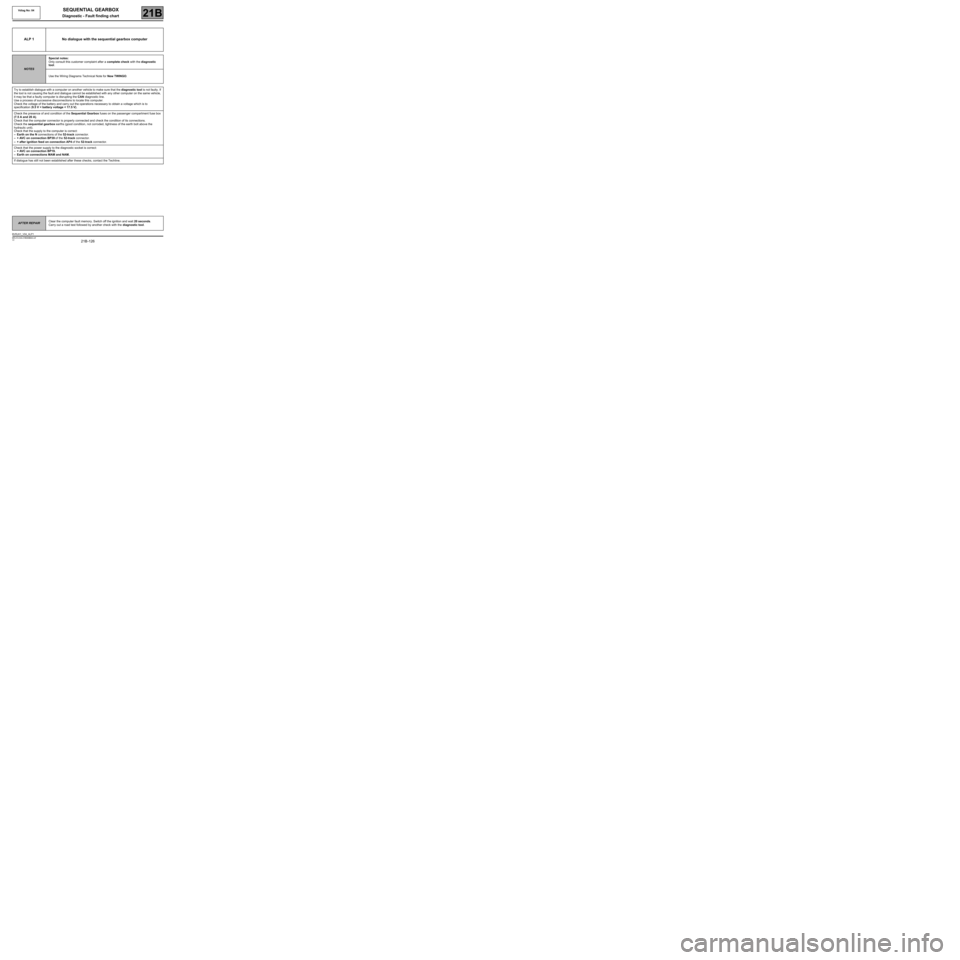

SEQUENTIAL GEARBOX

Diagnostic - Fault finding chart

ALP 1 No dialogue with the sequential gearbox computer

NOTESSpecial notes:

Only consult this customer complaint after a complete check with the diagnostic

tool.

Use the Wiring Diagrams Technical Note for New TWINGO.

Try to establish dialogue with a computer on another vehicle to make sure that the diagnostic tool is not faulty. If

the tool is not causing the fault and dialogue cannot be established with any other computer on the same vehicle,

it may be that a faulty computer is disrupting the CAN diagnostic line.

Use a process of successive disconnections to locate this computer.

Check the voltage of the battery and carry out the operations necessary to obtain a voltage which is to

specification (9.5 V < battery voltage < 17.5 V).

Check the presence of and condition of the Sequential Gearbox fuses on the passenger compartment fuse box

(7.5 A and 20 A).

Check that the computer connector is properly connected and check the condition of its connections.

Check the sequential gearbox earths (good condition, not corroded, tightness of the earth bolt above the

hydraulic unit).

Check that the supply to the computer is correct:

–Earth on the N connections of the 52-track connector.

–+ AVC on connection BP39 of the 52-track connector.

–+ after ignition feed on connection AP4 of the 52-track connector.

Check that the power supply to the diagnostic socket is correct:

–+ AVC on connection BP19.

–Earth on connections MAM and NAM.

If dialogue has still not been established after these checks, contact the Techline.

AFTER REPAIRClear the computer fault memory. Switch off the ignition and wait 20 seconds.

Carry out a road test followed by another check with the diagnostic tool.

BVRJH1_V04_ALP1

MR-413-X44-21B000$944.mif

Vdiag No: 04