engine RENAULT TWINGO 2015 3.G Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2015, Model line: TWINGO, Model: RENAULT TWINGO 2015 3.GPages: 216, PDF Size: 5.06 MB

Page 148 of 216

4.8

Frequency of checking coolant level

Check the coolant level regularly

(very severe damage is likely to be

caused to the engine if it runs out of

coolant).

If the level needs to be topped up, only

use products approved by our Technical

Department which ensure:

– protection against freezing;

– an anti-corrosion protection for the cooling system.

No operations should be

carried out on the cooling

circuit when the engine is

hot.

Risk of burns.

Replacement interval

Refer to the Maintenance Document for

your vehicle.

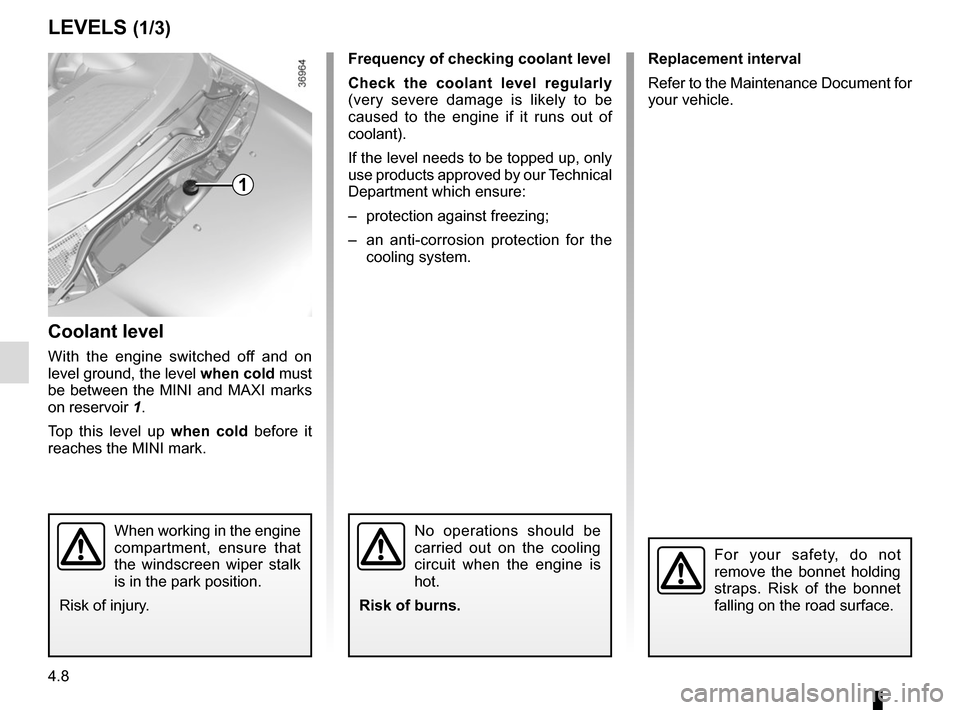

Coolant level

With the engine switched off and on

level ground, the level when cold must

be between the MINI and MAXI marks

on reservoir 1.

Top this level up when cold before it

reaches the MINI mark.

LEVELS (1/3)

1

When working in the engine

compartment, ensure that

the windscreen wiper stalk

is in the park position.

Risk of injury.

For your safety, do not

remove the bonnet holding

straps. Risk of the bonnet

falling on the road surface.

Page 149 of 216

4.9

Level 2

It is normal for the level to drop as the

brake shoes become worn, but it must

never drop lower than the “MINI" warn-

ing line.

If you wish to check the disc and drum

wear yourself, you should obtain the

document explaining the checking pro-

cedure from the manufacturer’s net-

work or web site.

Topping up

After any operation on the hydraulic cir-

cuit, a specialist must replace the brake

fluid.

Only use fluids approved by our

Technical Department (and taken from

a sealed container).

Replacement interval

Refer to the Maintenance Document for

your vehicle.

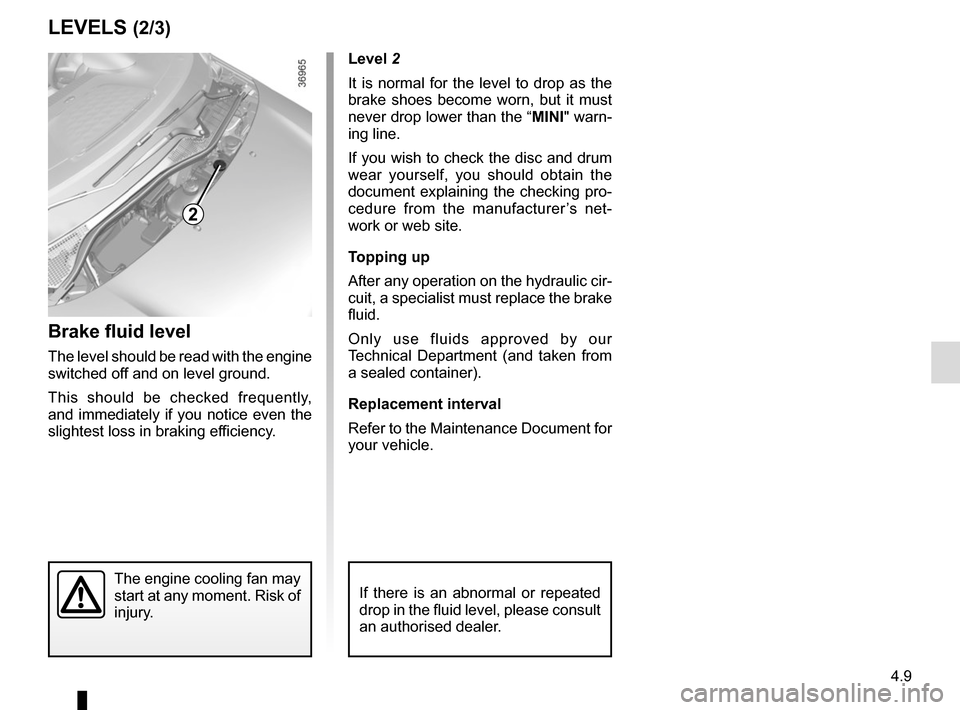

Brake fluid level

The level should be read with the engine

switched off and on level ground.

This should be checked frequently,

and immediately if you notice even the

slightest loss in braking efficiency.

LEVELS (2/3)

2

The engine cooling fan may

start at any moment. Risk of

injury.If there is an abnormal or repeated

drop in the fluid level, please consult

an authorised dealer.

Page 150 of 216

4.10

Filters

The filter elements (air filter, passenger

compartment filter, etc.) should be re-

placed during the maintenance opera-

tions carried out on your vehicle.

Replacement intervals for filter el-

ements: refer to the Maintenance

Document for your vehicle.

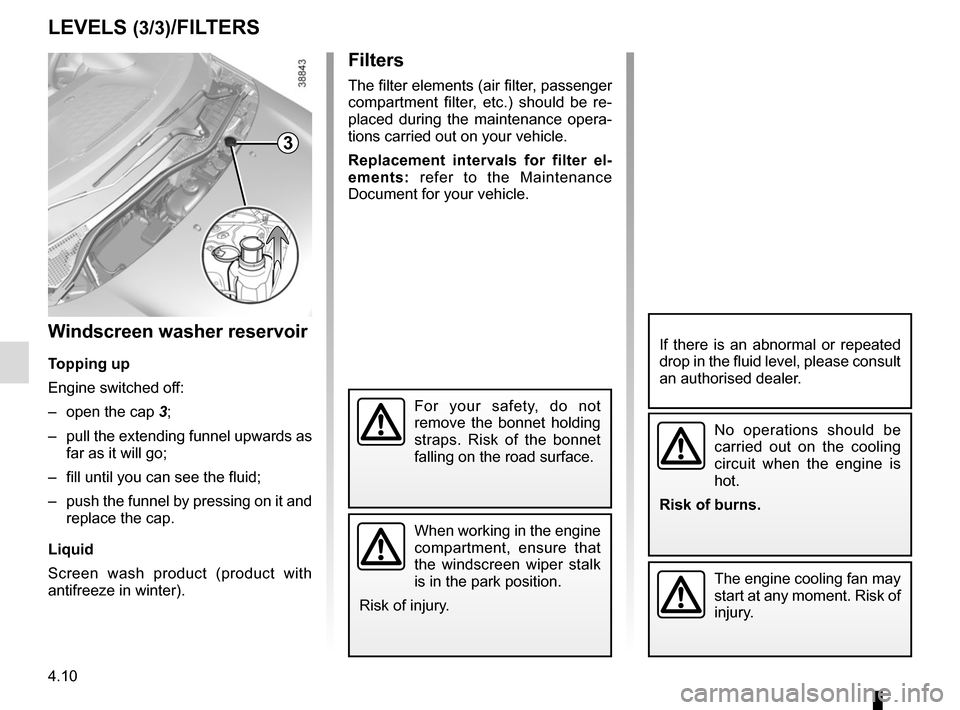

Windscreen washer reservoir

Topping up

Engine switched off:

– open the cap 3;

– pull the extending funnel upwards as far as it will go;

– fill until you can see the fluid;

– push the funnel by pressing on it and replace the cap.

Liquid

Screen wash product (product with

antifreeze in winter).

LEVELS (3/3)/FILTERS

3

When working in the engine

compartment, ensure that

the windscreen wiper stalk

is in the park position.

Risk of injury.

The engine cooling fan may

start at any moment. Risk of

injury.

No operations should be

carried out on the cooling

circuit when the engine is

hot.

Risk of burns.

If there is an abnormal or repeated

drop in the fluid level, please consult

an authorised dealer.

For your safety, do not

remove the bonnet holding

straps. Risk of the bonnet

falling on the road surface.

Page 151 of 216

4.11

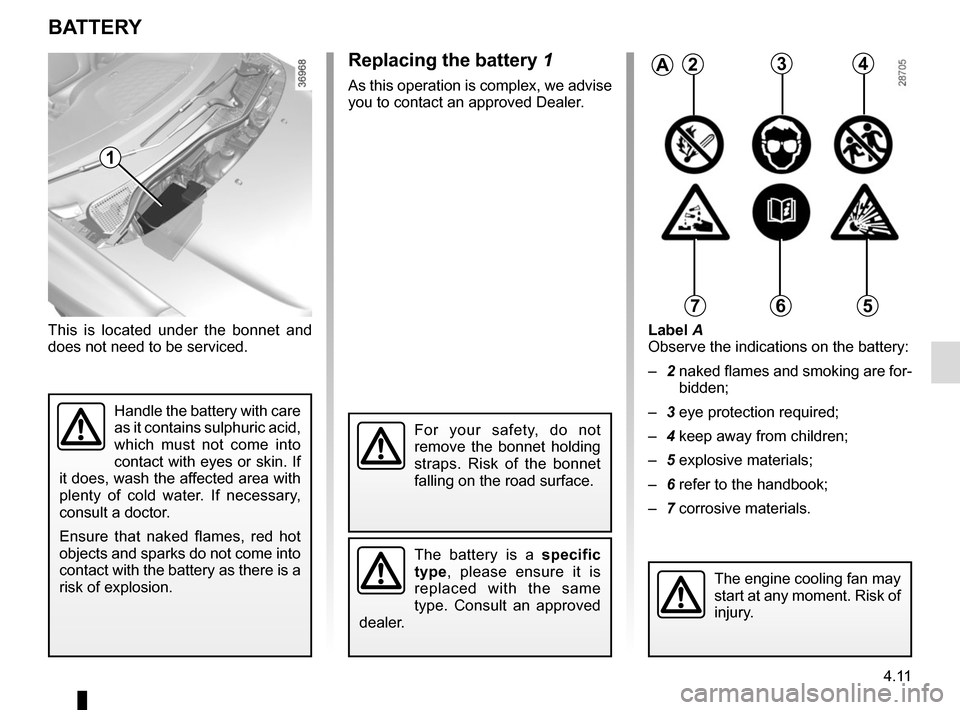

This is located under the bonnet and

does not need to be serviced.Label A

Observe the indications on the battery:

–

2 naked flames and smoking are for-

bidden;

– 3 eye protection required;

– 4 keep away from children;

– 5 explosive materials;

– 6 refer to the handbook;

– 7 corrosive materials.

BATTERY

2

Handle the battery with care

as it contains sulphuric acid,

which must not come into

contact with eyes or skin. If

it does, wash the affected area with

plenty of cold water. If necessary,

consult a doctor.

Ensure that naked flames, red hot

objects and sparks do not come into

contact with the battery as there is a

risk of explosion.

The battery is a specific

type, please ensure it is

replaced with the same

type. Consult an approved

dealer.

A234

567

The engine cooling fan may

start at any moment. Risk of

injury.

Replacing the battery 1

As this operation is complex, we advise

you to contact an approved Dealer.

1

For your safety, do not

remove the bonnet holding

straps. Risk of the bonnet

falling on the road surface.

Page 154 of 216

4.14

BODYWORK MAINTENANCE (1/2)

You should

Wash your car frequently, with the

engine off, with cleaning products rec-

ommended by the manufacturer (never

use abrasive products). Rinse thor-

oughly beforehand with a jet:

– spots of tree resin and industrial

grime;

– mud in the wheel arches and under-

neath the body which forms damp

patches;

– bird droppings , which cause a

chemical reaction with the paint that

rapidly discolours paintwork and

may even cause the paint to peel

off;

wash the vehicle immediately to

remove these marks since it is im-

possible to remove them by polish-

ing;

– salt, particularly in the wheel arches

and underneath the body after driv-

ing in areas where the roads have

been gritted.

Remove any plant matter (resin, leaves,

etc.) from the vehicle regularly.

What you should not doDo not degrease or clean mechani-

cal components (e.g. the engine com-

partment), underneath the body, parts

with hinges (e.g. inside the doors) and

painted plastic external fittings (e.g.

bumpers) using high-pressure clean-

ing equipment or by spraying on prod-

ucts not approved by our Technical

Department. Doing this could give rise

to corrosion or operational faults.

Wash the vehicle in bright sunlight or

freezing temperatures.

Do not scrape off mud or dirt without

pre-wetting.

Allow dirt to accumulate on the exterior.

Allow rust to form following minor im-

pacts.

Do not use solvents not approved by

our Technical Department to remove

stains as this could damage the paint-

work.

Do not drive in snow or muddy condi-

tions without washing the vehicle, par-

ticularly under the wheel arches and

body.

A well-maintained vehicle will last

longer. It is therefore recommended to

maintain the exterior of the vehicle reg-

ularly.

Your vehicle has been treated with very

effective anti-corrosion products. It is

nevertheless subject to various outside

influences.

Corrosive agents in the atmosphere

–

atmospheric pollution (built-up and

industrial areas),

– saline atmospheres (near the sea,

particularly in hot weather),

– seasonal and damp weather condi-

tions (e.g. road salt in winter, water

from road cleaners, etc.).

Minor impacts

Abrasive action

Dust and sand in the air, mud, road grit

thrown up by other vehicles, etc.

You should take a number of minor pre-

cautions in order to safeguard your ve-

hicle against such risks.

Page 161 of 216

5.3

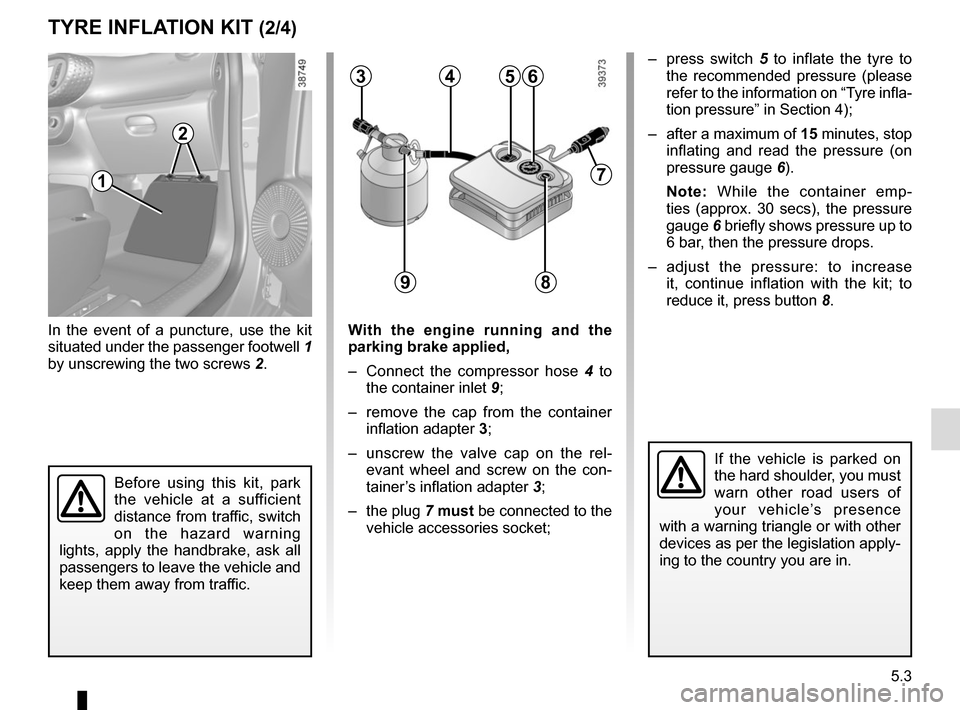

TYRE INFLATION KIT (2/4)

In the event of a puncture, use the kit

situated under the passenger footwell 1

by unscrewing the two screws 2.With the engine running and the

parking brake applied,

– Connect the compressor hose 4 to

the container inlet 9;

– remove the cap from the container inflation adapter 3;

– unscrew the valve cap on the rel- evant wheel and screw on the con-

tainer’s inflation adapter 3;

– the plug 7 must be connected to the

vehicle accessories socket;

563

Before using this kit, park

the vehicle at a sufficient

distance from traffic, switch

on the hazard warning

lights, apply the handbrake, ask all

passengers to leave the vehicle and

keep them away from traffic.

9

If the vehicle is parked on

the hard shoulder, you must

warn other road users of

your vehicle’s presence

with a warning triangle or with other

devices as per the legislation apply-

ing to the country you are in.

– press switch 5 to inflate the tyre to

the recommended pressure (please

refer to the information on “Tyre infla-

tion pressure” in Section 4);

– after a maximum of 15 minutes, stop inflating and read the pressure (on

pressure gauge 6).

Note: While the container emp-

ties (approx. 30 secs), the pressure

gauge 6 briefly shows pressure up to

6 bar, then the pressure drops.

– adjust the pressure: to increase it, continue inflation with the kit; to

reduce it, press button 8.

7

4

8

1

2

Page 167 of 216

5.9

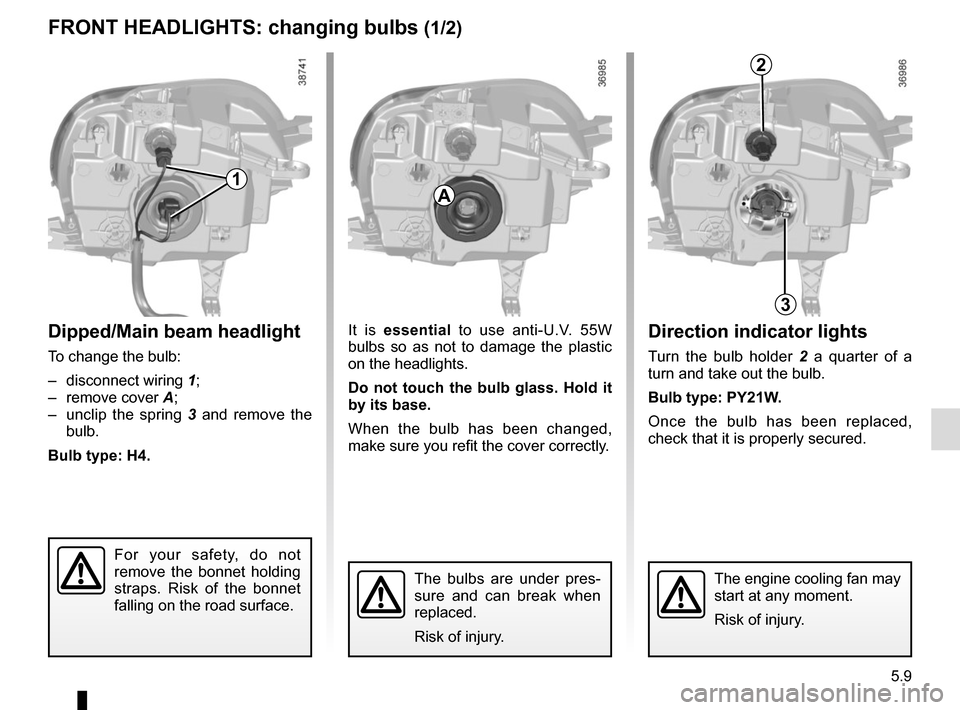

Direction indicator lights

Turn the bulb holder 2 a quarter of a

turn and take out the bulb.

Bulb type: PY21W.

Once the bulb has been replaced,

check that it is properly secured.

Dipped/Main beam headlight

To change the bulb:

– disconnect wiring 1;

– remove cover A;

– unclip the spring 3 and remove the

bulb.

Bulb type: H4.

FRONT HEADLIGHTS: changing bulbs (1/2)

The engine cooling fan may

start at any moment.

Risk of injury.

It is essential to use anti-U.V. 55W

bulbs so as not to damage the plastic

on the headlights.

Do not touch the bulb glass. Hold it

by its base.

When the bulb has been changed,

make sure you refit the cover correctly.

A

3

2

The bulbs are under pres-

sure and can break when

replaced.

Risk of injury.

1

For your safety, do not

remove the bonnet holding

straps. Risk of the bonnet

falling on the road surface.

Page 173 of 216

5.15

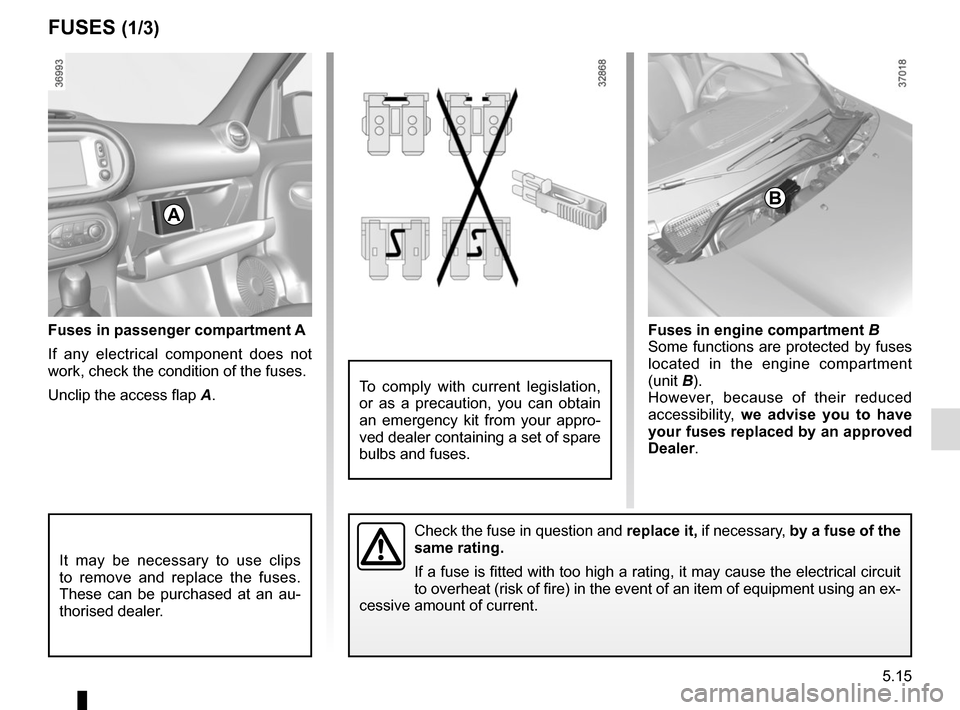

Fuses in passenger compartment A

If any electrical component does not

work, check the condition of the fuses.

Unclip the access flap A.

FUSES (1/3)

Fuses in engine compartment B

Some functions are protected by fuses

located in the engine compartment

(unit B).

However, because of their reduced

accessibility, we advise you to have

your fuses replaced by an approved

Dealer .

AB

It may be necessary to use clips

to remove and replace the fuses.

These can be purchased at an au-

thorised dealer.

Check the fuse in question and replace it, if necessary, by a fuse of the

same rating.

If a fuse is fitted with too high a rating, it may cause the electrical \

circuit

to overheat (risk of fire) in the event of an item of equipment using \

an ex-

cessive amount of current.

To comply with current legislation,

or as a precaution, you can obtain

an emergency kit from your appro-

ved dealer containing a set of spare

bulbs and fuses.

Page 177 of 216

5.19

BATTERY: breakdown recovery (1/2)

To avoid all risk of sparks:

– Ensure that any electrical consumers (courtesy lights, etc.) are switched

off before disconnecting or recon-

necting the battery.

– When charging, stop the charger before connecting or disconnecting

the battery.

– Do not place metal objects on the battery to avoid creating a short cir-

cuit between the terminals.

– Always wait at least one minute after the engine has been switched off

before disconnecting a battery.

– Make sure that you reconnect the battery terminals after refitting.

Connecting a battery charger

The battery charger must be com-

patible with a battery with nominal

voltage of 12 volts.

Do not disconnect the battery while the

engine is running. Follow the instruc-

tions given by the manufacturer of

the battery charger you are using.

Special procedures may be

required to charge some

batteries. Contact your ap-

proved dealer.

Avoid all risk of sparks which may

cause an immediate explosion, and

charge the battery in a well-venti-

lated area. Risk of serious injury.

Handle the battery with care

as it contains sulphuric acid,

which must not come into

contact with eyes or skin. If

it does, wash the affected area with

plenty of cold water.

Ensure that naked flames, red hot

objects and sparks do not come into

contact with the battery as there is a

risk of explosion.

The engine may be hot when car-

rying out operations in close prox-

imity. In addition, the engine cooling

fan can come on at any moment.

Risk of injury.

Page 178 of 216

5.20

Start the engine. As soon as it is run-

ning, disconnect the cables A and B in

reverse order ( 1 - 4 - 3 - 2 ) and posi-

tion the red protective cover by press-

ing it down.

BATTERY: breakdown recovery (2/2)

Depending on the vehicle, unclip the

red protective cover to access termi-

nal 2 (+).

Connect the positive cable B to the ter-

minal 2 (+) then to the terminal 3 (+) of

the battery supplying the current.

Connect the negative cable A to the

terminal 4 (–) of the battery supplying

the current, then to the terminal 1 (–) of

the discharged battery.

Starting the vehicle using the

battery from another vehicle

If you have to use the battery from an-

other vehicle to start, obtain suitable

jump leads (with a large cross section)

from an approved dealer or, if you al-

ready have jump leads, ensure that

they are in perfect condition.

The two batteries must have an iden-

tical nominal voltage of 12 volts. The

battery supplying the current should

have a capacity (amp-hours, Ah) which

is at least the same as that of the dis-

charged battery.

Ensure that there is no risk of contact

between the two vehicles (risk of short

circuiting when the positive terminals

are connected) and that the discharged

battery is properly connected. Switch

off your vehicle ignition.

Start the engine of the vehicle supply-

ing the current and run it at an interme-

diate engine speed.

Check that there is no con-

tact between cables A

and B, and that the positive

cable B is not touching any

metal parts of the vehicle supplying

the current.

Risk of injury and/or damage to the

vehicle.

1

2

21

3

B

A

4

For your safety, do not remove the bonnet holding straps. Risk of the

bonnet falling on the road surface.