battery RENAULT TWINGO RS 2009 2.G Chasiss ESP Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 101

Page 4 of 101

38C -4V3 MR-413-X44-38C050$010.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Introduction

Bosch 8.1 ESP

Vdiag No.: 05

38C

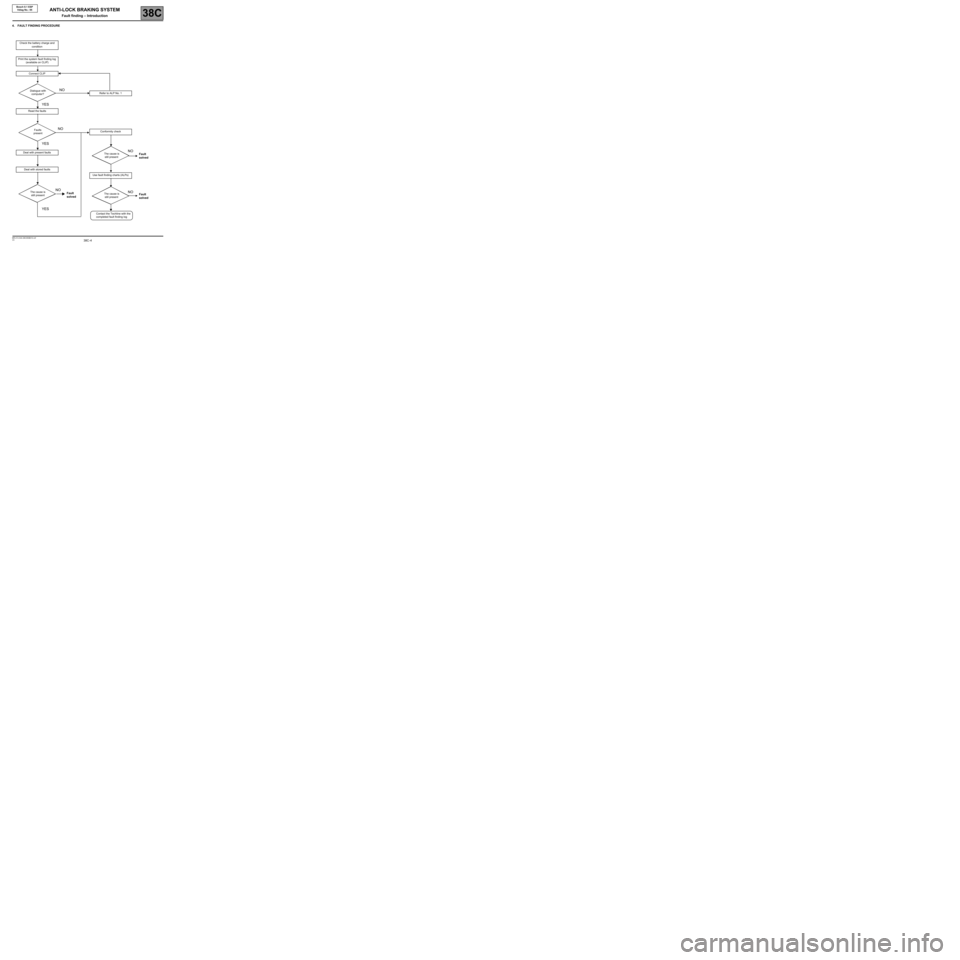

4. FAULT FINDING PROCEDURE

Check the battery charge and

condition

Print the system fault finding log

(available on CLIP)

Connect CLIP

Refer to ALP No. 1

Read the faults

Deal with present faults

Deal with stored faults

Conformity check

Use fault finding charts (ALPs)

Dialogue with

computer?

Faults

present

The cause is

still present

The cause is

still presentThe cause is

still present

Contact the Techline with the

completed fault finding log

NO

NONO

NO NO

YES

YES

YES

Fault

solvedFault

solved Fault

solved

Page 8 of 101

38C -8V3 MR-413-X44-38C050$010.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Introduction

Bosch 8.1 ESP

Vdiag No.: 05

38C

5. FAULT FINDING LOG

You will always be asked for this log:

–when requesting technical assistance from the Techline,

–when requesting approval before replacing parts for which approval is compulsory,

–to be attached to monitored parts for which reimbursement is requested. The log is needed for warranty

reimbursement, and enables better analysis of the parts removed.

6. SAFETY INSTRUCTIONS

Safety rules must be observed during any work on a component to prevent any material damage or personal injury:

–check the battery voltage to avoid incorrect operation of computer functions,

–use the proper tools.

It is forbidden to carry out a road test with the diagnostic tool in dialogue with the ECU because the ABS and

Electronic Brake Distribution functions are deactivated. Braking pressure is identical on both vehicle axles

(risk of a spin under heavy braking).IMPORTANTIMPORTANT

All faults involving a complex system call for thorough diagnostics with the appropriate tools. The

FAULT FINDING LOG, which should be completed during the fault finding procedure, ensures a

record is kept of the procedure carried out. It is an essential document when consulting the

manufacturer.

IT IS THEREFORE ESSENTIAL THAT THE FAULT FINDING LOG IS FILLED OUT EVERY TIME IT IS

REQUESTED BY TECHLINE OR THE WARRANTY RETURNS DEPARTMENT.

Page 11 of 101

38C-11V3 MR-413-X44-38C050$030.mif

38C

Bosch 8.1 ESP

Vdiag No.: 05

Number Description

1Computer/hydraulic unit assembly

2Steering wheel angle

3Torque setpoint on the engine management computer

4Sequential gearbox operating phase (if fitted)

5Instrument panel

6Diagnostic socket

7 UCH

8Vehicle speed wire

9Brake light control relay

10Combined sensor: lateral acceleration and yaw speed

11Brake disc with instrumented bearing target

12Wheel speed sensor

13Battery

14Traction control deactivation button (Only on RS version)

15Brake switch

Electric circuit

Hydraulic circuit

Private multiplex line

Vehicle multiplex line

ANTI-LOCK BRAKING SYSTEM

Fault finding – Functional diagram

Page 14 of 101

38C-14V3 MR-413-X44-38C050$060.mif

38C

Bosch 8.1 ESP

Vdiag No.: 05

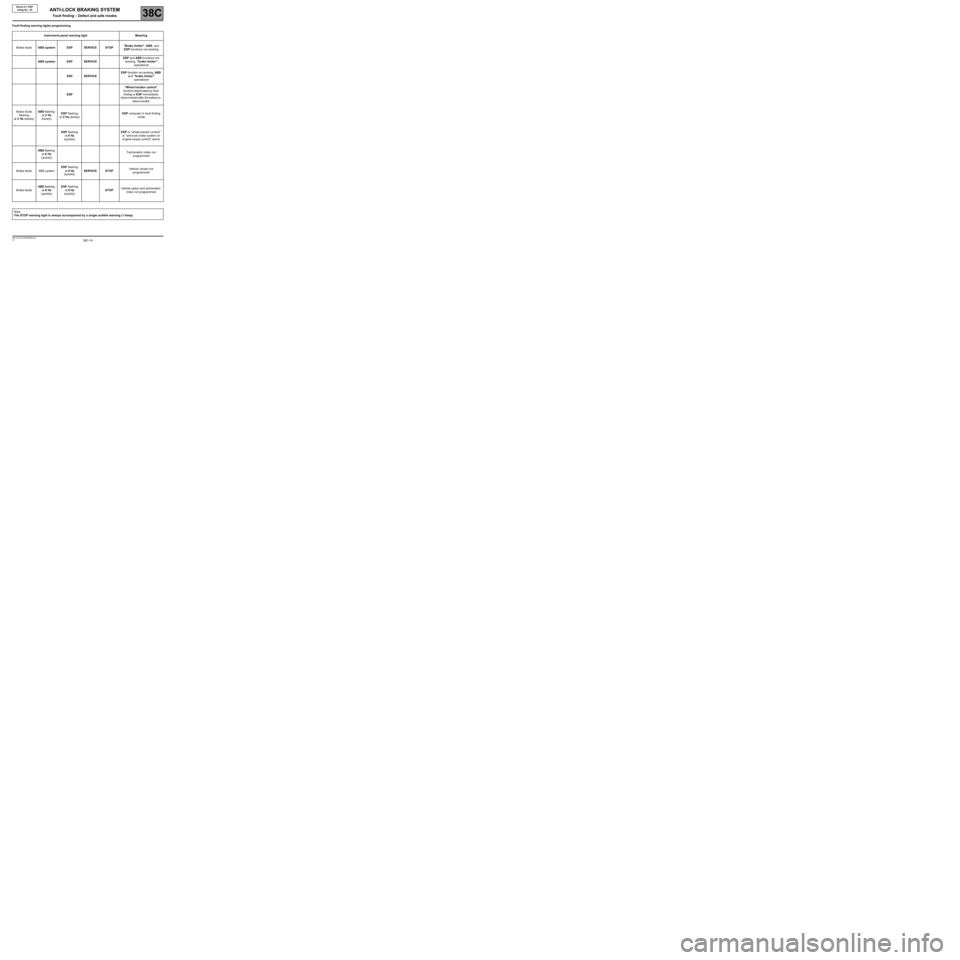

Fault finding warning lights programming

Instrument panel warning light Meaning

Brake faultsABS system ESP SERVICE STOP"Brake limiter", ABS, and

ESP functions not working

ABS system ESP SERVICEESP and ABS functions not

working, "brake limiter"

operational

ESP SERVICEESP function not working, ABS

and "brake limiter"

operational

ESP

"Wheel traction control"

function deactivated by fault

finding orESPmomentarily

disco nnected a fter the battery is

disconnected

Brake faults

flashing

at 2 H z (slowly)ABS flashing

at 2 Hz

(slowly)ESP flashing

at 2 Hz (slowly)ESP computer in fault finding

mode

ESP flashing

at 8 Hz

(quickly)ESP or "wheel traction control"

or "anti-lock brake system on

engine torque control" active

ABS flashing

at 8 Hz

(quickly)Tachometric index not

programmed

Brake faults ABS systemESP flashing

at 8 Hz

(quickly)SERVICE STOPVehicle variant not

programmed

Brake faultsABS flashing

at 8 Hz

(quickly)ESP flashing

at 8 Hz

(quickly)STOPVehicle option and tachometric

index not programmed

Note:

The STOP warning light is always accompanied by a single audible warning (1 beep).

ANTI-LOCK BRAKING SYSTEM

Fault finding – Defect and safe modes

Page 19 of 101

38C-19

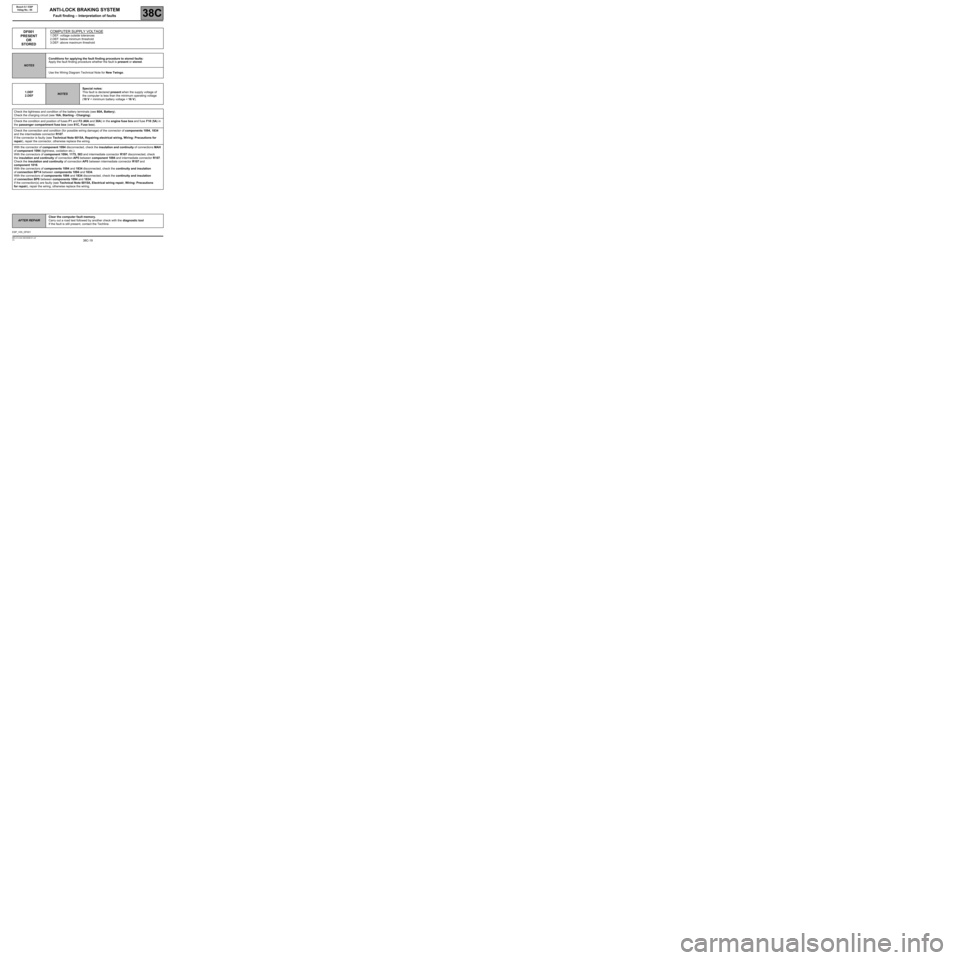

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$101.mif

38C

Bosch 8.1 ESP

Vdiag No.: 05

DF001

PRESENT

OR

STOREDCOMPUTER SUPPLY VOLTAGE

1.DEF: voltage outside tolerances

2.DEF: below minimum threshold

3.DEF: above maximum threshold

NOTESConditions for applying the fault finding procedure to stored faults:

Apply the fault finding procedure whether the fault is present or stored.

Use the Wiring Diagram Technical Note for New Twingo.

1.DEF

2.DEF

NOTESSpecial notes:

This fault is declared present when the supply voltage of

the computer is less than the minimum operating voltage

(10 V < minimum battery voltage < 16 V).

Check the tightness and condition of the battery terminals (see 80A, Battery).

Check the charging circuit (see 16A, Starting - Charging).

Check the condition and position of fuses F1 and F2 (40A and 30A) in the engine fuse box and fuse F10 (5A) in

the passenger compartment fuse box (see 81C, Fuse box).

Check the connection and condition (for possible wiring damage) of the connector of components 1094, 1834

and the intermediate connector R107.

If the connector is faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the connector, otherwise replace the wiring.

With the connector of component 1094 disconnected, check the insulation and continuity of connections MAH

of component 1094 (tightness, oxidation etc.).

With the connectors of component 1094, 1175, 583 and intermediate connector R107 disconnected, check

the insulation and continuity of connection AP5 between component 1094 and intermediate connector R107.

Check the insulation and continuity of connection AP5 between intermediate connector R107 and

component 1016.

With the connectors of components 1094 and 1834 disconnected, check the continuity and insulation

of connection BP14 between components 1094 and 1834.

With the connectors of components 1094 and 1834 disconnected, check the continuity and insulation

of connection BP8 between components 1094 and 1834.

If the connection(s) are faulty (see Technical Note 6015A, Electrical wiring repair, Wiring: Precautions

for repair), repair the wiring, otherwise replace the wiring.

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults

ESP_V05_DF001

Page 20 of 101

38C-20

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$101.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

DF001

CONTINUED

3.DEFNOTESSpecial notes:

Special notes: This fault appears if the computer supply

voltage is above the maximum operating voltage

(16 V < maximum battery voltage < 19.6 V).

This fault may appear when starting using a charger

or a 24 V battery.

Check the charging circuit (see 16A, Starting - Charging).

Page 27 of 101

38C-27

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$101.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

DF011

PRESENT

OR

STOREDSOLENOID VALVE SUPPLY

DEF: Abnormal voltage

NOTESConditions for applying the fault finding procedure to stored faults:

Apply the fault finding procedure whether the fault is present or stored.

Use the Wiring Diagram Technical Note for New Twingo.

Check the tightness and condition of the battery terminals (see 80A, Battery).

Check the charging circuit (see 16A, Starting - Charging).

Check the condition and position of fuse F2 (30A) in the engine fuse box.

Check the connection and condition (possible wiring damage) of the connector of component 1094.

If the connector is faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions

for repair), repair the connector, otherwise replace the wiring.

With the connector of component 1094 disconnected, check the insulation and continuity of connections MAH

of component 1094 (tightness, oxidation, etc.).

With the connectors of components 1094 and 1834 disconnected, check the continuity and insulation

of connection BP8 between components 1094 and 1834.

If the connection or connections are faulty (see Technical Note 6015A, Electrical wiring repair, Wiring:

Precautions for repair), repair the connectors or wiring, otherwise replace the wiring.

ESP_V05_DF011

Page 28 of 101

38C-28

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$101.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

DF017

PRESENT

OR

STOREDCOMPUTER

1. DEF: Supply fault or internal electronic fault

NOTESConditions for applying the fault finding procedure to stored faults:

Apply the fault finding procedure whether the fault is present or stored.

Use the Wiring Diagram Technical Note for New Twingo.

Check the tightness and condition of the battery terminals (see 80A, Battery).

Check the charging circuit (see 16A, Starting - Charging).

Check the condition and position of fuses F1 and F2 (40A and 30A) in the engine fuse box and fuse F10 (5A) in

the passenger compartment fuse box (see MR413, Fault finding, 81C, Fuse box).

Check the connection and condition (possible wiring damage) of the connector of component 1094.

If the connector is faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions

for repair), repair the connector, otherwise replace the wiring.

With the connector of component 1094 disconnected, check the insulation and continuity of connections MAH

of component 1094 (tightness, oxidation etc.).

With the connectors of component 1094, 1175, 583 and intermediate connector R107 disconnected, check

the insulation and continuity of connection AP5 between component 1094 and intermediate connector R107.

Check the insulation and continuity of connection AP5 between intermediate connector R107 and

component 1016.

With the connectors of components 1094 and 1834 disconnected, check the continuity and insulation

of connection BP14 between components 1094 and 1834.

With the connectors of components 1094 and 1834 disconnected, check the continuity and insulation

of connection BP8 between components 1094 and 1834.

If the connection(s) are faulty (see Technical Note 6015A, Electrical wiring repair, Wiring: Precautions

for repair), repair the wiring, otherwise replace the wiring.

ESP_V05_DF017

Page 61 of 101

38C-61

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$102.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

DF190

CONTINUED

3.DEFNOTESNone.

Check the tightness and condition of the battery terminals (see 80A, Battery).

Check the charging circuit (see 16A, Starting - Charging).

Apply the fault finding procedure for fault DF189 Combined sensor circuit.

Page 66 of 101

38C-66

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$102.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

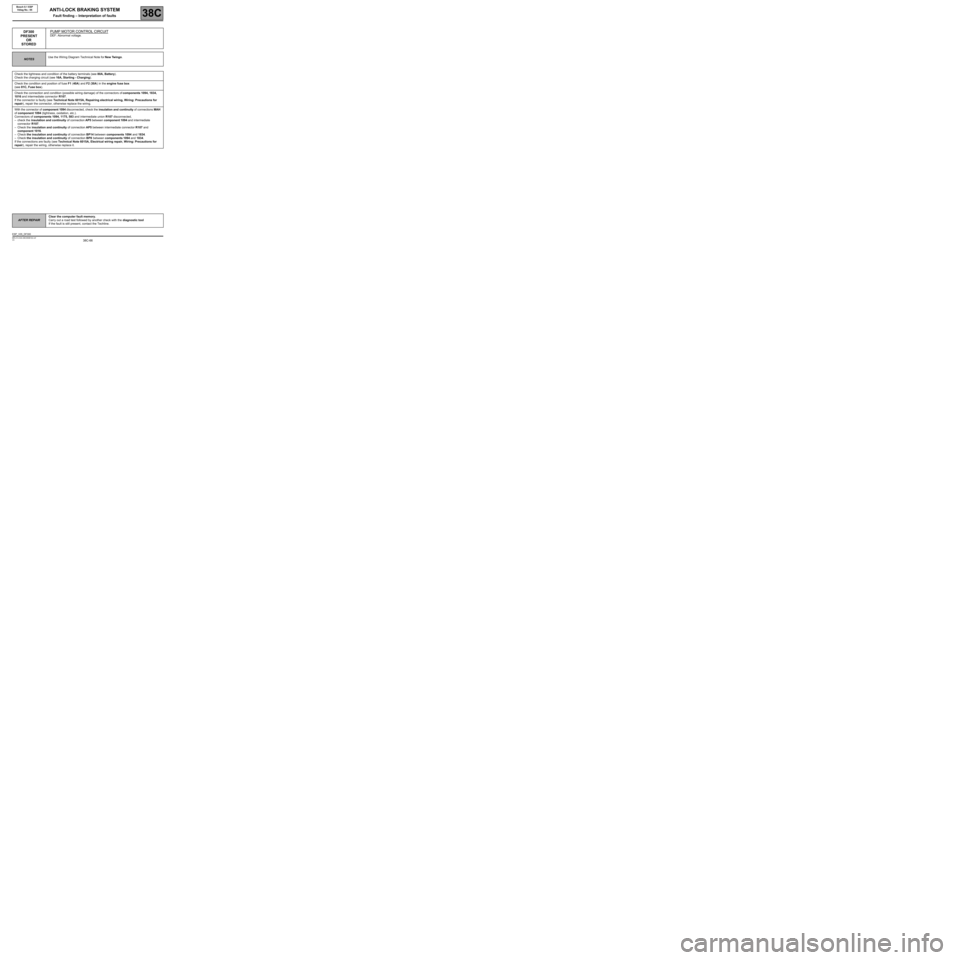

DF300

PRESENT

OR

STOREDPUMP MOTOR CONTROL CIRCUIT

DEF: Abnormal voltage.

NOTESUse the Wiring Diagram Technical Note for New Twingo.

Check the tightness and condition of the battery terminals (see 80A, Battery).

Check the charging circuit (see 16A, Starting - Charging).

Check the condition and position of fuse F1 (40A) and F2 (30A) in the engine fuse box

(see 81C, Fuse box).

Check the connection and condition (possible wiring damage) of the connectors of components 1094, 1834,

1016 and intermediate connector R107.

If the connector is faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the connector, otherwise replace the wiring.

With the connector of component 1094 disconnected, check the insulation and continuity of connections MAH

of component 1094 (tightness, oxidation, etc.).

Connectors of components 1094, 1175, 583 and intermediate union R107 disconnected,

–check the insulation and continuity of connection AP5 between component 1094 and intermediate

connector R107.

–Check the insulation and continuity of connection AP5 between intermediate connector R107 and

component 1016.

–Check the insulation and continuity of connection BP14 between components 1094 and 1834.

–Check the insulation and continuity of connection BP8 between components 1094 and 1834.

If the connections are faulty (see Technical Note 6015A, Electrical wiring repair, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

ESP_V05_DF300