engine RENAULT TWINGO RS 2009 2.G Electrical Equipment - Petrol Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 348

Page 154 of 348

17B-154V7 MR-413-X44-17B000$133.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

Only Vdiag 54

DF569

PRESENT

OR

STOREDTURBOCHARGING CIRCUIT

1.DEF: Signal outside lower limit

2.DEF: Signal outside upper limit

3.DEF: OBD

NOTESConditions for applying the fault finding procedure to stored faults

The fault is declared present with the engine running.

Special note:

Defect mode 4: speed limited to less than 66 mph (110 km/h) in 5th and 6

th and the

accelerator pedal feels spongy.

Defect mode 5: the ESP and Cruise control - Speed limiter are deactivated.

Defect mode 6: the wastegate is not controlled and opens freely.

The engine runs without turbocharging, like a naturally aspirated engine.

Use the Wiring Diagrams Technical Note for NEW TWINGO, E33, CLIO III, or

MODUS.

Check the connection of the turbocharging ducts.

Check the condition of the connector of the turbocharger pressure sensor (component code 1071), of the

wastegate solenoid valve (component code 436), and of the engine management computer (component

code 120).

If the connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Use the universal bornier to check the insulation and continuity of the following connections:

●3AHN between components 436 and 120,

●3AT between components 436 and 120,

●3LN between components 1071 and 120,

●3LP between components 1071 and 120,

●3LQ between components 1071 and 120.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, contact the Techline.

SIM32_V54_DF569

AFTER REPAIRFollow the instructions to confirm repair:

–If the fault is present, continue to deal with the fault.

–If the fault is stored, ignore it.

Deal with any other faults.

Clear the stored faults.

Page 156 of 348

17B-156V7 MR-413-X44-17B000$133.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

DF612

PRESENT

OR

STOREDOIL VAPOUR DEFREEZE RESISTOR CIRCUIT

CO.0: Open circuit or short circuit to earth

CC.1: Short circuit to + 12 V

NOTESSpecial notes:

Oil leaks and odours are possible.

Use the Wiring Diagrams Technical Note for NEW TWINGO, E33, CLIO III,

or MODUS.

Check the condition of the connector of the oil vapour rebreathing hose heater (component code 979) and of the

engine management computer (component code 120).

If the connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

With the ignition on, check for + 12 V on connection 3FB of the oil vapour re-breathing pipe heater and the earthing

of connection 3YC on the injection computer connector.

Use the universal bornier to check the insulation and continuity of the following connections:

●3FB between components 979 and 238,

●3YC between components 979 and 120 (for NEW TWINGO or E33),

●3JP between components 979 and 120 (for CLIO III or MODUS).

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, contact the Techline.

SIM32_V44_DF612 / SIM32_V4C_DF612 / SIM32_V50_DF612 / SIM32_V54_DF612

AFTER REPAIRFollow the instructions to confirm repair:

–If the fault is present, continue to deal with the fault.

–If the fault is stored, ignore it.

Deal with any other faults.

Clear the stored faults.

Page 157 of 348

17B-157V7 MR-413-X44-17B000$133.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

DF623

PRESENT

OR

STOREDCLOSING BRAKE SIGNAL

1.DEF: Multiplex line connection fault

NOTESConditions for applying the fault finding procedure to stored faults

The fault is declared present when the ignition is switched on or with the engine

running.

Special notes:

The cruise control/speed limiter is deactivated.

Use the Wiring Diagrams Technical Note for NEW TWINGO, E33, CLIO III,

or MODUS.

Check that the pedal assembly is in good condition.

Check the cleanliness and condition of the dual-contact brake switch and its connections (component code 160)

and the engine management computer connector (component code 120).

If the connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

With the ignition on, check for + 12 V on connections 65A and 5A of the brake pedal switch, component code 160.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

SIM32_V44_DF623 / SIM32_V4C_DF623 / SIM32_V50_DF623 / SIM32_V54_DF623

AFTER REPAIRFollow the instructions to confirm repair:

–If the fault is present, continue to deal with the fault.

–If the fault is stored, ignore it.

Deal with any other faults.

Clear the stored faults.

Page 159 of 348

17B-159V7 MR-413-X44-17B000$133.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

DF624

PRESENT

OR

STOREDUPC MULTIPLEX CONNECTION

1.DEF: Multiplex line connection fault

2.DEF: EOBD

NOTESConditions for applying the fault finding procedure to stored faults

The fault is declared present when the ignition is switched on.

Use the Wiring Diagrams Technical Note for NEW TWINGO, E33, CLIO III,

or MODUS.

Run a multiplex network test (see 88B, Multiplex).

Check the condition of the engine management computer connector (component code 120).

If the connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

For NEW TWINGO or E33:

Use the universal bornier to check the insulation and continuity of the following connections:

●133B between components 120 and 645,

●133C between components 120 and 645,

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, run fault finding on the UCH system (see 87B, Passenger compartment connection

unit).

For CLIO III or MODUS:

Use the universal bornier to check the insulation and continuity of the following connections:

●133B between components 120 and 1337,

●133C between components 120 and 1337.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, carry out fault finding on the UPC system (see 87G, Engine compartment connection

unit).

If the fault is still present, contact the Techline.

SIM32_V44_DF624 / SIM32_V4C_DF624 / SIM32_V50_DF624 / SIM32_V54_DF624

AFTER REPAIRFollow the instructions to confirm repair:

–If the fault is present, continue to deal with the fault.

–If the fault is stored, ignore it.

Deal with any other faults.

Clear the stored faults.

Page 161 of 348

17B-161V7 MR-413-X44-17B000$133.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

DF650

CONTINUED

Check that PR030 Accelerator pedal position is correct and carry out checks only if PR030 > 15% with no load

or if PR030 < 90%. "Full load"

Check that the pedal mechanism has not seized.

Repair if necessary.

Check the condition of the pedal potentiometer connector (component code 921) and the engine management

computer connector (component code 120).

If the connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Use the universal bornier to check the insulation and continuity of the following connections:

●3LR between components 921 and 120,

●3LS between components 921 and 120,

●3LT between components 921 and 120,

●3LU between components 921 and 120,

●3LV between components 921 and 120,

●3LW between components 921 and 120.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Measure the resistance of the pedal potentiometer gang 1 between connections 3LR and 3LT:

If the resistance is not between:

●0.8 kΩ < X < 2.6 kΩ with no load, replace the accelerator pedal.

Measure the resistance of the pedal potentiometer gang 2 between connections 3LR and 3LV:

If the resistance is not between:

●0.8 kΩ < X < 4.9 kΩ with no load, replace the accelerator pedal.

AFTER REPAIRFollow the instructions to confirm repair:

–If the fault is present, continue to deal with the fault.

–If the fault is stored, ignore it.

Deal with any other faults.

Clear the stored faults.

Page 162 of 348

17B-162V7 MR-413-X44-17B000$133.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

Vdiag 4C only

DF893

PRESENT

OR

STOREDCONTROLLED COOLANT THERMOSTAT CIRCUITCO: Open circuit

CC.0: Short circuit to earth

CC.1: Short circuit to + 12 V

1.DEF: EOBD

NOTESPriorities when dealing with a number of faults:

Deal first with fault DF084 Actuator relay control circuit or DF046 Battery voltage

if they are present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is considered present when the engine is running.

Special note:

Controlled coolant thermostat:

–For CO and CC.1:

Thermostat not controlled; temperature regulation performed at 110˚C.

–For CC 0:

Thermostat continuously controlled; temperature regulation performed at 90˚C.

Use Wiring Diagram Technical Note for CLIO III or MODUS.

Check the condition of the controlled coolant thermostat connector (see Technical Note Wiring Diagram, CLIO III

or MODUS, component code 1458).

Check the condition of the engine management computer connector (see Technical Note Wiring Diagram,

CLIO III or MODUS, component code 120).

If the connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

If the fault is still present, check (with the ignition on) for + 12 V on connection 3FB of the controlled coolant

thermostat.

If the connection is faulty and if there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Use the "universal bornier" to check the insulation and continuity of the following connection:

●3VL between components 1458 and 120.

If the connection is faulty and if there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

SIM32_V4C_DF893

AFTER REPAIRFollow the instructions to confirm repair:

–If the fault is present, continue to deal with the fault.

–If the fault is stored, ignore it.

Deal with any other faults.

Clear the stored faults.

Page 164 of 348

17B-164V7 MR-413-X44-17B000$133.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

DF1058

PRESENT

OR

STOREDINLET PRESSURE CONSISTENCY

1.DEF: Signal outside upper limit

NOTESConditions for applying the fault finding procedure to stored faults:

1.DEF: The fault is declared present with the engine running after a few seconds.

Use the Wiring Diagram Technical Note for E33, CLIO III or MODUS.

Check the condition of the manifold pressure sensor and its connections (component code 147) and of the engine

management computer (component code 120).

If the connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Measure the voltage of the manifold pressure sensor between connections 3LG and 3CK.

If the voltage is not between:

●4.75 V < X < 5.25 V with the engine stopped, replace the manifold pressure sensor, component code 147.

Use the universal bornier to check the insulation and continuity of the following connections:

●3LG between components 147 and 120,

●3F between components 147 and 120,

●3CK between components 147 and 120.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

SIM32_V44_DF1058 / SIM32_V4C_DF1058 / SIM32_V50_DF1058 / SIM32_V54_DF1058

AFTER REPAIRFollow the instructions to confirm repair:

–If the fault is present, continue to deal with the fault.

–If the fault is stored, ignore it.

Deal with any other faults.

Clear the stored faults.

Page 165 of 348

17B-165V7 MR-413-X44-17B000$133.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

For Clio III and Modus:

DF1072

PRESENT

OR

STOREDAIR CONDITIONING COMPRESSOR RELAY CONTROLCO: Open circuit

CC.0: Short circuit to earth

CC.1: Short circuit to + 12 V

1.DEF: EOBD

NOTESConditions for applying the fault finding procedure to stored faults

The fault is declared present when the engine is running.

Special notes:

CO or CC.1: Not possible to control the air conditioning and the customer is complaining

that driving comfort is reduced.

CO: No impact on the system.

CC.0: The compressor is still active, risk of irreversible damage to the compressor (loss

of capacity). The customer is complaining that the air conditioning is operating

continuously.

Use the Wiring Diagrams Technical Note for NEW TWINGO, E33, CLIO III, or

MODUS.

Check the condition of the UPC connectors, component code 1337.

Check the condition of the engine management computer connector, component code 120.

If the connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Run a test on the UPC computer (see 87G, Engine compartment connection unit).

Run command AC180 Air conditioning compressor relay control and check for + 12 V on connection 38R of

the air conditioning compressor clutch, component code 171.

If the fault is still present, contact the Techline.

SIM32_V44_DF1072 / SIM32_V4C_DF1072 / SIM32_V50_DF1072 / SIM32_V54_DF1072

AFTER REPAIRFollow the instructions to confirm repair:

–If the fault is present, continue to deal with the fault.

–If the fault is stored, ignore it.

Deal with any other faults.

Clear the stored faults.

Page 166 of 348

17B-166V7 MR-413-X44-17B000$133.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

For New Twingo and E33

DF1072

CONTINUED

Check the condition of the air conditioning compressor clutch relay connector, component code 584.

Check the condition of the engine management computer connector, component code 120.

If the connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Run command AC180 Air conditioning compressor relay control

If the command does not work, with the ignition on, check for + 12 V on connection 3FB of the air conditioning

compressor clutch relay, component code 584 and for the earthing of connection 38K of the injection computer

connector, component code 120.

Use the universal bornier to check the insulation and continuity of the following connections:

●3FB between components 584 and 238,

●38K between components 584 and 120.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, contact the Techline.

AFTER REPAIRFollow the instructions to confirm repair:

–If the fault is present, continue to deal with the fault.

–If the fault is stored, ignore it.

Deal with any other faults.

Clear the stored faults.

Page 168 of 348

17B-168V7 MR-413-X44-17B000$150.mif

17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

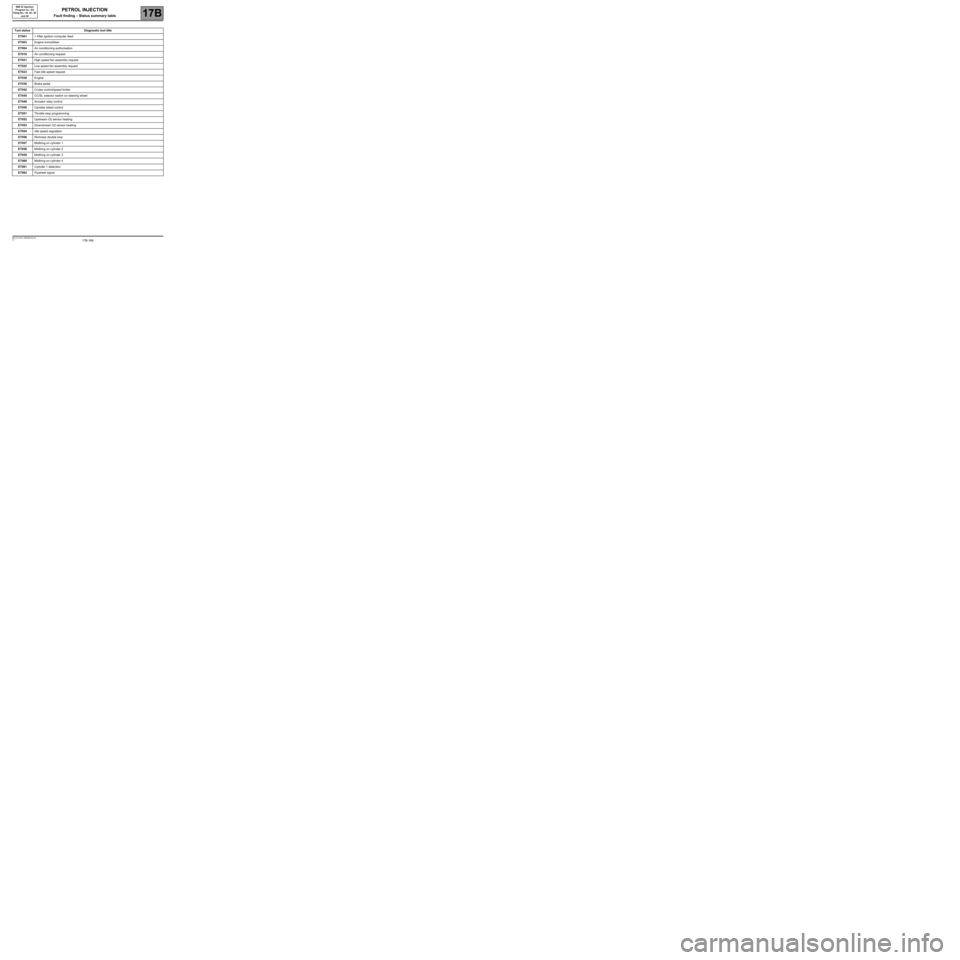

Tool statusDiagnostic tool title

ET001+ After ignition computer feed

ET003Engine immobiliser

ET004Air conditioning authorisation

ET018Air conditioning request

ET021High speed fan assembly request

ET022Low speed fan assembly request

ET023Fast idle speed request

ET038Engine

ET039Brake pedal

ET042Cruise control/speed limiter

ET045CC/SL selector switch on steering wheel

ET048Actuator relay control

ET050Canister bleed control

ET051Throttle stop programming

ET052Upstream O2 sensor heating

ET053Downstream O2 sensor heating

ET054Idle speed regulation

ET056Richness double loop

ET057Misfiring on cylinder 1

ET058Misfiring on cylinder 2

ET059Misfiring on cylinder 3

ET060Misfiring on cylinder 4

ET061Cylinder 1 detection

ET062Flywheel signal

PETROL INJECTION

Fault finding – Status summary table