warning RENAULT TWINGO RS 2009 2.G Electrical Equipment - Petrol Injection Owner's Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 348

Page 116 of 348

17B-116V7 MR-413-X44-17B000$132.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

DF109

PRESENT

OR

STOREDLOW FUEL LEVEL MISFIRING

1.DEF: Destructive misfiring

2.DEF: Polluting misfiring

3.DEF: EOBD

NOTESPriorities when dealing with a number of faults:

Firstly, deal with the following faults:

–DF085 Fuel pump relay control circuit,

–DF026 Cylinder 1 injector circuit

–DF027 Cylinder 2 injector circuit, DF028 Cylinder 3 injector circuit,

–DF029 Cylinder 4 injector circuit,

–DF059 Misfiring on cylinder 1,

–DF060 Misfiring on cylinder 2,

–DF061 Misfiring on cylinder 3,

–DF062 Misfiring on cylinder 4,

–DF436 Combustion misfiring detection,

if they are present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is considered present when the engine is running.

Special notes:

1.DEF: As soon as the fault is detected, the injection is cut for the faulty cylinder(s) to

limit the rise in temperature inside the catalytic converter. The OBD warning light

flashes for as long as the fault is present.

2.DEF: The OBD warning light is continuously lit.

Check:

–the level of fuel in the tank,

–the conformity and the grade of the fuel, apply test 1 Petrol conformity check,

–the fuel filter,

–the fuel pump,

–the fuel lines,

–the fuel pressure.

If there is no present or stored misfiring fault, the misfiring was caused by the low fuel level.

SIM32_V44_DF109/SIM32_V4C_DF109/SIM32_V50_DF109/SIM32_V54_DF109

AFTER REPAIRFollow the instructions to confirm repair:

- If the fault is present, continue to deal with the fault.

- If the fault is stored, ignore it.

Deal with any other faults.

Clear the stored faults.

Page 126 of 348

17B-126V7 MR-413-X44-17B000$133.mif

17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

DF196

PRESENT

OR

STOREDPEDAL SENSOR CIRCUIT GANG 1CO.0: Open circuit or short circuit to earth

CC.1: Short circuit to + 12 V

1.DEF: Inconsistency between pedal gang 1 and gang 2

2.DEF: EOBD

NOTESPriorities when dealing with a number of faults:

Deal first with fault DF012 Sensor feed voltage no. 2 if it is present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after the accelerator pedal is depressed several times.

Special notes:

The level 1 fault warning light is lit, the throttle valve goes into defect mode 4, causing

a maximum speed limitation of 66 mph (110 km/h) and a loss of power when

accelerating (impression of having a "soft" pedal).

CO.0: The vehicle has a tendency to decelerate.

CC.1: The vehicle has a tendency to accelerate.

2.DEF: The throttle valve goes into defect mode 3, causing a driver's request loss

(no response from the accelerator pedal).

Use the Wiring Diagrams Technical Note for NEW TWINGO, E33, CLIO III,

or MODUS.

Check that the pedal mechanism has not seized.

Repair if necessary.

Check the condition of the pedal potentiometer connector (component code 921) and the engine management

computer connector (component code 120).

If the connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

SIM32_V44_DF196/SIM32_V4C_DF196/SIM32_V50_DF196/SIM32_V54_DF196

PETROL INJECTION

Fault finding – Interpretation of faults

AFTER REPAIRFollow the instructions to confirm repair:

–If the fault is present, continue to deal with the fault.

–If the fault is stored, ignore it.

Deal with any other faults.

Clear the stored faults.

Page 128 of 348

17B-128V7 MR-413-X44-17B000$133.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

DF198

PRESENT

OR

STOREDPEDAL SENSOR CIRCUIT GANG 2

CO.0: Open circuit or short circuit to earth

CC.1: Short circuit to + 12 V

1.DEF: EOBD

NOTESPriorities when dealing with a number of faults:

Deal first with fault DF096 Sensor feed voltage no. 1 whether it is present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after the accelerator pedal is depressed several times.

Special notes:

The vehicle is liable to hesitate. The level 1 fault warning light is lit, the throttle valve

goes into defect mode 4, causing a maximum speed limitation of 66 mph (110 km/h)

and a loss of power when accelerating (impression of having a "soft" pedal).

Use the Wiring Diagrams Technical Note for NEW TWINGO, E33, CLIO III,

or MODUS.

Check that the pedal mechanism has not seized.

Repair if necessary.

Check the condition of the pedal potentiometer connector (component code 921) and the engine management

computer connector (component code 120).

If the connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

SIM32_V44_DF198/SIM32_V4C_DF198/SIM32_V50_DF198/SIM32_V54_DF198

AFTER REPAIRFollow the instructions to confirm repair:

–If the fault is present, continue to deal with the fault.

–If the fault is stored, ignore it.

Deal with any other faults.

Clear the stored faults.

Page 142 of 348

17B-142V7 MR-413-X44-17B000$133.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

DF394

PRESENT

OR

STOREDCATALYTIC CONVERTER OPERATING FAULT

1.DEF: Component in bad condition

2.DEF: EOBD

NOTESPriorities when dealing with a number of faults:

Deal with any other fault first.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after the engine starts.

Special notes:

The OBD warning light is lit.

Use the Wiring Diagrams Technical Note for NEW TWINGO, E33, CLIO III,

or MODUS.

Only for Vdiag 4C, 50 and 54

Check the appearance and condition of the catalytic converter. Check there are no air leaks, thermal shock,

misfiring, coolant or oil consumption.

Run command SC006 Running OBD Test: catalytic converter. Before carrying out this test, repair all the

electrical faults and clear the fault memory. Check that fault DF436 Misfiring detection is not present and program

the engine flywheel target ET089 Flywheel target programming.

Carry out this test when the engine is warm, which reduces the time it takes for the catalytic converter to heat up.

At the end of this test, four different results are possible:

–Status 1: Fault finding not carried out/impossible to obtain the necessary conditions.

–Status 2: Component in an average condition.

–Status 3: Component in good condition.

–Status 4: Component in poor condition.

When fault finding is completed and the result read, stop the engine and start it again to establish normal operating

conditions.

If the result is status 1: check that there are no faults, and check the engine flywheel target programming using

ET089 Programming engine flywheel target.

If the result is status 2 or 4: replace the catalytic converter.

If the result is status 3: the catalytic converter is in good condition.

If the fault is still present, contact the Techline.

SIM32_V44_DF394/SIM32_V4C_DF394/SIM32_V50_DF394/SIM32_V54_DF394

AFTER REPAIREnsure that all the faults have been dealt with.

Clear the stored faults. Do not clear the programming.

To check that the system has been properly repaired:

–there must be no further electrical faults,

–programming has been carried out,

the engine must be warm (minimum 75˚C), and idling, with all electrical consumers

running for 15 minutes.

Page 146 of 348

17B-146V7 MR-413-X44-17B000$133.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

DF436

PRESENT

OR

STOREDDETECTION OF ENGINE MISFIRING1.DEF: Destructive misfiring

2.DEF: Polluting misfiring

3.DEF: EOBD

4.DEF: Component in poor condition

NOTESPriorities when dealing with a number of faults:

Firstly, deal with the following faults:

–ignition

DF351 Ignition coil circuit 1-4,

DF352 Ignition coil circuit 2-3,

–fuel supply circuit

DF026 Cylinder 1 injector circuit

DF027 Cylinder 2 injector circuit,

DF028 Cylinder 3 injector circuit

DF029 Cylinder 4 injector circuit,

DF085 Fuel pump relay control circuit,

–engine flywheel signal

DF154 Flywheel signal sensor circuit,

DF457 Engine flywheel target.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after the engine has been running for at least 15 minutes.

Special notes:

1.DEF: As soon as the fault is detected, the injection is cut off on the faulty cylinder(s)

to limit the temperature increase in the catalytic converter. The OBD warning light

flashes for as long as the fault is present.

2.DEF: The OBD warning light is continuously lit.

SIM32_V44_DF436/SIM32_V4C_DF436/SIM32_V50_DF436/SIM32_V54_DF436

AFTER REPAIREnsure that all the faults have been dealt with.

Clear the stored faults. Do not clear the programming.

To check that the system has been properly repaired:

–there must be no further electrical faults,

–programming has been carried out,

the engine must be warm (minimum 75˚C), and idling, with all electrical consumers

running for 15 minutes.

Page 149 of 348

17B-149V7 MR-413-X44-17B000$133.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

DF457

PRESENT

OR

STOREDFLYWHEEL TARGET1.DEF: Flywheel target fault:

–Missing tooth

–Tooth length outside tolerances

–Eccentricity on the target

–Air gap outside tolerances

2.DEF: EOBD

NOTESConditions for applying the fault finding procedure to stored faults

The fault is considered present when the engine is running.

Special note:

1.DEF: The OBD warning light is lit.

Check the cleanliness and condition of the engine flywheel.

Check the mounting and condition of the engine speed sensor.

Check the condition and count the number of target teeth, if possible.

Repair or replace the engine flywheel if necessary.

If the flywheel has been replaced or removed, reinitialise the flywheel target, then program it.

Reinitialise programming:

Run command RZ005 Programming.

Programming the flywheel signal:

The engine must be warm. Decelerate a first time with injection cut-off (feet off the brake, accelerator, and clutch

pedals) between 3500 and 3000 rpm, in a gear above 3rd for at least 5 seconds for manual gearboxes.

Decelerate a second time with injection cut-off (feet off the brake, accelerator, and clutch pedals) between

2400 and 2000 rpm, in a gear above 3rd for at least 5 seconds for manual gearboxes.

If the fault is still present, contact the Techline.

SIM32_V44_DF457/SIM32_V4C_DF457/SIM32_V50_DF457/SIM32_V54_DF457

AFTER REPAIRFollow the instructions to confirm repair:

–If the fault is present, continue to deal with the fault.

–If the fault is stored, ignore it.

Deal with any other faults.

Clear the stored faults.

Page 150 of 348

17B-150V7 MR-413-X44-17B000$133.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

DF508

PRESENT

OR

STOREDMOTORISED THROTTLE VALVE CONTROL

1.DEF: Component in bad condition

2.DEF: EOBD

CC.1: Short circuit to 12 V

WARNING:

Never drive the vehicle without having confirmed that no faults involving the throttle valve are present.

NOTESPriorities when dealing with a number of faults:

If faults DF095 Throttle potentiometer circuit gang 1 and DF096 Throttle

potentiometer circuit gang 2 are present, deal with these first.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared as present with the ignition on or the engine running, or during

command AC027 Motorised throttle.

Special notes:

In the event of faults, the level 1 warning light comes on, the injection goes into defect

mode 1 and 2, causing a limitation of vehicle and engine speed. The ESP and the cruise

control - speed limiter are deactivated.

Use the Wiring Diagrams Technical Note for NEW TWINGO, E33, CLIO III,

or MODUS.

Check the condition of the connector of the engine throttle valve (component code 120) and of the throttle valve

(component code 1076).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

SIM32_V44_DF508/SIM32_V4C_DF508/SIM32_V50_DF508/SIM32_V54_DF508

AFTER REPAIRIf the throttle valve has been replaced, program the throttle stops (see

Configurations and programming).

Follow the instructions to confirm repair:

–If the fault is present, continue to deal with the fault.

–If the fault is stored, ignore it.

Deal with any other faults.

Clear the stored faults.

Page 153 of 348

17B-153V7 MR-413-X44-17B000$133.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

DF561

PRESENT

OR

STOREDHIGH-SPEED FAN ASSEMBLY RELAY CONTROLCO: Open circuit

CC.0: Short circuit to earth

CC.1: Short circuit to + 12 V

1.DEF: EOBD

NOTESConditions for applying the fault finding procedure to stored faults

The fault is declared present with the engine running.

Special note:

CO or CC.1: High speed fan assembly not activated, risk of engine overheating (the

coolant warning light should warn of overheating), risk of loss of air conditioning.

CC.0: High-speed fan assembly permanently activated.

The customer complains of slight overconsumption and noise in CC.0.

Use the Wiring Diagrams Technical Note for NEW TWINGO, E33, CLIO III,

or MODUS.

Check the condition of the high-speed fan assembly relay connector (component code 234) and the engine

management computer connector (component code 120).

If the connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Run command AC153 High speed fan assembly.

If the command does not work, with the ignition on, check for + 12 V on connection 3FB of the high-speed fan

assembly relay and the earthing of connection 3JP on the injection computer connector.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Use the universal bornier to check the insulation and continuity of the following connections:

●3FB between components 234 and 238,

●3JP between components 234 and 120.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, contact the Techline.

SIM32_V44_DF561/SIM32_V4C_DF561/SIM32_V50_DF561/SIM32_V54_DF561

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

Page 160 of 348

17B-160V7 MR-413-X44-17B000$133.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

DF650

PRESENT

OR

STOREDACCELERATOR PEDAL POSITION SIGNAL

1.DEF: Signal incoherent

NOTESConditions for applying the fault finding procedure to stored faults:

If the customer complains of intermittent faults typical of defect mode type 3

(no accelerator pedal, cruise control or speed limiter), and that the ESP indicator

light comes on but the injection system displays no present faults, apply this fault

finding procedure.

Special notes:

This fault finding procedure enables an accelerator pedal mechanical seizure type fault

to be displayed whilst the pedal is depressed (when the driver's foot is lifted, the pedal

position remains the same). In this case, the driver will brake.

This program enables an inconsistency in the driver's behaviour, such as the brake

pedal and accelerator being depressed simultaneously to be detected (but enables

heel/toe points and left foot braking to be performed without displaying a fault).

There are two possible cases:

1. The fault finding procedure detects constant acceleration then braking with the

acceleration still maintained => change to reversible type 3 defect mode (see

System operation) which no longer recognises the accelerator pedal => warning

light does not come on, fault is not stored. If the accelerator pedal changes position

before the end of a time delay (approximately 31 seconds), it exits defect mode

and returns to normal mode.

2. If the accelerator pedal does not change position for the entire time delay

(approximately 31 seconds), it goes irreversibly into defect mode (requires the

ignition to be switched off to exit it). The warning light comes on and the fault is

stored. This fault finding procedure has no relation with the throttle position.

An accelerator fault (locking, for example) is needed to show the stored fault.

Use the Wiring Diagrams Technical Note for NEW TWINGO, E33, CLIO III,

or MODUS.

SIM32_V44_DF650 / SIM32_V4C_DF650 / SIM32_V50_DF650 / SIM32_V54_DF650

AFTER REPAIRFollow the instructions to confirm repair:

–If the fault is present, continue to deal with the fault.

–If the fault is stored, ignore it.

Deal with any other faults.

Clear the stored faults.

Page 169 of 348

17B-169V7 MR-413-X44-17B000$150.mif

PETROL INJECTION

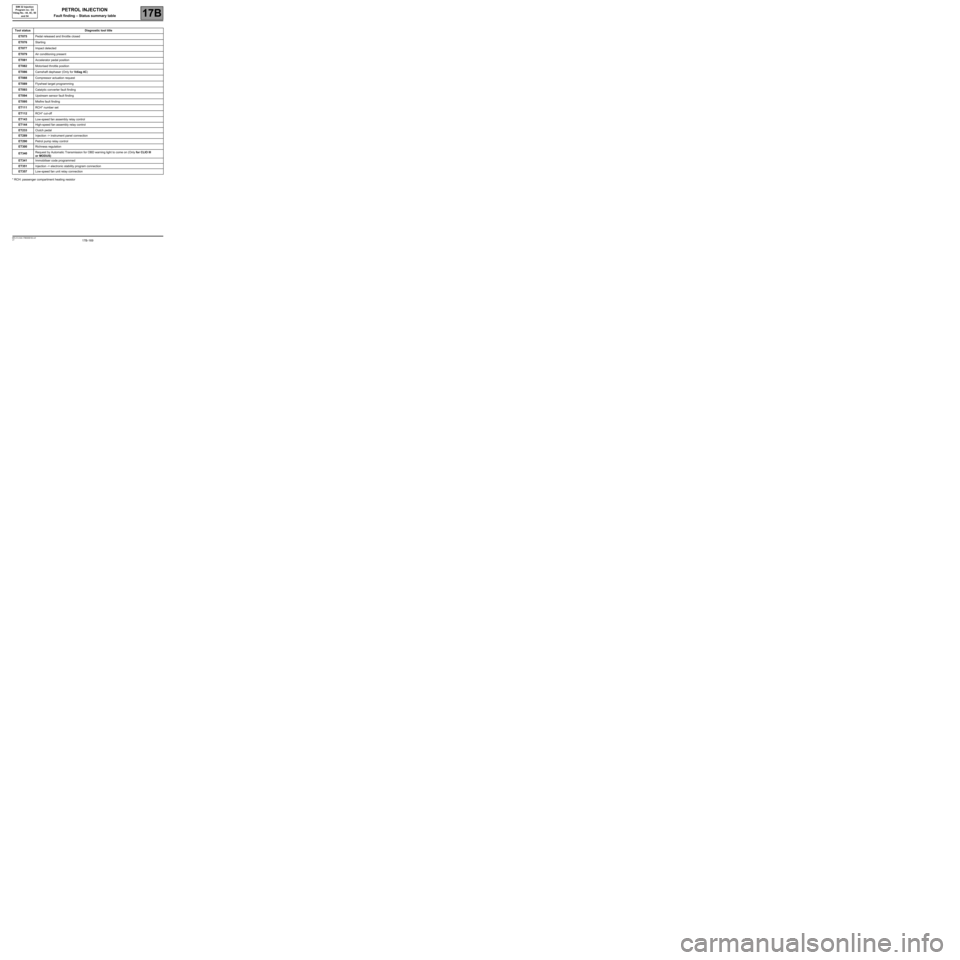

Fault finding – Status summary table17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

* RCH: passenger compartment heating resistor

Tool statusDiagnostic tool title

ET075Pedal released and throttle closed

ET076Starting

ET077Impact detected

ET079Air conditioning present

ET081Accelerator pedal position

ET082Motorised throttle position

ET086Camshaft dephaser (Only for Vdiag 4C)

ET088Compressor actuation request

ET089Flywheel target programming

ET093Catalytic converter fault finding

ET094Upstream sensor fault finding

ET095Misfire fault finding

ET111RCH* number set

ET112RCH* cut-off

ET143Low-speed fan assembly relay control

ET144High-speed fan assembly relay control

ET233Clutch pedal

ET289Injection -> instrument panel connection

ET290Petrol pump relay control

ET300Richness regulation

ET340Request by Automatic Transmission for OBD warning light to come on (Only for CLIO III

or MODUS)

ET341Immobiliser code programmed

ET351Injection -> electronic stability program connection

ET357Low-speed fan unit relay connection