lock RENAULT TWINGO RS 2009 2.G Electrical Equipment User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 241

Page 57 of 241

84A-2

CONTROL - SIGNALS

Steering column switch assembly: Removal - Refitting84A

REMOVAL

I - REMOVAL PREPARATION OPERATION

a

Set the wheels straight ahead.

aLock the airbag computer using the Diagnostic tool

(see Fault finding - Replacement of components)

(88C, Airbags and pretensioners).

aDisconnect the battery (see 80A, Battery, Battery:

Removal - Refitting, page 80A-2) .

aRemove the rev counter (see 83A, Instrument pa-

nel, Rev counter: Removal - Refitting, page 83A-

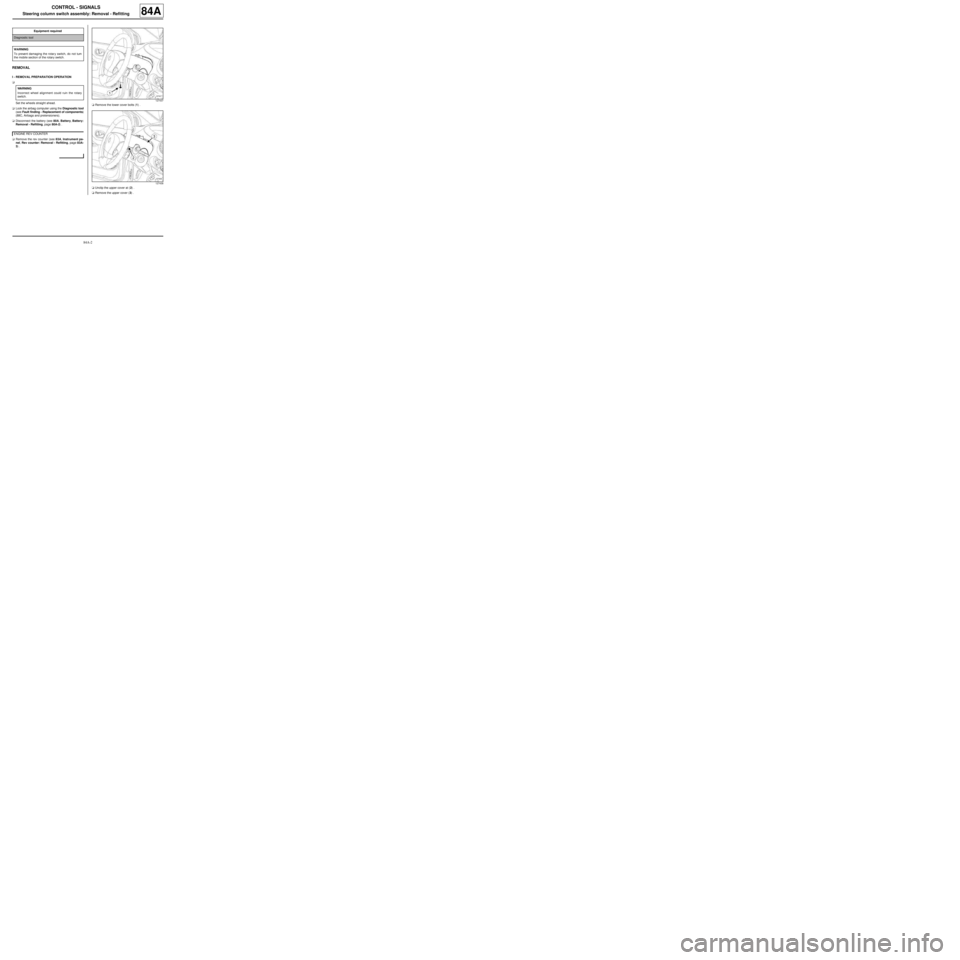

3) .aRemove the lower cover bolts (1) .

aUnclip the upper cover at (2) .

aRemove the upper cover (3) . Equipment required

Diagnostic tool

WARNING

To prevent damaging the rotar y switch, do not turn

the mobile section of the rotary switch.

WARNING

Incorrect wheel alignment could ruin the rotary

switch.

ENGINE REV COUNTER

127437

127438

Page 58 of 241

84A-3

CONTROL - SIGNALS

Steering column switch assembly: Removal - Refitting84A

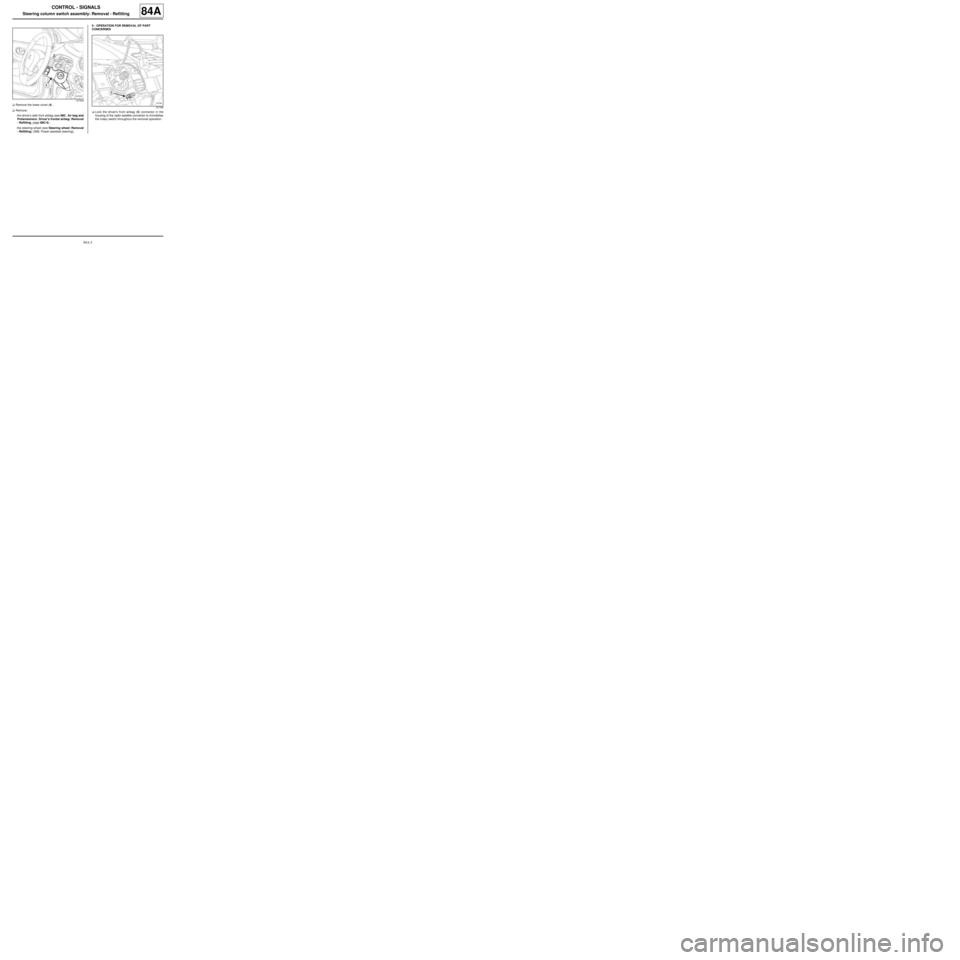

aRemove the lower cover (4) .

aRemove:

-the driver's side front airbag (see 88C, Air bag and

Pretensioners, Driver's frontal airbag: Removal

- Refitting, page 88C-6) ,

-the steering wheel (see Steering wheel: Removal

- Refitting) (36B, Power-assisted steering),II - OPERATION FOR REMOVAL OF PART

CONCERNED

aLock the driver's front airbag (5) connector in the

housing of the radio satellite connector to immobilise

the rotary switch throughout the removal operation.

127439

127766

Page 60 of 241

84A-5

CONTROL - SIGNALS

Steering column switch assembly: Removal - Refitting84A

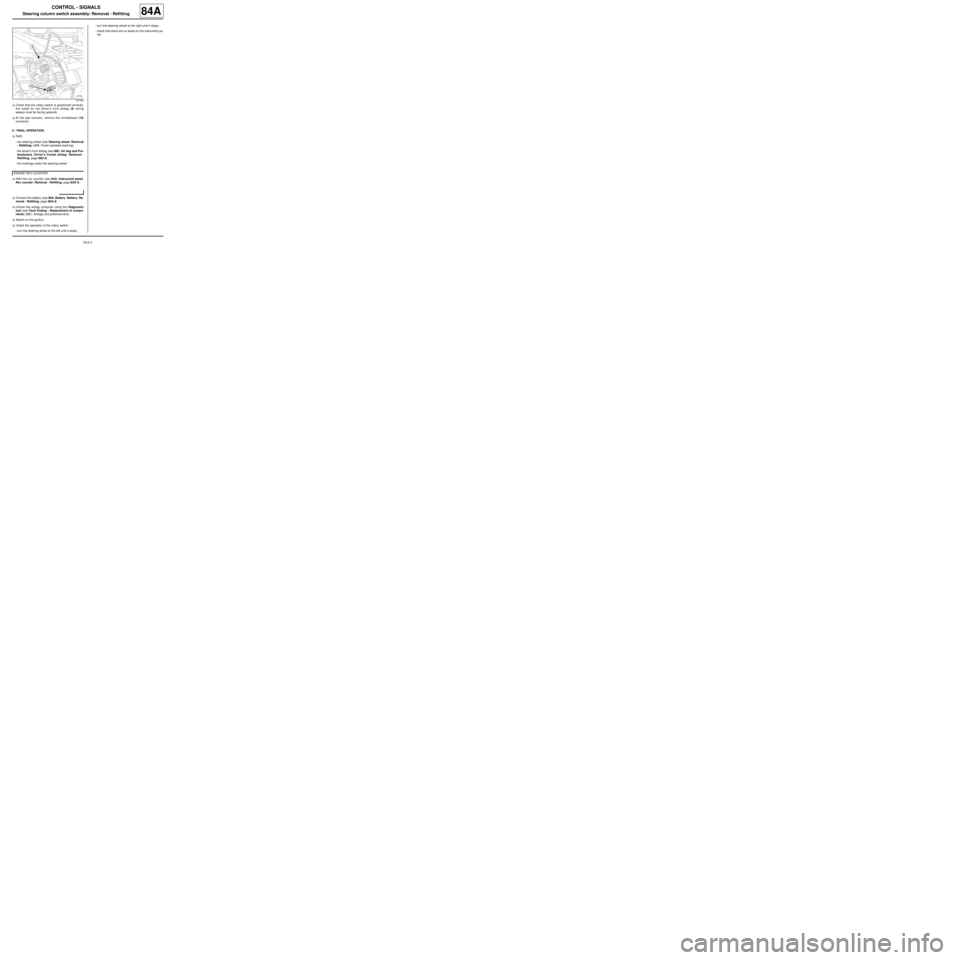

aCheck that the rotary switch is positioned correctly:

the outlet for the driver's front airbag (9) wiring

always must be facing upwards.

aAt the last moment, remove the immobilised (10)

connector.

II - FINAL OPERATION.

aRefit:

-the steering wheel (see Steering wheel: Removal

- Refitting) (36B, Power-assisted steering),

-the driver's front airbag (see 88C, Air bag and Pre-

tensioners, Driver's frontal airbag: Removal -

Refitting, page 88C-6) .

-the cowlings under the steering wheel.

aRefit the rev counter (see 83A, Instrument panel,

Rev counter: Removal - Refitting, page 83A-3) .

aConnect the battery (see 80A, Battery, Battery: Re-

moval - Refitting, page 80A-2) .

aUnlock the airbag computer using the Diagnostic

tool (see Fault finding - Replacement of compo-

nents) (88C, Airbags and pretensioners).

aSwitch on the ignition.

aCheck the operation of the rotary switch:

-turn the steering wheel to the left until it stops,-turn the steering wheel to the right until it stops,

-check that there are no faults on the instrument pa-

nel.

127766

ENGINE REV COUNTER

Page 65 of 241

84A-10

CONTROL - SIGNALS

Hazard warning lights and central door control: Removal - Refitting84A

REMOVAL

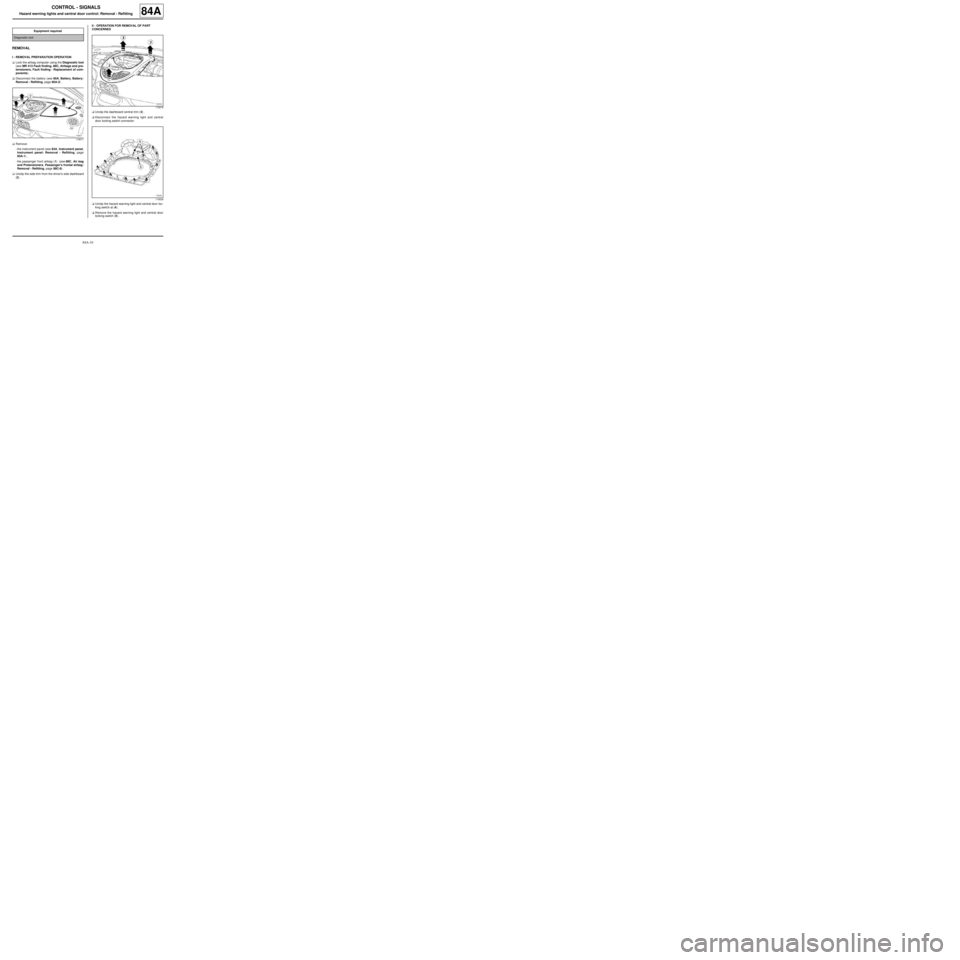

I - REMOVAL PREPARATION OPERATION

aLock the airbag computer using the Diagnostic tool

(see MR 413 Fault finding, 88C, Airbags and pre-

tensioners, Fault finding - Replacement of com-

ponents).

aDisconnect the battery (see 80A, Battery, Battery:

Removal - Refitting, page 80A-2) .

aRemove:

-the instrument panel (see 83A, Instrument panel,

Instrument panel: Removal - Refitting, page

83A-1) ,

-the passenger front airbag (1) (see 88C, Air bag

and Pretensioners, Passenger's frontal airbag:

Removal - Refitting, page 88C-8) .

aUnclip the side trim from the driver's side dashboard

(2) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aUnclip the dashboard central trim (3) .

aDisconnect the hazard warning light and central

door locking switch connector.

aUnclip the hazard warning light and central door loc-

king switch at (4) .

aRemove the hazard warning light and central door

locking switch (5) . Equipment required

Diagnostic tool

119517

119518

119539

Page 66 of 241

84A-11

CONTROL - SIGNALS

Hazard warning lights and central door control: Removal - Refitting84A

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit the hazard warning light and central door loc-

king switch.

aConnect the hazard warning light and central door

locking switch connector.

II - FINAL OPERATION.

aClip on:

-the dashboard central trim,

-the side trim from the driver's side dashboard.

aRefit:

-the passenger front airbag (see 88C, Air bag and

Pretensioners, Passenger's frontal airbag: Re-

moval - Refitting, page 88C-8) ,

-the instrument panel (see 83A, Instrument panel,

Instrument panel: Removal - Refitting, page

83A-1) .

aConnect the battery (see 80A, Battery, Battery: Re-

moval - Refitting, page 80A-2) .

aUnlock the airbag computer using the Diagnostic

tool (see MR 413 Fault finding, 88C, Airbags and

pretensioners, Fault finding - Replacement of

components).

Page 115 of 241

87B-1

PASSENGER COMPARTMENT CONNECTION UNIT

UCH: Removal - Refitting

87B

REMOVAL

I - OPERATION FOR REMOVAL OF PART

CONCERNED

aWhen replacing, carry out the necessary operations

using the Diagnostic tool (see Fault finding - Re-

placement of components) (MR 413, 87B, Pas-

senger compartment connection unit).

a

aLock the airbag computer using the Diagnostic tool

(see Fault finding - Replacement of compo-

nents)(MR 413, 88C, Airbags and seat belt preten-

sioners).

aSwitch off the ignition.

aDisconnect the battery (see 80A, Battery, Battery:

Removal - Refitting, page 80A-2) .aUnclip the dashboard lower trim (1)

aDisconnect the different connectors (2) from the

dashboard lower trim. Equipment required

Diagnostic tool

RIGHT-HAND DRIVE

IMPORTANT

To avoid any risk of triggering when working on

or near a pyrotechnic component (airbags or pre-

tensioners), lock the airbag computer using the

diagnostic tool.

When this function is activated, all the trigger

lines are inhibited and the airbag warning light on

the instrument panel lights up continuously (igni-

tion on).

IMPORTANT

Never handle the pyrotechnic systems (preten-

sioners or airbags) near to a source of heat or

naked flame - they may be triggered.

LEFT-HAND DRIVE

120278

119711

Page 118 of 241

87B-4

PASSENGER COMPARTMENT CONNECTION UNIT

UCH: Removal - Refitting

87B

aRefit:

-the passenger front airbag (see 88C, Air bag and

Pretensioners, Passenger's frontal airbag: Re-

moval - Refitting, page 88C-8) ,

-the glovebox (see Glovebox: Removal - Refit-

ting) (MR 412, 57A, Interior equipment).

aConnect the battery (see 80A, Battery, Battery: Re-

moval - Refitting, page 80A-2) .

aUnlock the airbag computer using the Diagnostic

tool (see Fault finding - Replacement of compo-

nents)(MR 413, 88C, Airbags and seat belt preten-

sioners).

aWhen replacing, carry out the necessary operations

using the Diagnostic tool (see Fault finding - Re-

placement of components) (MR 413, 87B, Pas-

senger compartment connection unit). RIGHT-HAND DRIVE

RIGHT-HAND DRIVE

Page 119 of 241

87C-1

OPENING ELEMENT MANAGEMENT

Opening elements management: List and location of components87C

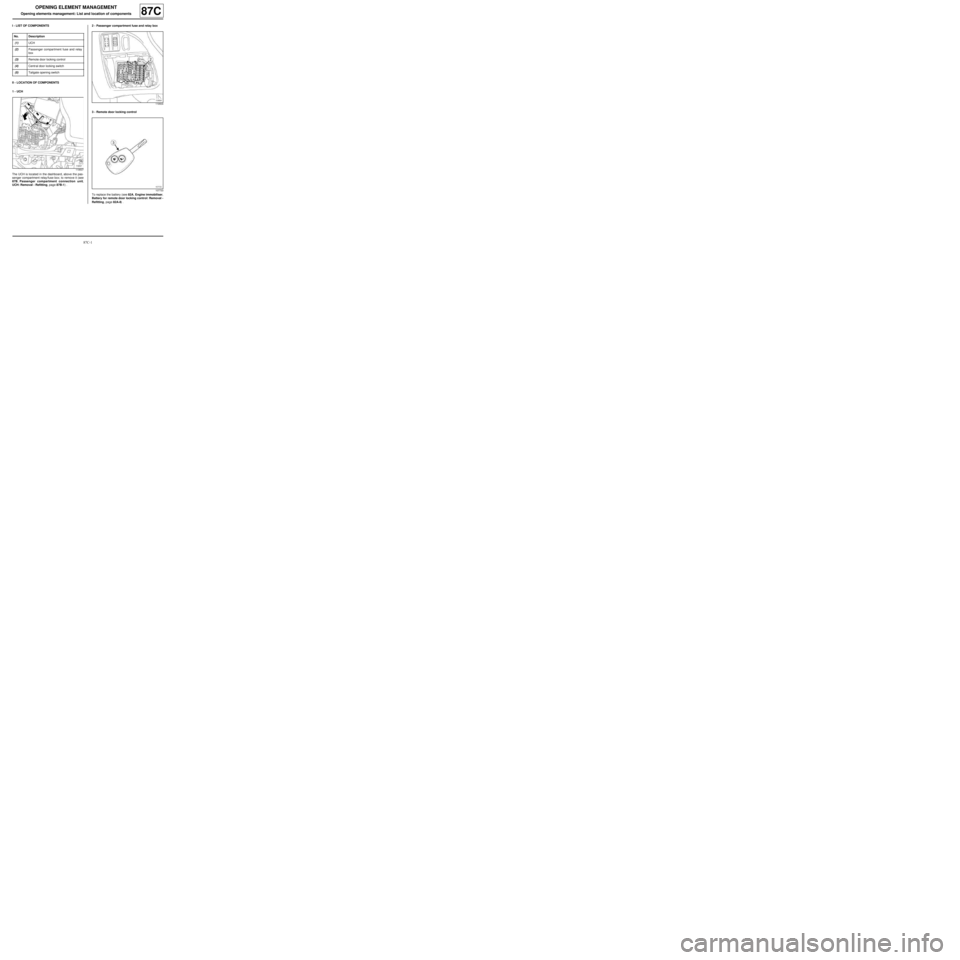

I - LIST OF COMPONENTS

II - LOCATION OF COMPONENTS

1 - UCH

The UCH is located in the dashboard, above the pas-

senger compartment relay/fuse box; to remove it (see

87B, Passenger compartment connection unit,

UCH: Removal - Refitting, page 87B-1) .2 - Passenger compartment fuse and relay box

3 - Remote door locking control

To replace the battery (see 82A, Engine immobiliser,

Battery for remote door locking control: Removal -

Refitting, page 82A-8) . No. Description

(1) UCH

(2) Passenger compartment fuse and relay

box

(3) Remote door locking control

(4) Centr al door locking switch

(5) Tailgate opening switch

119507

119504

107733

Page 120 of 241

87C-2

OPENING ELEMENT MANAGEMENT

Opening elements management: List and location of components87C

4 - Central door locking switch

To remove it (see 84A, Control - Signals, Hazard

warning lights and central door control: Removal -

Refitting, page 84A-10) .

5 - Tailgate opening switch

121084

120162

Page 138 of 241

88A-2

WIRING HARNESS

Wiring: Precautions for the repair

88A

I - SAFETY

1 - Potentially dangerous components

Do not leave any unused +12V connectors exposed to

the air without any protection (see Connector: Sea-

ling and locking) (Technical Note 6015A, 88A, Wi-

ring).

Check that there is no contact between the wiring and

the fuel and brake pipes.

Avoid mounting the wiring in areas with a temperature

above 100˚C.

2 - Advice to be followed before any operation

Before carrying out any work on the wiring, disconnect

the battery.

3 - Instructions to be followed during the operation

To prevent the wiring from being damaged, check that

the surrounding area is not mechanically harmful (e.g.:

door windows, sharp corners, burrs, studs, etc.).

The wiring should be at least 30 mm away from any

moving components (belt, pulley, steering column,

etc.).

Depending on the surrounding area, check that the

unused connectors respect the necessary sealing

constraints (see Connector: Sealing and locking)

(Technical Note 6015A, 88A, Wiring).

All of the connections (connectors) used in the engine

compartment are sealed; do not remove the seal from

around the connectors.II - GENERAL RECOMMENDATIONS

Do not connect an earth to a stud with insulating pro-

tection (paint,etc.).

Do not use more than two earth terminals on the same

point.

Do not use power earths on the same point as electro-

nic earths.

To prevent water flowing into the connectors, make a

low point just on the wiring routing (just before the con-

nector).

For connections between fixed and mobile compo-

nents, secure the wiring on the fixed part.

Overlapping of the battery feed wires (positive and ne-

gative) causes disruption; they must be secured sepa-

rately.

Wiring mountings:

- use plastic clips, ensuring that the colour coding is

respected,

-do not use steel clips that are not protected with rub-

ber,

- keep the clips integrated into the wiring during a re-

placement operation,

- do not leave steering wheel wires without protection.

Check that:

- the shunts are correctly secured,

- the connectors are correctly housed and locked.

Wiring routing:

- when it is visible it must be aesthetically pleasing, and

resemble the routing marked during removal,

- prohibit wiring routing in grooves and overlaps (risk of

wear through friction),

- prohibit mounting several wires on the same clip,

- do not lock the connectors or wiring in areas that are

sensitive to drilling (number plate etc.). WARNING

To prevent damaging the connectors, consult the

disconnection procedure (see Connector: Discon-

nection and reconnection) (Technical Note

6015A, 88A, Wiring).

WARNING

To prevent any risk of noise, premature wear, short

circuits, etc. after the refitting operation, mark the

wiring routing and how to connect the connectors.

WARNING

To prevent any damage during the removal opera-

tion, check that the wiring is free from its mountings

(retaining clip, plastic clip, adhesive tape, connec-

tor, etc.).