check engine RENAULT TWINGO RS 2009 2.G Engine And Peripherals Owners Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 652

Page 592 of 652

19B-10

EXHAUST

Exhaust: Precautions for the repair

19B

Exhaust trunking with 1 bolt

Exhaust trunking with 2 bolts

Fit the exhaust trunking onto the part of the exhaust

system fitted to the vehicle.

Position the pipe onto the lugs (2) inside the exhaust

trunking.

Tighten the exhaust trunking bolt(s) slightly (depending

on the version).

Position the second part of the exhaust system under

the vehicle, fitting it in the exhaust trunking.Position the second exhaust pipe onto the lugs inside

the exhaust trunking.

Check that the two cut marks (3) are aligned (if applica-

ble).

Position the trunking so that there is no risk of contact

between its bolt or bolts and the heat shields.

Torque tighten

-the exhaust trunking nut with 1 bolt (25 N.m) (if fit-

ted),

-the exhaust trunking nuts with 2 bolts (18 N.m) (if

fitted).

Check the following and deal with if necessary:

-no underbody contact between the exhaust system

and the heat shields,

-all of the heat shields are present and secure.

Start the engine.

Check that there are no leaks: deal with any leaks.

95478

119681

Note:

If necessary, use a workshop jack to lift and hold

the heavy and bulky components of the exhaust

system.

99227

Note:

Any damaged heat shields must be replaced.

Page 596 of 652

19B-14

EXHAUST

Catalytic converter: Removal - Refitting

K9K

19B

aIf they are replaced, torque tighten the catalytic

converter studs on the turbocharger (9 Nm ).

II - REFITTING OPERATION FOR PART

CONCERNED

aFrom underneath the vehicle, fit:

-the catalytic converter on the turbocharger fitted

with a new seal between the catalytic converter

and the turbocharger,

-one of the catalytic converter nuts on the turbo-

charger.

aIn order, fit (without tightening):

-the catalytic converter upstream strut bolts on the

engine,

-the catalytic converter downstream strut bolt and

nut on the gearbox,

-the catalytic converter upstream strut bolts on the

catalytic converter,

-the catalytic converter downstream strut bolt on the

catalytic converter,

-the catalytic converter nuts on the turbocharger,

aTorque tighten and in order:

-the catalytic converter nuts on the turbocharger

(26 Nm),

-the catalytic converter upstream strut bolts on

the engine (44 Nm),

-the catalytic converter downstream strut bolts

on the gearbox (21 Nm),

-the catalytic converter downstream strut nut on

the gearbox (21 Nm),

-the catalytic converter upstream strut bolts on

the catalytic converter (26 Nm),

-the catalytic converter downstream strut bolt

on the catalytic converter (21 Nm).

aFit in order:

-a new exhaust system sealing ring on the catalytic

converter,

-the exhaust pipe on the catalytic converter,

-the exhaust pipe springs and bolts on the catalytic

converter.aTorque tighten the exhaust pipe bolts on the cata-

lytic converter (21 Nm).

aCheck the following and deal with if necessary:

-that there is no contact with the underbody,

-the presence and correct positioning of all the ex-

haust pipe heat shields.

III - FINAL OPERATION.

aRefit:

-the engine tie-bar (see 19D, Engine mounting,

Lower engine tie-bar: Removal - Refitting, page

19D-18) ,

-the air filter box (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the scoop under the scuttle panel grille ( (see

Scoop under the scuttle panel grille: Removal -

Refitting) ),

-the scuttle panel grille ( (see Scuttle panel grille:

Removal - Refitting) ),

-the windscreen wiper arms ( (see Windscreen

wiper arm: Removal - Refitting) ).

aConnect the battery ( (see Battery: Removal - Re-

fitting) ).

aStart the engine.

aCheck that there are no leaks and deal with them if

necessary. Note:

Check that there is no contact between the cata-

lytic conver ter and the turbocharger oil return

pipe during the entire catalytic converter tighten-

ing operation.

Page 608 of 652

19B-26

EXHAUST

Expansion chamber: Removal - Refitting

K4M

19B

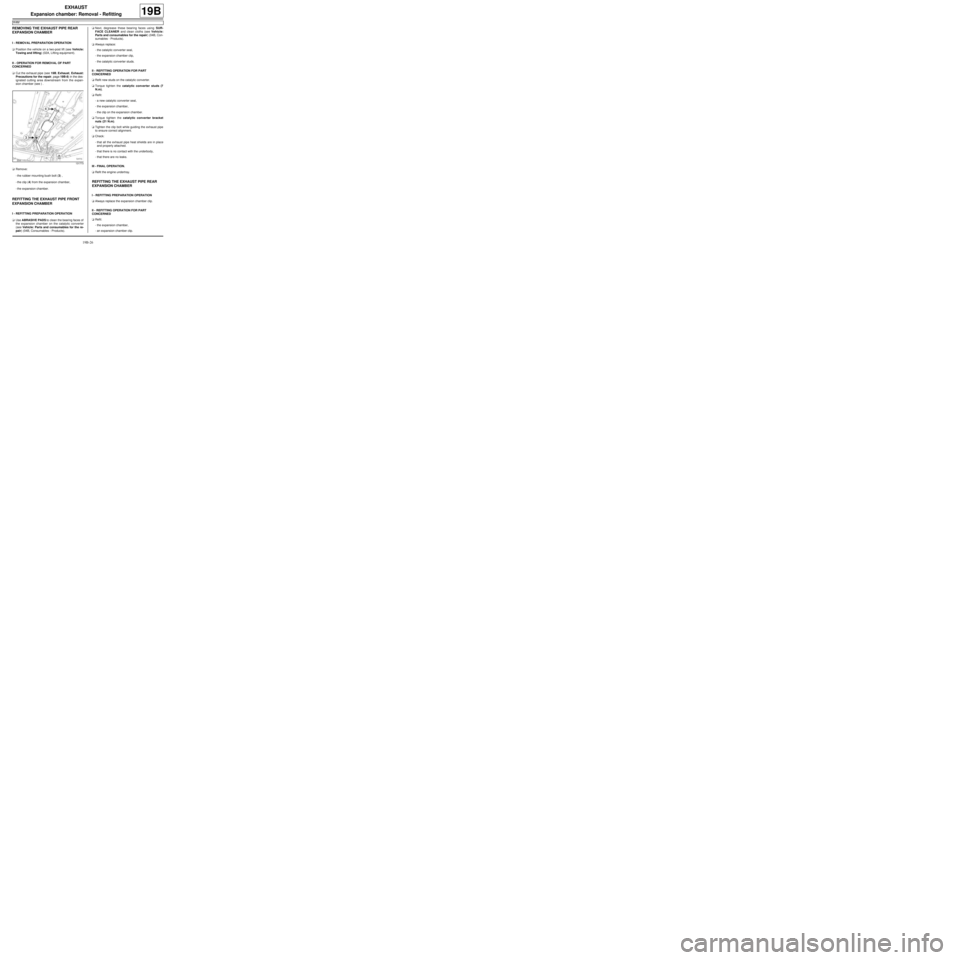

REMOVING THE EXHAUST PIPE REAR

EXPANSION CHAMBER

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aCut the exhaust pipe (see 19B, Exhaust, Exhaust:

Precautions for the repair, page 19B-8) in the des-

ignated cutting area downstream from the expan-

sion chamber (see ) .

aRemove:

-the rubber mounting bush bolt (3) ,

-the clip (4) from the expansion chamber,

-the expansion chamber.

REFITTING THE EXHAUST PIPE FRONT

EXPANSION CHAMBER

I - REFITTING PREPARATION OPERATION

aUse ABRASIVE PADS to clean the bearing faces of

the expansion chamber on the catalytic converter

(see Vehicle: Parts and consumables for the re-

pair) (04B, Consumables - Products).aNext, degrease these bearing faces using SUR-

FACE CLEANER and clean cloths (see Vehicle:

Parts and consumables for the repair) (04B, Con-

sumables - Products).

aAlways replace:

-the catalytic converter seal,

-the expansion chamber clip,

-the catalytic converter studs.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit new studs on the catalytic converter.

aTorque tighten the catalytic converter studs (7

N.m).

aRefit:

-a new catalytic converter seal,

-the expansion chamber,

-the clip on the expansion chamber.

aTorque tighten the catalytic converter bracket

nuts (21 N.m).

aTighten the clip bolt while guiding the exhaust pipe

to ensure correct alignment.

aCheck:

-that all the exhaust pipe heat shields are in place

and properly attached.

-that there is no contact with the underbody,

-that there are no leaks.

III - FINAL OPERATION.

aRefit the engine undertray.

REFITTING THE EXHAUST PIPE REAR

EXPANSION CHAMBER

I - REFITTING PREPARATION OPERATION

aAlways replace the expansion chamber clip.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the expansion chamber,

-an expansion chamber clip.

131773

Page 611 of 652

19B-29

EXHAUST

Intermediate pipe: Removal - Refitting

K9K

19B

REFITTING THE INTERMEDIATE PIPE

REFITTING OPERATION FOR PART CONCERNED

aRefit:

-the rubber mounting bush of the intermediate pipe,

-the rubber mounting bush bolt on the intermediate

pipe.

aFit the intermediate pipe.

aAttach the intermediate pipe to the vehicle using the

intermediate pipe rubber mounting bush bolt.

aFit a new After-Sales sleeve and follow the instruc-

tions (see 19B, Exhaust, Exhaust: Precautions

for the repair, page 19B-8) .

aRefit a new clip between the front section of the in-

termediate pipe and the intermediate pipe.

aCheck the following and deal with if necessary:

-that there is no contact with the underbody,

-the presence and correct positioning of all the ex-

haust pipe heat shields.

aStart the engine.

aCheck that there are no leaks and deal with them if

necessary.Note:

If replacing the rubber mounting bush, spray the

inside of the rubber mounting bush with BRAKE

CLEANER ( (see Vehicle: Parts and consum-

ables for the repair) ) in the form of an aerosol

spray to facilitate fitting.