fuel cap RENAULT TWINGO RS 2009 2.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 652

Page 145 of 652

11A-28

TOP AND FRONT OF ENGINE

Timing belt: Removal - Refitting

D7F, and 800

11A

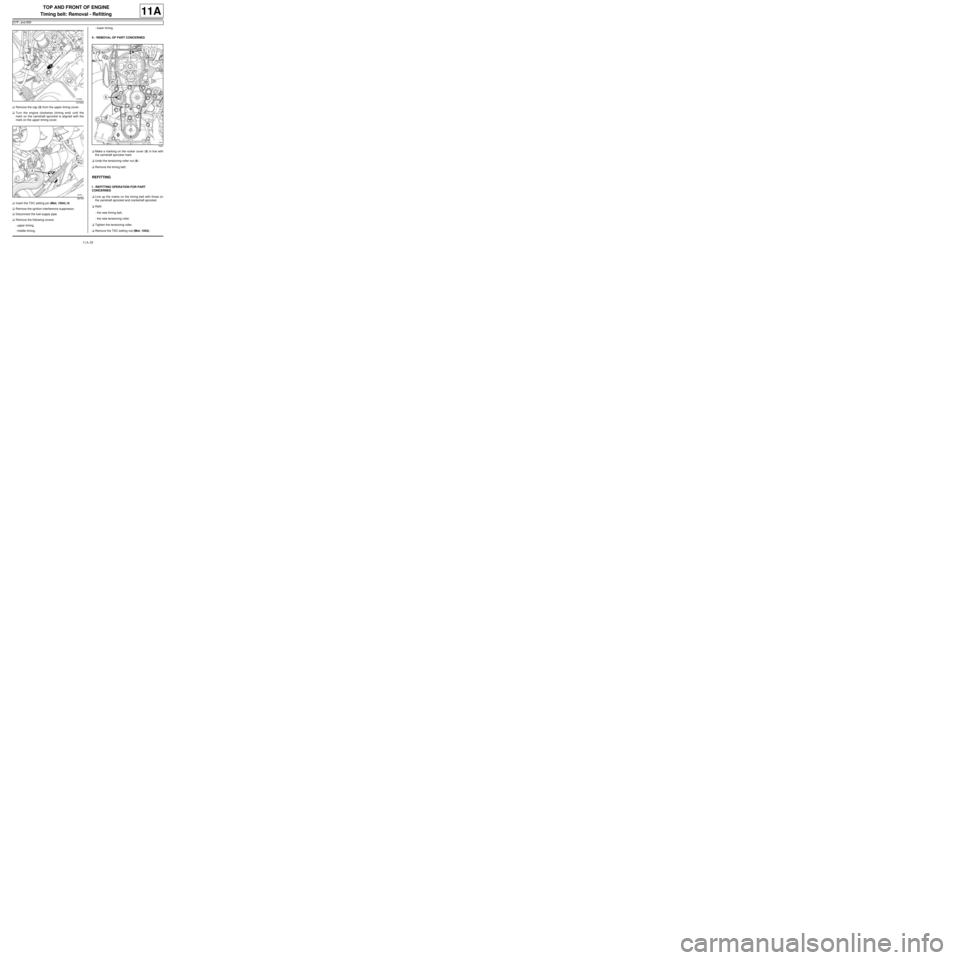

aRemove the cap (3) from the upper timing cover.

aTurn the engine clockwise (timing end) until the

mark on the camshaft sprocket is aligned with the

mark on the upper timing cover.

aInsert the TDC setting pin (Mot. 1054) (4)

aRemove the ignition interference suppressor.

aDisconnect the fuel supply pipe.

aRemove the following covers:

-upper timing,

-middle timing,-lower timing.

II - REMOVAL OF PART CONCERNED

aMake a marking on the rocker cover (5) in line with

the camshaft sprocket mark

aUndo the tensioning roller nut (6) .

aRemove the timing belt.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aLine up the marks on the timing belt with those on

the camshaft sprocket and crankshaft sprocket.

aRefit:

-the new timing belt,

-the new tensioning roller.

aTighten the tensioning roller.

aRemove the TDC setting rod (Mot. 1054).

107259

99795

1041

Page 199 of 652

11A-82

TOP AND FRONT OF ENGINE

Camshaft: Removal - Refitting

D4F, and 772

11A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove:

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the crankshaft accessories pulley (see 11A, Top

and front of engine, Crankshaft accessories

pulley: Removal - Refitting, page 11A-20) ,

-the timing belt (see 11A, Top and front of engine,

Timing belt: Removal - Refitting, page 11A-27) ,-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the inlet distributor (see 12A, Fuel mixture, Inlet

distributor: Removal - Refitting, page 12A-29) ,

-the rocker cover (see 11A, Top and front of en-

gine, Rocker cover: Removal - Refitting, page

11A-66) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

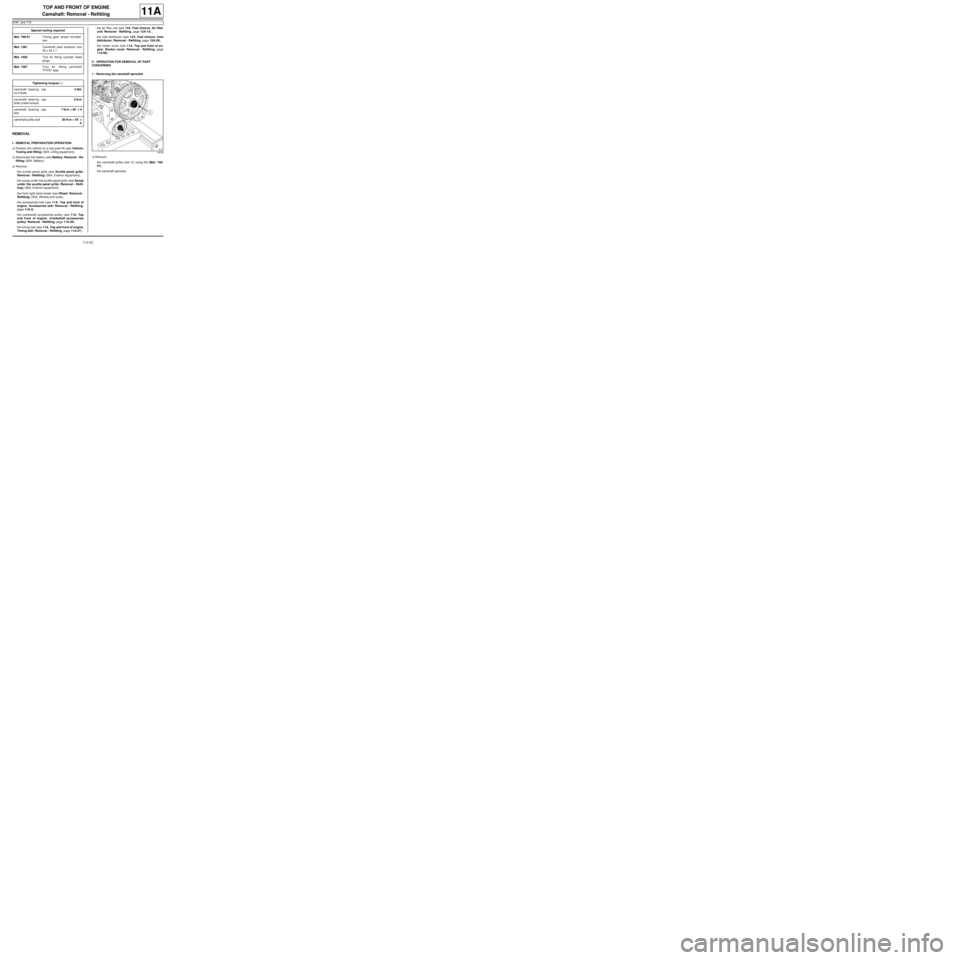

1 - Removing the camshaft sprocket

aRemove:

-the camshaft pulley bolt (1) using the (Mot. 799-

01),

-the camshaft sprocket. Special tooling required

Mot. 799-01Timing gear wheel immobil-

iser.

Mot. 1381Camshaft seal extractor tool

30 x 42 x 7.

Mot. 1605Tool for fitting cylinder head

plugs.

Mot. 1587Tool for fitting camshaft

"PTFE" seal.

Tightening torquesm

camshaft bearing cap

no.5 bolts5 Nm

camshaft bearing cap

bolts (initial torque)5 N.m

camshaft bearing cap

bolt7 N.m + 50˚ ±± ± ±

6

camshaft pulley bolt30 N.m + 45˚ ±± ± ±

6

18722

Page 208 of 652

11A-91

TOP AND FRONT OF ENGINE

Camshaft: Removal - Refitting

D4F, and 780 or 782

11A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove:

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the ignition coil (see 17A, Ignition, Coils: Remov-

al - Refitting, page 17A-1) ,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

-the timing belt (see 11A, Top and front of engine,

Timing belt: Removal - Refitting, page 11A-27) ,-the rocker cover (see 11A, Top and front of en-

gine, Rocker cover: Removal - Refitting, page

11A-66) .

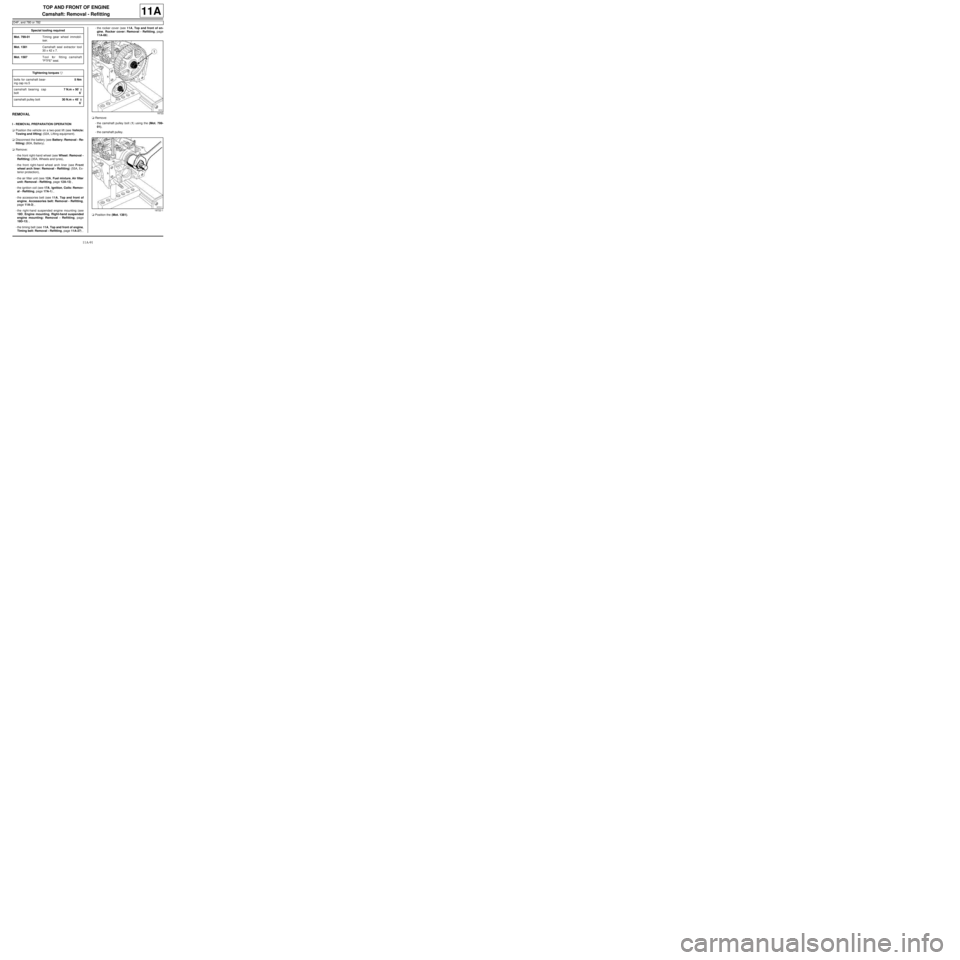

aRemove:

-the camshaft pulley bolt (1) using the (Mot. 799-

01),

-the camshaft pulley.

aPosition the (Mot. 1381). Special tooling required

Mot. 799-01Timing gear wheel immobil-

iser.

Mot. 1381Camshaft seal extractor tool

30 x 42 x 7.

Mot. 1587Tool for fitting camshaft

"PTFE" seal.

Tightening torquesm

bolts for camshaft bear-

ing cap no.55 Nm

camshaft bearing cap

bolt7 N.m + 50˚ ±± ± ±

6˚

camshaft pulley bolt30 N.m + 45˚ ±± ± ±

6˚

18722

18722-1

Page 297 of 652

12A-32

FUEL MIXTURE

Inlet distributor: Removal - Refitting

D7F

12A

aIt is essential to apply a bead of FLUORSTAR 2L

grease with a diameter of 2 mm around the inner

edge of the high tension caps.

aConnect the high voltage wiring harness to the spark

plugs.

aClip the high voltage wiring harness onto the inlet

distributor.

aRefit:

-the intermediate plate,

-the intermediate bracket bolts on the throttle valve,

-the motorised throttle valve,

-the motorised throttle valve bolts.

aTorque tighten the motorised throttle valve bolts

(10 N.m)

aRefit:

-the dipstick,

-the air filter unit air outlet pipe.

-the air filter unit air inlet pipe,

-the air inlet scoop on the front end panel.aFit the alternator in place.

aRefit:

-the alternator upper bolt,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) .

106640

AIR CONDITIONING

Page 301 of 652

12A-36

FUEL MIXTURE

Inlet distributor: Removal - Refitting

D4F, and 772

12A

III - FINAL OPERATION

aIt is essential to apply a bead of FLUOSTAR 2L

grease (see Vehicle: Parts and consumables for

the repair) (04B, Consumables - Products) 2 mm in

diameter on the inner edge of the high tension caps.

aConnect:

-the high voltage wiring harnesses to the spark

plugs,

-the fuel supply pipe union on the injector rail,

-the motorised throttle valve connector,

-the injector connectors,

-the air inlet temperature sensor connector,

-the non-return valve pipe on the brake servo,

-the petrol vapour rebreather pipe.

aRefit the dipstick.

aClip the engine wiring onto the inlet distributor.

aRefit the air filter unit (see 12A, Fuel mixture, Air fil-

ter unit: Removal - Refitting, page 12A-13) .

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

106640

Page 348 of 652

13A-5

FUEL SUPPLY

Fuel filter: Removal - Refitting

K9K

13A

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the fuel filter mounting nut (3) ,

-the fuel filter from its mounting.

aDetach the water detection sensor offset connector

on the fuel filter mounting (if fitted).

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aaAttach the water detection sensor offset connector

to the fuel filter mounting (if fitted).

aRefit the fuel filter to its mounting.

aFit the fuel filter mounting nut.

II - FINAL OPERATION.

aPosition the fuel pipes.

aConnect to the fuel filter:

-the manual priming pump outlet pipe,

-the high pressure pump inlet pipe.

aOpen the bleed screw on top of the fuel filter.

aPrime the fuel circuit using a manual priming pump

until the disconnected pipes are filled with fuel.

aClose the bleed screw on top of the fuel filter.

aCheck that there are no fuel leaks.

aStart the engine.

aCheck that there are no fuel leaks.

aSwitch off the engine.

aRefit the engine cover.

BLEEDING

aRemove the fuel filter mounting nut.

aDetach the manual priming pump.

aRemove the fuel filter without pulling on the water

detection sensor wiring harness in the diesel fuel.

aPosition a container under the fuel filter which has

been removed from its mounting.

aTurn the bleed cap or the water detection sensor in

the diesel fuel (depending on equipment) by no

more than one turn.

aAllow it to flow until diesel fuel appears.

aClose the bleed cap or the water detection sensor

(depending on equipment).

121441

Note:

If the fuel filter is to be reused, fit blanking plugs

to the fuel supply pipes and fuel filter openings,

using the appropriate blanking plug kit, depend-

ing on the engine (see 13B, Diesel injection,

Diesel injection: Precautions for the repair,

page 13B-1) .

WARNING

Do not remove the blanking plugs from each

component until the last moment.

Also, do not remove the components from their

packaging until they are to be fitted to the vehi-

cle.

Note:

Chec k that the fuel filter is correctly positioned

and secure on its mounting by shaking it: the fil-

ter must not move.

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

Page 362 of 652

13B-1

DIESEL INJECTION

Diesel injection: Precautions for the repair

K9K

13B

I - RISKS RELATING TO CONTAMINATION

The high-pressure direct injection system is highly sen-

sitive to contamination. The risks caused by contami-

nation are:

-damage to or destruction of the high pressure injec-

tion system,

-a component seizing,

-a component not being properly sealed.

All After-Sales operations must be performed under

very clean conditions. Having carried out an operation

in good conditions means that no impurities (particles a

few microns in size) have penetrated the system during

dismantling.

The cleanliness principle must be applied from the filter

to the injectors.

What are the sources of contamination?

-metal or plastic swarf,

-paint,

-fibres:

•cardboard,

•brushes,

•paper,

•clothing,

•cloth,

-foreign bodies such as hair,

-ambient air,

-etc.

1 - Cleaning cloths

Use lint-free cleaning cloths (see Vehicle: Parts and

consumables for the repair) (04B, Consumables -

Products).

It is prohibited to use cloths or ordinary paper towels:

these produce lint and lose fibres, which then contami-

nate the fuel circuit.

Each cloth must only be used once.2 - Blanking plugs

The blanking plugs are used to cap the fuel circuit once

it is opened and to therefore prevent contaminants

from entering.

A set of blanking plugs should be used once only and

used plugs must be discarded after use: once used,

the plugs are soiled and cleaning them is not sufficient

to make them reusable.

Unused plugs must also be discarded and must not be

used when carrying out work on an injection system.

Part number for set of blanking plugs: (see Vehicle:

Parts and consumables for the repair) (04B, Con-

sumables - Products).

3 - Protective bags

Use hermetically-resealable plastic bags, using adhe-

sive tape, for example, to store components which will

be refitted and reused. Stored parts will therefore be

less subject to the risk of contamination.

These are single-use bags: after use they must be dis-

carded.

4 - Cleaning products

Two cleaning products can be used:

-an injector cleaner (see Vehicle: Parts and consum-

ables for the repair) (04B, Consumables - Products),

-an aerosol spray brake cleaner (see Vehicle: Parts

and consumables for the repair) (04B, Consum-

ables - Products).

To use the injector cleaner, be sure to have a clean

brush in good condition (the brush must not lose any

bristles) as well as a clean container which has no im-

purities in it. WARNING

Do not clean the engine with a high pressure

cleaner to prevent damaging the connections.

Note:

There is no specific set of blanking plugs for S9U

and S9W engines. In order to comply with the

cleanliness recommendations, use plugs that are

compatible with the blanking plug sets for F9Q,

G9U, G9T or ZD3 engines.

Note:

Use a new injector cleaner each time work is car-

ried out (a used cleaning agent will contain impuri-

ties).

Page 363 of 652

13B-2

DIESEL INJECTION

Diesel injection: Precautions for the repair

K9K

13B

II - ADVICE TO BE FOLLOWED BEFORE ANY

OPERATION

1) Carry out the work in a clean working area and take

care to protect removed components from dust using

plastic bags which are hermetically-resealable, for ex-

ample.

2) Always order the following from the Parts Depart-

ment before carrying out work:

-a new set of blanking plugs, specific to the engine,

-enough lint-free cleaning cloths.

-one of the two cleaning products for fuel pipe

unions,

-the parts that are always to be replaced after each

removal operation, mentioned in the operational pro-

cedures specific to the vehicle (see related Workshop

Repair Manual).

3) Wear safety goggles fitted with side shields to pre-

vent the cleaning product from splashing the eyes.

4) Wear leaktight protective gloves (Nitrile type) to

avoid prolonged contact with the skin.

5) Before carrying out work on the injection system,

use plastic bags or clean rags, for example, to protect:

-the accessories and timing belts,

-the electrical accessories (starter, alternator, power-

assisted steering pump, sensors and electrical con-

nectors),

-the flywheel face.

III - INSTRUCTIONS TO BE FOLLOWED DURING

THE OPERATION

Wash your hands before and while carrying out the

work.

Replace leaktight protective gloves (Nitrile type) when

they are soiled or damaged.

All components removed from the injection system

must be stored in a hermetically sealed plastic bag

once they have been capped.

Reseal the bag hermetically, for example using adhe-

sive tape, even if the bag must be opened shortly after-

wards: ambient air can be a source of impurities.After opening the fuel circuit, the use of brushes, clean-

ing agents, air blow guns, rifle-type brushes or stan-

dard cloths is strictly prohibited: these items are likely

to allow impurities to enter the system.

When replacing a component with a new one or when

refitting it after storing it in a plastic bag, do not unpack

it until it is time to fit it on the vehicle.

IV - CLEANING

There are currently two procedures for cleaning the

fuel circuit before opening it in order to carry out work in

the workshop.

These procedures enable the fuel circuit to be cleaned

to prevent contamination from entering: they both have

the same end result and neither is preferred over the

other.

1 - Cleaning using injector cleaner

Clear the access to the unions that need opening, fol-

lowing the work procedures specific to the vehicle (see

the relevant Workshop Repair Manual).

Protect sections which are sensitive to fuel leaks.

Pour the injector cleaning agent into a container which

is free from impurities.

Dip a clean brush, which is not shedding bristles, into

the container of injector cleaning agent.

Clean the unions carefully using the brush and the in-

jector cleaning agent.

Blast the components that have been cleaned with

compressed air (tools, workbench, and also parts,

unions and around the injection system). Check that no

bristles from the brush have come away and that the

area is clean.

Wipe the sections that were cleaned with fresh clean-

ing cloths.

Open the circuit at the unions and immediately fit the

relevant blanking plugs. Note:

When using leather protective gloves, wear a pair of

leaktight protective gloves (Nitrile type) over the top.

IMPORTANT

Wear leaktight gloves (Nitrile type) for this opera-

tion.

IMPORTANT

Wear goggles with side protectors for this opera-

tion.

Page 393 of 652

13B-32

DIESEL INJECTION

Venturi: Removal - Refitting

K9K

13B

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the diesel return pipe (2) on the venturi.

aFit anti-contamination caps.

aRemove the high pressure pump venturi bolt (3) .

aRemove the venturi (by hand with small tugs and

successive turns).

aMake sure that no impurities enter the high pressure

pump when the venturi is removed.REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

a

aRefit the venturi to the high pressure pump.

aRefit the venturi bolt to the high pressure pump.

aTorque tighten the venturi bolt on the high pres-

sure pump (5.5 Nm).

aRemove the blanking plugs.

aConnect the diesel return pipe to the venturi.

II - FINAL OPERATION.

aClip the high pressure pump diesel return pipe onto

the neck.

aRemove the blanking plugs.

aConnect the diesel return pipe to the high pressure

pump.

aAttach the diesel return pipe to the neck.

aRemove the protection on the alternator to prevent

fuel flowing out.

102316

Note:

Make preparations for fuel outfl ow.

Note:

Make preparations for fuel outfl ow.

WARNING

Do not blast with compressed air once the fuel

circuit is open, otherwise impurities may enter

the system. Only use cleaning cloths.

WARNING

Do not remove the components from their pack-

aging until just before fitting them to the vehicle.

Note:

Do not lubricate the seals with grease or old die-

sel fuel. Use the applicator provided in the kit for

the new par t.

Page 460 of 652

17A-4

IGNITION

Coils: Removal - Refitting

D4F, and 772

17A

aWhen refitting the spark plug wiring, always apply a

bead of FLUOSTAR 2L (2 mm in diameter) to the in-

ner edge of the high-tension caps on the side of the

spark plugs and coil.

aConnect:

-the ignition coil connector,

-the ignition coil high voltage wiring harness.

II - FINAL OPERATION

aRefit the air filter unit (see 12A, Fuel mixture, Air fil-

ter unit: Removal - Refitting, page 12A-13) .

aConnect the battery (see Battery: Removal - Refit-

ting) .

106640