width RENAULT TWINGO RS 2009 2.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 652

Page 47 of 652

10A-41

ENGINE AND CYLINDER BLOCK ASSEMBLY

Conrod bearing shell: Removal - Refitting

K9K

10A

a

Pull the con rod - piston assembly using the tie rod of

the tool (Mot. 1914), taking care not to allow the pis-

ton to touch the piston base cooling jets.

aRemove the upper con rod bearing shell.

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consum-

ables - products) to clean the bearing mating face on

the con rod body.

REFITTING

I - REFITTING OPERATION FOR THE CON ROD

BEARING SHELLS ON CYLINDER NO.2

aparts always to be replaced: con rod cap boltsa

Fit the head of the tool (Mot. 1920) with the marking

" K9K INF " on the threaded sleeve of the tool (Mot.

1914).

aPosition the lower con rod bearing shell on the tool

(Mot. 1920).

139315

WARNING

Failure to observe the following procedure may

damage the piston base cooling jets.

Note:

If reusing the con rod bearing shells, mark the

position of the upper con rod bearing shell in

relation to the con rod body.

Note:

Always replace con rod bearing shells with a

width of 20 mm by con rod bearing shells with a

width of 18 mm.

If the set of con rod bearing shells only includes

con rod bearing shells which are 18mm wide,

only use the head of the tool (Mot. 1920) with the

mar king " K9K SUP ".

Page 60 of 652

10A-54

ENGINE AND CYLINDER BLOCK ASSEMBLY

Oil pump: Removal - Refitting

D4F or D7F

10A

REFITTING

I - REFITTING PREPARATION OPERATION

aClean the joint faces (see Vehicle: Parts and con-

sumables for the repair) (04B, Consumables -

Products).

aparts always to be replaced: engine oil strainer

seal.

aparts always to be replaced: Crankshaft seal on

timing end.

aApply a BEAD OF SILICONE ADHESIVE SEAL-

ANT (see Vehicle: Parts and consumables for

the repair) (04B, Consumables - Products) with a

width of 1.3 mm to ensure the sealing of the oil

pump.

II - REFITTING OPERATION FOR PART

CONCERNED

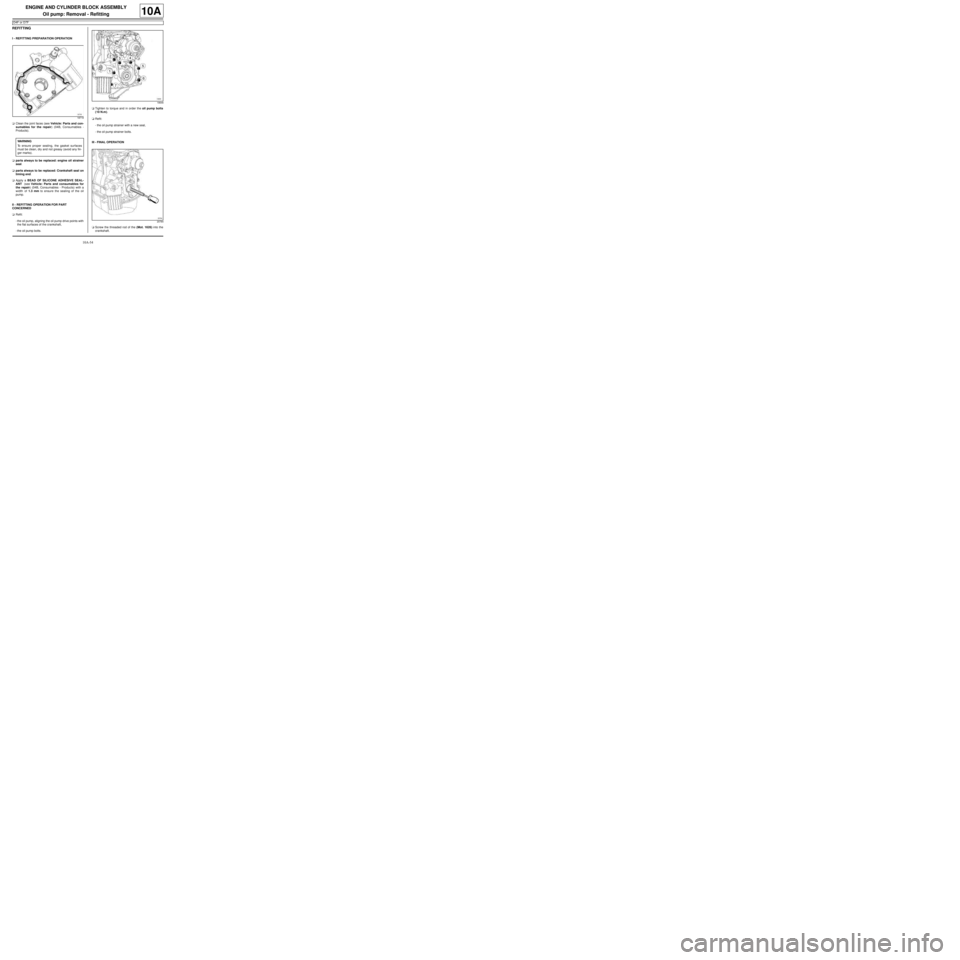

aRefit:

-the oil pump, aligning the oil pump drive points with

the flat surfaces of the crankshaft,

-the oil pump bolts.aTighten to torque and in order the oil pump bolts

(10 N.m).

aRefit:

-the oil pump strainer with a new seal,

-the oil pump strainer bolts.

III - FINAL OPERATION

aScrew the threaded rod of the (Mot. 1626) into the

crankshaft.

18718

WARNING

To ensure proper sealing, the gasket surfaces

must be clean, dry and not greasy (avoid any fin-

ger marks).

18646

20784

Page 202 of 652

11A-85

TOP AND FRONT OF ENGINE

Camshaft: Removal - Refitting

D4F, and 772

11A

aApply:

-two beads of MASTIXO (see Vehicle: Parts and

consumables for the repair) (04B, Consumables

- Products) with a width of 2 mm at the bearing

No.5 end of the cylinder head,

-two points of MASTIXO (see Vehicle: Parts and

consumables for the repair) (04B, Consumables

- Products) with a width of 2 mm at the bearing

No.1 end of the cylinder head.

aApply a drop of oil to the camshaft bearings.II - REFITTING OPERATION FOR PART

CONCERNED

1 - Refitting the camshaft

aPosition the pistons at mid-stroke to prevent any

contact with the valves when tightening the cam-

shaft bearings.

aRefit:

-the camshaft,

-the camshaft caps.

aTorque tighten the camshaft bearing cap no.5

bolts (5 Nm ).

19595

19594

18724-2

Page 211 of 652

11A-94

TOP AND FRONT OF ENGINE

Camshaft: Removal - Refitting

D4F, and 780 or 782

11A

aApply:

-two beads (3) of MASTIXO (see Vehicle: Parts

and consumables for the repair) (04B, Consum-

ables - Products) with a width of 2 mm to bearing

No.5 on the cylinder head,

-two points (4) of MASTIXO (see Vehicle: Parts

and consumables for the repair) (04B, Consum-

ables - Products) to bearing No.1 on the cylinder

head.aApply a blob of oil to the camshaft bearings.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the camshaft.

19595

19594

WARNING

Applying excess sealant could cause it to be

squeezed out when parts are tightened. A mix-

ture of sealant and fluid could damage certain

components (engine, radiator, etc.).

18724-3

Page 542 of 652

19A-32

COOLING

Coolant pump: Removal - Refitting

K4M

19A

a

aApply a bead (2) of SEALING RESIN (see Vehicle:

Parts and consumables for the repair) (04B, Con-

sumables - Products) with a width of 0.6 to 1 mm.II - REFITTING OPERATION

a

aRefit the coolant pump.

aTighten to torque and in order:

-bolt 1 of the coolant pump (27 N.m),

-bolts 2 to 8 of the water pump (10 N.m).

III - FINAL OPERATION

aRefit:

-the camshaft dephaser (see 11A, Top and front of

engine, Camshaft dephaser: Removal - Refit-

ting, page 11A-135) ,

-the timing belt (see 11A, Top and front of engine,

Timing belt: Removal - Refitting, page 11A-27) ,

-the crankshaft accessories pulley (see 11A, Top

and front of engine, Crankshaft accessories

pulley: Removal - Refitting, page 11A-20) ,

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

10063

WARNING

Applying excess sealant could cause it to be

squeezed out when parts are tightened. A mix-

ture of sealant and fluid could damage certain

components (engine, radiator, etc.).

WARNING

Failure to observe the following procedure may

cause irreparable damage to the water pump

bearing.

Note:

To fit the pump on the two pins of the cylinder

block, never apply pressure to the water pump

pinion; instead use the pump mounting bolts by

pre-tightening them.

14505

Note:

Apply one to tw o drops of FRENETANCHE (see

Vehicle: Parts and consumables for the

repair) (04B, Consumables - Products) to the

coolant pump bolts (1) and (4) .