steering RENAULT TWINGO RS 2009 2.G General Vehicle Information Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 46

Page 14 of 46

01D-1

MECHANICAL INTRODUCTION

Vehicle: Precautions for the repair

01D

GENERAL INFORMATION

All information contained in these manuals is intended

exclusively for automotive industry professionals.

The documentation is intended to cover all vehicles in

the RENAULT range throughout the world, but may not

cover equipment designed for use in specific countries.

The procedures and fault finding procedures recom-

mended and described in this manual have been de-

signed by automotive industry repair professionals.

1 - General recommendations

Observe basic principles of vehicle repair.

The quality of repair depends first and foremost on the

care exercised by the person in carrying it out.

To ensure good repair:

-protect the sensitive areas of the vehicle (seats,

steering wheel, wings, etc.),

-unless otherwise indicated, all repairs must be done

with the ignition off,

-when welding on the vehicle, it is advisable to remove

or disconnect components near the repair area that

could be affected by the heat,

-use recommended professional products and original

parts,

-observe the tightening torques,

-replace roll pins, self-locking or bonded nuts or bolts

every time they are removed,

-take care with electrical and electronic components

which cannot withstand excess voltage and improper

handling; replace any electrical and electronic com-

ponents which have experienced a voltage drop,

-make sure that the connectors are correctly clipped,

-do not pull on the wiring,

-check for the sealing plugs on the connectors,

-Do not splash any liquid, regardless of its type (oil,

cleaner, etc.), on the electric and electronic compo-

nents (computers, sensors, etc.)

-do not just replace parts one after the other, carry out

detailed fault finding beforehand,

-carry out a final check before returning the vehicle to

the customer (set the clock, check the alarm opera-

tion, check the lights and indicators etc.),

-clean and degrease the sections to be bonded

(threads, stub axle splines) to ensure proper adher-

ence,-protect the accessories and timing belts, the electrical

accessories (starter, blanking cover, electric power

assisted steering pump) and the mating face to pre-

vent diesel fuel spilling onto the clutch friction plate.

The design quality of our vehicles demands that noth-

ing is left to chance in making a good repair, and it is

essential to refit parts or components exactly as they

were originally (for instance: heat shields, wiring rout-

ing, pipe routing, particularly in the area of the exhaust

pipe).

Do not blow away asbestos particles or dust (brakes,

clutch, etc.), vacuum them up or clean the component

with a cleaning agent (such as a brake cleaning prod-

uct).

Use professional products and apply them with care,

for example do not apply too much sealing paste to the

sealing surface.

Exhaust gases (petrol and diesel) are pollutants. Oper-

ate engines with care and always use exhaust gas ex-

tractors.

Ensure that there is no risk of a short circuit occurring

when the electrical connections are reconnected (e.g.

starter, alternator, etc.). Some points need greasing,

others do not, therefore particular attention should be

paid during refitting operations to ensure that they work

properly under all conditions.

2 - Special tooling - ease of use

The repair procedures have been designed using spe-

cial tools; they must therefore be carried out using

these tools to ensure a high degree of working safety

and quality of repair.

The equipment we have approved has undergone

careful research and testing, and must be used and

maintained with care.

3 - Reliability - updating

New repair procedures are constantly being developed

in the interests of repair quality, either with new prod-

ucts (emission control, injection, electronics, etc.), or in

fault finding. Be sure to consult the Workshop Repair

Manuals or Technical Notes or fault finding summaries

before any servicing operation.

Since vehicle specifications are subject to change dur-

ing their commercial life, it is essential to check wheth-

er there are any updated Technical Notes when

seeking information.

Page 20 of 46

02A-1

LIFTING EQUIPMENT

Vehicle: Towing and lifting

02A

I - TOWING1 - Position of front attachment point

2 - Position of rear attachment point

II - LIFTING BY TROLLEY JACK Equipment required

Diagnostic tool

safety strap(s)

WARNING

See the current towing regulations in each country.

Never use the drive shafts as attachment points.

The towing points may only be used for towing on

the road.

Never use the towing points for removing the vehi-

cle from a ditch or to lift the vehicle, either directly

or indirectly.

Screw in and lock the towing ring before towing.

Vehicles fitted with automatic transmission:

-The vehicle should preferably be transported on a

platform or towed by lifting the front wheels. As an

exception, the vehicle may be towed with the

wheels on the ground but at a speed below 12

mph (20km/h) and over a maximum distance of

18 miles (30 kms) (with the gear lever in neutral).

Vehicles fitted with Renault Card:

-If the vehicle battery is flat, the steering column

remains locked. In this case, fit a new battery or

connect to an electrical source to lock the airbag

computer using the Diagnostic tool (see Airbag

and pretensioners: Precautions for the repair)

(88C, Airbag and pretensioners), which unlocks

the steering column.

-If it is not possible to lock the airbag computer, the

front of the vehicle must be lifted.

120735

120450

IMPORTANT

To prevent any accidents, the trolley jack must only

be used to lift and/or move the vehicle. The vehicle

height must be maintained with axle stands which

are strong enough to support the weight of the vehi-

cle.

Page 39 of 46

04B-4

CONSUMABLES - PRODUCTS

Vehicle: Parts and consumables for the repair

04B

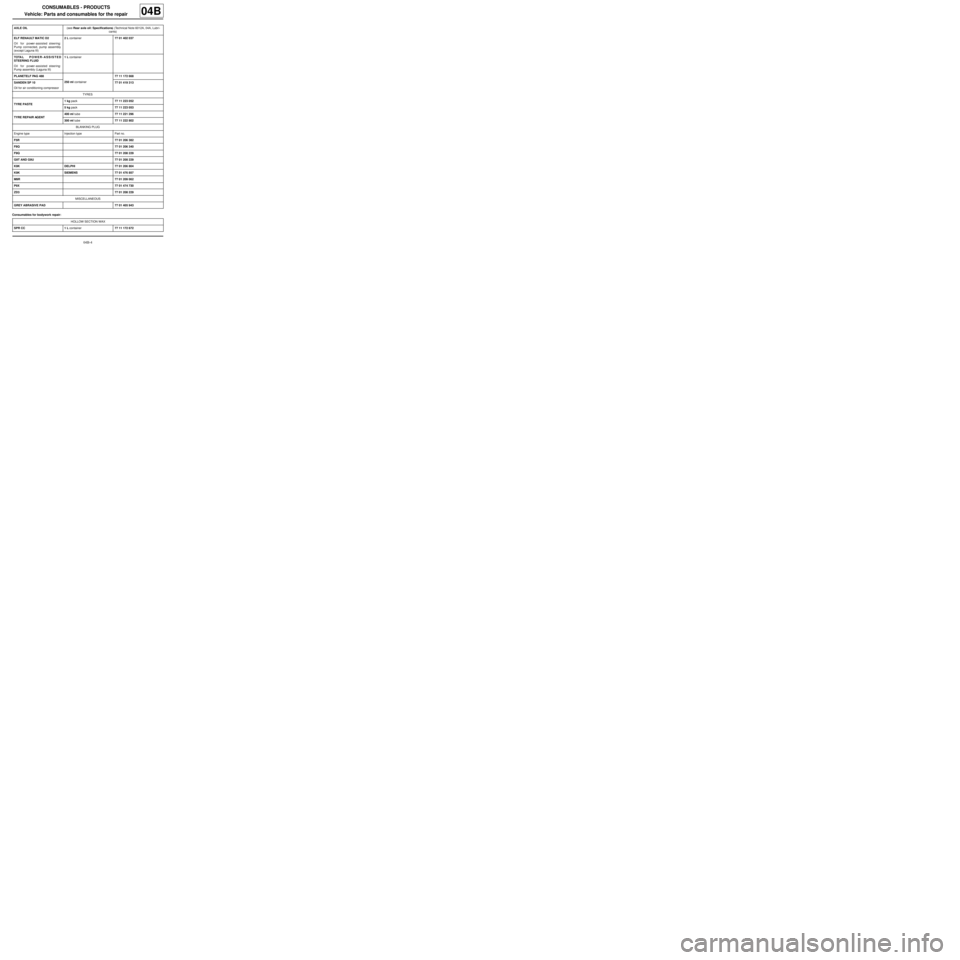

Consumables for bodywork repair:AXLE OIL (see Rear axle oil: Specifications) (Technical Note 6012A, 04A, Lubr i-

cants)

ELF RENAULT MATIC D2

Oil for power-assisted steering:

Pump connected, pump assembly

(except Laguna III)2 L container77 01 402 037

TOTAL POWER-ASSISTED

STEERING FLUID

Oil for power-assisted steering:

Pump assembly (Laguna III)1 L container

PLANETELF PAG 488

250 ml container77 11 172 668

SANDEN SP 10

Oil for air conditioning compressor77 01 419 313

TYRES

TYRE PASTE1 kg pack77 11 223 052

5 kg pack77 11 223 053

TYRE REPAIR AGENT400 ml tube77 11 221 296

300 ml tube77 11 222 802

BLANKING PLUG

Engine type Injection type Part no.

F5R77 01 206 382

F8Q77 01 206 340

F9Q77 01 208 229

G9T AND G9U 77 01 208 229

K9K DELPHI 77 01 206 804

K9K SIEMENS 77 01 476 857

M9R 77 01 209 062

P9X77 01 474 730

ZD377 01 208 229

MISCELLANEOUS

GREY ABRASIVE PAD 77 01 405 943

HOLLOW SECTION WAX

SPR CC 1 L container77 11 172 672