lock RENAULT TWINGO RS 2009 2.G Heating And Air Conditioning - Heating Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 29

Page 3 of 29

61A-3

MR-413-X44-61A000$125_eng.mif

V1

HEATING

Fault finding - Introduction61A

4. FAULT FINDING PROCEDURE

Wiring check

Fault finding problems

Disconnecting the connectors and/or manipulating the wiring harness may temporarily remove the cause of a fault.

Electrical measurements of voltage, resistance and insulation are generally correct, especially if the fault is not

present when the analysis is made (stored fault).

Visual inspection of the connection:

●Check that the connector is connected correctly and that the male and female parts of the connection are

correctly coupled.

Visual inspection of the area around the connection:

●Check the condition of the mounting (pin, strap, adhesive tape, etc.) if the connectors are attached to the vehicle.

●Check that there is no damage to the wiring trim (sheath, foam, adhesive tape, etc.) near the wiring.

●Check that there is no damage to the electrical wires at the connector outputs, in particular on the insulating

material (wear, cuts, burns, etc.).

Disconnect the connector to continue the checks.

Visual inspection of the plastic casing:

●Check that there is no mechanical damage (casing crushed, cracked, broken, etc.), in particular to the fragile

components (lever, lock, openings, etc.).

●Check that there is no heat damage (casing melted, darker, deformed, etc.).

●Check that there are no stains (grease, mud, liquid, etc.).

Visual inspection of the metal contacts:

(The female contact is called CLIP. The male contact is called TAB.)

●Check that there are no bent contacts (the contact is not inserted correctly and can come out of the back of the

connector). The spring contact of the connector when the wire is gently pulled.

●Check that there is no damage (folded tabs, clips open too wide, blackened or melted contact, etc.).

●Check that there is no oxidation on the metal contacts. Note:

Carry out each requested check visually. Do not remove a connector if it is not required.

Note:

Repeated connections and disconnections alter the functionality of the connectors and increase the risk of poor

electrical contact. Limit the number of connections/disconnections as much as possible.

Note:

The check is carried out on the 2 parts of the connection. There may be two types of connections:

–Connector / Connector

–Connector / Device

Page 20 of 29

61A-20

MR-413-X44-61A000$875_eng.mif

V1

HEATING

Fault finding - Fault finding charts61A

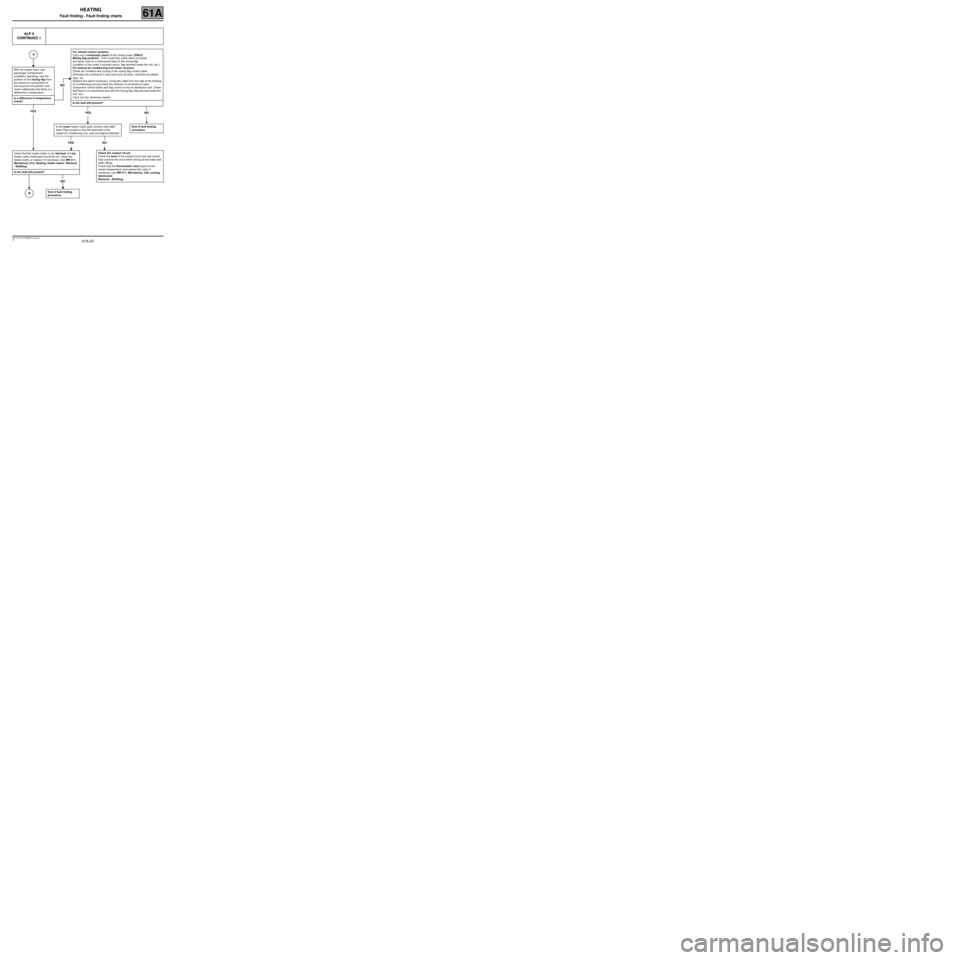

ALP 6

CONTINUED 1

With the engine warm and

passenger compartment

ventilation operating, vary the

position of the mixing flap from

the maximum cold position to

the maximum hot position and

check subjectively that there is a

dif ference in temperature.

Is a difference in temperature

noted?

YES

NO

For climate control systems:

Carry out a conformity check on the mixing motor (PR012

Mixing flap position). If the conformity check does not reveal

any faults, look for a mechanical fault on the mixing flap

(condition of the motor ’s notched sector, flap jammed inside the unit, etc.).

For manual air conditioning and heater versions:

Check the condition and routing of the mixing flap control cable.

Eliminate any constraints it may have such as kinks, restriction by plastic

clips, etc.

Replace the lead if necessary. Unclip the cable from the side of the heating/

air conditioning unit and check the stiffness of movement of each

component: control button and flap control on the air distribution unit. Check

that there is no mechanical fault with the mixing flap (flap jammed inside the

unit, etc.).

Carry out any necessary repairs.

Is the fault still present?

YES NO

Is the lower heater matrix pipe (coolant inlet) hot?

Note: Pipe located on the left-hand side of the

heater-air conditioning unit, near the engine bulkhead.

YES NO

End of fault finding

procedure.

Check that the heater matrix is not blocked: the top

heater matrix outlet pipe should be hot. Clean the

heater matrix or replace it if necessary (see MR 411,

Mechanical, 61A, Heating, Heater matrix: Removal

- Refitting).

Is the fault still present?

NO

Check the coolant circuit:

Check the level of the coolant circuit (too low a level

may unprime the circuit when driving at low loads and

when idling).

Check that the thermostatic valve opens at the

correct temperature, and replace the valve if

necessary (see MR 411, Mechanical, 19A, cooling,

thermostat:

Removal - Refitting).

End of fault finding

procedure.

A

B