torque RENAULT TWINGO RS 2009 2.G Sequential Transmission Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 138

Page 8 of 138

21B-8

MR-413-X44-21B000$177.mif

V2

21B

SEQUENTIAL GEARBOX

Fault finding - System operation

1. Sequential gearbox functions

The electrohydraulic system attached to the gearbox comprises two actuators, one for gear selection and changing,

the other for operating the clutch, and a hydraulic power unit which supplies power to the actuators.

The assembly is linked to the sequential gearbox computer, which itself is linked to the engine management

computer by a multiplex line connection. The gear lever is used to select gears: in automatic mode, gear changes

are controlled by the computer which uses auto-adaptive shift patterns; in manual mode, the driver moves a lever

which, via the computer, change the gears.

When the gear is changed, the sequential gearbox computer controls the engine management computer and the

torque in such a way as to reduce bucking, leaving the driver free to leave his foot on the accelerator pedal.

Description of user operation:

The interface between the driver and the sequential gearbox system inside the passenger compartment comprises:

–a gear lever (mechanical section and internal electronic section),

–a display,

–a buzzer.

Using this interface, the driver can:

–request gear changes (up or down),

–request a specific gear change (into neutral or reverse),

–switch between manual and automatic mode,

Description of passenger compartment control:

Description of gear lever positions:

–“S”: Standby: this is the only stable gear lever position. Each time the driver presses the lever, it returns to the S

position.

–“R”: Reverse: moving the lever to this position enables the driver to select reverse gear. Given the lever position

of the reverse function, if the movement is too slow, the sequential gearbox computer can read the N signal and

hence neutral is selected before reverse.

–“N”: Neutral: moving the lever to this position enables the driver to select neutral.

–“A/M”: AUTO/MANUAL: moving the lever to this position enables the driver to select either the manual mode (or

semi-automatic) or automatic mode. If AUTO mode is selected, moving the lever will enable the driver to select

manual mode, if manual mode is selected; moving the lever will enable the driver to select automatic mode. The automatic mode used by the sequential gearbox is based on the design of the DP0 automatic gearbox which

uses

shift patterns that adapt automatically to the driving style and road conditions.

The gear change is determined by a set of gear change graphs as a function of the accelerator pedal position and

the vehicle speed.

The sequential gearbox is a conventional manual gearbox with an electrohydraulic control.

Vdiag No: 04

MR-413-X44-21B000$177.mif

Page 22 of 138

21B-22

MR-413-X44-21B000$354.mif

V2

21B

SEQUENTIAL GEARBOX

Fault finding - Fault summary table

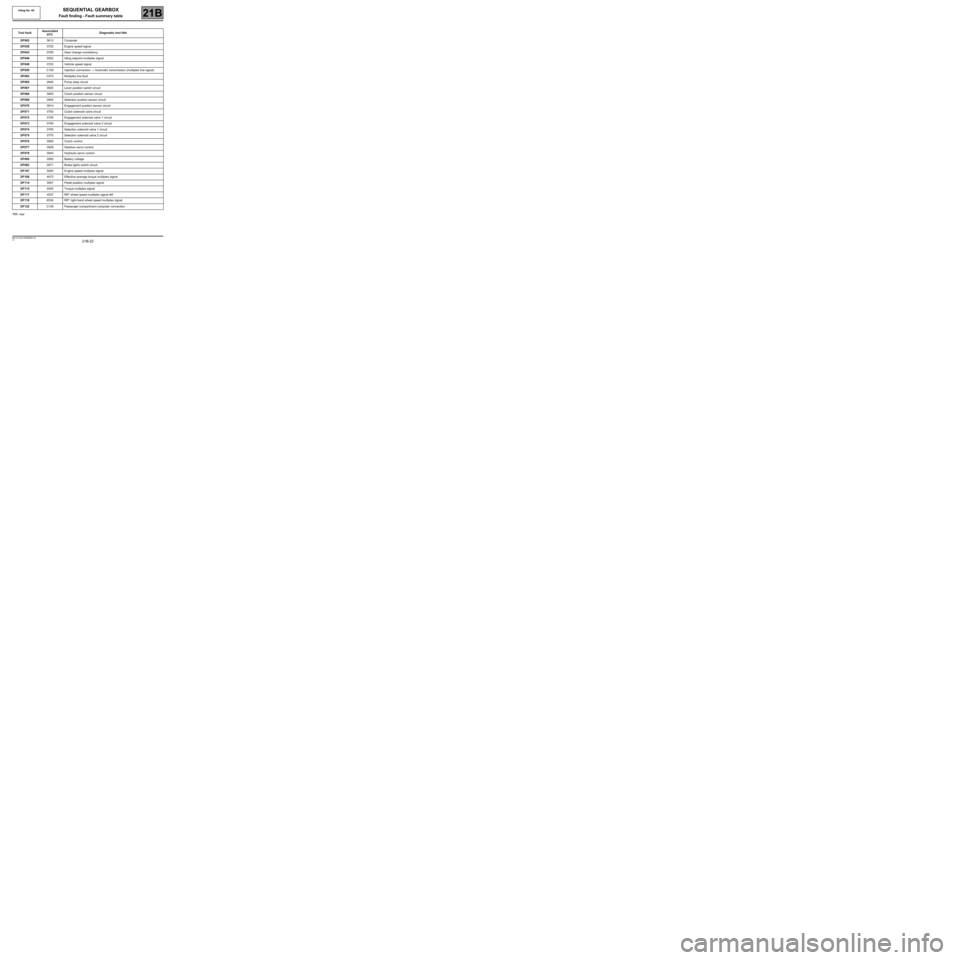

*RR: rearTool faultAssociated

DTCDiagnostic tool title

DF0020613 Computer

DF0390725 Engine speed signal

DF0430785 Gear change consistency

DF0465002 Idling setpoint multiplex signal

DF0480720 Vehicle speed signal

DF059C100 Injection connection → Automatic transmission (multiplex line signal)

DF062C073 Multiplex line fault

DF0650945 Pump relay circuit

DF0670820 Lever position switch circuit

DF0680805 Clutch position sensor circuit

DF0690904 Selection position sensor circuit

DF0700914 Engagement position sensor circuit

DF0710750 Clutch solenoid valve circuit

DF0720755 Engagement solenoid valve 1 circuit

DF0730760 Engagement solenoid valve 2 circuit

DF0740765 Selection solenoid valve 1 circuit

DF0750770 Selection solenoid valve 2 circuit

DF0760900 Clutch control

DF0770928 Gearbox servo control

DF0780944 Hydraulic servo control

DF0800560 Battery voltage

DF0820571 Brake lights switch circuit

DF1075000 Engine speed multiplex signal

DF1084073 Effective average torque multiplex signal

DF1145007 Pedal position multiplex signal

DF1155005 Torque multiplex signal

DF1174037 RR* wheel speed multiplex signal left

DF118403A RR* right-hand wheel speed multiplex signal

DF122C140 Passenger compartment computer connection

Vdiag No: 04

MR-413-X44-21B000$354.mif

Page 23 of 138

21B-23

MR-413-X44-21B000$354.mif

V2

Vdiag No: 04SEQUENTIAL GEARBOX

Fault finding - Fault summary table21B

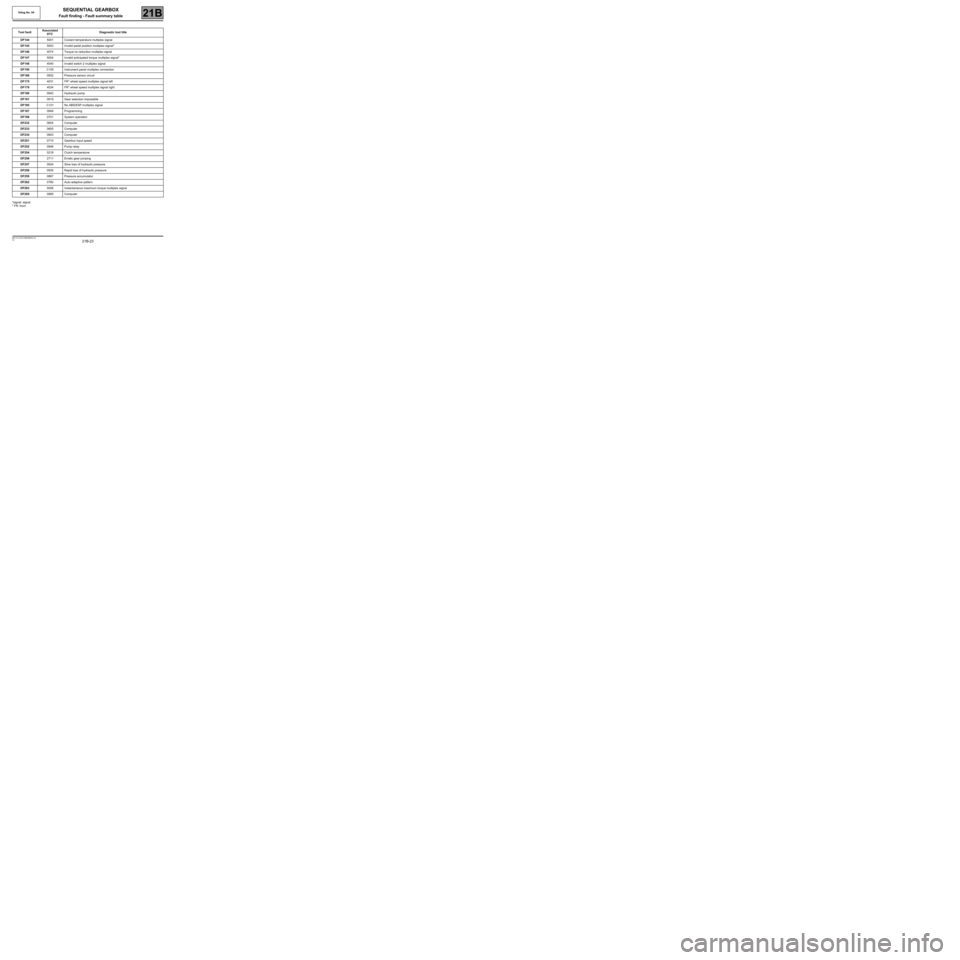

*signal: signal

* FR: frontTool faultAssociated

DTCDiagnostic tool title

DF1445001 Coolant temperature multiplex signal

DF1455003 Invalid pedal position multiplex signal*

DF1464074 Torque no reduction multiplex signal

DF1475004 Invalid anticipated torque multiplex signal*

DF1484040 Invalid switch 2 multiplex signal

DF150C155 Instrument panel multiplex connection

DF1660932 Pressure sensor circuit

DF1754031 FR* wheel speed multiplex signal left

DF1764034 FR* wheel speed multiplex signal right

DF1800942 Hydraulic pump

DF1810919 Gear selection impossible

DF185C121 No ABS/ESP multiplex signal

DF1870949 Programming

DF1880701 System operation

DF2320604 Computer

DF2330605 Computer

DF2340603 Computer

DF2510715 Gearbox input speed

DF2520946 Pump relay

DF2540218 Clutch temperature

DF2562711 Erratic gear jumping

DF2570934 Slow loss of hydraulic pressure

DF2580935 Rapid loss of hydraulic pressure

DF2590867 Pressure accumulator

DF2620780 Auto-adaptive pattern

DF2635006 Instantaneous maximum torque multiplex signal

DF2650885 Computer

Page 48 of 138

21B-48

MR-413-X44-21B000$413.mif

V2

SEQUENTIAL GEARBOX

Fault finding - Interpretation of faults

Vdiag No.: 04

21B

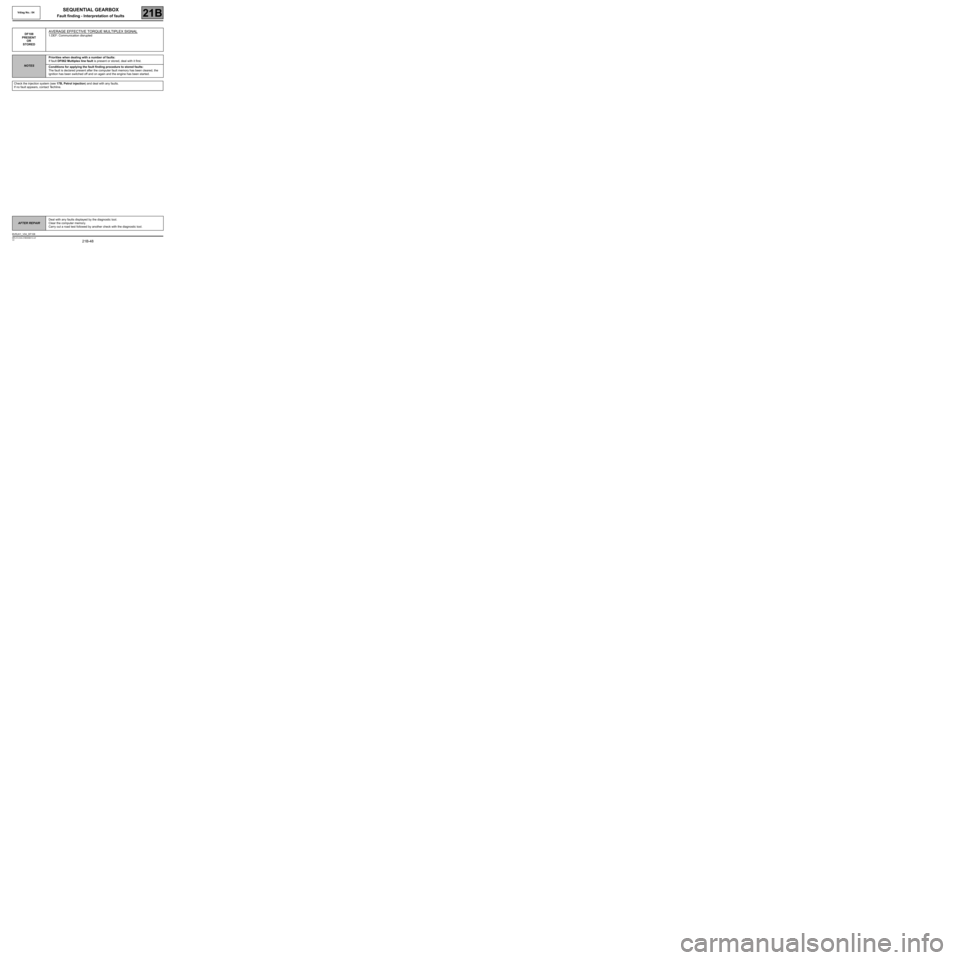

DF108

PRESENT

OR

STOREDAVERAGE EFFECTIVE TORQUE MULTIPLEX SIGNAL

1.DEF: Communication disrupted

NOTESPriorities when dealing with a number of faults:

If fault DF062 Multiplex line fault is present or stored, deal with it first.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after the computer fault memory has been cleared, the

ignition has been switched off and on again and the engine has been started.

Check the injection system (see 17B, Petrol injection) and deal with any faults.

If no fault appears, contact Techline.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

BVRJH1_V04_DF108

Page 50 of 138

21B-50

MR-413-X44-21B000$413.mif

V2

SEQUENTIAL GEARBOX

Fault finding - Interpretation of faults

Vdiag No.: 04

21B

DF115

PRESENT

OR

STOREDTORQUE MULTIPLEX SIGNAL

1.DEF: Communication disrupted

NOTESPriorities when dealing with a number of faults:

If fault DF062 Multiplex line fault is present or stored, deal with it first.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after the computer fault memory has been cleared, the

ignition has been switched off and on again and the engine has been started.

Check the injection system (see 17B, Petrol injection) and deal with any faults.

If no fault appears, contact Techline.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

BVRJH1_V04_DF115

Page 55 of 138

21B-55

MR-413-X44-21B000$472.mif

V2

SEQUENTIAL GEARBOX

Fault finding - Interpretation of faults

Vdiag No: 04

21B

DF146

PRESENT

OR

STOREDTORQUE NO REDUCTION MULTIPLEX SIGNAL

1.DEF : Communication disrupted

NOTESPriorities when dealing with a number of faults:

If fault DF062 Multiplex line fault is present or stored, deal with it first.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after the computer fault memory has been cleared, the

ignition has been switched off and on again and the engine has been started.

Run fault finding on the injection system (see 17B, Petrol injection).

Run a multiplex network test (see 88B, Multiplex).

If no faults are present or stored, contact Techline.

AFTER REPAIRDeal with any faults detected by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

BVRJH1_V04_DF146

Page 56 of 138

21B-56

MR-413-X44-21B000$472.mif

V2

SEQUENTIAL GEARBOX

Fault finding - Interpretation of faults

Vdiag No: 04

21B

DF147

PRESENT

OR

STOREDINVALID ANTICIPATED TORQUE MULTIPLEX SIGNAL

1.DEF : Communication disrupted

NOTESPriorities when dealing with a number of faults:

If fault DF062 Multiplex line fault is present or stored, deal with it first.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after the computer fault memory has been cleared, the

ignition has been switched off and on again and the engine has been started.

Run fault finding on the injection system (see 17B, Petrol injection).

Run a multiplex network test (see 88B, Multiplex).

If no faults are present or stored, contact Techline.

AFTER REPAIRDeal with any faults detected by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

BVRJH1_V04_DF147

Page 76 of 138

21B-76

MR-413-X44-21B000$472.mif

V2

SEQUENTIAL GEARBOX

Fault finding - Interpretation of faults

Vdiag No: 04

21B

DF263

PRESENT

OR

STOREDINSTANTANEOUS MAXIMUM TORQUE MULTIPLEX SIGNAL

1.DEF : Communication disrupted

NOTESPriorities when dealing with a number of faults:

If fault DF062 Multiplex line fault is present or stored, deal with it first.

Run a check of the injection system (see 17B, Petrol injection).

Check the condition and connection of the connectors of components 119 and 120.

If the connectors are faulty and if there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, W iring: Precautions for repair), repair the connectors; otherwise, replace the wiring.

Check the continuity and insulation of the following connections:

●Connection code 3MS,

●Connection code 3MT,

between components 119 and 120.

If the connection(s) are faulty and there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, W iring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any faults detected by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

BVRJH1_V04_DF263

Page 103 of 138

21B -103

MR-413-X44-21B000$649.mif

V2

SEQUENTIAL GEARBOX

Fault finding - Interpretation of statuses

Vdiag No: 04

21B

ET065

PROGRESSIVITY PROGRAMMING

STATUS

DEFINITIONThis signal indicates the status of the programming of the progressivity of the

transmission of engine torque and has the specification "NOT DONE" or "DONE".

NOTESNone

Engine stopped, ignition on

ET065: DONE

If "NOT DONE", refer to the section "replacement of components".

AFTER REPAIRCarry out another fault finding check on the system.

Deal with any other faults.

Clear the stored faults.

BVRJH1_V04_ET065

Page 105 of 138

21B -105

MR-413-X44-21B000$708.mif

V2

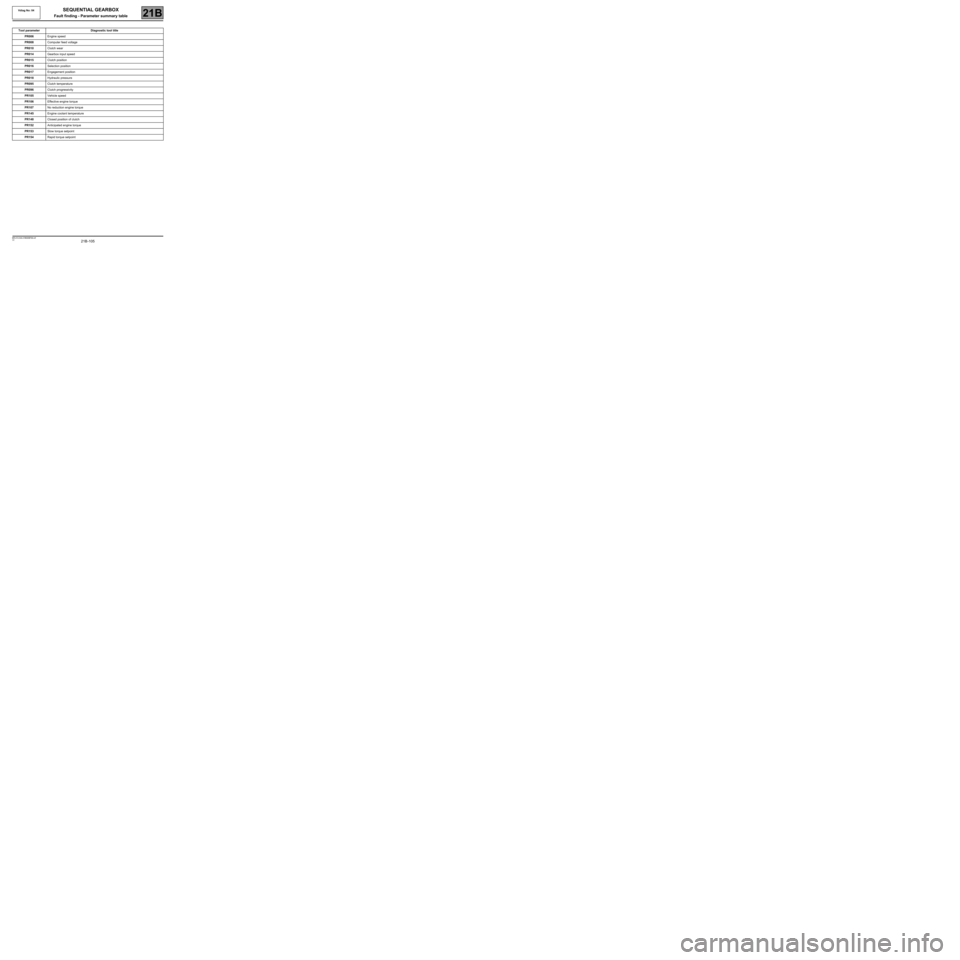

21B

SEQUENTIAL GEARBOX

Fault finding - Parameter summary table

Tool parameter Diagnostic tool title

PR006Engine speed

PR008Computer feed voltage

PR010Clutch wear

PR014Gearbox input speed

PR015Clutch position

PR016Selection position

PR017Engagement position

PR018Hydraulic pressure

PR095Clutch temperature

PR096Clutch progressivity

PR105Vehicle speed

PR106Effective engine torque

PR107No reduction engine torque

PR145Engine coolant temperature

PR148Closed position of clutch

PR152Anticipated engine torque

PR153Slow torque setpoint

PR154Rapid torque setpoint

Vdiag No: 04

MR-413-X44-21B000$708.mif