engine RENAULT ZOE 2017 1.G Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2017, Model line: ZOE, Model: RENAULT ZOE 2017 1.GPages: 220, PDF Size: 4.07 MB

Page 165 of 220

4.9

BODYWORK MAINTENANCE (1/2)

What you should not doDo not degrease or clean mechani-

cal components (e.g. the engine com-

partment), underneath the body, parts

with hinges (e.g. inside the doors) and

painted plastic external fittings (e.g.

bumpers) using high-pressure clean-

ing equipment or by spraying on prod-

ucts not approved by our Technical

Department. Doing this could give rise

to corrosion or operational faults.

Wash the vehicle in bright sunlight or

freezing temperatures.

Do not scrape off mud or dirt without

pre-wetting.

Allow dirt to accumulate on the exterior.

Allow rust to form following minor im-

pacts.

Do not use solvents not approved by

our Technical Department to remove

stains as this could damage the paint-

work.

Do not drive in snow or muddy condi-

tions without washing the vehicle, par-

ticularly under the wheel arches and

body.

A well-maintained vehicle will last

longer. It is therefore recommended to

maintain the exterior of the vehicle reg-

ularly.

Your vehicle has been treated with very

effective anti-corrosion products. It is

nevertheless subject to various outside

influences.

Corrosive agents in the atmosphere

–

atmospheric pollution (built-up and

industrial areas),

– saline atmospheres (near the sea,

particularly in hot weather),

– seasonal and damp weather condi-

tions (e.g. road salt in winter, water

from road cleaners, etc.).

Minor impacts

Abrasive action

Dust and sand in the air, mud, road grit

thrown up by other vehicles, etc.

You should take a number of minor pre-

cautions in order to safeguard your ve-

hicle against such risks.You should

Wash your car frequently, with the

engine off , with cleaning products rec-

ommended by the manufacturer (never

use abrasive products). Rinse thor-

oughly beforehand with a jet:

– spots of tree resin and industrial

grime;

– mud in the wheel arches and under-

neath the body which forms damp

patches;

– bird droppings , which cause a

chemical reaction with the paint that

rapidly discolours paintwork and

may even cause the paint to peel

off;

wash the vehicle immediately to

remove these marks since it is im-

possible to remove them by polish-

ing;

– salt, particularly in the wheel arches

and underneath the body after driv-

ing in areas where the roads have

been gritted.

Withdraw the vegetable falls (resin, film

etc.) from the vehicle regularly.

Page 166 of 220

4.10

Using a roller type car wash

Return the windscreen wiper stalk to

the Park position (refer to the informa-

tion on the “Windscreen washer, wiper”

in Section 1). Check the mounting of

external accessories, additional lights

and mirrors, and ensure that the wiper

blades are secured with adhesive tape.

Remove the radio aerial mast if your

vehicle is fitted with this equipment.

Remember to remove the tape and refit

the antenna after washing.

Observe the vehicle stopping distances

when driving on gravelled surfaces to

prevent paint damage.

Repair, or have repaired quickly, areas

where the paint has been damaged, to

prevent corrosion spreading.

Remember to visit the body shop pe-

riodically in order to maintain your

anti-corrosion warranty. Refer to the

Maintenance Document.

Respect local regulations about wash-

ing vehicles (e.g. do not wash your ve-

hicle on a public highway).

If it is necessary to clean mechani-

cal components, hinges, etc., spray

them with products approved by our

Technical Department to protect them

after they have been cleaned.

BODYWORK MAINTENANCE (2/2)

Cleaning the headlights

As the headlights are made of plastic

“glass”, use a soft cloth or cotton wool

to clean them. If this does not clean

them properly, moisten the cloth with

soapy water, then wipe clean with a soft

damp cloth or cotton wool.

Finally, carefully dry off with a soft dry

cloth.

Cleaning products containing alco-

hol must not be used.

Vehicles with a matte paint

finish

This type of paint requires certain pre-

cautions.

Do not do the following

– use wax-based products (polishing);

– rub too hard;

– wash the vehicle in a roller-type car

wash;

– wash the vehicle using a high-pres-

sure device;

– attach stickers to the paintwork (risk

of leaving marks).

You should do the following

Wash the vehicle by hand using plenty

of water, using a soft cloth or a gentle

sponge.

We have selected special products

to care for your vehicle and you can

obtain these from the manufactur-

er’s accessory outlets.

Washing the vehicle

Never wash the engine

compartment, the charging

connection or the traction

battery with a high-pressure jet.

This risks damaging the electric cir-

cuit.

Never wash the vehicle while it is

charging.

Risk of electric shock and a risk to

life.

Page 172 of 220

5.4

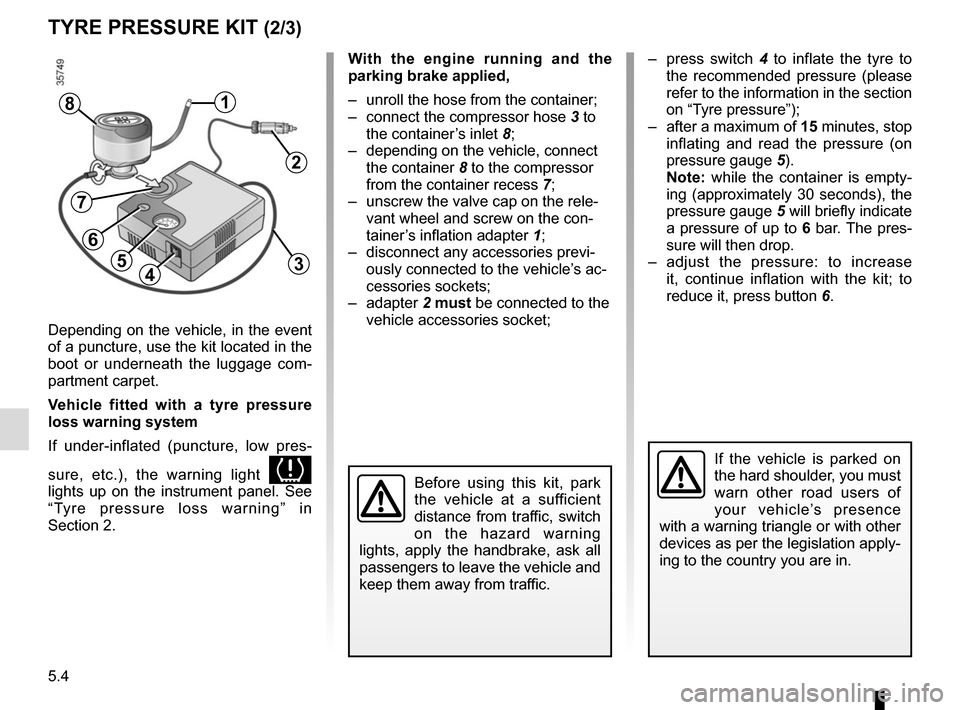

TYRE PRESSURE KIT (2/3)

Depending on the vehicle, in the event

of a puncture, use the kit located in the

boot or underneath the luggage com-

partment carpet.

Vehicle fitted with a tyre pressure

loss warning system

If under-inflated (puncture, low pres-

sure, etc.), the warning light

lights up on the instrument panel. See

“Tyre pressure loss warning” in

Section 2.

With the engine running and the

parking brake applied,

– unroll the hose from the container;

– connect the compressor hose 3 to

the container’s inlet 8;

– depending on the vehicle, connect the container 8 to the compressor

from the container recess 7;

– unscrew the valve cap on the rele- vant wheel and screw on the con-

tainer’s inflation adapter 1;

– disconnect any accessories previ- ously connected to the vehicle’s ac-

cessories sockets;

– adapter 2 must be connected to the

vehicle accessories socket;

45

1

Before using this kit, park

the vehicle at a sufficient

distance from traffic, switch

on the hazard warning

lights, apply the handbrake, ask all

passengers to leave the vehicle and

keep them away from traffic.

8

If the vehicle is parked on

the hard shoulder, you must

warn other road users of

your vehicle’s presence

with a warning triangle or with other

devices as per the legislation apply-

ing to the country you are in.

– press switch 4 to inflate the tyre to

the recommended pressure (please

refer to the information in the section

on “Tyre pressure”);

– after a maximum of 15 minutes, stop inflating and read the pressure (on

pressure gauge 5).

Note: while the container is empty-

ing (approximately 30 seconds), the

pressure gauge 5 will briefly indicate

a pressure of up to 6 bar. The pres-

sure will then drop.

– adjust the pressure: to increase it, continue inflation with the kit; to

reduce it, press button 6.

2

3

7

6

Page 177 of 220

5.9

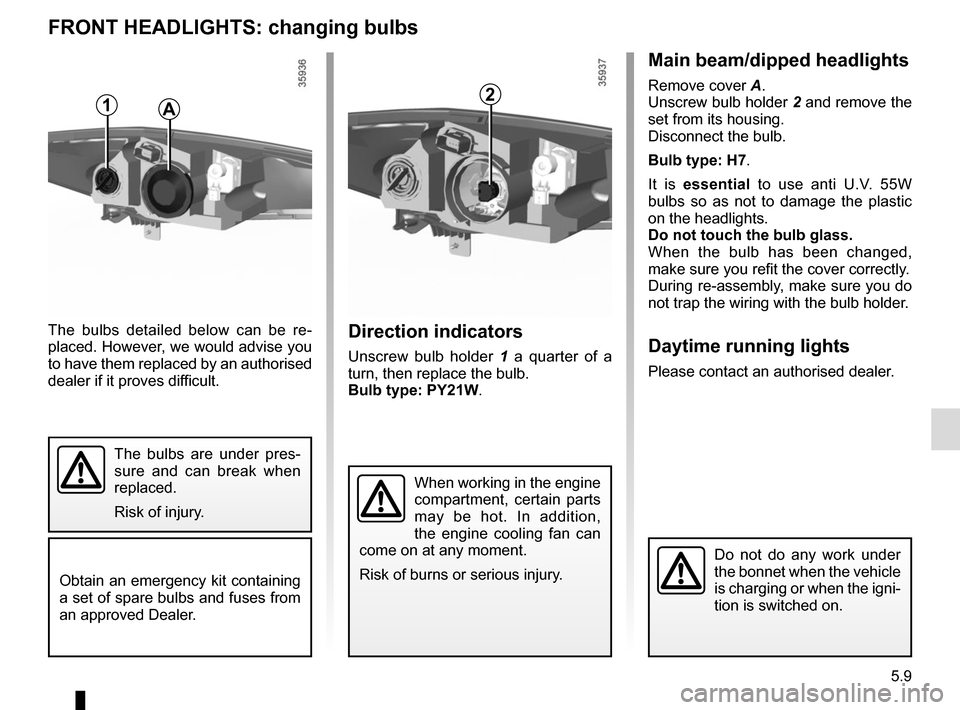

FRONT HEADLIGHTS: changing bulbs

Direction indicators

Unscrew bulb holder 1 a quarter of a

turn, then replace the bulb.

Bulb type: PY21W.

The bulbs detailed below can be re-

placed. However, we would advise you

to have them replaced by an authorised

dealer if it proves difficult.

1A

Obtain an emergency kit containing

a set of spare bulbs and fuses from

an approved Dealer.

Main beam/dipped headlights

Remove cover A.

Unscrew bulb holder 2 and remove the

set from its housing.

Disconnect the bulb.

Bulb type: H7.

It is essential to use anti U.V. 55W

bulbs so as not to damage the plastic

on the headlights.

Do not touch the bulb glass.

When the bulb has been changed,

make sure you refit the cover correctly.

During re-assembly, make sure you do

not trap the wiring with the bulb holder.

Daytime running lights

Please contact an authorised dealer.

The bulbs are under pres-

sure and can break when

replaced.

Risk of injury.

2

When working in the engine

compartment, certain parts

may be hot. In addition,

the engine cooling fan can

come on at any moment.

Risk of burns or serious injury.

Do not do any work under

the bonnet when the vehicle

is charging or when the igni-

tion is switched on.

Page 186 of 220

5.18

WINDSCREEN WIPER BLADES

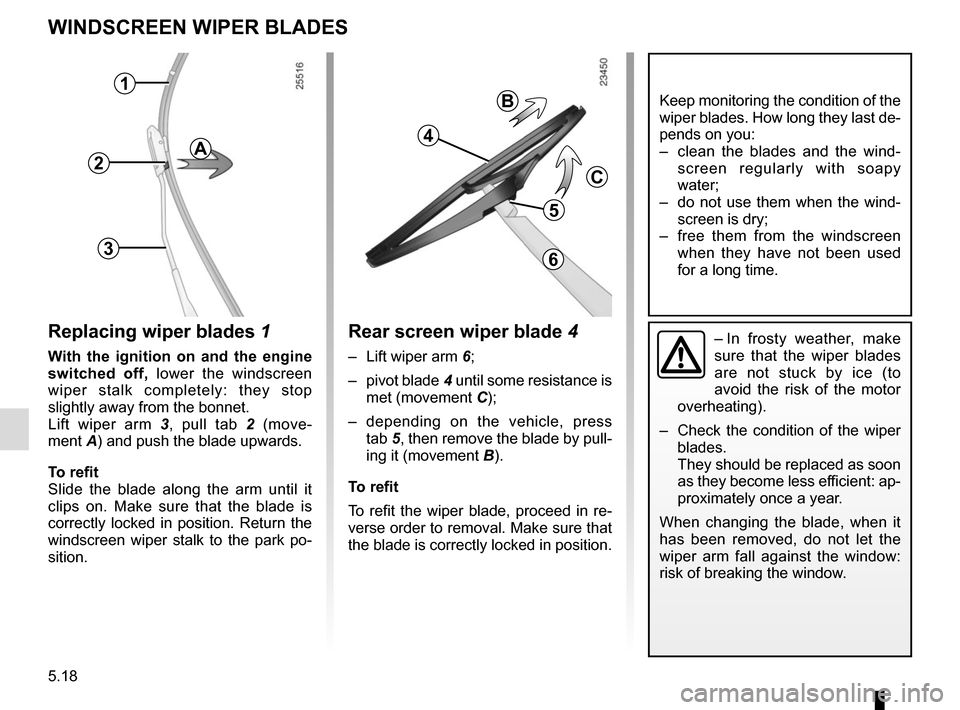

Replacing wiper blades 1

With the ignition on and the engine

switched off, lower the windscreen

wiper stalk completely: they stop

slightly away from the bonnet.

Lift wiper arm 3 , pull tab 2 (move-

ment A) and push the blade upwards.

To refit

Slide the blade along the arm until it

clips on. Make sure that the blade is

correctly locked in position. Return the

windscreen wiper stalk to the park po-

sition.

1

2

3

Keep monitoring the condition of the

wiper blades. How long they last de-

pends on you:

– clean the blades and the wind- screen regularly with soapy

water;

– do not use them when the wind- screen is dry;

– free them from the windscreen when they have not been used

for a long time.

A

– In frosty weather, make

sure that the wiper blades

are not stuck by ice (to

avoid the risk of the motor

overheating).

– Check the condition of the wiper

blades.

They should be replaced as soon

as they become less efficient: ap-

proximately once a year.

When changing the blade, when it

has been removed, do not let the

wiper arm fall against the window:

risk of breaking the window.Rear screen wiper blade 4

– Lift wiper arm 6;

– pivot blade 4 until some resistance is

met (movement C);

– depending on the vehicle, press tab 5, then remove the blade by pull-

ing it (movement B).

To refit

To refit the wiper blade, proceed in re-

verse order to removal. Make sure that

the blade is correctly locked in position.

4

5

B

C

6

Page 187 of 220

5.19

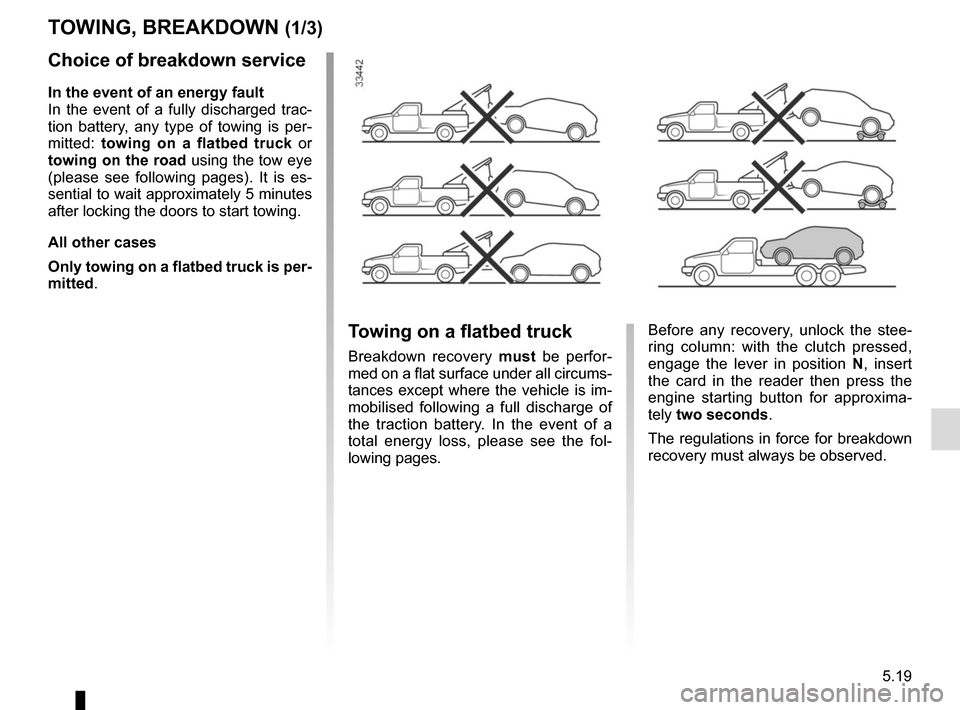

Choice of breakdown service

In the event of an energy fault

In the event of a fully discharged trac-

tion battery, any type of towing is per-

mitted: towing on a flatbed truck or

towing on the road using the tow eye

(please see following pages). It is es-

sential to wait approximately 5 minutes

after locking the doors to start towing.

All other cases

Only towing on a flatbed truck is per-

mitted.

TOWING, BREAKDOWN (1/3)

Before any recovery, unlock the stee-

ring column: with the clutch pressed,

engage the lever in position N, insert

the card in the reader then press the

engine starting button for approxima-

tely two seconds.

The regulations in force for breakdown

recovery must always be observed.Towing on a flatbed truck

Breakdown recovery must be perfor-

med on a flat surface under all circums-

tances except where the vehicle is im-

mobilised following a full discharge of

the traction battery. In the event of a

total energy loss, please see the fol-

lowing pages.

Page 188 of 220

5.20

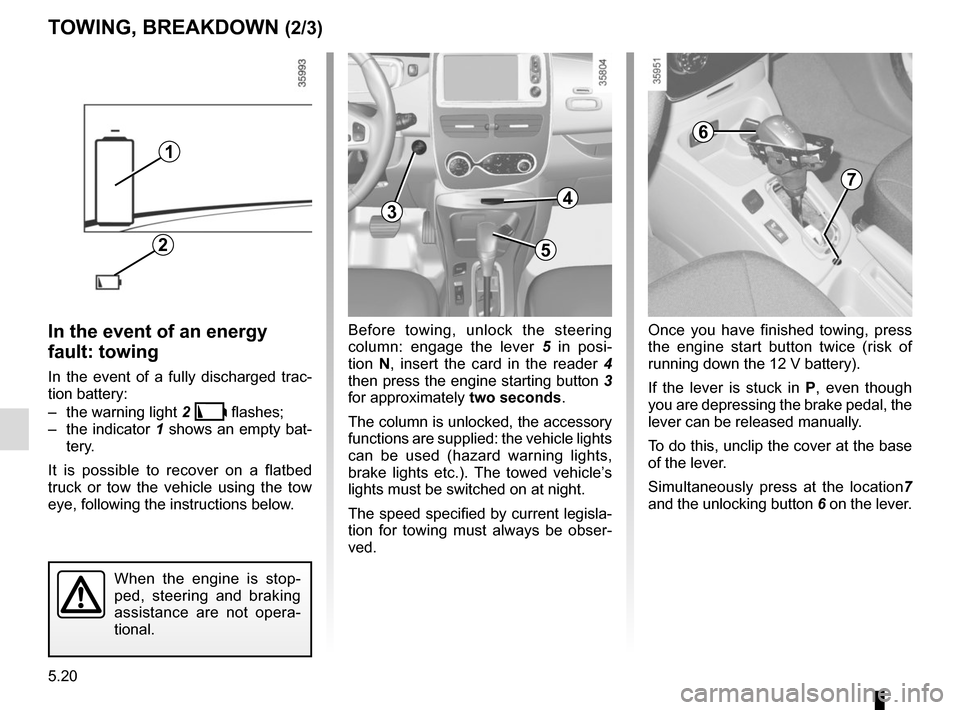

Once you have finished towing, press

the engine start button twice (risk of

running down the 12 V battery).

If the lever is stuck in P, even though

you are depressing the brake pedal, the

lever can be released manually.

To do this, unclip the cover at the base

of the lever.

Simultaneously press at the location 7

and the unlocking button 6 on the lever.

TOWING, BREAKDOWN (2/3)

6

7

In the event of an energy

fault: towing

In the event of a fully discharged trac-

tion battery:

– the warning light 2

Ṏ flashes;

– the indicator 1 shows an empty bat-

tery.

It is possible to recover on a flatbed

truck or tow the vehicle using the tow

eye, following the instructions below.

When the engine is stop-

ped, steering and braking

assistance are not opera-

tional.

Before towing, unlock the steering

column: engage the lever 5 in posi-

tion N, insert the card in the reader 4

then press the engine starting button 3

for approximately two seconds.

The column is unlocked, the accessory

functions are supplied: the vehicle lights

can be used (hazard warning lights,

brake lights etc.). The towed vehicle’s

lights must be switched on at night.

The speed specified by current legisla-

tion for towing must always be obser-

ved.

3

5

4

1

2

Page 191 of 220

5.23

OPERATING FAULTS (2/4)

FAULTSPOSSIBLE CAUSESWHAT TO DO

The programmable air conditioning

fails to work. One of the usage conditions is not

complied with (the traction battery

is not charged, etc).Please refer to the information on “Air-

conditioning: programming” in Section 3.

The remote control does not lock or

unlock the doors. The remote control battery is flat. Use the emergency key.

Use of appliances operating on

the same frequency as the remote

control (mobile phone, etc.).Stop using the devices or use the key.

Vehicle located in a high electro-

magnetic radiation zone.

Secondary 12 V battery dis-

charged. Replace the battery. You can still lock/unlock

and start your vehicle (refer to the information

on “Locking, unlocking the opening elements”

in Section 1 and “Starting, stopping the engine”

in Section 2).

The steering column remains

locked. Steering wheel locked.

Move the steering wheel while pressing the

engine start button (refer to Section 2 “Starting

the engine”).

Vibrations. Tyres not inflated to correct pres-

sures, incorrectly balanced or dam-

aged. Check the tyre pressures. If this is not the

problem, have them checked by an approved

Dealer.

Page 195 of 220

6.1

Section 6: Technical specifications

Vehicle identification plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . 6.2

Engine identification plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . . . . . . 6.3

Engine specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . 6.3

Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.4

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.5

Replacement parts and repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . 6.6

Service sheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.7

Anticorrosion check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . 6.13

Page 197 of 220

6.3

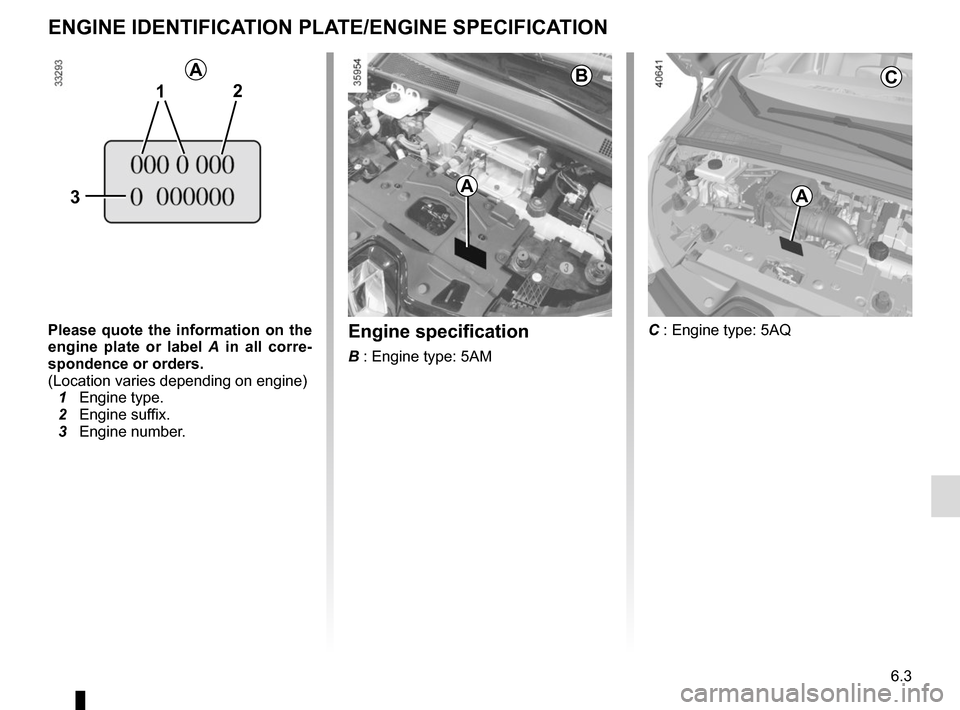

ENGINE IDENTIFICATION PLATE/ENGINE SPECIFICATION

Please quote the information on the

engine plate or label A in all corre-

spondence or orders.

(Location varies depending on engine)

1 Engine type.

2 Engine suffix.

3 Engine number.

A

2

3

1

Engine specification

B : Engine type: 5AM

A

C : Engine type: 5AQ

A

BC