light SAAB 9-3 2005 Owners Manual

[x] Cancel search | Manufacturer: SAAB, Model Year: 2005, Model line: 9-3, Model: SAAB 9-3 2005Pages: 292, PDF Size: 23 MB

Page 233 of 292

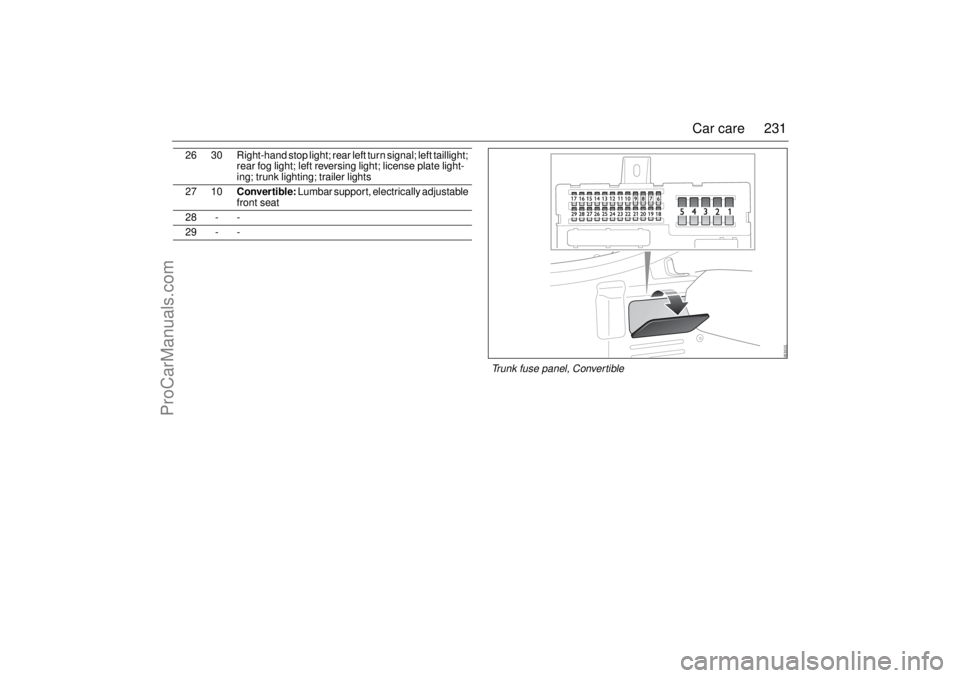

231 Car care

26 30 Right-hand stop light; rear left turn signal; left taillight;

rear fog light; left reversing light; license plate light-

ing; trunk lighting; trailer lights

27 10Convertible: Lumbar support, electrically adjustable

front seat

28 - -

29 - -

Trunk fuse panel, Convertible

ProCarManuals.com

Page 234 of 292

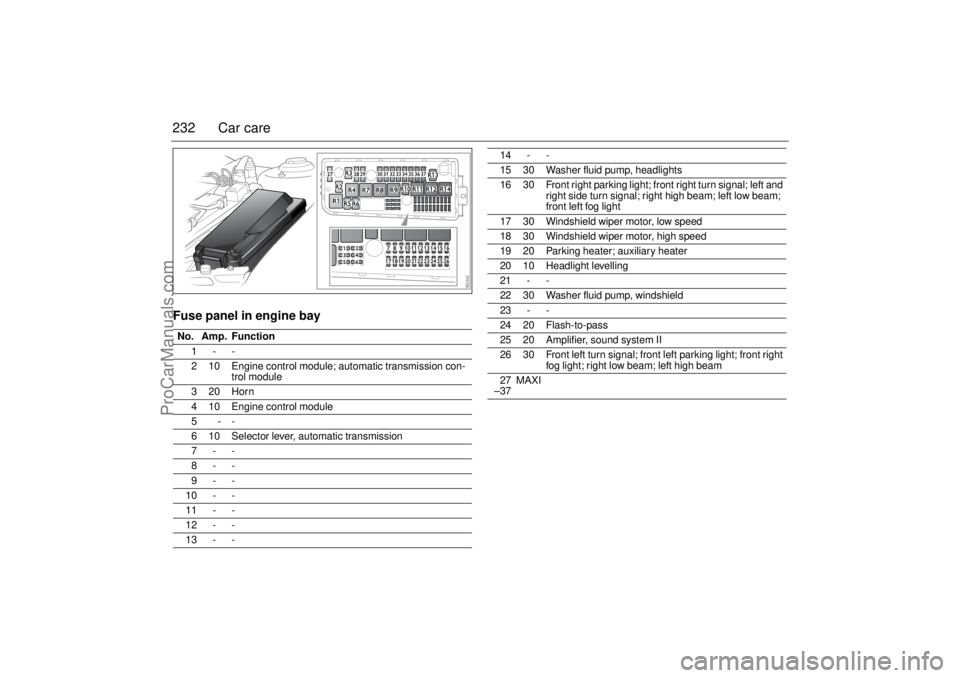

232 Car careFuse panel in engine bayNo. Amp. Function

1--

2 10 Engine control module; automatic transmission con-

trol module

320Horn

4 10 Engine control module

5--

6 10 Selector lever, automatic transmission

7--

8--

9--

10 - -

11 - -

12 - -

13 - -

14 - -

15 30 Washer fluid pump, headlights

16 30 Front right parking light; front right turn signal; left and

right side turn signal; right high beam; left low beam;

front left fog light

17 30 Windshield wiper motor, low speed

18 30 Windshield wiper motor, high speed

19 20 Parking heater; auxiliary heater

20 10 Headlight levelling

21 - -

22 30 Washer fluid pump, windshield

23 - -

24 20 Flash-to-pass

25 20 Amplifier, sound system II

26 30 Front left turn signal; front left parking light; front right

fog light; right low beam; left high beam

27

–37MAXI

ProCarManuals.com

Page 235 of 292

233 Car care

Fuse panel in front of battery

Relays

R 1 Washer fluid pump, windshield

R2 -

R3 -

R4 -

R 5 Flash-to-pass

R6 Horn

R7 -

R8 Starter motor

R 9 Windshield wipers ON/OFF

R10 -

R11 Ignition +15

R12 Windshield wipers, high/low speed

R13 -

R14 Washer fluid pump, headlights

R15 -

R16 -

No. Amp. Function

1--

2 20 Fuel pump; preheated oxygen sensors (lambda

probe)

310A/C compressor

430Main relay

Relays

1-

2 A/C-compressor

3 Preheated oxygen sensors (lambda probe)

4 Main relay, engine (ECM/EVAP/injectors)

ProCarManuals.com

Page 240 of 292

238 Car careUniform Tire Quality GradingQuality grades can be found where applica-

ble on the tire sidewall between tread shoul-

der and maximum section width. For exam-

ple:

Treadwear 200 Traction AA Temperature

A

The following information relates to the

system developed by the United States

National Highway Traffic Safety Administra-

tion, which grades tires by treadwear, trac-

tion and temperature performance. (This

applies only to vehicles sold in the United

States.) The grades are molded on the side-

walls of most passenger car tires. The Uni-

form Tire Quality Grading system does not

apply to deep tread, winter-type snow tires,

space-saver or temporary use spare tires,

tires with nominal rim diameters of 10 to 12

inches (25 to 30 cm), or to some limited-pro-

duction tires.

While the tires available on General Motors

passenger cars and light trucks may vary

with respect to these grades, they must also

conform to federal safety requirements and

additional General Motors Tire Perfor-

mance Criteria (TPC) standards.Treadwear

The treadwear grade is a comparative

rating based on the wear rate of the tire

when tested under controlled conditions on

a specified government test course. For

example, a tire graded 150 would wear one

and a half (1.5) times as well on the govern-

ment course as a tire graded 100. The rela-

tive performance of tires depends upon the

actual conditions of their use, however, and

may depart significantly from the norm due

to variations in driving habits, service prac-

tices and differences in road characteristics

and climate.

Traction – AA, A, B, C

The traction grades, from highest to lowest,

are AA, A, B, and C. Those grades repre-

sent the tire’s ability to stop on wet pave-

ment as measured under controlled condi-

tions on specified government test surfaces

of asphalt and concrete. A tire marked C

may have poor traction performance. Warn-

ing: The traction grade assigned to this tire

is based on straight-ahead braking traction

tests, and does not include acceleration,

cornering, hydroplaning, or peak traction

characteristics.Temperature – A, B, C

The temperature grades are A (the highest),

B, and C, representing the tire’s resistance

to the generation of heat and its ability to dis-

sipate heat when tested under controlled

conditions on a specified indoor laboratory

test wheel. Sustained high temperature can

cause the material of the tire to degenerate

and reduce tire life, and excessive temper-

ature can lead to sudden tire failure. The

grade C corresponds to a level of perfor-

mance which all passenger car tires must

meet under the Federal Motor Vehicle

Safety Standard No. 109. Grades B and A

represent higher levels of performance on

the laboratory test wheel than the minimum

required by law.

Warning: The temperature grade for this tire

is established for a tire that is properly

inflated and not overloaded. Excessive

speed, underinflation, or excessive loading,

either separately or in combination, can

cause heat buildup and possible tire failure.

ProCarManuals.com

Page 245 of 292

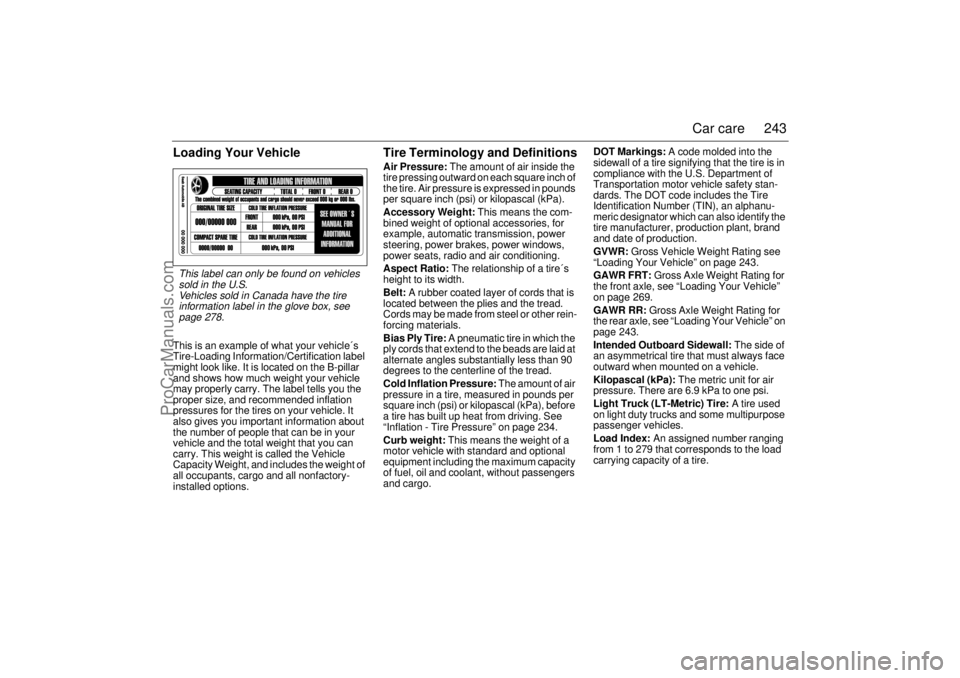

243 Car care

Loading Your VehicleThis is an example of what your vehicle´s

Tire-Loading Information/Certification label

might look like. It is located on the B-pillar

and shows how much weight your vehicle

may properly carry. The label tells you the

proper size, and recommended inflation

pressures for the tires on your vehicle. It

also gives you important information about

the number of people that can be in your

vehicle and the total weight that you can

carry. This weight is called the Vehicle

Capacity Weight, and includes the weight of

all occupants, cargo and all nonfactory-

installed options.

Tire Terminology and DefinitionsAir Pressure: The amount of air inside the

tire pressing outward on each square inch of

the tire. Air pressure is expressed in pounds

per square inch (psi) or kilopascal (kPa).

Accessory Weight: This means the com-

bined weight of optional accessories, for

example, automatic transmission, power

steering, power brakes, power windows,

power seats, radio and air conditioning.

Aspect Ratio: The relationship of a tire´s

height to its width.

Belt: A rubber coated layer of cords that is

located between the plies and the tread.

Cords may be made from steel or other rein-

forcing materials.

Bias Ply Tire: A pneumatic tire in which the

ply cords that extend to the beads are laid at

alternate angles substantially less than 90

degrees to the centerline of the tread.

Cold Inflation Pressure: The amount of air

pressure in a tire, measured in pounds per

square inch (psi) or kilopascal (kPa), before

a tire has built up heat from driving. See

“Inflation - Tire Pressure” on page 234.

Curb weight: This means the weight of a

motor vehicle with standard and optional

equipment including the maximum capacity

of fuel, oil and coolant, without passengers

and cargo.DOT Markings: A code molded into the

sidewall of a tire signifying that the tire is in

compliance with the U.S. Department of

Transportation motor vehicle safety stan-

dards. The DOT code includes the Tire

Identification Number (TIN), an alphanu-

meric designator which can also identify the

tire manufacturer, production plant, brand

and date of production.

GVWR: Gross Vehicle Weight Rating see

“Loading Your Vehicle” on page 243.

GAWR FRT: Gross Axle Weight Rating for

the front axle, see “Loading Your Vehicle”

on page 269.

GAWR RR: Gross Axle Weight Rating for

the rear axle, see “Loading Your Vehicle” on

page 243.

Intended Outboard Sidewall: The side of

an asymmetrical tire that must always face

outward when mounted on a vehicle.

Kilopascal (kPa): The metric unit for air

pressure. There are 6.9 kPa to one psi.

Light Truck (LT-Metric) Tire: A tire used

on light duty trucks and some multipurpose

passenger vehicles.

Load Index: An assigned number ranging

from 1 to 279 that corresponds to the load

carrying capacity of a tire.

This label can only be found on vehicles

sold in the U.S.

Vehicles sold in Canada have the tire

information label in the glove box, see

page 278.

ProCarManuals.com

Page 246 of 292

244 Car careMaximum Load rating: The load rating for

a tire at the maximum permissible inflation

pressure for that tire.

Maximum Loaded Vehicle Weight: The

sum of curb weight; accessory weight; vehi-

cle capacity weight; and production options

weight.

Maximum Permissible Inflation Pres-

sure: The maximum cold inflation pressure

to which a tire may be inflated.

Normal occupant weight: The number of

occupants a vehicle is designed to seat mul-

tipled by 150 pounds (68 kg). See “Loading

Your Vehicle” on page 243.

Occupant Distribution: Designated seat-

ing positions.

Outward Facing Sidewall: The side of a

asymmetrical tire that has a particular side

that faces outward when mounted on a vehi-

cle. The side of the tire that contains a white-

wall bears white lettering or bears manufac-

turer, brand and or model name molding on

the other sidewall of the tire.

Passenger (P-Metric) Tire: A tire used on

passenger cars and some light duty trucks

and multipurpose vehicles.Recommended Inflation Pressure: Vehi-

cle manufacturer´s recommended tire infla-

tion pressure shown on the tire placard, see

“Inflation - Tire Pressure” on page 234 and

“Loading Your Vehicle” on page 243.

Radial Ply Tire: A pneumatic tire in which

the ply cords that extend to the beads are

laid at substantially 90 degrees to the cen-

terline of the tread.

Rim: A metal support for a tire or a tire and

tube assembly upon which the tire beads

are seated.

Sidewall: The portion of a tire between the

tread and the bead.

Speed rating: An alphanumeric code

assigned to a tire indicating the maximum

speed at which a tire can operate.

Traction: The friction between the tire and

the road surface. The amount of grip pro-

vided.

Treadwear Indicators: Narrow bands,

sometimes called “wear bars”, that show

across the tread of a tire when only

2/32 inch of tread remains. See “When It Is

Time for New Tires” on page 236.Tread Width: The width of the tire´s tread.

UTQGS: Uniform Tire Quality Grade Stan-

dards, a tire information system that pro-

vides consumers with ratings for a tire´s

traction, temperature and treadwear. Rat-

ings are determined by tire manufacturers

using government testing procedures. The

rating are molded into the sidewall of the

tire. See “Uniform Tire Quality Grading” on

page 238.

Vehicle Capacity Weight: Is the number of

designated seating positions multipled by

150 pounds (68 kg) plus the rated cargo

load. See “Loading Your Vehicle” on

page 243.

Vehicle Maximum Load on the Tire: Load

on an individual tire due to curb weight,

accessory weight, occupant weight and

cargo weight.

Vehicle Placard: A label permanently

attached to a vehicle showing original

equipment tire size and the recommended

cold inflation pressure. See “Loading Your

Vehicle” on page 243.

ProCarManuals.com

Page 248 of 292

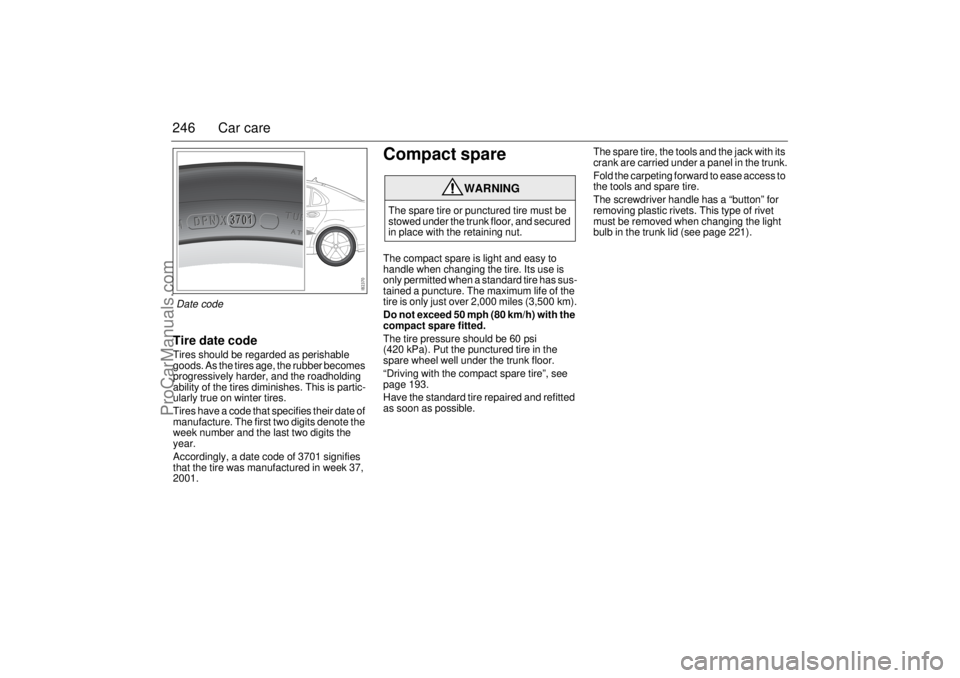

246 Car careTire date codeTires should be regarded as perishable

goods. As the tires age, the rubber becomes

progressively harder, and the roadholding

ability of the tires diminishes. This is partic-

ularly true on winter tires.

Tires have a code that specifies their date of

manufacture. The first two digits denote the

week number and the last two digits the

year.

Accordingly, a date code of 3701 signifies

that the tire was manufactured in week 37,

2001.

Compact spareThe compact spare is light and easy to

handle when changing the tire. Its use is

only permitted when a standard tire has sus-

tained a puncture. The maximum life of the

tire is only just over 2,000 miles (3,500 km).

Do not exceed 50 mph (80 km/h) with the

compact spare fitted.

The tire pressure should be 60 psi

(420 kPa). Put the punctured tire in the

spare wheel well under the trunk floor.

“Driving with the compact spare tire”, see

page 193.

Have the standard tire repaired and refitted

as soon as possible.The spare tire, the tools and the jack with its

crank are carried under a panel in the trunk.

Fold the carpeting forward to ease access to

the tools and spare tire.

The screwdriver handle has a “button” for

removing plastic rivets. This type of rivet

must be removed when changing the light

bulb in the trunk lid (see page 221).

WARNING

The spare tire or punctured tire must be

stowed under the trunk floor, and secured

in place with the retaining nut.

Date code

ProCarManuals.com

Page 250 of 292

248 Car careChanging a tire

WARNING

Lifting a vehicle and getting under it to do

maintenance or repairs is dangerous

without the appropriate safety equipment

and training. The jack provided with your

vehicle is designed only for changing a

flat tire. If it is used for anything else, you

or others could be badly injured or killed if

the vehicle slips off the jack. Use the jack

provided with your vehicle only for chang-

ing a flat tire.

Changing a tire can be dangerous. The

vehicle can slip off the jack and roll over

or fall on you or other people. You and

they could be badly injured or even killed.

Find a level place to change your tire. To

help prevent the vehicle from moving:

1 Set the parking brake firmly.

2 If you have an automatic transmis-

sion, put the shift lever in PARK (P).

For a manual transmission, leave the

car in gear (1st or REVERSE (R)).

3 Turn off the engine and do not restart

while the vehicle is raised.

4 Do not allow passengers to remain in

the vehicle.

To be even more certain the vehicle won't

move, you should put blocks at the front

and rear of the tire farthest away from the

one being changed. That would be the

tire, on the other side, at the opposite end

of the vehicle.

The car jack is designed solely for use

in changing a tire or fitting snow

chains. It must not be used to

support the car during repair work

or servicing.

Never crawl under a car that is

supported only by a jack. Always use

axle stands.

Raising your vehicle too high or with

the jack improperly positioned can

damage the vehicle and even make

the vehicle fall. To help avoid personal

injury and vehicle damage, be sure to

fit the jack lift head into the proper

location before raising the vehicle, and

raise the vehicle only far enough off

the ground so there is enough room for

the spare tire to fit (no more than

25 mm or 1 inch clearance between

the ground and the bottom of the tire).

Switch on the hazard warning lights if

the car is on a road.

The jack should be stored correctly

under the carpeting in the trunk. If it

lies loose in the car, it could thrown

forward and cause personal injury in

the event of a crash or if the car rolls

over.

Grit, salt and rust can clog the inner

threads of the wheel bolts if the car has

been driven for several years exclu-

sively with alloy wheels.

If steel wheels are being installed, the

bolt hole threads in the brake hubs

should be cleaned before the thinner

steel wheels are fitted. It may other-

wise not be possible to achieve the

correct clamping force, despite tight-

ening the wheel bolts to the correct

torque.

ProCarManuals.com

Page 251 of 292

249 Car care

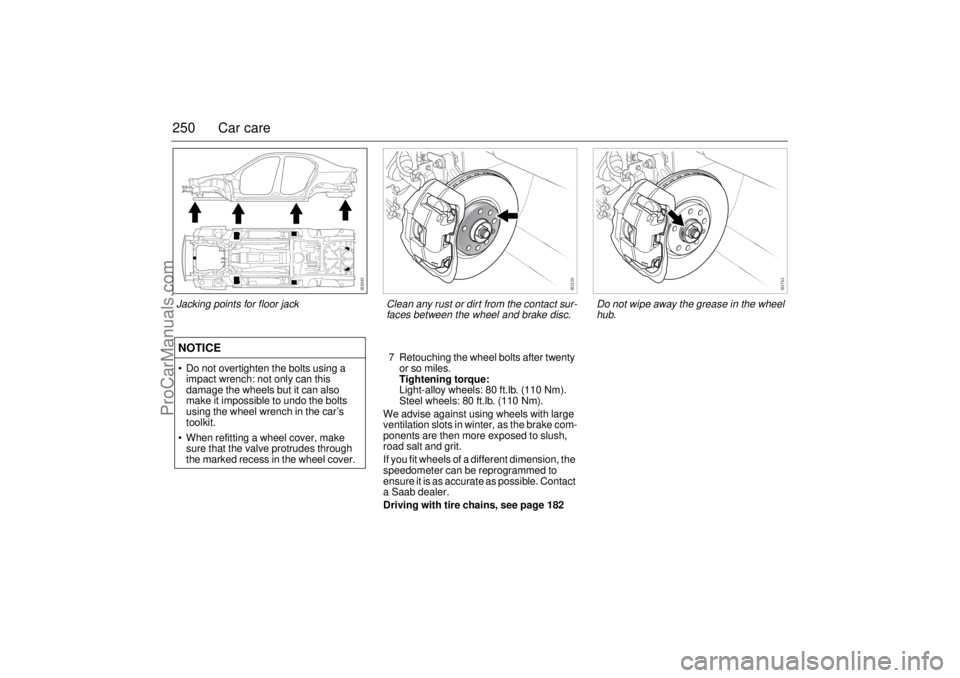

When the car has to be lifted, the jack must

be positioned at one of the four jacking

points (front or rear) under the sill members.

If a floor jack is used, the lifting plate must

be positioned under the normal jacking

points, see illustration. If the car is equipped

with a towbar, the jack can also be placed

under this.

1 Wind the jack up to a suitable height

before placing it under the jacking point.

Each jacking point is indicated by an

arrow on the sill (see illustration).

Make sure that the jack fully engages

the jacking point in the underside of the

sill member and that the entire foot of the

jack is steady and flat on the ground.

The jack must not stand on snow, ice or

similar.

Wind up the jack until it just begins to lift

the car.2 It is not necessary to remove the wheel

cover.

If, none the less, you wish to remove the

wheel cover, take hold of the outer edge

and pull it straight out.

Loosen the wheel bolts half a turn.

3 Wind the jack to raise the wheel clear of

the ground. Remove the wheel bolts and

lift off the wheel.4 Clean any rust or dirt from the contact

surfaces between the wheel and brake

disc. Do not wipe away the grease in the

wheel hub.

5 Add a thin layer of grease on the bolts

before fitting, see page 251. Fit the

wheel and screw in the bolts in the

sequence shown on page 251 (opposite

pairs).

Tighten the bolts enough for the bolts

and wheel to be seated correctly.

6 Lower the car and tighten the wheel

bolts to torque in sequence as shown on

the following page.

Tightening torque:

Light-alloy wheels: 80 ft.lb. (110 Nm).

Steel wheels: 80 ft.lb. (110 Nm).NOTICEApply the jack only to the jacking points

indicated on the body.

Jacking points

Marking of jacking points

ProCarManuals.com

Page 252 of 292

250 Car care

7 Retouching the wheel bolts after twenty

or so miles.

Tightening torque:

Light-alloy wheels: 80 ft.lb. (110 Nm).

Steel wheels: 80 ft.lb. (110 Nm).

We advise against using wheels with large

ventilation slots in winter, as the brake com-

ponents are then more exposed to slush,

road salt and grit.

If you fit wheels of a different dimension, the

speedometer can be reprogrammed to

ensure it is as accurate as possible. Contact

a Saab dealer.

Driving with tire chains, see page 182

NOTICE Do not overtighten the bolts using a

impact wrench: not only can this

damage the wheels but it can also

make it impossible to undo the bolts

using the wheel wrench in the car’s

toolkit.

When refitting a wheel cover, make

sure that the valve protrudes through

the marked recess in the wheel cover.

Do not wipe away the grease in the wheel

hub.

Clean any rust or dirt from the contact sur-

faces between the wheel and brake disc.

Jacking points for floor jack

ProCarManuals.com