wheel SAAB 9-3 2005 Repair Manual

[x] Cancel search | Manufacturer: SAAB, Model Year: 2005, Model line: 9-3, Model: SAAB 9-3 2005Pages: 292, PDF Size: 23 MB

Page 249 of 292

247 Car care

Your Saab is equipped with a trip computer

and you can use its “Speed warning” func-

tion, to monitor driving speed since you

must not exceed 50 mph (80 km/h).

NOTICETo avoid damaging an alloy wheel with a

flat tire, this can be placed outside up in

the spare-wheel well but only while driv-

ing to the closest workshop.

A general rule is that all heavy loads must

be well secured in the luggage compart-

ment (see page 143).

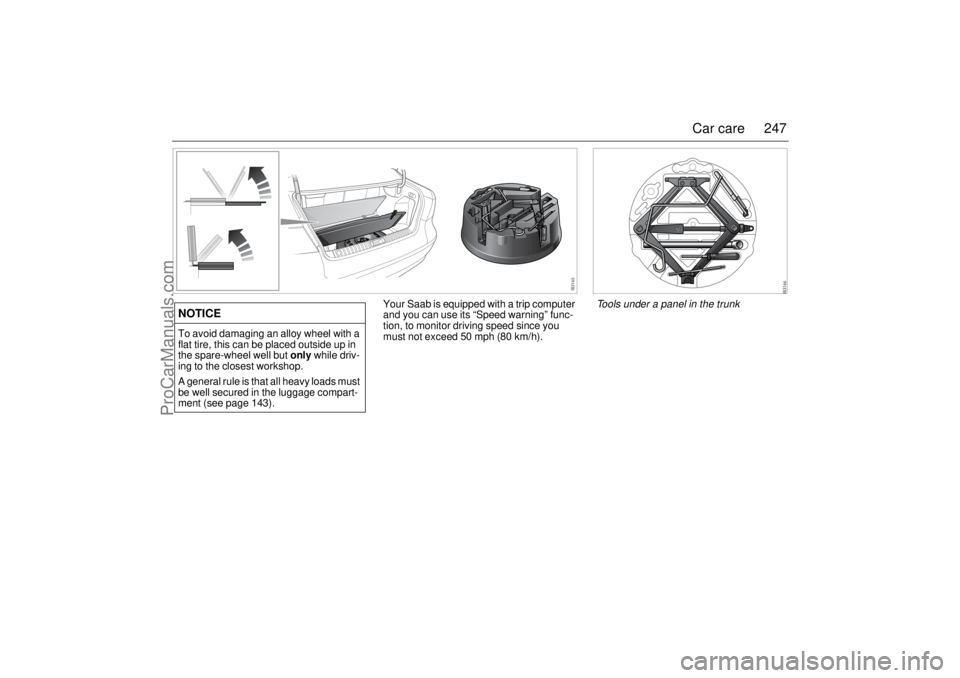

Tools under a panel in the trunk

ProCarManuals.com

Page 250 of 292

248 Car careChanging a tire

WARNING

Lifting a vehicle and getting under it to do

maintenance or repairs is dangerous

without the appropriate safety equipment

and training. The jack provided with your

vehicle is designed only for changing a

flat tire. If it is used for anything else, you

or others could be badly injured or killed if

the vehicle slips off the jack. Use the jack

provided with your vehicle only for chang-

ing a flat tire.

Changing a tire can be dangerous. The

vehicle can slip off the jack and roll over

or fall on you or other people. You and

they could be badly injured or even killed.

Find a level place to change your tire. To

help prevent the vehicle from moving:

1 Set the parking brake firmly.

2 If you have an automatic transmis-

sion, put the shift lever in PARK (P).

For a manual transmission, leave the

car in gear (1st or REVERSE (R)).

3 Turn off the engine and do not restart

while the vehicle is raised.

4 Do not allow passengers to remain in

the vehicle.

To be even more certain the vehicle won't

move, you should put blocks at the front

and rear of the tire farthest away from the

one being changed. That would be the

tire, on the other side, at the opposite end

of the vehicle.

The car jack is designed solely for use

in changing a tire or fitting snow

chains. It must not be used to

support the car during repair work

or servicing.

Never crawl under a car that is

supported only by a jack. Always use

axle stands.

Raising your vehicle too high or with

the jack improperly positioned can

damage the vehicle and even make

the vehicle fall. To help avoid personal

injury and vehicle damage, be sure to

fit the jack lift head into the proper

location before raising the vehicle, and

raise the vehicle only far enough off

the ground so there is enough room for

the spare tire to fit (no more than

25 mm or 1 inch clearance between

the ground and the bottom of the tire).

Switch on the hazard warning lights if

the car is on a road.

The jack should be stored correctly

under the carpeting in the trunk. If it

lies loose in the car, it could thrown

forward and cause personal injury in

the event of a crash or if the car rolls

over.

Grit, salt and rust can clog the inner

threads of the wheel bolts if the car has

been driven for several years exclu-

sively with alloy wheels.

If steel wheels are being installed, the

bolt hole threads in the brake hubs

should be cleaned before the thinner

steel wheels are fitted. It may other-

wise not be possible to achieve the

correct clamping force, despite tight-

ening the wheel bolts to the correct

torque.

ProCarManuals.com

Page 251 of 292

249 Car care

When the car has to be lifted, the jack must

be positioned at one of the four jacking

points (front or rear) under the sill members.

If a floor jack is used, the lifting plate must

be positioned under the normal jacking

points, see illustration. If the car is equipped

with a towbar, the jack can also be placed

under this.

1 Wind the jack up to a suitable height

before placing it under the jacking point.

Each jacking point is indicated by an

arrow on the sill (see illustration).

Make sure that the jack fully engages

the jacking point in the underside of the

sill member and that the entire foot of the

jack is steady and flat on the ground.

The jack must not stand on snow, ice or

similar.

Wind up the jack until it just begins to lift

the car.2 It is not necessary to remove the wheel

cover.

If, none the less, you wish to remove the

wheel cover, take hold of the outer edge

and pull it straight out.

Loosen the wheel bolts half a turn.

3 Wind the jack to raise the wheel clear of

the ground. Remove the wheel bolts and

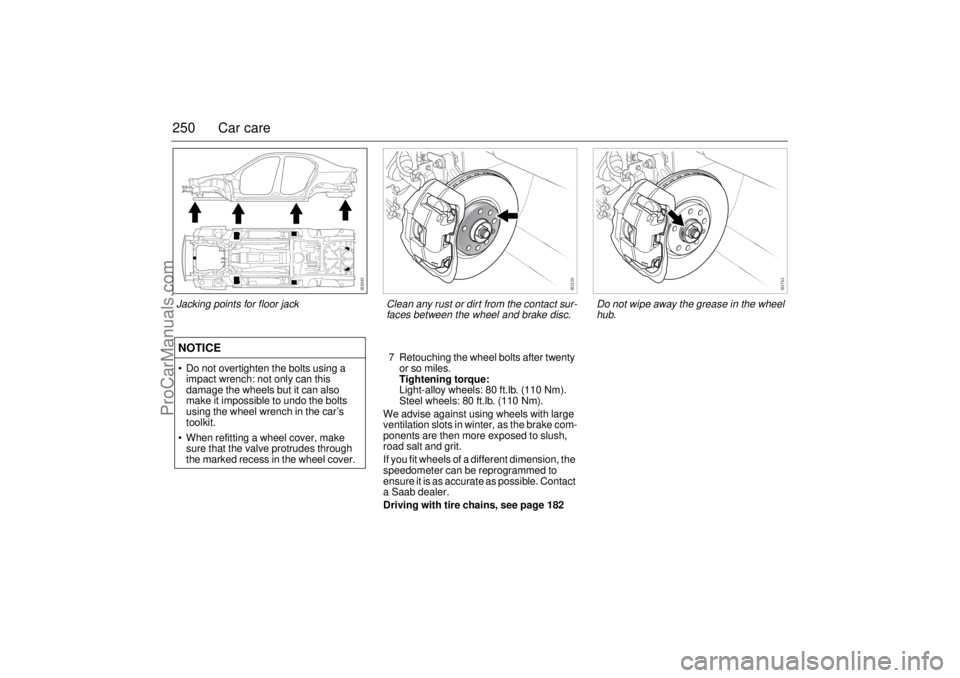

lift off the wheel.4 Clean any rust or dirt from the contact

surfaces between the wheel and brake

disc. Do not wipe away the grease in the

wheel hub.

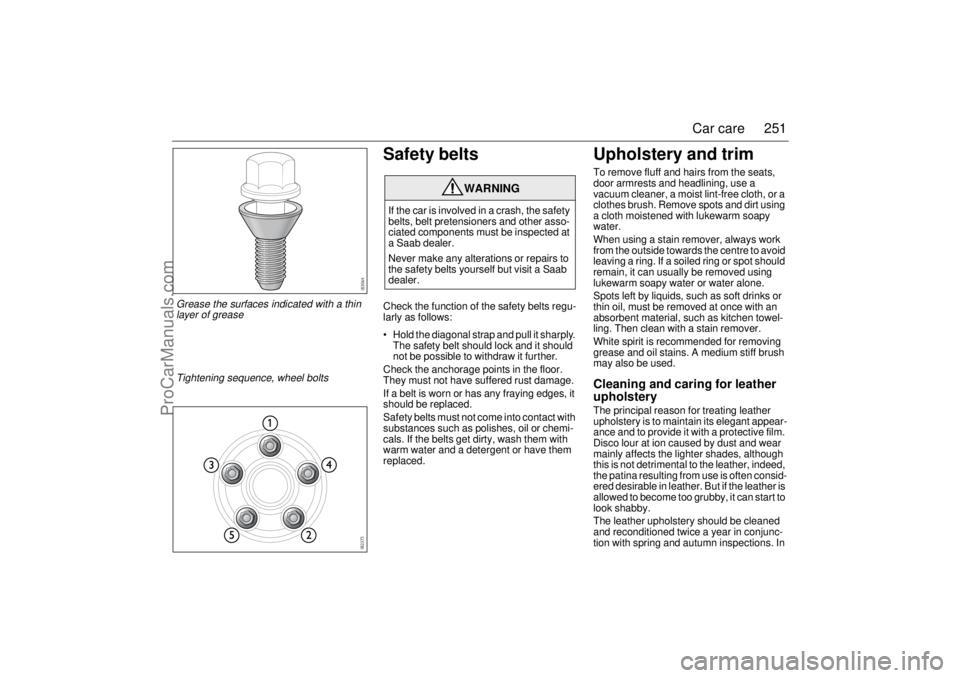

5 Add a thin layer of grease on the bolts

before fitting, see page 251. Fit the

wheel and screw in the bolts in the

sequence shown on page 251 (opposite

pairs).

Tighten the bolts enough for the bolts

and wheel to be seated correctly.

6 Lower the car and tighten the wheel

bolts to torque in sequence as shown on

the following page.

Tightening torque:

Light-alloy wheels: 80 ft.lb. (110 Nm).

Steel wheels: 80 ft.lb. (110 Nm).NOTICEApply the jack only to the jacking points

indicated on the body.

Jacking points

Marking of jacking points

ProCarManuals.com

Page 252 of 292

250 Car care

7 Retouching the wheel bolts after twenty

or so miles.

Tightening torque:

Light-alloy wheels: 80 ft.lb. (110 Nm).

Steel wheels: 80 ft.lb. (110 Nm).

We advise against using wheels with large

ventilation slots in winter, as the brake com-

ponents are then more exposed to slush,

road salt and grit.

If you fit wheels of a different dimension, the

speedometer can be reprogrammed to

ensure it is as accurate as possible. Contact

a Saab dealer.

Driving with tire chains, see page 182

NOTICE Do not overtighten the bolts using a

impact wrench: not only can this

damage the wheels but it can also

make it impossible to undo the bolts

using the wheel wrench in the car’s

toolkit.

When refitting a wheel cover, make

sure that the valve protrudes through

the marked recess in the wheel cover.

Do not wipe away the grease in the wheel

hub.

Clean any rust or dirt from the contact sur-

faces between the wheel and brake disc.

Jacking points for floor jack

ProCarManuals.com

Page 253 of 292

251 Car care

Safety beltsCheck the function of the safety belts regu-

larly as follows:

Hold the diagonal strap and pull it sharply.

The safety belt should lock and it should

not be possible to withdraw it further.

Check the anchorage points in the floor.

They must not have suffered rust damage.

If a belt is worn or has any fraying edges, it

should be replaced.

Safety belts must not come into contact with

substances such as polishes, oil or chemi-

cals. If the belts get dirty, wash them with

warm water and a detergent or have them

replaced.

Upholstery and trimTo remove fluff and hairs from the seats,

door armrests and headlining, use a

vacuum cleaner, a moist lint-free cloth, or a

clothes brush. Remove spots and dirt using

a cloth moistened with lukewarm soapy

water.

When using a stain remover, always work

from the outside towards the centre to avoid

leaving a ring. If a soiled ring or spot should

remain, it can usually be removed using

lukewarm soapy water or water alone.

Spots left by liquids, such as soft drinks or

thin oil, must be removed at once with an

absorbent material, such as kitchen towel-

ling. Then clean with a stain remover.

White spirit is recommended for removing

grease and oil stains. A medium stiff brush

may also be used.Cleaning and caring for leather

upholsteryThe principal reason for treating leather

upholstery is to maintain its elegant appear-

ance and to provide it with a protective film.

Disco lour at ion caused by dust and wear

mainly affects the lighter shades, although

this is not detrimental to the leather, indeed,

the patina resulting from use is often consid-

ered desirable in leather. But if the leather is

allowed to become too grubby, it can start to

look shabby.

The leather upholstery should be cleaned

and reconditioned twice a year in conjunc-

tion with spring and autumn inspections. In

WARNING

If the car is involved in a crash, the safety

belts, belt pretensioners and other asso-

ciated components must be inspected at

a Saab dealer.

Never make any alterations or repairs to

the safety belts yourself but visit a Saab

dealer.

Tightening sequence, wheel boltsGrease the surfaces indicated with a thin

layer of grease

ProCarManuals.com

Page 256 of 292

254 Car carethen be primed with two thin coats of primer

applied by brush.

After the primer has dried, apply several thin

layers of topcoat until the surface of the

repaired area is flush with the surrounding

paintwork.

Stir both primer and touch-up paint thor-

oughly before use and allow each coat to

dry before applying the next.Two-coat enamelAs the name implies, two-coat enamel is

applied in two operations. The first coat, the

base color, contains the pigment, metal

flakes and binder. The second coat consists

of a clear enamel, which provides the final

gloss for the paintwork and protects the

base from moisture and environmental con-

taminants.

Touch-up stone-chip damage as follows:

1 Thoroughly clean the damaged area.

2 Then apply the primer, base color and

finally, the clear enamel. To achieve the

best finish, apply two or three coats of

primer.

Anti-corrosion

treatmentThe entire car undergoes a series of anti-

corrosion processes during production.

These include electrophoretic priming,

PVC-based coating to protect against stone

chip damage and corrosion, and treatment

of body cavities and members with thin,

penetrating rustproofing oil.

In addition, most body panels, such as the

hood, doors and floor pan are galvanized.

The anti-corrosion treatment on some parts

of the car is constantly exposed to wear and

prone to damage. This applies particularly

to the underside of the car and inside the

wheel arches, where grit, road salt and the

like that are thrown up can give rise to cor-

rosion where the underseal has worn away.

The extent of this obviously depends on the

conditions in which the car is used.

Accordingly, make it a habit to hose the

underside of the car often and to inspect the

condition of the underseal. The anti-corro-

sion warranty does not relieve the car owner

of the need to carry out normal maintenance

to the rustproofing and to make good any

damage.

Surface treatment composition1 Body panel

2 Zinc (certain components only) 7.5 µm

3 Phosphate coating 3 –5 µm

4 Cathodic ED 23 µm

5 Intermediate coat 35 µm

6 Metallic base/solid base 11 µm

7 Clear enamel 45 µm

ProCarManuals.com

Page 258 of 292

256 Car care2Clean the underside of the car during

the winter. Use high pressure water to

clean the car’s underside (floor panels,

wheel wells) at least at mid-winter and in

the spring.

3Inspect the car frequently for leaks or

damage, and arrange for needed

repairs promptly. After washing or after

heavy rain, check for leaks. When wash-

ing the car inspect body surfaces for

paint damage. While checking for leaks,

lift the floor mats and check underneath

them. Water can collect in these areas

and remain for prolonged periods. Dry

any wet areas including the floor mats.

Have leaks repaired as soon as possi-

ble.

Use touch-up paint to repair small

scratches or minor finish damage. Areas

where metal is exposed will rust quickly

and MUST be repaired immediately by

touch-up or professional repainting.

Rust must be removed, the bare metal

primed and painted. Major body

damage should be repaired immediately

and new panels or exposed areas

should be undercoated with anti- corro-

sion material.

Repairs of this type are the owner’s

responsibility and are not covered under

warranty.Inspect the undercoating and touch up if

necessary. Pay particular attention to the

fenders and wheel housings, which are

exposed to abrasion by flying gravel, etc. If

the composition has worn or flaked off, the

steel must be thoroughly cleaned and dried

before a fresh coat is applied. The cleaning

is best done with a scraper and a steel wire

brush, followed by washing with solvent.

Apply the new coating thinly, otherwise it

may run off or fall off when dry.

Recovery and/or

recycling of automotive

materialsA typical car consists of metals (65–75 %),

plastics (10–15 %), rubber (5 %) and small

quantities of glass, wood, paper and tex-

tiles. The recycling of metals has been com-

monplace for a long time now.

To facilitate the sorting of other materials,

plastic parts, for instance, have been

marked to identify the precise nature of the

plastic.

ProCarManuals.com

Page 260 of 292

258 Car careNote:

The A/C system cannot be switched on

when the outside temperature is below 32°F

(0°C). Turn on the A/C system when the car

is standing in a warm place. Simplest is to

always have the A/C button pressed in. The

A/C system will then cut in automatically

when the outside temperature is high

enough.

Headlight aimingThe vehicle has a visual optical headlight

aiming system equipped with vertical

aiming device. The aim has been preset at

the factory and should normally not need

further adjustments.

If your headlights are damaged in a crash,

the headlight aim may be affected. If you

believe your headlights need to be re-

aimed, we recommend that you take it to

your Saab dealer for service. However, it is

possible for you to re-aim your headlights as

described in the following procedure.To check the aim, the vehicle should be

properly prepared as follows:

The vehicle shall be placed so that the

headlights are 25 ft (7.6 m) from a light

colored wall or other flat surface. The

aiming area should be darkened, this will

improve your ability to see the beam of the

low beam headlight being aimed.

An optical headlamp aimer can also be

used and will than replace the wall.

The vehicle must have all four wheels on

a perfectly level surface which is level all

the way to the wall or other flat surface.

The vehicle should be placed so it is per-

pendicular to the wall or other flat surface.

The vehicle should be unloaded and fuel

tank full, and one person or 160 lbs.

(75 kg) on the drivers seat.

The vehicle should be fully assembled

and all other work stopped while headlight

aiming is being done.

The vehicle should not have any snow, ice

or mud attached to it.

Tires should be inflated to the prescribed

pressure.

Close all doors.

Rock the vehicle to stabilize the suspen-

sion.

Headlight aiming is done with the vehicle

low beam lamps. The high beam lamps will

be correctly aimed if the low beam lamps

are aimed properly.

If you find that the headlight needs adjust-

ment follow these steps:

WARNING

Before checking/adjusting the headlight

aiming, switch off the engine to avoid

danger of fingers and hands being injured

by moving parts.

The radiator fan can start up even when

the engine is switched off.NOTICETo make sure that your headlights are

aimed properly read all instructions

before beginning. Failure to follow these

instructions could cause damage to

headlight parts or a not correctly aimed

headlight.

ProCarManuals.com

Page 268 of 292

266 Customer Assistance and InformationVehicle Data Collection and

Event Data RecordersYour vehicle, like other modern motor vehi-

cles, has a number of sophisticated com-

puter systems that monitor and control sev-

eral aspects of the vehicle’s performance.

Your vehicle uses on-board vehicle comput-

ers to monitor emission control components

to optimize fuel economy, to monitor condi-

tions for air bag deployment and, if so

equipped, to provide anti-lock braking and

to help the driver control the vehicle in diffi-

cult driving situations. Some information

may be stored during regular operations to

facilitate repair of detected malfunctions;

other information is stored only in a crash

event by computer systems commonly

called event data recorders (EDR).

In a crash event, computer systems, such

as the Air Bag Sensing and Diagnostic

Module (SDM) in your vehicle may record

information about the condition of the vehi-

cle and how it was operated, such as data

related to engine speed, brake application,

throttle position, vehicle speed, steering

wheel angle, lateral acceleration, safety belt

usage, air bag readiness, air bag perfor-

mance, and the severity of a collision. This

information has been used to improve vehi-

cle crash performance and may be used to

improve crash performance of future vehi-

cles and driving safety. Unlike the data

recorders on many airplanes, these on-

board systems do not record sounds, such

as conversation of vehicle occupants.To read this information, special equipment

is needed and access to the vehicle or the

SDM is required.

Saab will not access information about a

crash event or share it with others other than

with the consent of the vehicle owner or, if

the vehicle is leased, with the consent of

the lessee,

in response to an official request of police

or similar government office,

as part of Saab’s defense of litigation

through the discovery process, or

as required by law.

In addition, once Saab collects or receives

data, Saab may

use the data for Saab research needs,

make it available for research where

appropriate confidentiality is to be main-

tained and need is shown, or

share summary data which is not tied to a

specific vehicle with non-Saab organiza-

tions for research purposes.

Others, such as law enforcement, may have

access to the special equipment that can

read the information if they have access to

the vehicle or SDM.

If your vehicle is equipped with OnStar®,

please check the OnStar® subscription ser-

vice agreement or manual for information

on its operations and data collection.

ProCarManuals.com

Page 269 of 292

267 Technical data

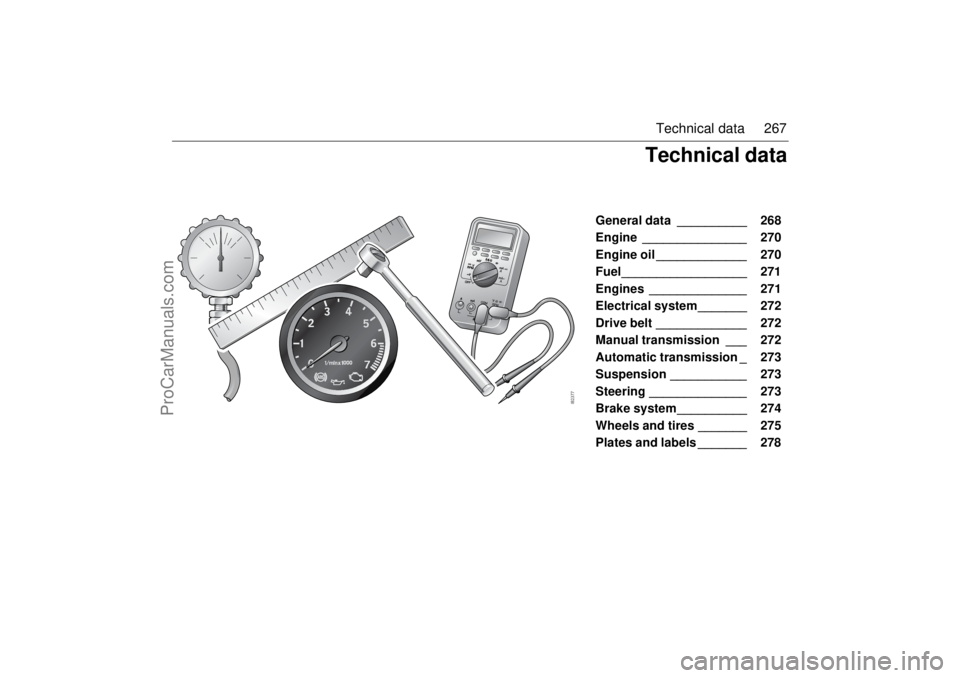

General data __________ 268

Engine _______________ 270

Engine oil _____________ 270

Fuel__________________ 271

Engines ______________ 271

Electrical system_______ 272

Drive belt _____________ 272

Manual transmission ___ 272

Automatic transmission _ 273

Suspension ___________ 273

Steering ______________ 273

Brake system__________ 274

Wheels and tires _______ 275

Plates and labels _______ 278

Technical data

ProCarManuals.com