light SAAB 9-5 2002 Owners Manual

[x] Cancel search | Manufacturer: SAAB, Model Year: 2002, Model line: 9-5, Model: SAAB 9-5 2002Pages: 272, PDF Size: 16.26 MB

Page 221 of 272

221 Car care and technical information

12 Horn

13 Extra lights (accessory)

14 High beam headlight

15 Low beam headlight

16 –

17 Windshield wipers

IB1798

Location of wallet for spare bulbs and

fuses (accessory)

ProCarManuals.com

Page 226 of 272

226 Car care and technical informationCompact spare wheelThe compact spare is light and easy to

handle when changing the tire. Its use is

only permitted when a standard tire has sus-

tained a puncture. The maximum life of the

tire is only 2000 miles (3,500 km).

Do not exceed 50 mph (80 km/h) with the

compact spare fitted.

The compact spare should be inflated to

60 psi (420 kPa). Carry the punctured tire in

the spare-wheel well under the luggage-

compartment floor.

Have the standard tire repaired and refitted

as soon as possible (see also page 179).The spare wheel, together with the jack ,

front towrope attachment eye and toolkit, is

stowed away underneath a panel in the lug-

gage-compartment floor. The jack handle is

kept in a cover beside the spare wheel.

If you need to change a wheel, remove the

tool kit first and then the spare wheel.

The panel over the spare wheel can be held

open by hooking the handle onto the rubber

seal.

NOTETo avoid damaging a punctured alloy

wheel it can be placed outside up in the

spare-wheel well but only while driving to

the closest workshop.

A general rule is that all heavy loads must

be well secured in the luggage compart-

ment, see page 134 and 137.

IB534

Panel hooked back, 9-5 Sedan

IB1232

Hanging up the cover and spare wheel

compartments mats, 9-5 Wagon

IB1186

Spare wheel (under panel in luggage

compartment)

ProCarManuals.com

Page 227 of 272

227 Car care and technical information

Changing a wheel

WARNING

The car jack is designed solely for use

in changing a wheel or fitting snow

chains. It must not be used to support

the car during repair work or servicing.

Never crawl under a car that is

supported only by a jack.

Special care must be taken if the car is

on a slope – use wheel chocks!

Position chocks, one ahead and one

behind, the wheel that is diagonally

opposite to the one to be changed.

Switch on the hazard warning lights if

the car is on a road.

Apply the parking brake and leave the

car in gear (1st or reverse). Automatic

transmission: move selector to the

P position.

Ensure that everybody is out of the car

before jacking it up.

Never start the engine while the car is

jacked up.

The jack must stand on a firm, level

surface.

Stow the jack in the place provided for

it under the panel in the floor of the lug-

gage compartment. Secure it properly

to avert injury to passengers in the

event of a crash.

Do not use the jack for any purpose

other than for jacking up the car.

ProCarManuals.com

Page 229 of 272

229 Car care and technical information

If a floor jack is used, it can be applied to the

standard jacking points used by the dealer.

A floor jack can lift both front wheels or both

rear wheels off the ground simultaneously.

A jack stand must then be applied under-

neath the front of the engine subframe (at

the fixing point for the towrope-attachment

eye) or to the rear towrope-attachment eye

(or under the trailer hitch, if fitted).

1 Put the car in 1st gear (automatic trans-

mission: move selector to the P position)

and apply the parking brake.2 Wind the jack up to a suitable height

before placing it under the recess in the

sill.

Make sure that the jack fully engages

the recess in the sill and that the base of

the jack is steady and flat on the ground.

3 Remove the wheel cover (where appli-

cable).

Loosen the wheel bolts by half a turn.

4 Wind the jack to raise the wheel clear of

the ground. Remove the wheel bolts and

lift off the wheel.

5 Clean the contact surfaces between the

wheel and brake disc.

6 Fit the wheel and screw in the bolts in the

sequence shown (opposite pairs).

Tighten the bolts enough for the bolts

and wheel to be seated correctly.

7 Lower the car and tighten the wheel

bolts to the correct torque in the

sequence shown (opposite pairs).

Tightening torqueLight-alloy wheels: 80 ft.lbs. (110 Nm)

Steel wheels: 80 ft.lbs. (110 Nm)

Do not overtighten the bolts using a per-

cussion nut tightener: not only can this

damage the wheels but it can also make it impossible to undo the bolts using the

wheel wrench in the car’s toolkit.

8 Check-tighten the wheel bolts after a

few miles.

Tightening torqueLight-alloy wheels: 80 ft.lbs. (110 Nm)

Steel wheels: 80 ft.lbs. (110 Nm)

NOTEApply the jack only to the jacking points

indicated.

NOTEWhen refitting wheel covers (where

applicable), make sure that the valve

protrudes through the hole in the wheel

cover.

IB1130

Jacking points for a trolley jack

ProCarManuals.com

Page 232 of 272

232 Car care and technical informationSafety beltsRegularly check the function of the safety

belts as follows:

Hold the diagonal strap and pull it sharply.

The safety belt should

lock

and it should

not be possible to withdraw it further.

Check the anchorage points in the floor.

They must not have suffered rust damage.

There must be no frayed threads in the web-

bing.

Safety belts must not come into contact with

substances such as polishes, oils or other

chemicals. If the straps are dirty, wash them

with warm water and a detergent or have

them replaced.

Upholstery and trimTo remove fluff or hairs from the seat uphol-

stery or headlining, use a moist, lint-free

cloth or a special lint remover (brush or

roller). Remove any dirty marks using a

cloth moistened with lukewarm soapy

water.

When using a stain remover, always work

from the outside towards the center to avoid

leaving a ring. If a soiled ring or spot should

remain, it can usually be removed using

lukewarm soapy water or water alone.

Wet patches left by spilt soft drinks or thin oil

must be wiped off immediately using an

absorbent material, such as kitchen paper,

and treated with stain remover.

Alcohol is recommended for removing

grease or oil stains, and a semi-stiff brush

may also be used.

Cleaning and caring for leather

upholsteryThe principal reason for treating leather

upholstery is to maintain its elegant appear-

ance and to provide it with a protective film.

Discoloration caused by dust and wear

mainly affects the lighter shades, although

this is not detrimental to the leather –

indeed, the patina resulting from use is often

considered desirable in leather. But if the

leather is allowed to become too grubby, it

can start to look shabby.

It is a good idea to clean and recondition the

leather twice a year – in conjunction with a

general spring-cleaning of the car – after the

winter and in the autumn, for instance. In

hot, dry climates, the leather will need to be

treated more frequently. Recommended

conditioner – Saab Leather Care Lotion.

Do not use unknown harsh polishing

agents, cleaning agents, sprays, coarse

soap or hot water.Textile carpetingVacuum clean the carpeting regularly. Car-

pets can also be cleaned using a brush, or

carpet shampoo applied with a sponge. Do

not use vacuum cleaners outdoors unless

they are properly grounded.

WARNING

If the car is involved in a crash, the safety

belts, belt pretensioners and other com-

ponents must be inspected by an autho-

rized Saab dealer.

Never make any alterations or repairs to

the safety belt yourself but visit an autho-

rized Saab dealer.

ProCarManuals.com

Page 233 of 272

233 Car care and technical information

Washing the carThe bodywork must be washed frequently.

When the car is new, the body should be

washed by hand using plain cold water and

a clean, soft brush, or in a brushless car-

wash that uses mild detergent. Automatic

car washes with brushes should be avoided

when the car is new. Do not use automatic

car washes for the first five or six months,

before the paintwork has hardened prop-

erly. Thereafter, use a high quality car wash

soap added to lukewarm water.

Do not use a pressure washer at close

range on stone chip damage, scratches or

other damage to the paintwork. The paint

can otherwise start to flake.

Remove any bird droppings without delay,

as these can discolor the paintwork and

prove difficult to polish out.

Use a soft cloth moistened with methyl alco-

hol to remove splashes of tar or asphalt. Do

not use strong cleaners, as these can dry

out the paintwork. The underside of the car also needs wash-

ing regularly, and this should be done extra

thoroughly at the end of winter. Clean the

underside of the car by hand if the car is usu-

ally washed in an automatic car wash with-

out special facilities for underbody cleaning.

Never wash or leave the car to dry in the

sun, but wipe it dry with a chamois leather

immediately after washing to avoid smears

and streaks.

Clean the window glass inside and out using

a high quality window cleaner. This is partic-

ularly important when the car is new, as

upholstery and trim have a tendency to

sweat a little at first.

Keep the glass well cleaned, as this helps to

prevent misting.

Waxing and polishingDo not wax a new car during the first three

or four months. In fact, there is no need to

polish the car before the paintwork has

started to go dull through oxidation. Other

than in exceptional cases, do not use abra-

sive polishes containing a cutting agent on

a new car. Always wash the car thoroughly

before waxing or polishing.Engine compartmentClean the engine compartment using an

engine detergent and rinse with hot water.

Cover the headlights. Do not use high-pres-

sure washer. Avoid spraying the hood liner,

as this can become heavy and hang down

and touch the engine when the hood is

closed.

Do not use gasoline as a cleaning agent or

solvent when carrying out repairs or mainte-

nance. Saab recommends the use of envi-

ronmentally safe degreasing agents.

NOTEAvoid using any alcohol-based cleaners

on the front and rear light clusters, as

these can cause cracking of the lenses.

NOTE The door mirrors must be fully

retracted before the car enters an

automatic car wash.

Remove fixed antennas, e.g. for

mobile phone, before putting car

through an automatic car wash.

Try your brakes on leaving a car wash.

Wet brake discs reduce the braking

effect.

ProCarManuals.com

Page 238 of 272

238 Car care and technical information1 A-pillar trim: PP, PP/EPDM

2 Windshield trim: PP, PP/EPDM

3 Seals: EPDM

4 C-pillar trim: ABS

5 Rear light cluster: PMMA

6 Rear bumper, cellular core: expanded PP;

sheathing: PP/EPDM

7 Side-window casing: PP/EPDM

8 Fuel tank: PE

9 Side trim: PVC

10 A-pillar upholstery trim: PC/ABS, textile

11 Rearview mirror: ABS

12 Sill scuff plate: PP/EPDM

13 Wheel-arch liner: PP

14 Wheel cover: PA

15 Direction-indicator lamp lens: PMMA

16 Washer-fluid reservoir: PE

17 Front spoiler: PP/EPDM

18 Front bumper, cellular core: expanded PP;

sheathing, grille: PP/EPDM

19 Fan shroud: PP

20 Scuttle panel finisher: PC/ASA

IB1801

ABS Acrylonitrile-butadiene-styrene

ASA Acrylonitrile-styrene (acrylic

plastic)

EPDM Ethylene-propylene rubber

PA Polyamide (plastic)

PC Polycarbonate (plastic)

PE Polyethylene

PMMA Polymethyl methacrylate

POM Acetal plastic

PPO Polyphenylene oxide (plastic)

PP Polypropylene

PUR Polyurethane

PVC Polyvinyl chloride 1234

5

6

87

9

10

11

12 13 14 15 18

1719

1620

ProCarManuals.com

Page 239 of 272

239 Car care and technical information

Headlight aimingThe vehicle has a visual optical headlight

aiming system equipped with vertical

aiming device. The aim has been preset at

the factory and should normally not need

further adjustments.

If your headlights are damaged in a crash,

the headlight aim may be affected. If you

believe your headlights need to be

re-aimed, we recommend that you take it to

your Saab dealer for service, however, it is

possible for you to re-aim your headlights as

described in the following procedure.To check the aim, the vehicle should be

properly prepared as follows:

The vehicle shall be placed so that the

headlights are 25 ft (7.6 m) from a light

colored wall or other flat surface. The

aiming area should be darkened, this will

improve your ability to see the beam of the

low beam headlight being aimed.

The vehicle must have all four wheels on

a perfectly level surface which is level all

the way to the wall or other flat surface.

The vehicle should be placed so it is

perpendicular to the wall or other flat

surface.

The vehicle should be unloaded and fuel

tank full, and one person or 160 lbs.

(75 kg) on the drivers seat. The vehicle should be fully assembled

and all other work stopped while headlight

aiming is being done.

The vehicle should not have any snow, ice

or mud attached to it.

Tires should be inflated to the prescribed

pressure.

Close all doors.

Rock the vehicle to stabilize the suspen-

sion.

Headlight aiming is done with the vehicle

low beam lamps. The high beam lamps will

be correctly aimed if the low beam lamps

are aimed properly.

WARNING

Before checking/adjusting the headlight

aiming, switch off the engine to avoid

danger of fingers and hands being injured

by moving parts.

The radiator fan can start up even when

the engine is switched off.NOTETo make sure that your headlights are

aimed properly read all instructions

before beginning. Failure to follow these

instructions could cause damage to

headlight parts or a not correctly aimed

headlight.

ProCarManuals.com

Page 240 of 272

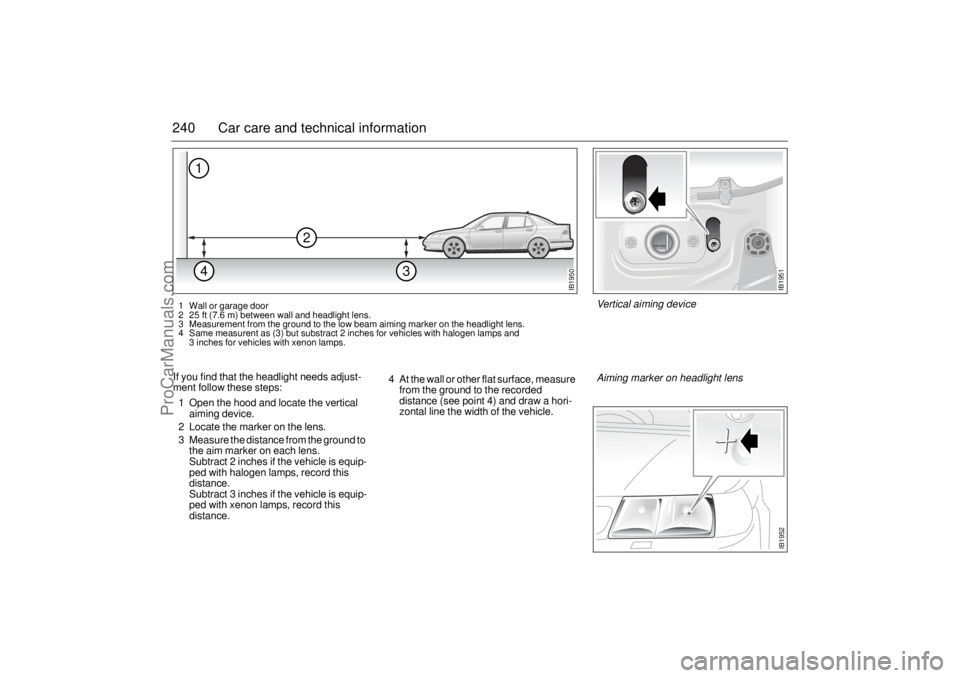

240 Car care and technical informationIf you find that the headlight needs adjust-

ment follow these steps:

1 Open the hood and locate the vertical

aiming device.

2 Locate the marker on the lens.

3 Measure the distance from the ground to

the aim marker on each lens.

Subtract 2 inches if the vehicle is equip-

ped with halogen lamps, record this

distance.

Subtract 3 inches if the vehicle is equip-

ped with xenon lamps, record this

distance.4 At the wall or other flat surface, measure

from the ground to the recorded

distance (see point 4) and draw a hori-

zontal line the width of the vehicle.

IB1950

2

14

3

1 Wall or garage door

2 25 ft (7.6 m) between wall and headlight lens.

3 Measurement from the ground to the low beam aiming marker on the headlight lens.

4 Same measurent as (3) but substract 2 inches for vehicles with halogen lamps and

3 inches for vehicles with xenon lamps.

IB1951

Vertical aiming device

IB1952

Aiming marker on headlight lens

ProCarManuals.com

Page 241 of 272

241 Car care and technical information

5 Turn on the low beam headlights and

place a piece of cardboard or equivalent

(although not directly on the lens) in front

of the headlight not being aimed. This

should allow the beam cut-off of the

headlight being aimed to be seen on the

flat surface.6 Turn the vertical aiming screw until the

horizontal cut-off of the headlight is alig-

ned with the horizontal line on the wall.NOTEDo not cover a headlight to improve beam

cut-off when aiming. Covering a headlight

may cause excessive heat build-up which

may cause damage to the headlight.

IB1953

Horizontal line on wall or other flat surface

IB1954

Correctly adjusted low beam

ProCarManuals.com