SAAB 9-5 2009 Owners Manual

Manufacturer: SAAB, Model Year: 2009, Model line: 9-5, Model: SAAB 9-5 2009Pages: 272, PDF Size: 21.53 MB

Page 231 of 272

231 Car care and technical information

Steps for Determining Correct

Load Limit1 Locate the statement “The

combined weight of occupants and

cargo should never exceed

XXX pounds” on your vehicle´s

label.

2 Determine the combined weight of

the driver and passengers that will

be riding in your vehicle.

3 Subtract the combined weight of the

driver and passengers from

XXX kilograms or XXX pounds.

4 The resulting figure equals the avail-

able amount of cargo and luggage

load capacity. For example, if the

“XXX” amount equals 1400 lbs. and

there will be five 150 lb. passengers

in your vehicle, the amount of avail-

able cargo and luggage load capac-

ity is 650 lbs. (1400–750 (5x150) =

650 lbs.).5 Determine the combined weight of

luggage and cargo being loaded on

the vehicle. That weight may not

safely exceed the available cargo

and luggage load capacity calcu-

lated in Step 4.

6 If your vehicle will be towing a trailer,

load from your trailer will be trans-

ferred to your vehicle. Consult this

manual to determine how this

reduces the available cargo and

luggage load capacity of your vehi-

cle.

Winter tiresWinter (snow) tires are recommended for

winter climates where the majority of your

driving will be done on snow and ice. Winter

tires should be fitted to all four wheels to

maintain a proper balance. Your Saab

dealer can advise you of to the correct size

tire for your car (if different from the original

size) and also supply Saab approved winter

tires pre-mounted on steel or alloy rims.

Winter tires normally use a different speed

rating compared to summer/all season tires.

Make sure not to exceed the stated speed

rating on the tires you use.

Make sure that wheels with sensors for tire

pressure monitoring are fitted during

replacement if the car has automatic tire

pressure monitoring.

Tire date codeTires should be regarded as perishable

goods. As the tires age, the rubber becomes

progressively harder, and the roadholding

ability of the tires diminishes. This is partic-

ularly true on winter tires.

Tires now have a date-code marking for the

year of manufacture. The first two digits

denote the week number and the two last

digits the year followed by a filled triangle.Tire direction of rotationThe direction of rotation is important for the

majority of tires. These tires have a marking

on the side of the tire. The marking may

state "Tire rotation" together with an arrow

or the text "Facing out". The tire must rotate

in the same direction for its entire service

life.

95_US_MY09.book Page 231 Tuesday, April 15, 2008 11:03 AM

ProCarManuals.com

Page 232 of 272

232 Car care and technical informationAutomatic tire pressure

monitoring systemThe system consists of a sensor in each

wheel and a commopn receiver. The sen-

sors are located inside the tire in direct con-

nection with the air pressure valves.

Make sure that wheels with sensors for tire

pressure monitoring are fitted during

replacement if the car has automatic tire

pressure monitoring.Tire pressure information is transmitted

wirelessly to the receiver.

The system checks the tire pressures when

speed exceeds 19 mph (30 km/h).

The system is self-programming which

means that the wheels can be shifted

around without any need for adjustment.

The spare wheel has no sensor.

The sensor batteries last for 10 years or

around 160 000 km. The battery cannot be

replaced. The whole sensor must be

replaced.The system does not warn if the tire pres-

sure is too high.

WARNING

The system is an aid to the driver. The

driver always has the responsibility that

the tires have the correct air pressure.

For optimum safety, economy and com-

fort tire pressures should be checked reg-

ularly even if the automatic tire pressure

monitoring has not alarmed.

NOTICETire replacement must take place with

great care to avoid damaging the sensors

that are built together with the valves.

Remove the rear side first.

Start to remove the tire opposite the

valve.

During removal the tire machine must

not come closer than ±10° from the

valve.

During fitting, start 20° after the valve

and finish 20° before the valve.

Do not inflate the tire with pressure

higher than 102 psi (700 kPa).

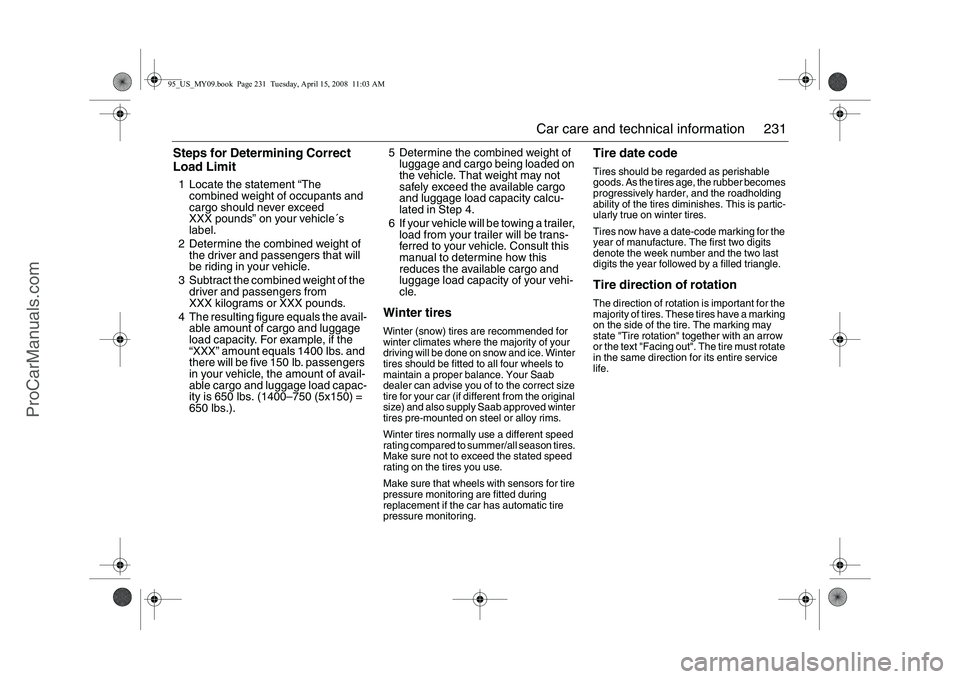

Valve with sensor

95_US_MY09.book Page 232 Tuesday, April 15, 2008 11:03 AM

ProCarManuals.com

Page 233 of 272

233 Car care and technical information

If the tire pressure decreasesIf the tire pressure decreases to 0.4 bar

(6 psi) below the recommended pressure

then a warning is shown on the SID as to

which tires are affected.

Adjust the pressure as soon as possible.If the tire pressure continues to decrease

then an alarm is shown on the SID when the

pressure has decreased to 23 psi (159 kPa)

which is the lowest permitted pressure for

the tire.

An alarm is also received when leakage is

greater than 3 psi/min. (20 kPa/min.).

Reduce speed (avoid heavy braking and

significant steering wheel movement) and

stop the car as soon as possible at a suita-

ble location. Replace the defective wheel.

The fault message can remain for up to

10 minutes after restarting the car. Then it

disappears if the tire pressure is correct.

Check/adjust the pressure in the other tires

when a fault message is shown.Note that the tire pressure can decrease

without a puncture. The pressure could

decrease around 3 psi (20 kPa) during a

three month period.

The outside temperature could also affect

tire pressure.

The specified tyre pressures are valid for

cold tyres. The increased tyre pressure

resulting from extensive driving must not be

reduced. Tyre pressure table, see page

263.

If the system has triggerd a low pressure

warning or alarm then the tire pressure must

be adjusted to the recommended pressure

in order to put out the warning or alarm.

For further information on tire air pres-

sure, see page 220.

Allow 10 minutes for the system to recogn-

ise the wheel/sensors positions after fitting

a new set of tires. During this period no low

pressure warning or alarm can be triggered.

Tire pressure low,

rear left. Check tires.

Low tire pressure front

right. Make a safe stop.

Valve without sensor95_US_MY09.book Page 233 Tuesday, April 15, 2008 11:03 AM

ProCarManuals.com

Page 234 of 272

234 Car care and technical informationMalfunctionsThe above message is shown on the SID if:

a wheel without pressure sensor has

been fitted (e.g. spare wheel)

one or more pressure sensors are broken

or missing

a fault has arisen in the receiver

a system error has arisen.

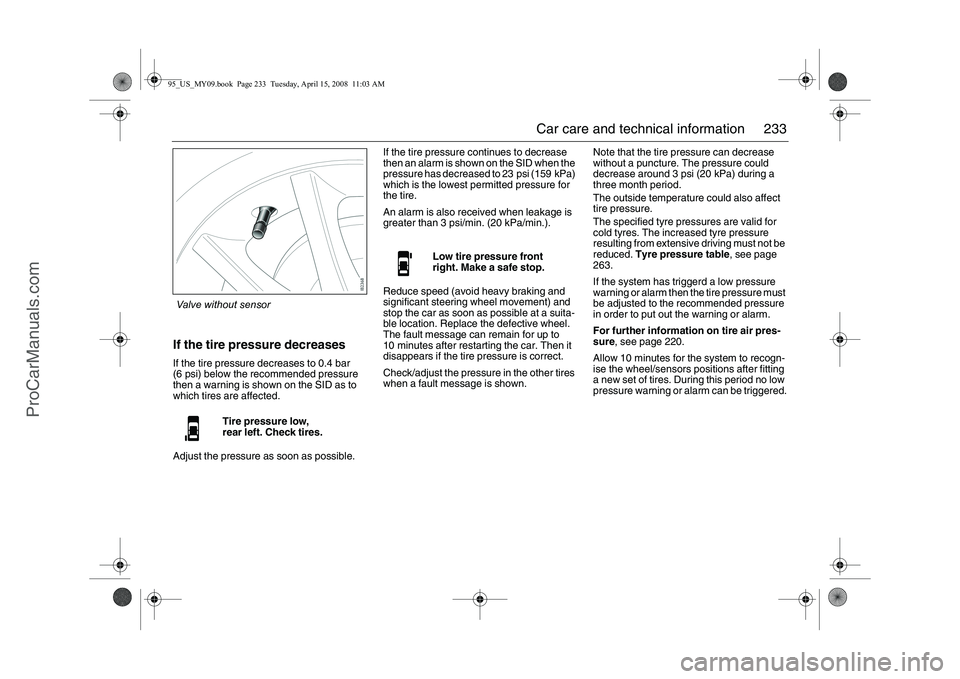

Removing a tireRemove the tire with a tire machine. It is

important to follow the instructions for the

tire machine as well.

Do not fit the tire tool in an area ±10° from

the valve.

Start removing opposite the valve.

Remove the rear side first.

Fitting a tireFit the tire with a tire machine. It is important

to follow the instructions for the tire machine

as well.

Start to fit about 20° after the valve.

Finish fitting before an area 20° from the

valve.

Do not inflate the tire to a pressure higher

than 102 psi (700 kPa). Tire pressure system

failure. Contact service.

95_US_MY09.book Page 234 Tuesday, April 15, 2008 11:03 AM

ProCarManuals.com

Page 235 of 272

235 Car care and technical information

Compact spare tireThe spare tire, together with the jack, front

towrope attachment eye and toolkit, is

stowed away underneath the luggage-com-

partment floor.

The compact spare is light and easy to

handle when changing the tire. Its use is

only permitted when a standard tire has sus-

tained a puncture. The maximum life of the

tire is only 2000 miles (3,500 km).

Do not exceed 50 mph (80 km/h) with the

compact spare fitted.

The compact spare should be inflated to

60 psi (420 kPa). Carry the punctured tire in

the spare-wheel well under the luggage-

compartment floor.

Have the standard tire repaired and refitted

as soon as possible.

WARNING

Stow all tools carefully away after use, so

that they cannot get loose and cause

injury in the event of a crash.

NOTICETo avoid damaging a punctured alloy

wheel it can be placed outside up in the

spare-wheel well but only while driving to

the closest dealer.

A general rule is that all heavy loads must

be well secured in the luggage compart-

ment, see page 131 and 135.

IB3233

Spare wheel (under panel in luggage

compartment)

95_US_MY09.book Page 235 Tuesday, April 15, 2008 11:03 AM

ProCarManuals.com

Page 236 of 272

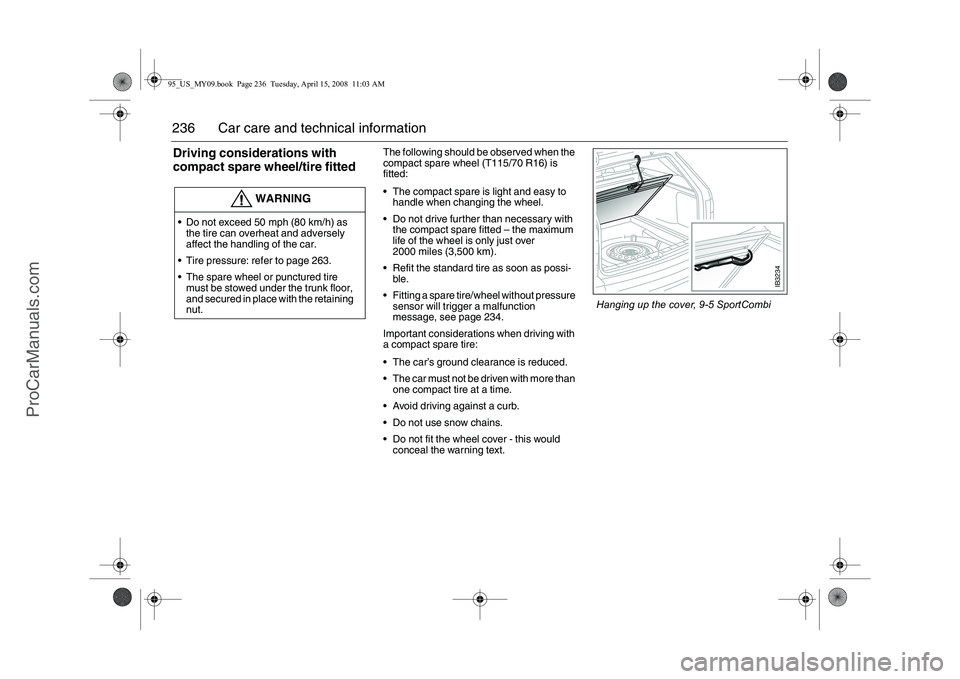

236 Car care and technical informationDriving considerations with

compact spare wheel/tire fitted

The following should be observed when the

compact spare wheel (T115/70 R16) is

fitted:

The compact spare is light and easy to

handle when changing the wheel.

Do not drive further than necessary with

the compact spare fitted – the maximum

life of the wheel is only just over

2000 miles (3,500 km).

Refit the standard tire as soon as possi-

ble.

Fitting a spare tire/wheel without pressure

sensor will trigger a malfunction

message, see page 234.

Important considerations when driving with

a compact spare tire:

The car’s ground clearance is reduced.

The car must not be driven with more than

one compact tire at a time.

Avoid driving against a curb.

Do not use snow chains.

Do not fit the wheel cover - this would

conceal the warning text.

WARNING

Do not exceed 50 mph (80 km/h) as

the tire can overheat and adversely

affect the handling of the car.

Tire pressure: refer to page 263.

The spare wheel or punctured tire

must be stowed under the trunk floor,

and secured in place with the retaining

nut.

IB3234

Hanging up the cover, 9-5 SportCombi

95_US_MY09.book Page 236 Tuesday, April 15, 2008 11:03 AM

ProCarManuals.com

Page 237 of 272

237 Car care and technical information

Changing a wheel

WARNING

Lifting a vehicle and getting under it to do

maintenance or repairs is dangerous

without the appropriate safety equipment

and training. The jack provided with your

vehicle is designed only for changing a

flat tire. If it is used for anything else, you

or others could be badly injured or killed if

the vehicle slips off the jack. Use the jack

provided with your vehicle only for chang-

ing a flat tire.

Changing a tire can be dangerous. The

vehicle can slip off the jack and roll over

or fall on you or other people. You and

they could be badly injured or even killed.

Find a level place to change your tire. To

help prevent the vehicle from moving:

1 Set the parking brake firmly.

2 If you have an automatic transmis-

sion, put the shift lever in PARK (P).

For a manual transmission, leave the

car in gear (1st or REVERSE (R)).

3 Turn off the engine and do not restart

while the vehicle is raised.

4 Do not allow passengers to remain in

the vehicle.

To be even more certain the vehicle won't

move, you should put blocks at the front

and rear of the tire farthest away from the

one being changed. That would be the

tire, on the other side, at the opposite end

of the vehicle.

The car jack is designed solely for use

in changing a wheel or fitting snow

chains. It must not be used to sup-

port the car during repair work or

servicing.

Never crawl under a car that is

supported only by a jack.

Raising your vehicle too high or with

the jack improperly positioned can

damage the vehicle and even make

the vehicle fall. To help avoid personal

injury and vehicle damage, be sure to

fit the jack lift head into the proper

location before raising the vehicle, and

raise the vehicle only far enough off

the ground so there is enough room

for the spare tire to fit (no more than

25 mm or 1 inch clearance between

the ground and the bottom of the tire).

Switch on the hazard warning lights if

the car is on a road.

The jack should be stored correctly

under the carpeting in the trunk. If it

lies loose in the car, it could thrown for-

ward and cause personal injury in the

event of a crash or if the car rolls over.

Grit, salt and rust can clog the inner

threads of the wheel bolts if the car has

been driven for several years exclu-

sively with alloy wheels.

If steel wheels are being installed, the

bolt hole threads in the brake hubs

should be cleaned before the thinner

steel wheels are fitted. It may other-

wise not be possible to achieve the

correct clamping force, despite tight-

ening the wheel bolts to the correct

torque.

95_US_MY09.book Page 237 Tuesday, April 15, 2008 11:03 AM

ProCarManuals.com

Page 238 of 272

238 Car care and technical informationTo jack up the car, apply the jack to one of

the special jacking points under the sills.

If a floor jack is used, it can be applied to the

standard jacking points used by the dealer.

A floor jack can lift both front wheels or both

rear wheels off the ground simultaneously.

A jack stand must then be applied under-

neath the front of the engine subframe (at

the fixing point for the towrope-attachment

eye) or to the rear towrope-attachment eye

(or under the trailer hitch, if fitted).1 Put the car in 1st gear (automatic trans-

mission: move selector to the P position)

and apply the parking brake.

2 Wind the jack up to a suitable height

before placing it under the recess in the

sill.

Make sure that the jack fully engages

the recess in the sill and that the base of

the jack is steady and flat on the ground.3 Remove the wheel cover (where appli-

cable).

Remove the wheel bolt caps and loosen

the wheel bolts by half a turn.

4 Wind the jack to raise the wheel clear of

the ground. Remove the wheel bolts and

lift off the wheel.

NOTICEApply the jack only to the jacking points

indicated on the body.Position for jack

IB3917

IB1130

Jacking points for a floor jack 95_US_MY09.book Page 238 Tuesday, April 15, 2008 11:03 AM

ProCarManuals.com

Page 239 of 272

239 Car care and technical information

5 Clean any rust or dirt from the contact

surfaces between the wheel and brake

disc. Do not wipe away the grease in the

hub.

6 Fit the wheel and screw in the bolts in the

sequence shown (opposite pairs) - see

page 240.

Tighten the bolts enough for the bolts

and wheel to be seated correctly.7 Lower the car and tighten the wheel

bolts to the correct torque in the

sequence shown (opposite

pairs).Replace the wheel bolt caps.

Tightening torque

Light-alloy wheels: 80 ft.lbs. (110 Nm)

Steel wheels: 80 ft.lbs. (110 Nm).

Lubricate the wheel stud head with a

small amount of petroleum jelly or simi-

lar and reinstall the plastic covers on the

wheel studs. The petroleum jelly facilita-

tes removal.

NOTICE When refitting wheel covers (where

applicable), make sure that the valve

protrudes through the marked hole in

the wheel cover.

Do not overtighten the bolts using an

impact wrench: not only can this

damage the wheels but it can also

make it impossible to undo the bolts

using the wheel wrench in the car’s

toolkit.

Clean any rust or dirt from the contact sur-

faces between the wheel and brake disc

IB2428

Do not wipe away the grease in the hub.

IB4529

Removing the plastic wheel bolt caps95_US_MY09.book Page 239 Tuesday, April 15, 2008 11:03 AM

ProCarManuals.com

Page 240 of 272

240 Car care and technical information8 Check-tighten the wheel bolts after a few

miles.

Tightening torque

Light-alloy wheels: 80 ft.lbs. (110 Nm)

Steel wheels: 80 ft.lbs. (110 Nm)

Safety beltsRegularly check the function of the safety

belts as follows:

Hold the diagonal strap and pull it sharply.

The safety belt should lock and it should

not be possible to withdraw it further.

Check the anchorage points in the floor.

They must not have suffered rust damage.

There must be no frayed threads in the web-

bing.

Safety belts must not come into contact with

substances such as polishes, oils or other

chemicals. If the straps are dirty, wash them

with warm water and a detergent or have

them replaced.

WARNING

If the car is involved in a crash, the safety

belts, belt pretensioners and other com-

ponents must be inspected by a work-

shop. We recommend that you contact an

authorized Saab dealer.

Never make any alterations or repairs to

the safety belt yourself.

IB1800IB1800

Removing the wheel cover

IB539

Tightening sequence, wheel bolts

95_US_MY09.book Page 240 Tuesday, April 15, 2008 11:03 AM

ProCarManuals.com