torque SATURN ASTRA 2009 Owners Manual

[x] Cancel search | Manufacturer: SATURN, Model Year: 2009, Model line: ASTRA, Model: SATURN ASTRA 2009Pages: 314, PDF Size: 1.94 MB

Page 158 of 314

Leaving the Vehicle with the

Engine Running

{CAUTION

It can be dangerous to leave the

vehicle with the engine running.

The vehicle could move suddenly

if the shift lever is not fully in

P (Park) with the parking brake

�rmly set. And, if you leave the

vehicle with the engine running, it

could overheat and even catch

�re. You or others could be

injured. Do not leave the vehicle

with the engine running.

If you have to leave the vehicle with

the engine running, be sure the

vehicle is in P (Park) and the parking

brake is �rmly set before you

leave it. After you have moved the

shift lever into P (Park), hold

the regular brake pedal down. Then,

see if you can move the shift

lever away from P (Park) without

�rst pushing the button.If you can, it means that the shift

lever was not fully locked in

P (Park).

Torque Lock

If you are parking on a hill and you

do not shift the transmission into

P (Park) properly, the weight of the

vehicle may put too much force on

the parking pawl in the transmission.

You may �nd it difficult to pull the

shift lever out of P (Park). This is

called torque lock. To prevent torque

lock, set the parking brake and then

shift into P (Park) properly before you

leave the driver seat. To �nd out

how, seeShifting Into Park on

page 8-11.

When you are ready to drive, move

the shift lever out of P (Park)before

you release the parking brake.If torque lock does occur, you may

need to have another vehicle

push your vehicle a little uphill to

take some of the pressure from the

parking pawl in the transmission,

so you can pull the shift lever out of

P (Park).

Shifting Out of Park

This vehicle has an electronic shift

lock release system. The shift

lock release is designed to:

Prevent ignition key removal

unless the shift lever is in

P (Park) with the shift lever

button fully released.

Prevent movement of the shift

lever out of P (Park), unless

the ignition is in the ON/RUN

position and the regular brake

pedal is applied.

The shift lock release is always

functional except in the case of an

uncharged or low voltage (less

than 9 volt) battery.

8-12 Driving and Operating

ProCarManuals.com

Page 208 of 314

Rear disc brake pads do not have

built-in brake pad wear indicators.

Periodic visual inspection of the rear

brake pads is required to determine

when to replace the pads. Visually

inspect the rear brake pads

whenever the rear wheels are

removed such as during tire rotation.

1. Set the parking brake and make

sure that the brakes have been

given enough time to cool.

2. Remove the rear wheels.

3. Visually inspect the rear brake

inner pads (C) at each rear

wheel through the inspection

window in the brake caliper (A).Brake pads should be replaced

when the inner pad (C) is

worn to 5/64 in (2 mm) of pad

thickness (B). New brake pads,

with no wear, are 25/64 of

an inch (10 mm) thick.

4. After brake pad inspection or

replacement, install the rear

wheels.

Some driving conditions or climates

can cause a brake squeal when

the brakes are �rst applied or

lightly applied. This does not mean

something is wrong with the brakes.Properly torqued wheel bolts are

necessary to help prevent brake

pulsation. When tires are rotated,

inspect brake pads for wear

and evenly tighten wheel bolts in

the proper sequence to torque

speci�cations inCapacities

and Specifications on page 10-2.

Brake linings should always

be replaced as complete axle sets.

Brake Pedal Travel

See your dealer/retailer if the brake

pedal does not return to normal

height, or if there is a rapid increase

in pedal travel. This could be a

sign that brake service might

be required.

Brake Adjustment

Every brake stop, the disc brakes

adjust for wear.

9-24 Vehicle Service and Care

ProCarManuals.com

Page 237 of 314

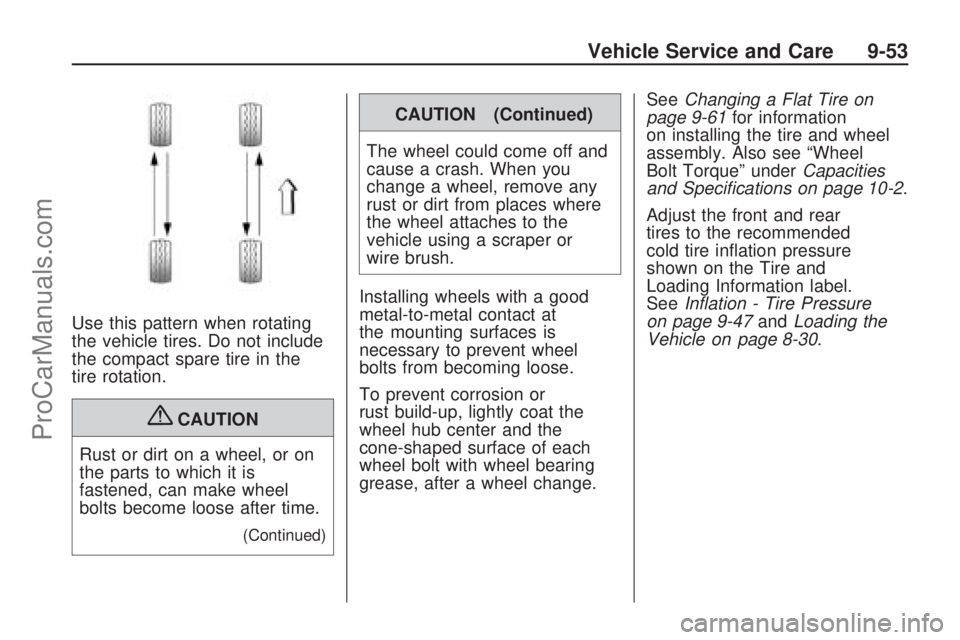

Use this pattern when rotating

the vehicle tires. Do not include

the compact spare tire in the

tire rotation.

{CAUTION

Rust or dirt on a wheel, or on

the parts to which it is

fastened, can make wheel

bolts become loose after time.

(Continued)

CAUTION (Continued)

The wheel could come off and

cause a crash. When you

change a wheel, remove any

rust or dirt from places where

the wheel attaches to the

vehicle using a scraper or

wire brush.

Installing wheels with a good

metal-to-metal contact at

the mounting surfaces is

necessary to prevent wheel

bolts from becoming loose.

To prevent corrosion or

rust build-up, lightly coat the

wheel hub center and the

cone-shaped surface of each

wheel bolt with wheel bearing

grease, after a wheel change.SeeChanging a Flat Tire on

page 9-61for information

on installing the tire and wheel

assembly. Also see “Wheel

Bolt Torque” underCapacities

and Specifications on page 10-2.

Adjust the front and rear

tires to the recommended

cold tire in�ation pressure

shown on the Tire and

Loading Information label.

SeeInflation - Tire Pressure

on page 9-47andLoading the

Vehicle on page 8-30.

Vehicle Service and Care 9-53

ProCarManuals.com

Page 250 of 314

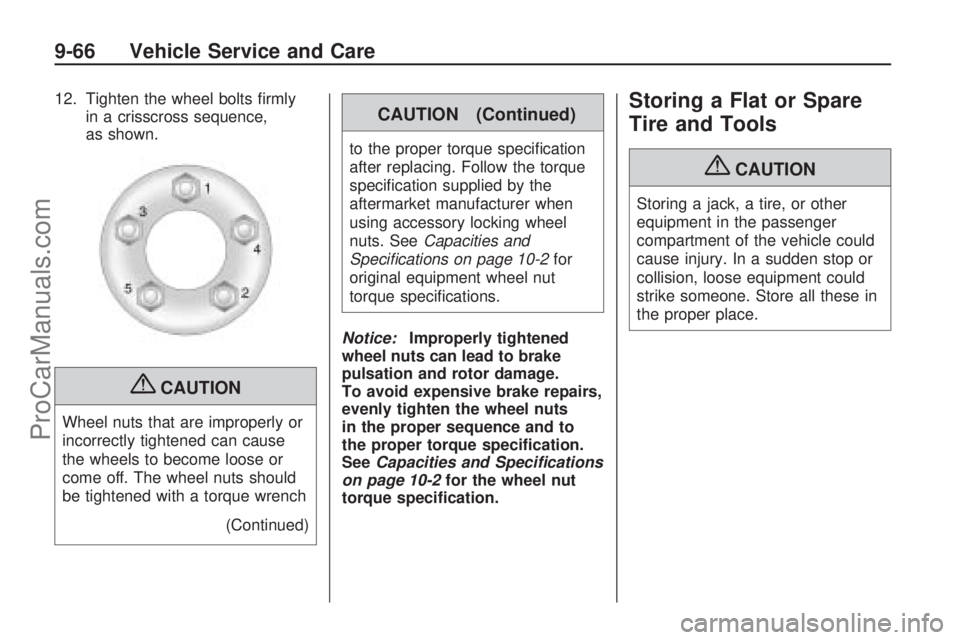

12. Tighten the wheel bolts �rmly

in a crisscross sequence,

as shown.

{CAUTION

Wheel nuts that are improperly or

incorrectly tightened can cause

the wheels to become loose or

come off. The wheel nuts should

be tightened with a torque wrench

(Continued)

CAUTION (Continued)

to the proper torque speci�cation

after replacing. Follow the torque

speci�cation supplied by the

aftermarket manufacturer when

using accessory locking wheel

nuts. SeeCapacities and

Specifications on page 10-2for

original equipment wheel nut

torque speci�cations.

Notice:Improperly tightened

wheel nuts can lead to brake

pulsation and rotor damage.

To avoid expensive brake repairs,

evenly tighten the wheel nuts

in the proper sequence and to

the proper torque speci�cation.

SeeCapacities and Specifications

on page 10-2for the wheel nut

torque speci�cation.

Storing a Flat or Spare

Tire and Tools

{CAUTION

Storing a jack, a tire, or other

equipment in the passenger

compartment of the vehicle could

cause injury. In a sudden stop or

collision, loose equipment could

strike someone. Store all these in

the proper place.

9-66 Vehicle Service and Care

ProCarManuals.com

Page 267 of 314

ApplicationCapacities

English Metric

Transmission Fluid Automatic Transmission 4.2 qt 4.0 L

Manual Transmission 1.6 qt 1.5 L

Wheel Bolt Torque 81 lb ft 110 Y

All capacities are approximate. When adding, be sure to �ll to the approximate level, as recommended in this

manual.

Engine Speci�cations

Engine VIN CodeTransmission Spark Plug Gap

1.8L L4 1Automatic

Manual 0.035 in (0.90 mm)

Technical Data 10-3

ProCarManuals.com