engine Seat Alhambra 2017 User Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2017, Model line: Alhambra, Model: Seat Alhambra 2017Pages: 320, PDF Size: 6.88 MB

Page 43 of 320

The essentials

Brake fluid Fig. 57

Engine compartment: brake fluid res-

er v

oir c

ap The brake fluid reservoir is located in the en-

gine c

omp

ar

tment ›››

page 271.

The level should be between the and

marks. If it is below , please visit a Techni-

cal Service.

››› in Checking the brake fluid level on

page 279

››› page 278 Windscreen washer

Fig. 58

In the engine compartment: wind-

s c

r

een washer reservoir top. The windscreen washer reservoir is located in

the en

gine c

omp

artment ›››

page 271.

To top up, mix water with a product recom-

mended by SEAT.

In cold temperatures, add anti-freeze.

››› in Checking and topping up the

windscreen washer reservoir on

page 280

››› page 280 Battery

The battery is located in the engine compart-

ment

›

›

› page 271. It does not require maintenance. It is checked as part of the In-

spection Ser

vice.

››› in Checking the electrolyte level of

the vehicle battery on page 282

››› page 280 41

Page 44 of 320

The essentials

Emergencies F u

se

s

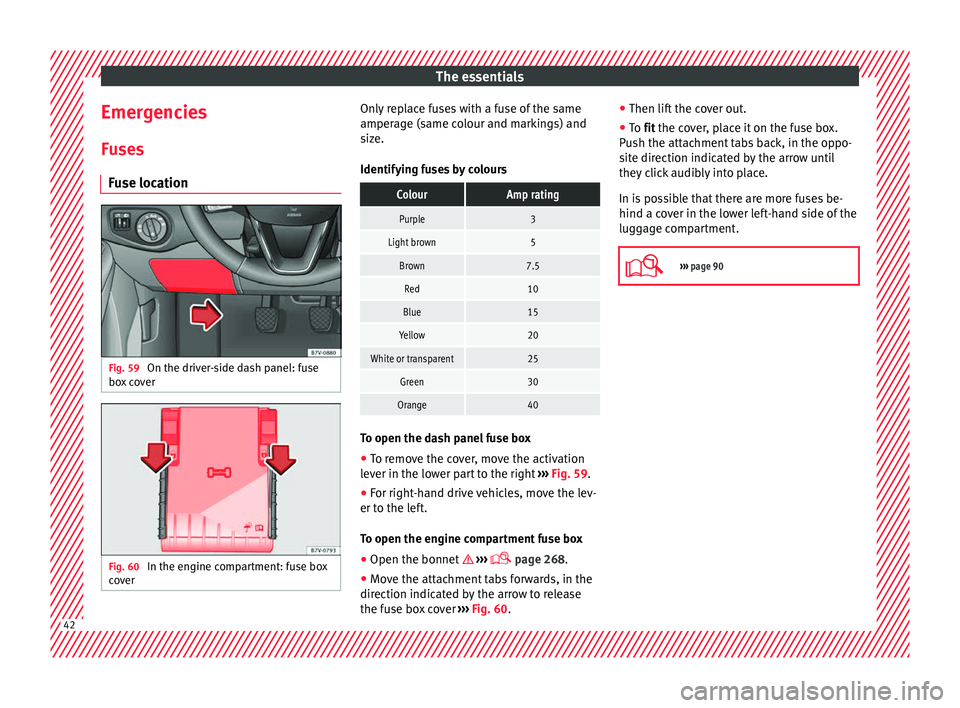

Fuse location Fig. 59

On the driver-side dash panel: fuse

bo x

c

over Fig. 60

In the engine compartment: fuse box

c o v

er Only replace fuses with a fuse of the same

amper

ag

e (s

ame colour and markings) and

size.

Identifying fuses by colours

ColourAmp rating

Purple3

Light brown5

Brown7.5

Red10

Blue15

Yellow20

White or transparent25

Green30

Orange40 To open the dash panel fuse box

●

To remove the cover, move the activation

l ev

er in the lo

wer part to the right ››› Fig. 59.

● For right-hand drive vehicles, move the lev-

er to the lef

t.

To open the engine compartment fuse box

● Open the bonnet ›››

page 268.

● Move the attachment tabs forwards, in the

direction indicat

ed by the arrow to release

the fuse box cover ››› Fig. 60. ●

Then lift the c

over out.

● To fit the cover, place it on the fuse box.

Pu

sh the attachment tabs back, in the oppo-

site direction indicated by the arrow until

they click audibly into place.

In is possible that there are more fuses be-

hind a cover in the lower left-hand side of the

luggage compartment.

››› page 90 42

Page 46 of 320

The essentials

Action in the event of a punc-

t ur

e

Wh

at to do first ●

Park the vehicle on a horizontal surface

and in a saf e p

lace as far away from traffic as

possible.

● Apply the handbrake.

● Switch on the hazard warning lights.

● Manual gearbox: select the 1s

t gear.

● Automatic gearbox: Move the sel

ector lever

to position P.

● If you are towing a trailer, unhitch it from

your v

ehicle.

● Keep the vehicle tool kit ready*

›››

page 82.

● Observe the applicable legislation for each

countr

y (reflective vest, warning triangles,

etc.).

● All occupants should leave the vehicle and

wait in a s

afe place (for instance behind the

roadside crash barrier). WARNING

● Alw a

ys observe the above steps and pro-

tect yourself and other road users.

● If you change the wheel on a slope, block

the wheel on the oppo

site side of the car with

a stone or similar to prevent the vehicle from

moving. Repairing a tyre with the anti-punc-

t

ur

e k

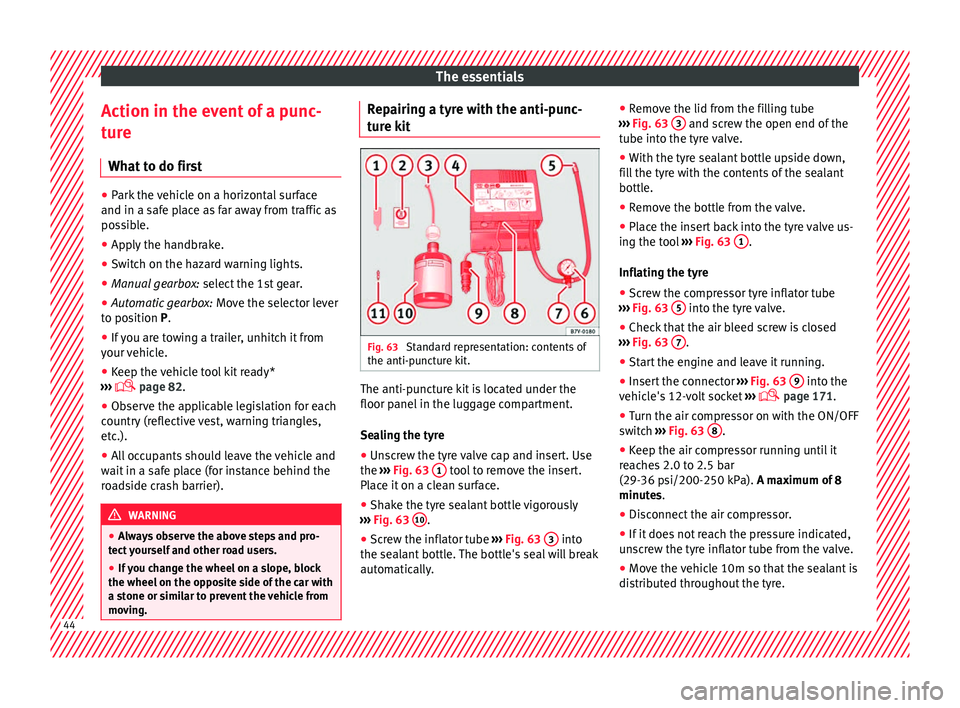

it Fig. 63

Standard representation: contents of

the anti-p u

nct

ure kit. The anti-puncture kit is located under the

floor p

anel

in the lug

gage compartment.

Sealing the tyre

● Unscrew the tyre valve cap and insert. Use

the ›››

Fig. 63 1 tool to remove the insert.

Pl ac

e it

on a clean surface.

● Shake the tyre sealant bottle vigorously

›››

Fig. 63 10 .

● Screw the inflator tube ››

›

Fig. 63 3 into

the se al

ant

bottle. The bottle's seal will break

automatically. ●

Remov

e the lid from the filling tube

››› Fig. 63 3 and screw the open end of the

t ube int

o the ty

re valve.

● With the tyre sealant bottle upside down,

fill

the tyre with the contents of the sealant

bottle.

● Remove the bottle from the valve.

● Place the insert back into the tyre valve us-

ing the too

l ››› Fig. 63 1 .

Infl atin

g the ty

re

● Screw the compressor tyre inflator tube

›››

Fig. 63 5 into the tyre valve.

● Check that the air bleed screw is closed

› ›

›

Fig. 63 7 .

● Start the engine and leave it running.

● Insert the connector ››

›

Fig. 63 9 into the

v ehic

l

e's 12-volt socket ›››

page 171.

● Turn the air compressor on with the ON/OFF

switc

h ››› Fig. 63 8 .

● Keep the air compressor running until it

r e

ac

hes 2.0 to 2.5 bar

(29-36 psi/200-250 kPa). A maximum of 8

minutes.

● Disconnect the air compressor.

● If it does not reach the pressure indicated,

uns

crew the tyre inflator tube from the valve.

● Move the vehicle 10m so that the sealant is

dis trib

uted throughout the tyre.44

Page 50 of 320

The essentials

The jack may be applied only at the jacking

points sho

wn (m

arks on chassis) ››› Fig. 69.

The mark indicates the jacking points below

the vehicle. The jacking points are on the ribs

behind the front edges ››› Fig. 70. Always the

relevant jacking point for the wheel to be

changed ››› .

R ai

se the

vehicle using only the designated

jacking points.

For your own safety and that of other passen-

gers, the following points should be ob-

served in the order given:

Select a suitable flat and firm surface for

raising the vehicle.

Switch off the engine, engage a gear

(manual gearbox) or place the selector

lever in position P ›››

page 192 and

turn on the electronic parking brake

››› page 187.

Block the wheel diagonally opposite the

wheel being changed with folding wheel

chocks* or other suitable objects.

When towing a trailer: unhook the trailer

from the towing vehicle and park it cor-

rectly.

Loosen the wheel bolts on the wheel to

be changed ››› page 46.

Look below the vehicle for the jacking

point ››› Fig. 69 closest to the tyre which

has to be changed.

1.

2.

3.

4.

5.

6. Raise the jack with the handle until it

can be inser

ted below the jacking point.

Ensure that the foot of the jack is firmly

on the ground and that it is placed im-

mediately below the lifting point on the

vehicle ››› Fig. 70.

Straighten the jack and continue raising

it using the handle until the claw holds

the vertical reinforcement beneath the

vehicle ››› Fig. 70.

Raise the vehicle until the wheel is clear

of the ground. WARNING

If the vehicle is not correctly raised, it could

fa l

l off the jack causing serious injury. Please

observe the following rules to minimise the

risk of injury:

● You should only use a jack approved by

SEAT f

or your vehicle. Other jacks, even those

approved for other SEAT models, might slip

out of place.

● The ground should be firm and flat. If the

ground i

s sloped or soft then the vehicle

could slip and fall off the jack. If necessary,

support the jack on a wide solid base.

● If the ground is slippery, such as tiles,

plac

e a non-slip surface (a floor mat, for in-

stance) beneath the jack to avoid slipping.

● Only fit the jack at the prescribed jacking

points. The c

law of the jack should grip the

reinforcement nerve on the underbody

››› Fig. 70. 7.

8.

9.

10.

●

You shou l

d never place a body limb such as

an arm or leg under a raised vehicle that is

solely supported by the jack.

● If you have to work underneath the vehicle,

you mus

t use suitable stands additionally to

support the vehicle, there is a risk of acci-

dent!.

● Never raise the vehicle if it is tilting to one

side or the engine i

s running.

● Never start the engine when the vehicle is

raised.

The vehicle may come loose from the

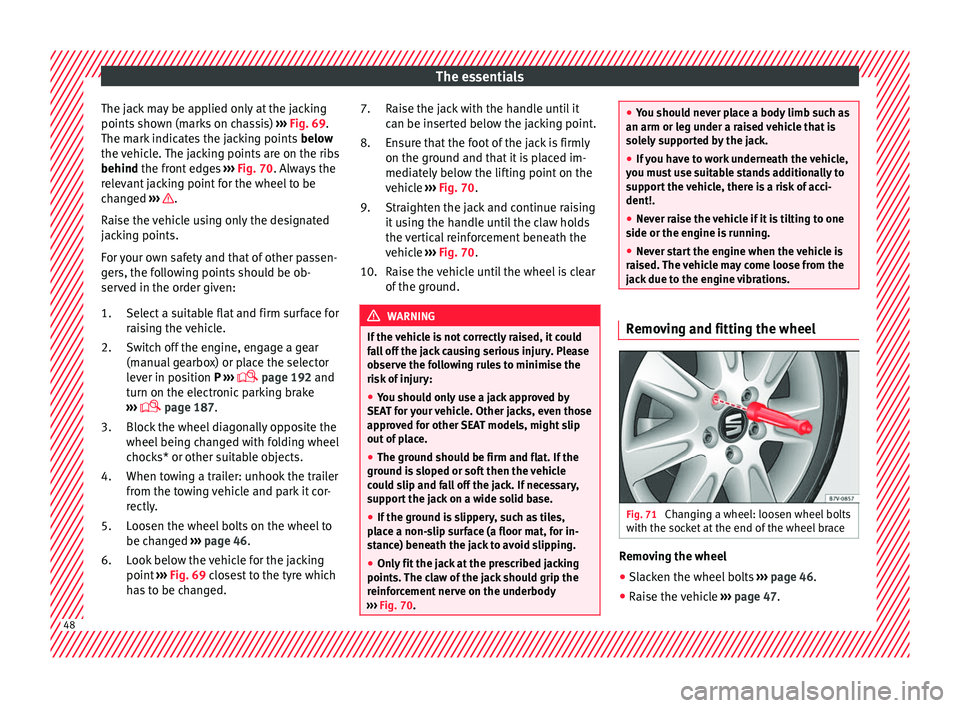

jack due to the engine vibrations. Removing and fitting the wheel

Fig. 71

Changing a wheel: loosen wheel bolts

w ith the soc

k

et at the end of the wheel brace Removing the wheel

● Slacken the wheel bolts ››

›

page 46.

● Raise the vehicle ›››

page 47. 48

Page 53 of 320

The essentials

Only secure the tow rope or tow bar to the

t o

wline anc

horage or specially designed fit-

ting.

Vehicles with a factory fitted towing device ,

can only be used for towing with a tow bar,

specially designed to fit on a tow hitch ball

››› page 234.

Towing vehicles with an automatic gearbox

Note the following for a towed vehicle: ● Make sure the gear selector lever is in the N

position.

● Do not

drive faster than 50 km/h (30 mph).

● Do not tow further than 50 km (30 miles).

● If a breakdown truck is used, the vehicle

must

be towed with the front wheels raised.

Note the following instructions for towing

four all-wheel drive vehicles.

Instructions for towing all-wheel drive vehi-

cles

All-wheel drive vehicles can be towed using a

toolbar or tow rope. If the vehicle is towed

with the front or rear axle raised, the engine

must be turned off to avoid transmission

damage.

For vehicles with a double clutched DSG ®

(di-

rect shift gearbox) the instructions for towing

vehicles with an automatic gearbox apply

››› page 51. Situations in which a vehicle should not be

tow

ed

In the following cases, the vehicle should not

be towed but transported on a trailer or spe-

cial vehicle:

● If the vehicle gearbox does not contain lu-

bricant due t

o a fault.

● If the vehicle battery is flat and, as a result,

the electronic

steering lock and electronic

parking brake cannot be disengaged if ap-

plied.

● If the vehicle to be towed has an automatic

gearbo

x and the distance to be covered is

greater than 50 km (30 miles).

››› in Introduction on page 87

››› page 87 Tow-starting

In general, the vehicle should not be started

b

y

t

owing. Jump-starting is much more pref-

erable ›››

page 51.

For technical reasons, the following vehicles

can not be tow started:

● Vehicles with an automatic gearbox. ●

Vehicl

es with the Keyless Access locking

and ignition system, since the electronic

steering lock may not unlock.

● Vehicles with an electronic parking brake,

given that

it is possible that the brake will

not be disengaged.

● If the vehicle battery is flat, it is possible

that the en

gine control units do not operate

correctly.

However, if your vehicle must absolutely be

tow-started (manual gearbox):

● Put it into second or third gear.

● Keep the clutch pressed down.

● Switch on the ignition and the hazard warn-

ing lights.

● Rel

ease the clutch when both vehicles are

movin

g.

● As soon as the engine starts, press the

clutc

h and move the gear lever into neutral.

This helps to prevent a collision with the tow-

ing vehicle.

How to jump start

Jump lea

ds If the engine fails to start because of a dis-

c

h

ar

ged battery, the battery of another vehi-

cle can be used to start the engine. Before » 51

Page 54 of 320

The essentials

starting, check the magic eye on the battery

› ›

›

page 280.

For starting assistance, jump lead cables con-

forming to the standard DIN 72553 are re-

quired (see the cable manufacturer instruc-

tions). The jump lead cable must be at least

25 mm 2

in section (0.038 inches 2

) for petrol

engines, and 35 mm 2

(0.054 inches 2

) for die-

sel engines.

For vehicles whose battery is not in the en-

gine compartment, the jump leads should

only be connected to the starting assistance

connection points in the engine compart-

ment. WARNING

Incorrect use of jump leads and incorrectly

jump st ar

ting could cause the battery to ex-

plode resulting in serious injury. Please ob-

serve the following rules to minimise the risk

of a battery explosion:

● The battery providing current must have

the same v

oltage (12V) and approximately

the same capacity (see markings on battery)

as the flat battery.

● Never charge a frozen or recently thawed

batter

y. A flat battery can also freeze at tem-

peratures close to 0°C (+32°F).

● If a battery is frozen and/or has been frozen

then it mus

t be replaced.

● A highly explosive mixture of gases is re-

lea

sed when the battery is being charged. Al- ways keep lit cigarettes, flames, sparks and

fire f

ar fr

om the battery. Never use a mobile

telephone when connecting and removing the

jump leads.

● Charge the battery only in well ventilated

area

s given that when the battery is charged

by outside assistance, it creates a mix of

highly explosive gases.

● Jump leads should never enter into contact

with mov

ing parts in the engine compart-

ment.

● Never switch the positive and negative

pole

s or connect the jump leads incorrectly.

● Note the instruction manual provided by

the manufact

urer of the jump leads. CAUTION

To avoid considerable damage to the vehicle

electric a

l system, note the following careful-

ly:

● If the jump leads are incorrectly connected,

this c

ould result in a short circuit.

● The vehicles must not touch each other,

otherwi

se electricity could flow as soon as

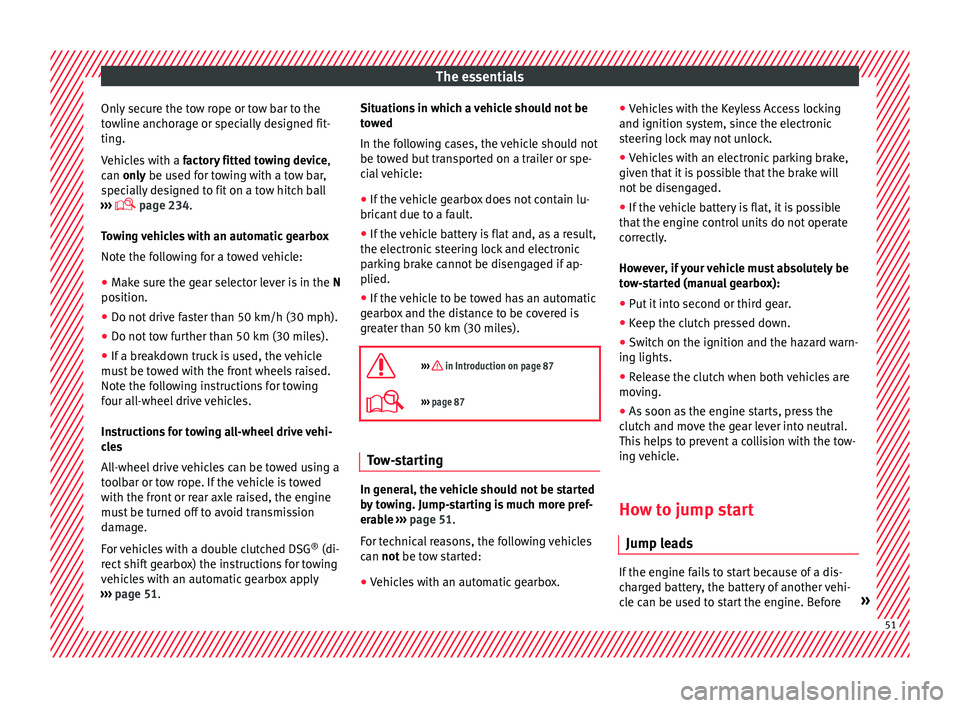

the positive terminals are connected. Positive pole on the jump lead con-

nection point

s Fig. 74

In the engine compartment: positive

po l

e f

or starting assistance + .

On some vehicles, there is a starting assis-

t

anc

e t

erminal in the engine compartment,

under a labelled cover. 52

Page 55 of 320

The essentials

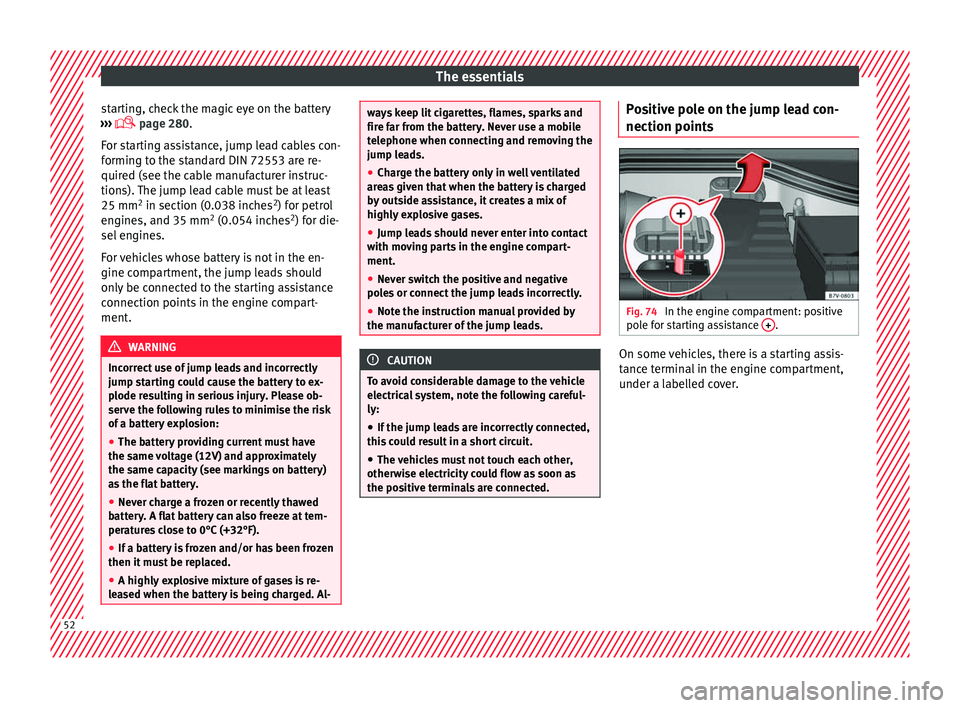

How to jump start: description Fig. 75

Diagram of connections for vehicles

w ithout

Start-Stop system. Fig. 76

Diagram of connections for vehicles

w ith

St

art-Stop system. Jump lead terminal connections

1. Switch off the ignition of both vehicles

››

›

. 2. Connect one end of the

re

d

jump lead to

the positive + terminal of the vehicle

w ith the fl

at

battery A

› ››

Fig. 75

.

3.

Connect the other end of the red

jump

lead to the positive terminal + in the ve-

hic l

e pr

oviding assistance B .

4. For vehicles without Start-Stop system:

connect

one end of

the black jump lead to

the negative terminal – of the vehicle

pr o

v

iding the current B

› ››

Fig. 75

.

– F

or vehicles with Start-Stop system: con-

nect one end of

the black jump lead X to a

s uit

ab

le ground terminal, to a solid piece of

metal in the engine block, or to the engine

block itself ››› Fig. 76.

5. Connect the other end of the black

jump

lead X to a solid metal component bolted

t o the en

gine b

lock or to the engine block

itself of the vehicle with the flat battery.

Do not connect it to a point near the bat-

tery A .

6. Position the leads in such a way that they cannot

c

ome into contact with any moving

parts in the engine compartment.

Starting

7. Start the engine of the vehicle with the boostin

g battery and let it run at idling

speed. 8. Start the engine of the vehicle with the flat

batter

y and wait for 2 or 3 minutes until

the engine is running.

Removing the jump leads

9. Before you remove the jump leads, switch off the dipped be

am headlights if they are

switched on.

10.Turn on the heater blower and heated rear window in the

vehicle with the flat battery.

This helps minimise voltage peaks which

are generated when the leads are discon-

nected.

11.When the engine is running, disconnect the lea

ds in reverse order to the details

given above.

Make sure the battery clamps have sufficient

metal-to-metal contact with the battery termi-

nals.

If the engine fails to start, switch off the start-

er after about 10 seconds and try again after

about 1 minute. WARNING

● Ple a

se note the safety warnings referring to

working in the engine compartment

››› page 268.

● The battery providing assistance must have

the same v

oltage as the flat battery (12V) and

approximately the same capacity (see imprint » 53

Page 56 of 320

The essentials

on battery). Failure to comply could result in

an exp

lo

sion.

● Never use jump leads when one of the bat-

teries

is frozen. Danger of explosion! Even af-

ter the battery has thawed, battery acid could

leak and cause chemical burns. If a battery

freezes, it should be replaced.

● Keep sparks, flames and lighted cigarettes

awa

y from batteries, danger of explosion.

Failure to comply could result in an explo-

sion.

● Observe the instructions provided by the

manufact

urer of the jump leads.

● Do not connect the negative cable from the

other vehic

le directly to the negative terminal

of the flat battery. The gas emitted from the

battery could be ignited by sparks. Danger of

explosion.

● Do not attach the negative cable from the

other vehic

le to parts of the fuel system or to

the brake line.

● The non-insulated parts of the battery

clamp

s must not be allowed to touch. The

jump lead attached to the positive battery

terminal must not touch metal parts of the ve-

hicle, this can cause a short circuit.

● Position the leads in such a way that they

cannot c

ome into contact with any moving

parts in the engine compartment.

● Do not lean on the batteries. This could re-

sult

in chemical burns. Note

The vehicles must not touch each other, oth-

erw i

se electricity could flow as soon as the

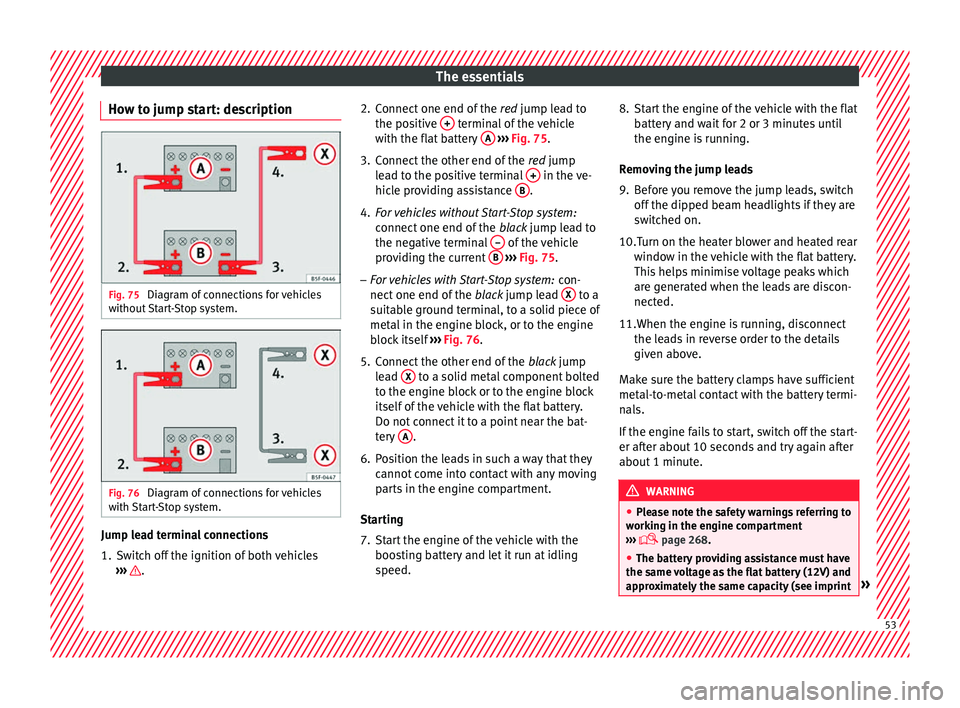

positive terminals are connected. Changing windscreen wipers

Wind s

creen wipers service position Fig. 77

Wipers in service position The wiper arms can be raised when the wip-

er

s

ar

e in service position ››› Fig. 77.

● Close the bonnet ›››

page 268.

● Switch the ignition on and off.

● Press the windscreen wiper lever down-

ward

s briefly ››› page 26 4 .

B ef

or

e driving, always lower the wiper arms.

Using the windscreen wiper lever, the wind- screen wiper arms return to their initial posi-

tion.

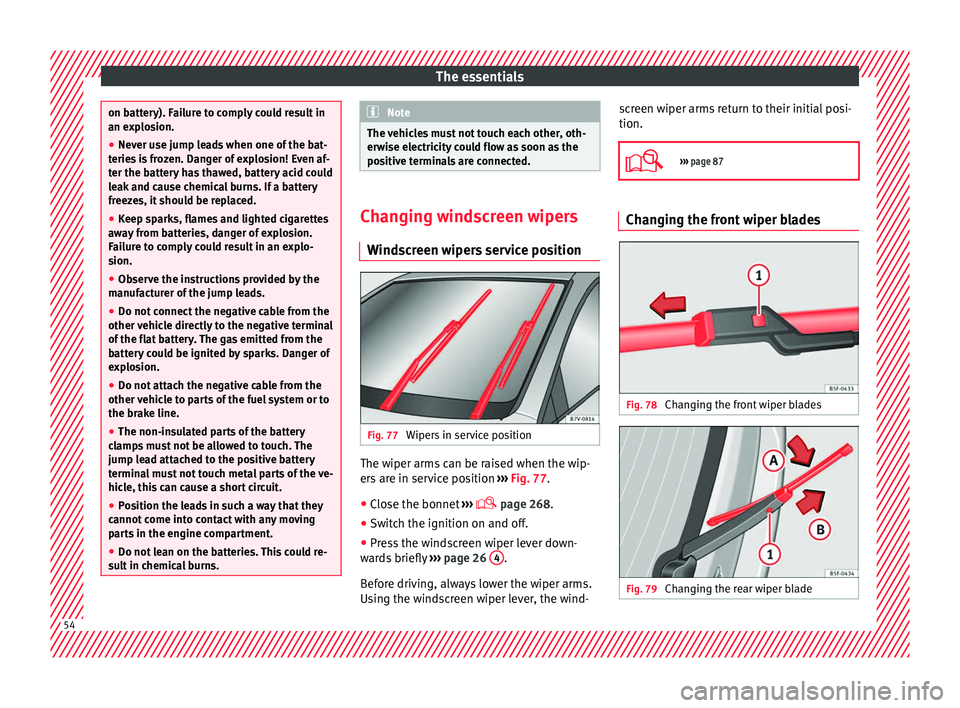

››› page 87 Changing the front wiper blades

Fig. 78

Changing the front wiper blades Fig. 79

Changing the rear wiper blade54

Page 72 of 320

Safety

The airbag system operation is monitored

el ectr

onic

ally. The airbag control lamp will il-

luminate for a few seconds every time the ig-

nition is switched on (self-diagnosis).

There is a fault in the system if the control

lamp :

● does not light up when the ignition is

switc

hed on,

● turns off after 4 seconds after the ignition

is sw

itched on

● turns off and then lights up again after the

ignition is sw

itched on

● illuminates or flashes while the vehicle is

movin

g.

The airbag system is not triggered if:

● the ignition is switched off

● there is a minor frontal collision

● there is a minor side collision

● there is a rear-end collision

● the vehicle turns over. WARNING

● The seat belt

s and airbags can only provide

maximum protection if the occupants are

seated correctly ››› page 57.

● If a fault has occurred in the airbag system,

have the sy

stem checked immediately by a

specialised workshop. Otherwise there is a danger that during a collision, the system

ma

y

fail to trigger, or not trigger correctly. Airbag activation

The airbags deploy extremely rapidly, within

thous

andths

of a second, to provide addi-

tional protection in the event of an accident.

The airbag system is only ready to function

when the ignition is on.

In special accidents instances, several air-

bags may activate at the same time.

In the event of minor head-on and side colli-

sions, rear-end collisions, overturning or roll-

over of the vehicle, airbags do not activate.

Activation factors

The conditions that lead to the airbag system

activating in each situation cannot be gener-

alised. Some factors play an important role,

such as the properties of the object the vehi-

cle hits (hard/soft), angle of impact, vehicle

speed, etc.

Deceleration trajectory is key for airbag acti-

vation.

The control unit analyses the collision trajec-

tory and activates the respective restraint

system.

If the deceleration rate is below the prede-

fined reference value in the control unit the airbags will not be triggered, even though

the acc

ident

may cause extensive damage to

the car.

The following airbags are triggered in seri-

ous head-on collisions

● Driver airbag.

● Front passenger front airbag

● Knee airbag for the driver.

The fol

lowing airbags are triggered in seri-

ous side-on collisions

● Front side airbag on the side of the acci-

dent.

● Re

ar side airbag on the side of the acci-

dent.

● Cur

tain (head) airbag on the side of the ac-

cident.

In an ac

cident with airbag activation:

● the interior lights switch on (if the interior

light swit

ch is in the courtesy light position);

● the hazard warning lights switch on;

● all doors are unlocked;

● the fuel supply to the engine is cut.

70

Page 86 of 320

Emergencies

The chocks should be placed directly in front

and behind the wheel and on

ly

be used on

firm ground. WARNING

If the folding chocks are assembled or used

incorr ectly

, an accident may occur and seri-

ous injury caused.

● Never use damaged chocks.

● Never use chocks to immobilize the vehicle

on a slope. Changing a wheel*

Intr oduction Read the additional information carefully

› ›

›

page 45

All Alhambra models have TMS (Tyre Mobility

System).

If a tyre needs to be changed the tools neces-

sary are available at spare parts dealers:

● Jack,

● box spanner for wheel bolts,

● tool to remove wheel bolt caps

The tyre

s mounted on the vehicle are anti-

puncture. The wheels should only be

changed when switching from summer to

winter tyres or vice-versa. See ›››

page 290 The vehicle only comes with the necessary

tool

s for changing wheels if factory supplied

with winter tyres. If this is not the case, you

need to go to a specialised workshop to get

the wheels changed.

You should only change the wheels yourself if

the vehicle is parked in a safe place, you are

familiar with the procedure and safety stand-

ards and you have all the necessary tools!

Otherwise, you should seek professional as-

sistance. WARNING

Changing a wheel can be dangerous, espe-

ci a

lly on the hard shoulder. Please observe

the following rules to minimise the risk of in-

jury:

● Stop the vehicle safely as soon as possible.

Park at

a safe distance from surrounding traf-

fic to change a wheel.

● When changing a wheel, keep all passen-

gers, and p

articularly children, a safe dis-

tance away from the work area.

● Turn on the hazard warning lights to warn

other roa

d users.

● Ensure the ground on which you park is flat

and solid. If nec

essary, support the jack on a

wide solid base.

● If you are changing a wheel yourself, you

should be f

amiliar with the required proce-

dure. Otherwise, you should seek professio-

nal assistance. ●

Only u

se suitable tools that are not dam-

aged when changing a wheel.

● Always stop the engine, turn on the elec-

tronic p

arking brake and place the gear selec-

tor lever in position P, for an automatic gear-

box, or engage a gear for a manual gearbox to

reduce the risk of the vehicle moving acciden-

tally.

● Have the tightening torque of the wheel

bolts

checked as soon as possible with a reli-

able torque wrench. WARNING

If the wheel trims are not appropriate or not

fitted c orr

ectly, they could cause major acci-

dents or damage.

● Incorrectly mounted wheel trims may come

off whil

e driving and endanger other road

users.

● Damaged trims must never be mounted on

the wheels.

● Alw

ays ensure that the brake ventilation

and coolin

g is not cut off or blocked. This is

also valid if hubcaps are fitted later. If there

is not enough air, you may require signifi-

cantly longer braking distances. CAUTION

Remove and remount wheel trims taking care

to av oid d

amage to the vehicle.84