change wheel Seat Altea 2005 User Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2005, Model line: Altea, Model: Seat Altea 2005Pages: 286, PDF Size: 9.59 MB

Page 227 of 286

If and when225

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Compact temporary spare wheel

The compact temporary spare wh eel is only intended for

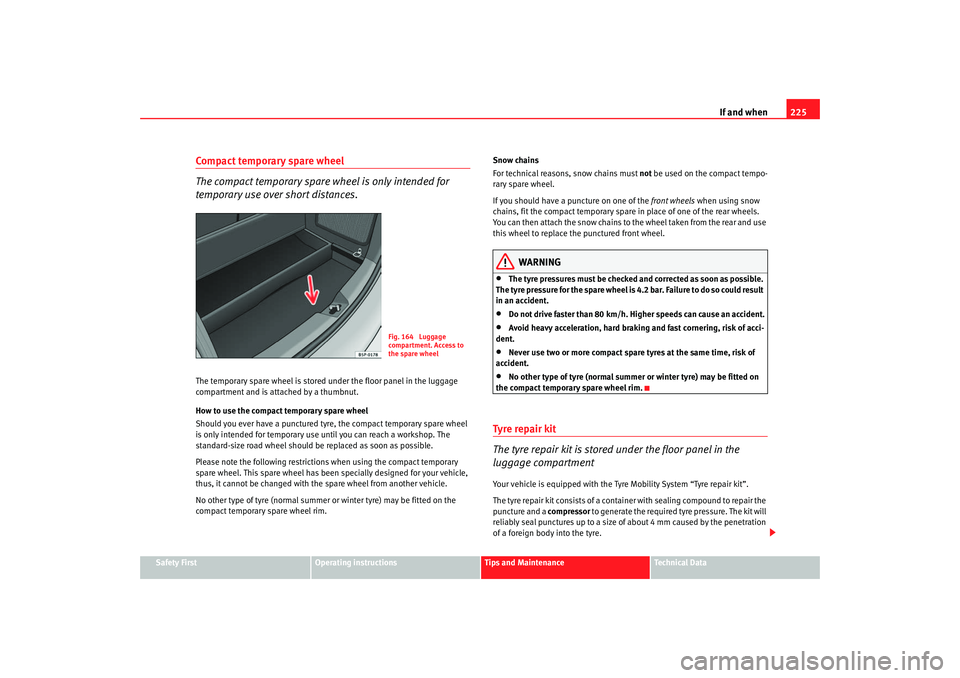

temporary use over short distances.The temporary spare wheel is stored under the floor panel in the luggage

compartment and is attached by a thumbnut.

How to use the compact temporary spare wheel

Should you ever have a punctured tyre, the compact temporary spare wheel

is only intended for temporary use until you can reach a workshop. The

standard-size road wheel should be replaced as soon as possible.

Please note the following restrictions when using the compact temporary

spare wheel. This spare wheel has been specially designed for your vehicle,

thus, it cannot be changed with th e spare wheel from another vehicle.

No other type of tyre (normal summer or winter tyre) may be fitted on the

compact temporary spare wheel rim. Snow chains

For technical reasons, snow chains must not

be used on the compact tempo-

rary spare wheel.

If you should have a puncture on one of the front wheels when using snow

chains, fit the compact temporary spare in place of one of the rear wheels.

You can then attach the snow chains to the wheel taken from the rear and use

this wheel to replace the punctured front wheel.

WARNING

•

The tyre pressures must be checked and corrected as soon as possible.

The tyre pressure for the spare wheel is 4.2 bar. Failure to do so could result

in an accident.

•

Do not drive faster than 80 km/h. High er speeds can cause an accident.

•

Avoid heavy acceleration, hard braking and fast cornering, risk of acci-

dent.

•

Never use two or more compact spare tyres at the same time, risk of

accident.

•

No other type of tyre (normal summer or winter tyre) may be fitted on

the compact temporary spare wheel rim.

Tyre repair kit

The tyre repair kit is stored under the floor panel in the

luggage compartmentYour vehicle is equipped with the Tyre Mobility System “Tyre repair kit”.

The tyre repair kit consists of a contai ner with sealing compound to repair the

puncture and a compressor to generate the required tyre pressure. The kit will

reliably seal punctures up to a size of about 4 mm caused by the penetration

of a foreign body into the tyre.

Fig. 164 Luggage

compartment. Access to

the spare wheel

altea_ingles Seite 225 Donnerstag, 19. Mai 2005 3:02 15

Page 228 of 286

If and when

226

Note•

Seek professional assistance if the repair of a tyre puncture is not

possible with the sealing compound.

Wheel changePreparation work

What you must do before changing a wheel.– If you have a flat tyre or puncture, park the vehicle as far away from the flow of traffic as possible. Choose a location that is as

level as possible.

– All passengers should leave the ve hicle. They should wait in a

safe area (for instance behind the roadside crash barrier).

– Switch off the engine. Switch on the hazard warning lights.

–Apply the handbrake firmly.

– Engage the first gear, or put the selector lever to position P for

those vehicles with an automatic gearbox.

– If you are towing a trailer, unhitch it from your vehicle.

– Take the vehicle tools and the spare wheel out of the luggage

compartment.

WARNING

Put the hazard warning lights on and place the warning triangle in position.

This is for your own safety and also warns other road users.

Caution

If you have to change the tyre on a gradient, block the wheel opposite the

wheel being changed by placing a stone or similar object under it to prevent

the vehicle from rolling away.

Note

Please observe legal requirements when doing so.Changing a wheelChange the wheel as described below

– Remove the wheel cover. Also refer to ⇒page 227, fig. 165

– Slacken the wheel bolts.

– Raise the car with the jack in the corresponding zone

– Ta k e o f f the wheel and then put on the spare wheel

– Lower the vehicle.

– Tighten the wheel bolts firmly in diagonal sequence with the box

spanner

–Replace the cover .

altea_ingles Seite 226 Donnerstag, 19. Mai 2005 3:02 15

Page 231 of 286

If and when229

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

WARNING

Loosen the wheel bolts only about one tu rn before raising the vehicle with

the jack, loosening the wheel bolts more than one turn can result in an acci-

dent.

Note

•

Do not use the hexagonal socket in th e screwdriver handle to loosen or

tighten the wheel bolts.

•

If the wheel bolt is very tight, you may be able to loosen it by pushing

down the end of the spanner carefully with your foot. Hold on to the vehicle

for support and take care not to slip.

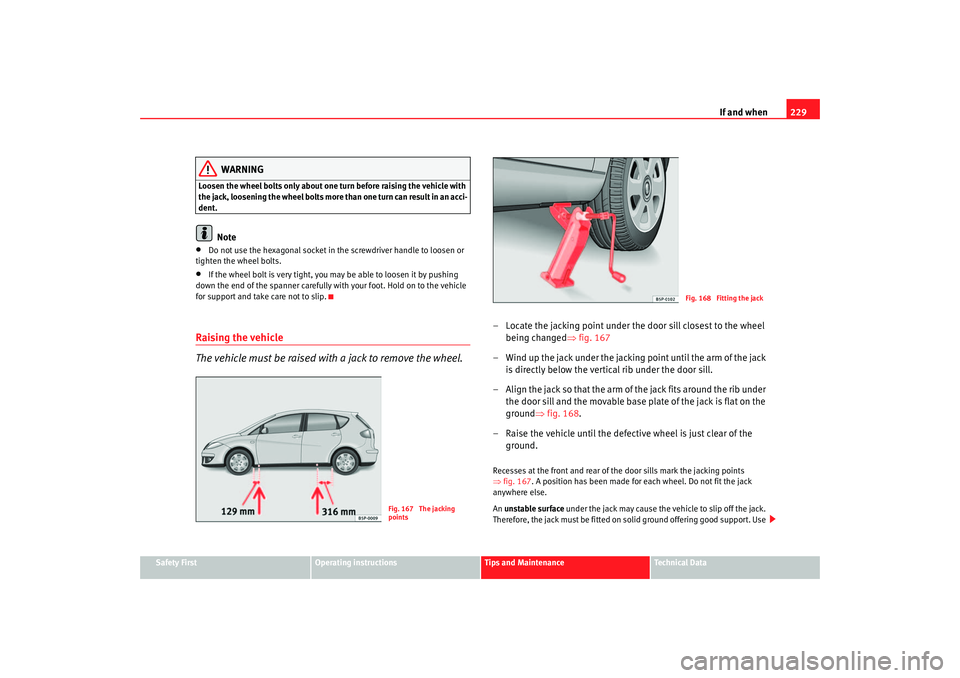

Raising the vehicle

The vehicle must be raised with a jack to remove the wheel.

– Locate the jacking point under the door sill closest to the wheel being changed ⇒fig. 167

– Wind up the jack under the jacking point until the arm of the jack is directly below the vertical rib under the door sill.

– Align the jack so that the arm of the jack fits around the rib under the door sill and the movable base plate of the jack is flat on the

ground ⇒fig. 168 .

– Raise the vehicle until the defect ive wheel is just clear of the

ground.Recesses at the front and rear of the door sills mark the jacking points

⇒ fig. 167 . A position has been made for each wheel. Do not fit the jack

anywhere else.

An unstable surface under the jack may cause the vehicle to slip off the jack.

Therefore, the jack must be fitted on solid ground offering good support. Use

Fig. 167 The jacking

points

Fig. 168 Fitting the jack

altea_ingles Seite 229 Donnerstag, 19. Mai 2005 3:02 15

Page 232 of 286

If and when

230a large and stable base, if necessary. On a hard, slippery surface (such as

tiles) use a rubber mat or similar to prevent the jack from slipping.

WARNING

•

Take all precautions so that the base of the jack does not slip. Failure to

do so could result in an accident.

•

The vehicle can be damaged if the jack is not applied at the correct

jacking points. There is also a risk of injury since the jack can slip off

suddenly if it is not properly engaged.

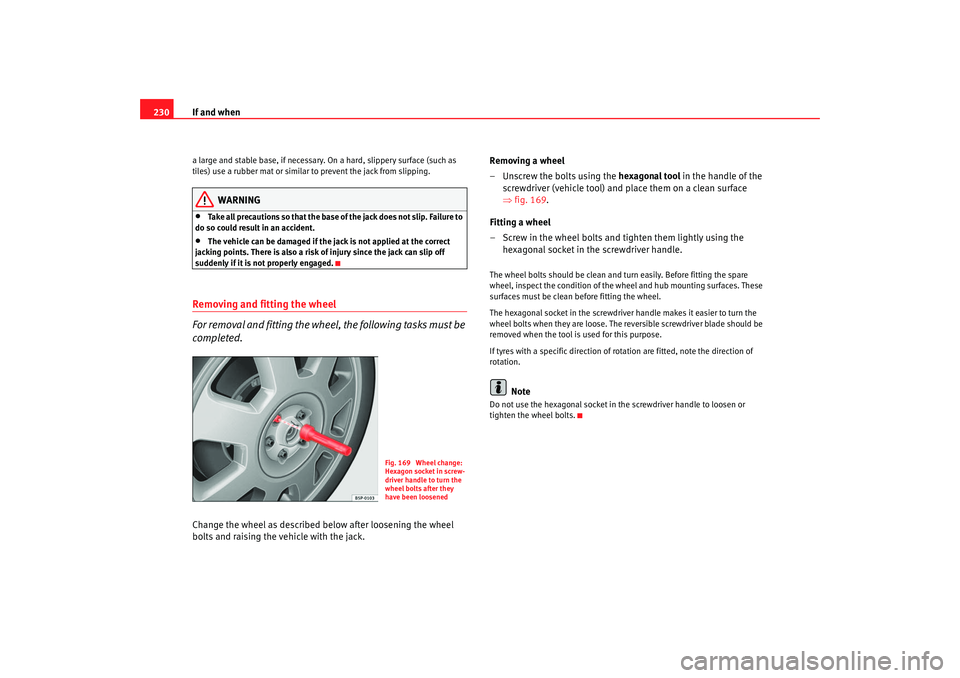

Removing and fitting the wheel

For removal and fitting the wheel, the following tasks must be

completed.Change the wheel as described below after loosening the wheel

bolts and raising the vehicle with the jack. Removing a wheel

– Unscrew the bolts using the

hexagonal tool in the handle of the

screwdriver (vehicle tool) and place them on a clean surface

⇒ fig. 169.

Fitting a wheel

– Screw in the wheel bolts and tighten them lightly using the hexagonal socket in the screwdriver handle.

The wheel bolts should be clean and turn easily. Before fitting the spare

wheel, inspect the condition of the whe el and hub mounting surfaces. These

surfaces must be clean before fitting the wheel.

The hexagonal socket in the screwdriver handle makes it easier to turn the

wheel bolts when they are loose. The reversible screwdrive r blade should be

removed when the tool is used for this purpose.

If tyres with a specific di rection of rotation are fitt ed, note the direction of

rotation.

Note

Do not use the hexagonal socket in the screwdriver handle to loosen or

tighten the wheel bolts.

Fig. 169 Wheel change:

Hexagon socket in screw-

driver handle to turn the

wheel bolts after they

have been loosened

altea_ingles Seite 230 Donnerstag, 19. Mai 2005 3:02 15

Page 255 of 286

If and when253

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Notes for the driver of the towing vehicle

– Drive slowly at first until the tow-rope is taut. Then accelerate

gradually.

– Begin and change gears cautiously. If you are driving an auto- matic vehicle, accelerate gently.

– Remember that the brake servo and power steering are not working in the vehicle you are towing. Brake earlier than you

would normally, but with a more gentle pressure on the brake.

Notes for the driver of the towed vehicle

– Ensure that the tow-rope remains taut at all times when towing.

Fitting the towing eye

– Take the towing ring and the wheel spanner out of the vehicle tool kit.

– Pull the lower front cover down and leave the cover hanging on the vehicle.

– Remove the cover of the screw hole, insert a screwdriver into the lower slot and lever gently.

– Screw the towing eye as shown by arrow anti-clockwise to the

limit position in the front ⇒page 252, fig. 194 or rear

⇒ page 252, fig. 195 threaded hole.

– Use the wrench for leverage to tighten the towing eye.Tow-rope or tow-bar

It is easier and safer to tow a vehicle with a tow-bar. You should only use a

tow-rope if you do not have a tow-bar. A tow-rope should be slightly elastic to

reduce the loading on both vehicles.

It is advisable to use a tow-rope made of synthetic fibre or similarly elastic

material.

Attach the tow-rope or the tow-bar only to the towing eyes provided or a

towing bracket.

Driving style

Towing requires some experience, especially when using a tow-rope. Both

drivers should be familiar with the technique required for towing. Inexperi-

enced drivers should not attempt to tow-start or tow away another vehicle.

Do not pull too hard with the towing vehicle and take care to avoid jerking the

tow-rope. When towing on an unpaved road, there is always a risk of over-

loading and damaging the anchorage points.

The ignition of the vehicle being towed must be switched on to prevent the

steering wheel from locking and also to allow the use of the turn signals,

horn, windscreen wipers and washers.

As the brake servo does not work if th e engine is not running, you must apply

considerably more pressure to the brake pedal than you normally would.

As the power assisted steering does not work if the engine is not running, you

will need more strength to steer than you normally would.

Towing vehicles with an automatic gearbox

•

Put the selector lever into position “N”.

•

Do not drive faster than 50 km/h when towing a vehicle.

•

Do not tow further than 50 km.

•

If a breakdown vehicle is used, the vehicle must be towed with the front

wheels raised.Note

•

Observe legal requirements when towing or tow-starting.

altea_ingles Seite 253 Donnerstag, 19. Mai 2005 3:02 15

Page 260 of 286

General notes on the technical data

258WeightsKerb weight refers to the basic model with a fuel tank filled to 90% capacity

and without optional extras. The figure quoted includes 75 kg to allow for the

weight of the driver.

For special versions and optional equipment fittings or for the addition of

accessories, the weight of the vehicle will increase ⇒.

WARNING

•

Please note that the centre of gravity may shift when transporting

heavy objects; this may affect the vehi cle's handling and lead to an acci-

dent. Always adjust your speed and dr iving style to suit road conditions

and requirements.

•

Never exceed the gross axle weight rating or the gross vehicle weight

rating. If the allowed axle load or the allowed total weight is exceeded, the

driving characteristics of the vehicle may change, leading to accidents,

injuries and damage to the vehicle.

To w i n g a t r a i l e rTrailer weightsTrailer weights

The trailer weights and drawbar loads approved are selected in intensive

trials according to precisely defined criteria. The approved trailer weights are

valid for vehicles in EU for maximum speeds of 80 km/h (in certain circum-

stances up to 100 km/h). The figures may be different in other countries. All

data in the official vehicle documents take precedence over these data ⇒. Drawbar load

The

maximum permitted weight exerted by the trailer drawbar on the ball joint

of the towing bracket must not exceed 75 kg.

In the interest of road safety, we recommend that you always tow

approaching the maximum drawbar load. The response of the trailer on the

road will be poor if th e drawbar load is too small.

If the maximum permissible drawbar load cannot be met (e.g. w ith small,

empty and light-weight single axle trailers or tandem axle trailers with an axle

base of less than 1 metre), at least 4% of the actual trailer weight is a legal

stipulation for a drawbar load.

WARNING

•

For safety reasons, you should not drive at speeds above 80 km/h when

towing a trailer. This also applies to countries where higher speeds are

permitted.

•

Never exceed the maximum trailer weights or the draw bar loading. If

the permissible axle load or the perm issible total weight is exceeded, the

driving characteristics of the vehicle may change, leading to accidents,

injuries and damage to the vehicle.

WheelsTyre pressure, snow chains, wheel boltsTyre pressures

The sticker with the tyre pressure values can be found on the inside of the

tank flap. The tyre pressure values given there are for cold tyres. The slightly

raised pressures of warm tyres must not be reduced ⇒.

altea_ingles Seite 258 Donnerstag, 19. Mai 2005 3:02 15

Page 261 of 286

General notes on the technical data 259

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Snow chains

Snow chains may be fitted only to the

front wheels.

Consult the chapter “wheels” of this manual.

Wheel bolts

After the wheels have been changed, the tightening torque of the wheel bolts

should be checked as soon as possible with a torque wrench ⇒. The tight-

ening torque for steel and alloy wheels is 120 Nm.

WARNING

•

Check the tyre pressure at least once per month. Correct tyre pressure

is very important. If the tyre pressure is too high or too low, there is an

increased danger of accidents, particularly at high speeds.

•

If the torque of the wheel bolts is too low, they could loosen whilst the

vehicle is in motion. Risk of accident! If the tightening torque is too high,

the wheel bolts and threads could be damaged.Note

We recommend that you ask your Authorised Service Centre for information

about appropriate wheel, tyre and snow chain size.

altea_ingles Seite 259 Donnerstag, 19. Mai 2005 3:02 15

Page 275 of 286

Technical Data273

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

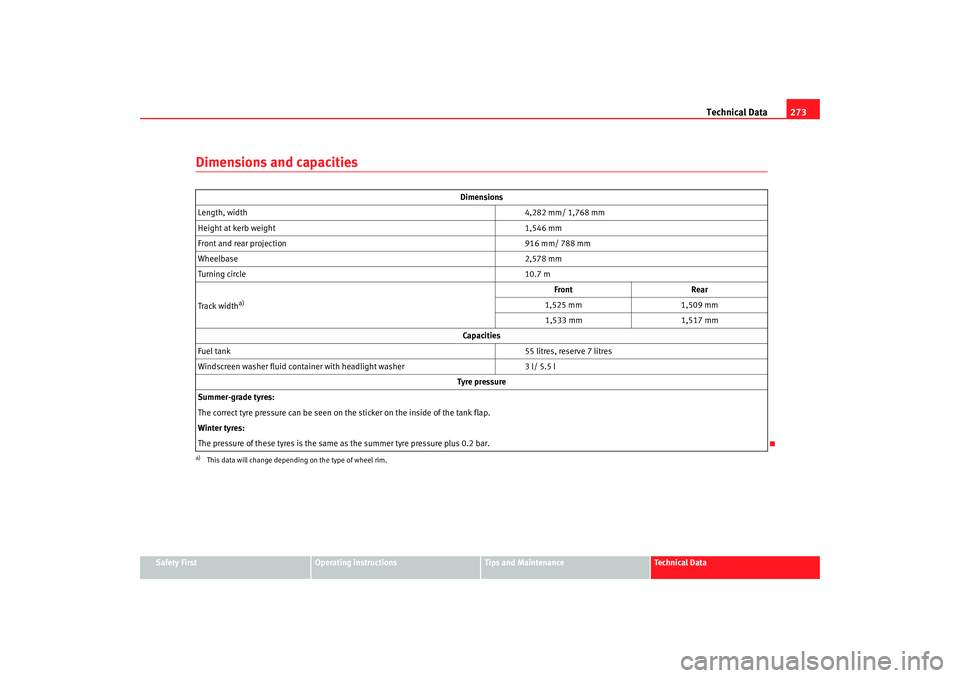

Dimensions and capacities

Dimensions

Length, width 4,282 mm/ 1,768 mm

Height at kerb weight 1,546 mm

Front and rear projection 916 mm/ 788 mm

Wheelbase 2,578 mm

Turning circle 10.7 m

Track width

a)

a)This data will change depending on the type of wheel rim.

Front Rear

1,525 mm 1,509

mm

1,533 mm 1,517 mm

Capacities

Fuel tank 55 litres, reserve 7 litres

Windscreen washer fluid container with headlight washer 3 l/ 5.5 l

Tyre pressure

Summer-grade tyres:

The correct tyre pressure can be seen on the sticker on the inside of the tank flap.

Winter tyres:

The pressure of these tyres is the same as the summer tyre pressure plus 0.2 bar.

altea_ingles Seite 273 Donnerstag, 19. Mai 2005 3:02 15

Page 278 of 286

Index

276Buzzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114, 157CCar care

Exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Car care products . . . . . . . . . . . . . . . . . . . . . . . 185

Car phone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Car washes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Catalytic converter . . . . . . . . . . . . . . . . . . . . . . 178

CD changer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Central locking . . . . . . . . . . . . . . . . . . . . . . . . . . 91 Automatic speed dependent locking and un-locking system* . . . . . . . . . . . . . . . . . . . . . 93

Emergency unlocking system . . . . . . . . . . . . 93

Locking system for invo luntary unlocking . . 93

Selective unlocking system* . . . . . . . . . . . . 92

Unlocking system* . . . . . . . . . . . . . . . . . . . . 93

Central locking button Central locking . . . . . . . . . . . . . . . . . . . . . . . 95

unlocking . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Centre arm rest . . . . . . . . . . . . . . . . . . . . . . . . . 132

Cetane number . . . . . . . . . . . . . . . . . . . . . . . . . 200

Changing gear See Manual gearbox . . . . . . . . . . . . . . . . . . 161

Changing the lamps Main headlight lamps . . . . . . . . . . . . . . . . . 241

rear lights . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Changing the main headlight lamps

dipped beam lights . . . . . . . . . . . . . . . . . . . 242

main beam lights . . . . . . . . . . . . . . . . . . . . 243 Side lights . . . . . . . . . . . . . . . . . . . . . . . . . . 244

turn signal lamps . . . . . . . . . . . . . . . . . . . . 242

Changing the rear lights indicator lights . . . . . . . . . . . . . . . . . . . . . . 246

luggage compartment lights . . . . . . . . . . . 247

rear fog light . . . . . . . . . . . . . . . . . . . . . . . . 246

reverse light . . . . . . . . . . . . . . . . . . . . . . . . . 246

side lights . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Changing windscreen wiper blades . . . . . . . . . 212

Chassis number . . . . . . . . . . . . . . . . . . . . . . . . 256

Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Checking battery electrolyte level . . . . . . . . . . 217

Checking engine oil level . . . . . . . . . . . . . . . . . 206

Child safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Child seat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 Categorisation in groups . . . . . . . . . . . . . . . 48

Group 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Group 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Group 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Groups 0 and 0+ . . . . . . . . . . . . . . . . . . . . . . 48

ISOFIX system . . . . . . . . . . . . . . . . . . . . . . . . 51

Safety notes . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Securing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Child seats on the front passenger seat . . . . . . . . . . . . . 31

Cigarette lighter* . . . . . . . . . . . . . . . . . . . . . . . . 140

Cleaning alloy wheels . . . . . . . . . . . . . . . . . . . . 190

Cleaning and caring for your vehicle . . . . . . . . 185

Cleaning chrome . . . . . . . . . . . . . . . . . . . . . . . . 189

Cleaning cloth seat covers . . . . . . . . . . . . . . . . 192

Cleaning dash panel . . . . . . . . . . . . . . . . . . . . . 191 Cleaning engine compartment . . . . . . . . . . . . . 191

Cleaning fabric trim . . . . . . . . . . . . . . . . . . . . . 192

Cleaning leather . . . . . . . . . . . . . . . . . . . . . . . . 192

Cleaning plastic parts . . . . . . . . . . . . . . . . . . . . 191

Cleaning seat belts . . . . . . . . . . . . . . . . . . . . . . 193

Cleaning steel wheels . . . . . . . . . . . . . . . . . . . . 189

Cleaning windows . . . . . . . . . . . . . . . . . . . . . . . 188

Cleaning wooden trim . . . . . . . . . . . . . . . . . . . . 192

Climatic* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Climatronic

General notes . . . . . . . . . . . . . . . . . . . . . . . 154

Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Clothes hook . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Cockpit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Control Light switches . . . . . . . . . . . . . . . . . . . . . . . 109

Control lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Control lighting . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Controls Electric windows . . . . . . . . . . . . . . . . . . . . . 104

Convenience closing Sliding/tilting roof . . . . . . . . . . . . . . . . . . . 107

Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Convenience opening Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209 monitor indicator . . . . . . . . . . . . . . . . . . . . . 64

Coolant Level . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Coolant level warning light . . . . . . . . . . . . . . . . . . . . . . . . . 74

altea_ingles Seite 276 Donnerstag, 19. Mai 2005 3:02 15

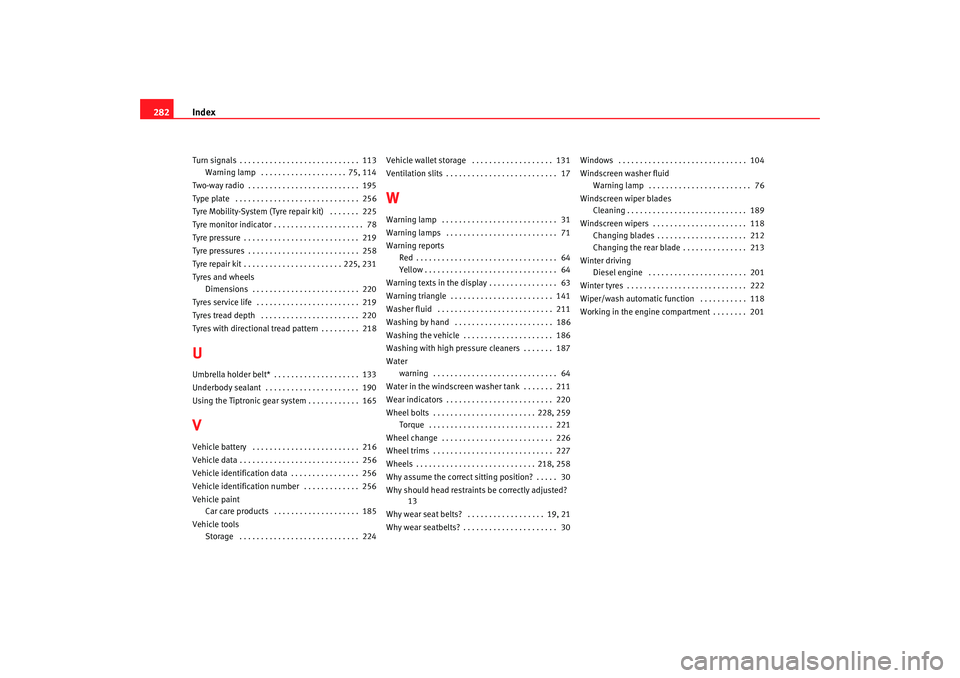

Page 284 of 286

Index

282Turn signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Warning lamp . . . . . . . . . . . . . . . . . . . . 75, 114

Two-way radio . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Type plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Tyre Mobility-System (Tyre repair kit) . . . . . . . 225

Tyre monitor indicator . . . . . . . . . . . . . . . . . . . . . 78

Tyre pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Tyre pressures . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Tyre repair kit . . . . . . . . . . . . . . . . . . . . . . . 225, 231

Tyres and wheels Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 220

Tyres service life . . . . . . . . . . . . . . . . . . . . . . . . 219

Tyres tread depth . . . . . . . . . . . . . . . . . . . . . . . 220

Tyres with directional tread pattern . . . . . . . . . 218UUmbrella holder belt* . . . . . . . . . . . . . . . . . . . . 133

Underbody sealant . . . . . . . . . . . . . . . . . . . . . . 190

Using the Tiptronic gear system . . . . . . . . . . . . 165VVehicle battery . . . . . . . . . . . . . . . . . . . . . . . . . 216

Vehicle data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Vehicle identification data . . . . . . . . . . . . . . . . 256

Vehicle identification number . . . . . . . . . . . . . 256

Vehicle paint Car care products . . . . . . . . . . . . . . . . . . . . 185

Vehicle tools Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224 Vehicle wallet storage . . . . . . . . . . . . . . . . . . . 131

Ventilation slits . . . . . . . . . . . . . . . . . . . . . . . . . . 17

WWarning lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Warning lamps . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Warning reports

Red . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Yellow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Warning texts in the display . . . . . . . . . . . . . . . . 63

Warning triangle . . . . . . . . . . . . . . . . . . . . . . . . 141

Washer fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Washing by hand . . . . . . . . . . . . . . . . . . . . . . . 186

Washing the vehicle . . . . . . . . . . . . . . . . . . . . . 186

Washing with high pressure cleaners . . . . . . . 187

Water warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Water in the windscreen washer tank . . . . . . . 211

Wear indicators . . . . . . . . . . . . . . . . . . . . . . . . . 220

Wheel bolts . . . . . . . . . . . . . . . . . . . . . . . . 228, 259 Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Wheel change . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Wheel trims . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218, 258

Why assume the correct sitting position? . . . . . 30

Why should head restraints be correctly adjusted? 13

Why wear seat belts? . . . . . . . . . . . . . . . . . . 19, 21

Why wear seatbelts? . . . . . . . . . . . . . . . . . . . . . . 30 Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Windscreen washer fluid

Warning lamp . . . . . . . . . . . . . . . . . . . . . . . . 76

Windscreen wiper blades Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Windscreen wipers . . . . . . . . . . . . . . . . . . . . . . 118 Changing blades . . . . . . . . . . . . . . . . . . . . . 212

Changing the rear blade . . . . . . . . . . . . . . . 213

Winter driving Diesel engine . . . . . . . . . . . . . . . . . . . . . . . 201

Winter tyres . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Wiper/wash automatic function . . . . . . . . . . . 118

Working in the engine compartment . . . . . . . . 201

altea_ingles Seite 282 Donnerstag, 19. Mai 2005 3:02 15