Seat Altea 2005 Owner's Manual

Manufacturer: SEAT, Model Year: 2005, Model line: Altea, Model: Seat Altea 2005Pages: 286, PDF Size: 9.59 MB

Page 231 of 286

If and when229

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

WARNING

Loosen the wheel bolts only about one tu rn before raising the vehicle with

the jack, loosening the wheel bolts more than one turn can result in an acci-

dent.

Note

•

Do not use the hexagonal socket in th e screwdriver handle to loosen or

tighten the wheel bolts.

•

If the wheel bolt is very tight, you may be able to loosen it by pushing

down the end of the spanner carefully with your foot. Hold on to the vehicle

for support and take care not to slip.

Raising the vehicle

The vehicle must be raised with a jack to remove the wheel.

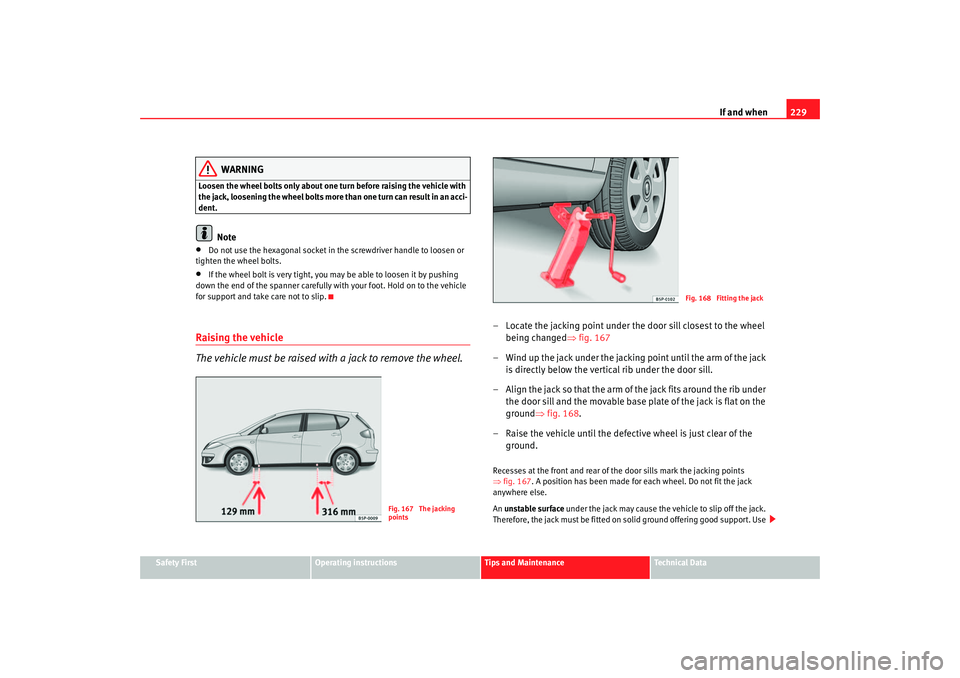

– Locate the jacking point under the door sill closest to the wheel being changed ⇒fig. 167

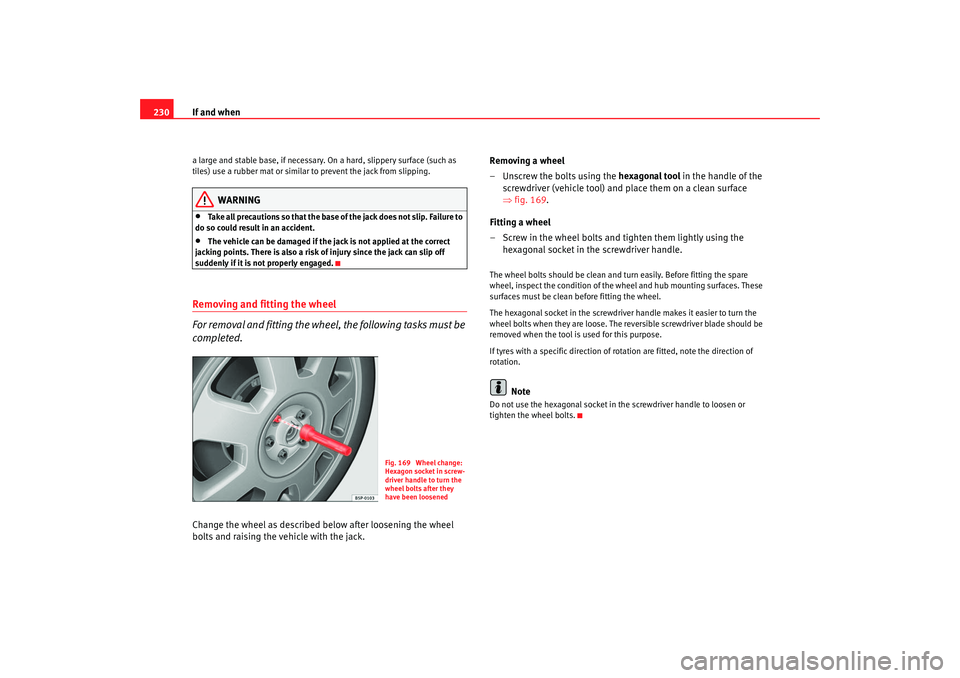

– Wind up the jack under the jacking point until the arm of the jack is directly below the vertical rib under the door sill.

– Align the jack so that the arm of the jack fits around the rib under the door sill and the movable base plate of the jack is flat on the

ground ⇒fig. 168 .

– Raise the vehicle until the defect ive wheel is just clear of the

ground.Recesses at the front and rear of the door sills mark the jacking points

⇒ fig. 167 . A position has been made for each wheel. Do not fit the jack

anywhere else.

An unstable surface under the jack may cause the vehicle to slip off the jack.

Therefore, the jack must be fitted on solid ground offering good support. Use

Fig. 167 The jacking

points

Fig. 168 Fitting the jack

altea_ingles Seite 229 Donnerstag, 19. Mai 2005 3:02 15

Page 232 of 286

If and when

230a large and stable base, if necessary. On a hard, slippery surface (such as

tiles) use a rubber mat or similar to prevent the jack from slipping.

WARNING

•

Take all precautions so that the base of the jack does not slip. Failure to

do so could result in an accident.

•

The vehicle can be damaged if the jack is not applied at the correct

jacking points. There is also a risk of injury since the jack can slip off

suddenly if it is not properly engaged.

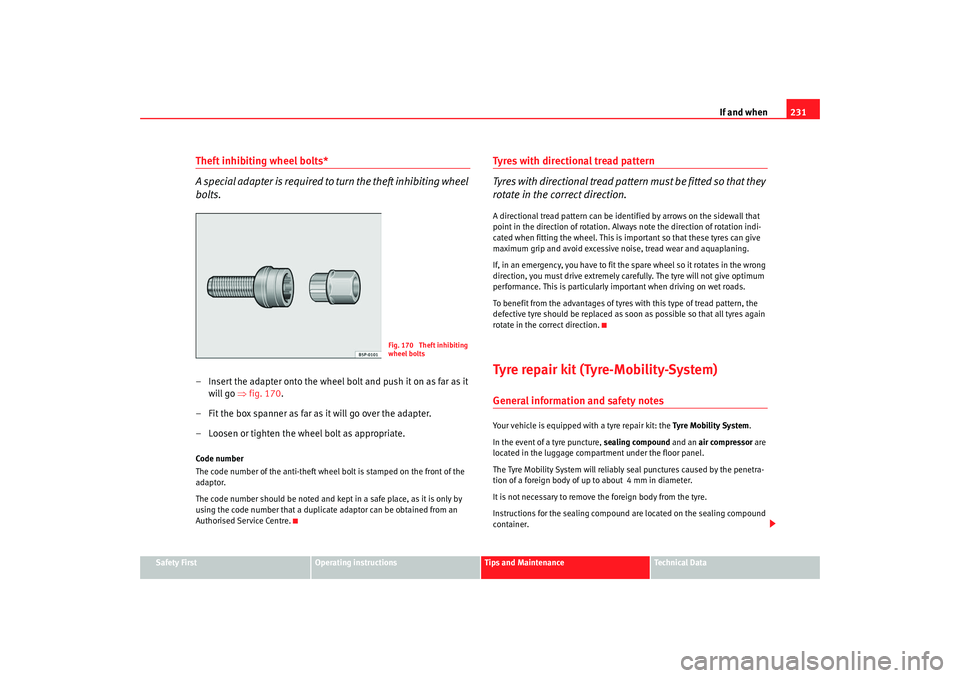

Removing and fitting the wheel

For removal and fitting the wheel, the following tasks must be

completed.Change the wheel as described below after loosening the wheel

bolts and raising the vehicle with the jack. Removing a wheel

– Unscrew the bolts using the

hexagonal tool in the handle of the

screwdriver (vehicle tool) and place them on a clean surface

⇒ fig. 169.

Fitting a wheel

– Screw in the wheel bolts and tighten them lightly using the hexagonal socket in the screwdriver handle.

The wheel bolts should be clean and turn easily. Before fitting the spare

wheel, inspect the condition of the whe el and hub mounting surfaces. These

surfaces must be clean before fitting the wheel.

The hexagonal socket in the screwdriver handle makes it easier to turn the

wheel bolts when they are loose. The reversible screwdrive r blade should be

removed when the tool is used for this purpose.

If tyres with a specific di rection of rotation are fitt ed, note the direction of

rotation.

Note

Do not use the hexagonal socket in the screwdriver handle to loosen or

tighten the wheel bolts.

Fig. 169 Wheel change:

Hexagon socket in screw-

driver handle to turn the

wheel bolts after they

have been loosened

altea_ingles Seite 230 Donnerstag, 19. Mai 2005 3:02 15

Page 233 of 286

If and when231

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

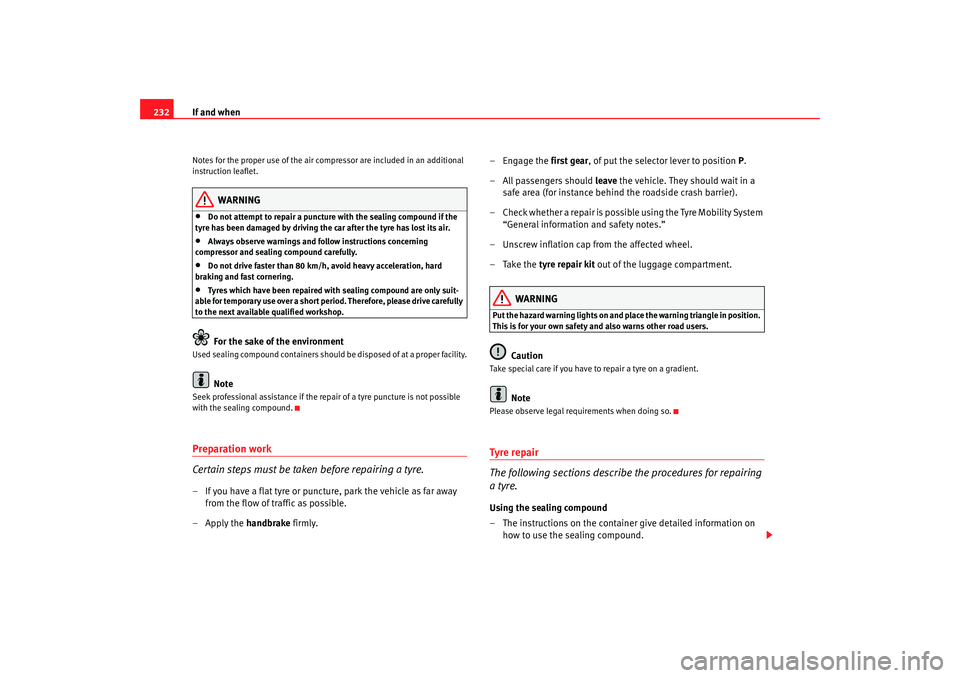

Theft inhibiting wheel bolts*

A special adapter is required to turn the theft inhibiting wheel

bolts.– Insert the adapter onto the wheel bolt and push it on as far as it

will go ⇒fig. 170 .

– Fit the box spanner as far as it will go over the adapter.

– Loosen or tighten the wheel bolt as appropriate.Code number

The code number of the anti-theft wheel bolt is stamped on the front of the

adaptor.

The code number should be noted and kept in a safe place, as it is only by

using the code number that a duplicat e adaptor can be obtained from an

Authorised Service Centre.

Tyres with directional tread pattern

Tyres with directional tread pattern must be fitted so that they

rotate in the correct direction.A directional tread pattern can be ident ified by arrows on the sidewall that

point in the direction of rotation. Always note the direction of rotation indi-

cated when fitting the wheel. This is important so that these tyres can give

maximum grip and avoid excessive noise, tread wear and aquaplaning.

If, in an emergency, you have to fit the spare wheel so it rotates in the wrong

direction, you must drive extremely care fully. The tyre will not give optimum

performance. This is particularly important when driving on wet roads.

To benefit from the advantages of tyres with this type of tread pattern, the

defective tyre should be replaced as soon as possible so that all tyres again

rotate in the correct direction.Tyre repair kit (Tyre-Mobility-System)General information and safety notesYour vehicle is equipped with a tyre repair kit: the Tyre Mobility System.

In the event of a tyre puncture, sealing compound and an air compressor are

located in the luggage compartment under the floor panel.

The Tyre Mobility System will reliably seal punctures caused by the penetra-

tion of a foreign body of up to about 4 mm in diameter.

It is not necessary to remove the foreign body from the tyre.

Instructions for the sealing compound are located on the sealing compound

container.

Fig. 170 Theft inhibiting

wheel bolts

altea_ingles Seite 231 Donnerstag, 19. Mai 2005 3:02 15

Page 234 of 286

If and when

232Notes for the proper use of the air comp ressor are included in an additional

instruction leaflet.

WARNING

•

Do not attempt to repair a puncture with the sealing compound if the

tyre has been damaged by driving the car after the tyre has lost its air.

•

Always observe warnings and follow instructions concerning

compressor and sealing compound carefully.

•

Do not drive faster than 80 km/h, avoid heavy acceleration, hard

braking and fast cornering.

•

Tyres which have been repaired with sealing compound are only suit-

able for temporary use over a short period. Therefore, please drive carefully

to the next available qualified workshop.For the sake of the environment

Used sealing compound cont ainers should be disposed of at a proper facility.

Note

Seek professional assistance if the repair of a tyre puncture is not possible

with the sealing compound.Preparation work

Certain steps must be taken before repairing a tyre.– If you have a flat tyre or puncture, park the vehicle as far away

from the flow of traffic as possible.

–Apply the handbrake firmly. – Engage the

first gear, of put the selector lever to position P.

– All passengers should leave the vehicle. They should wait in a

safe area (for instance behind the roadside crash barrier).

– Check whether a repair is possible using the Tyre Mobility System “General information and safety notes.”

– Unscrew inflation cap from the affected wheel.

–Take the tyre repair kit out of the luggage compartment.

WARNING

Put the hazard warning lights on and place the warning triangle in position.

This is for your own safety and also warns other road users.

Caution

Take special care if you have to repair a tyre on a gradient.

Note

Please observe legal requirements when doing so.Tyre repair

The following sections describe the procedures for repairing

a tyre.Using the sealing compound

– The instructions on the container give detailed information on

how to use the sealing compound.

altea_ingles Seite 232 Donnerstag, 19. Mai 2005 3:02 15

Page 235 of 286

If and when233

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Inflating the tyre.

– Remove the air compressor and hose from the container.

– Screw the retaining nut onto the valve.

– Plug the compressor cable into a 12 volt socket.

– Turn on compressor and monitor the pressure shown on the pres-

sure gauge.

Completing the repair

– Remove the compressor hose from the valve.

– Fit the valve cap.

– Unplug the compressor from the socket.

– Return all tools to their proper storing location.

NoteThe compressor should never be allowed to run for longer than 6 minutes.

FusesChanging a fuse

If a fuse has blown it must be replaced

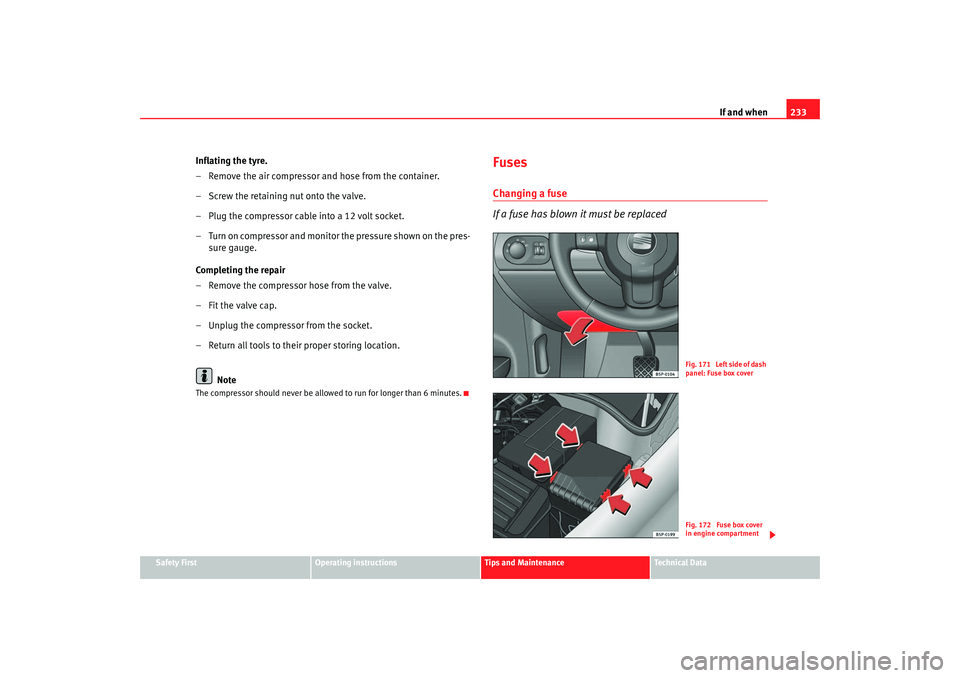

Fig. 171 Left side of dash

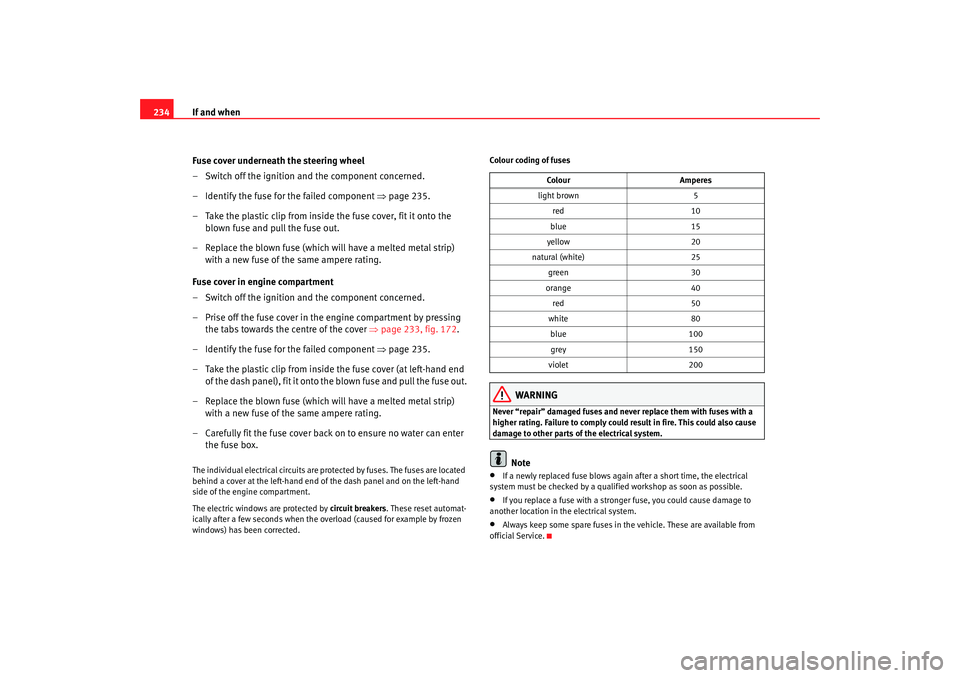

panel: Fuse box coverFig. 172 Fuse box cover

in engine compartment

altea_ingles Seite 233 Donnerstag, 19. Mai 2005 3:02 15

Page 236 of 286

If and when

234

Fuse cover underneath the steering wheel

– Switch off the ignition and the component concerned.

– Identify the fuse for the failed component ⇒page 235.

– Take the plastic clip from inside the fuse cover, fit it onto the

blown fuse and pull the fuse out.

– Replace the blown fuse (which will have a melted metal strip) with a new fuse of the same ampere rating.

Fuse cover in engine compartment

– Switch off the ignition and the component concerned.

– Prise off the fuse cover in the engine compartment by pressing the tabs towards the centre of the cover ⇒page 233, fig. 172 .

– Identify the fuse for the failed component ⇒page 235.

– Take the plastic clip from inside the fuse cover (at left-hand end of the dash panel), fit it onto the blown fuse and pull the fuse out.

– Replace the blown fuse (which will have a melted metal strip) with a new fuse of the same ampere rating.

– Carefully fit the fuse cover back on to ensure no water can enter

the fuse box.The individual electrical circuits are pr otected by fuses. The fuses are located

behind a cover at the left-hand end of the dash panel and on the left-hand

side of the engine compartment.

The electric windows are protected by circuit breakers. These reset automat-

ically after a few seconds when the overload (caused for example by frozen

windows) has been corrected. Colour coding of fuses

WARNING

Never “repair” damaged fuses and neve

r replace them with fuses with a

higher rating. Failure to comply could result in fire. This could also cause

damage to other parts of the electrical system.

Note

•

If a newly replaced fuse blows again after a short time, the electrical

system must be checked by a qualifi ed workshop as soon as possible.

•

If you replace a fuse with a stronger fuse, you could cause damage to

another location in th e electrical system.

•

Always keep some spare fuses in the vehicle. These are available from

official Service. Colour

Amperes

light brown 5

red 10

blue 15

yellow 20

natural (white) 25

green 30

orange 40

red 50

white 80

blue 100

grey 150

violet 200

altea_ingles Seite 234 Donnerstag, 19. Mai 2005 3:02 15

Page 237 of 286

If and when235

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Fuses on left side of dash panelFuses

Number Electrical equipment Amperes

1 Electro-chromatic mirror / relay 50 5

2 Engine control unit 5

3 Lights switch / Headlight control unit / Right hand side headlight / Telephone 5

4 Telephone pre-installation 5

5 Flow meter, frequency tube 10

6A ir b ag 5

7 Vacant

8 Vacant

9 Power steering 5

10 Diagnosis, reverse gear switch 5

11 Heated windscreen 5

12 FSI measure 10

13 Trailer control unit 5

14 ESP/TCP, ABS/ESP control unit 5

15 Automatic gearbox 5

16 Heating controls / Climatronic / Pressure sensor / Heated seats 10

17 Engine 7,5

18 Vacant

19 Vacant

20 Engine fuse box supply 5

21 Gear lever 5

altea_ingles Seite 235 Donnerstag, 19. Mai 2005 3:02 15

Page 238 of 286

If and when

236

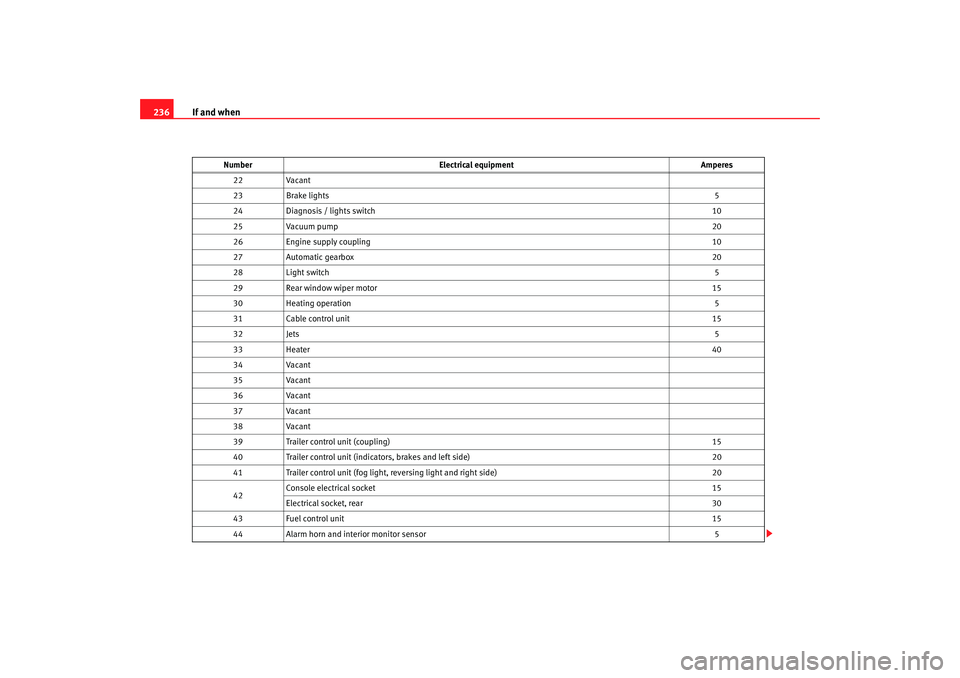

22 Vacant

23 Brake lights 5

24 Diagnosis / lights switch 10

25 Vacuum pump 20

26 Engine supply coupling 10

27 Automatic gearbox 20

28 Light switch 5

29 Rear window wiper motor 15

30 Heating operation 5

31 Cable control unit 15

32 Jets 5

33 Heater 40

34 Vacant

35 Vacant

36 Vacant

37 Vacant

38 Vacant

39 Trailer control unit (coupling) 15

40 Trailer control unit (indicators, brakes and left side) 20

41 Trailer control unit (fog light, reversing light and right side) 20

42 Console electrical socket

15

Electrical socket, rear 30

43 Fuel control unit 15

44 Alarm horn and interior monitor sensor 5

Number

Electrical equipment Amperes

altea_ingles Seite 236 Donnerstag, 19. Mai 2005 3:02 15

Page 239 of 286

If and when237

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Location under steering wheel, on relay carrier

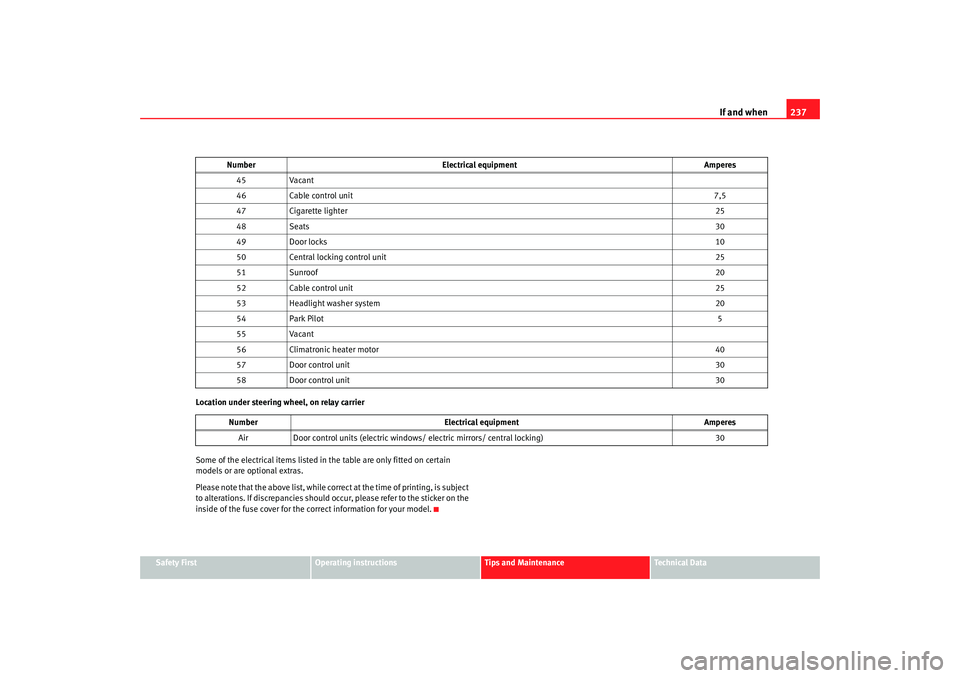

Some of the electrical items listed in

the table are only fitted on certain

models or are optional extras.

Please note that the above list, while correct at the time of printing, is subject

to alterations. If discrepancies should occur, please refer to the sticker on the

inside of the fuse cover for the co rrect information for your model.

45

Vacant

46 Cable control unit 7,5

47 Cigarette lighter 25

48 Seats 30

49 Door locks 10

50 Central locking control unit 25

51 Sunroof 20

52 Cable control unit 25

53 Headlight washer system 20

54 Park Pilot 5

55 Vacant

56 Climatronic heater motor 40

57 Door control unit 30

58 Door control unit 30

Number Electrical equipment Amperes

Air Door control units (electric windows/ electric mirrors/ central locking) 30

Number

Electrical equipment Amperes

altea_ingles Seite 237 Donnerstag, 19. Mai 2005 3:02 15

Page 240 of 286

If and when

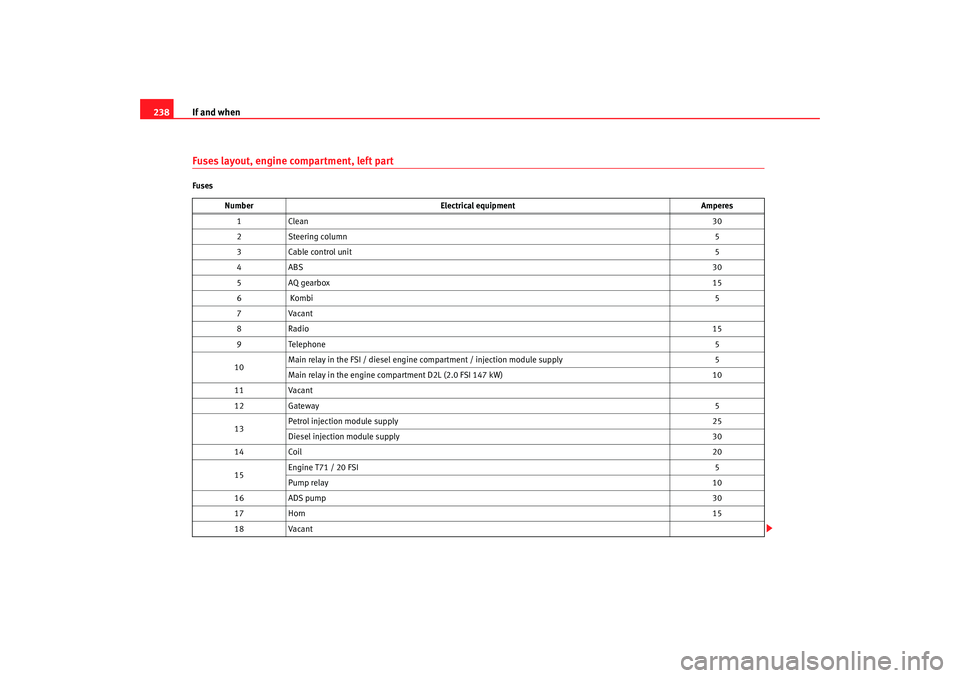

238Fuses layout, engine compartment, left partFuses

Number Electrical equipment Amperes

1C le a n 30

2 Steering column 5

3 Cable control unit 5

4A BS 30

5 AQ gearbox 15

6 Kombi 5

7 Vacant

8R ad io 15

9 Telephone 5

10 Main relay in the FSI / diesel engine compartment / injection module supply

5

Main relay in the engine compartment D2L (2.0 FSI 147 kW) 10

11 Vacant

12 Gateway 5

13 Petrol injection module supply

25

Diesel injection module supply 30

14 Coil 20

15 Engine T71 / 20 FSI

5

Pump relay 10

16 ADS pump 30

17 Horn 15

18 Vacant

altea_ingles Seite 238 Donnerstag, 19. Mai 2005 3:02 15