headlight Seat Altea 2006 User Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2006, Model line: Altea, Model: Seat Altea 2006Pages: 288, PDF Size: 8.61 MB

Page 184 of 288

Driving and the environment

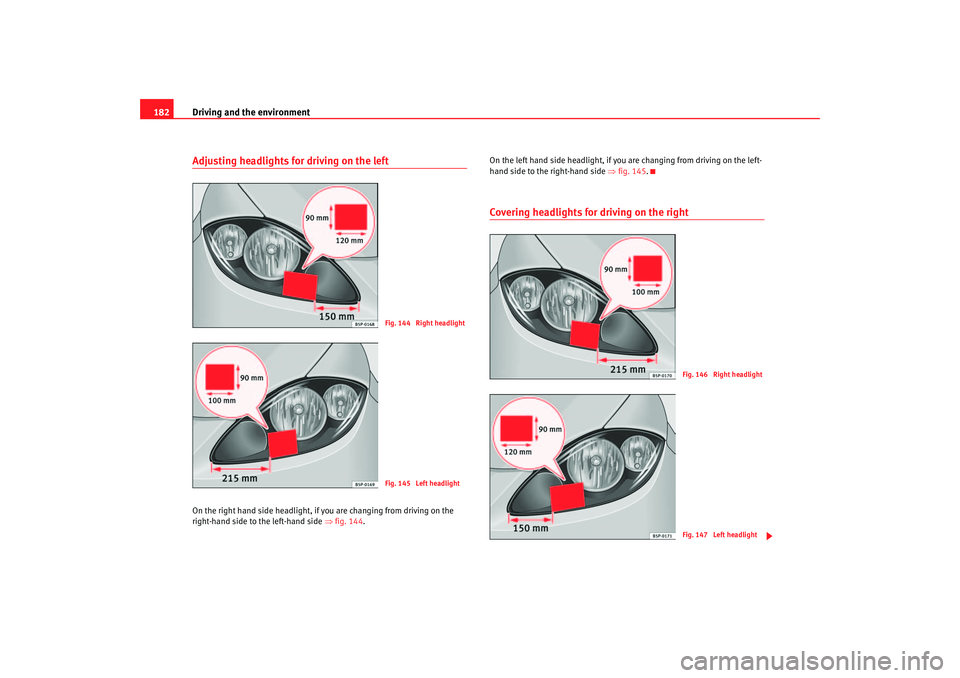

182Adjusting headlights for driving on the leftOn the right hand side headlight, if you are changing from driving on the

right-hand side to the le ft-hand side ⇒ fig. 14

4. On the left hand side headlight, if you are changing from driving on the left-

hand side to the righ

t-hand side ⇒ fig.

145.

Covering headlights for driving on the right

Fig. 144 Right headlightFig. 145 Left headlight

Fig. 146 Right headlightFig. 147 Left headlight

altea_ingles Seite 182 Dienstag, 4. Oktober 2005 6:57 18

Page 185 of 288

Driving and the environment183

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

On the right headlight, if you are changing from driving on the left-hand side

to the right-hand side.

On the left headlight, if you are changing from driving on the left-hand side to

the right-hand side.

Trailer towingWhat do you need to bear in mind when towing a trailer?Your vehicle may be used to tow a trailer when fitted with the correct equip-

ment.

If the car is supplied with a

factory-fitted towing bracket it will already have

the necessary technical modifications and meet the statutory requirements

for towing a trailer. For the posterior fitting of a trailer towing bracket see

⇒ page 198.

Connectors

Your vehicle is fitted with a 12-pin co nnector for the electrical connection

between the trailer and the vehicle.

If the trailer has a 7-pin plug you will need to use an adapter cable. This is

available from any Technical Service.

Trailer weight / draw bar loading

Never exceed the authorised towing limit. If you do not load the trailer up to

the maximum permitted trailer weight , you can then climb correspondingly

steeper gradients.

The maximum trailer weights listed are only applicable for altitudes up to

1,000 m above sea level. With increasing altitude the engine power and

therefore the vehicle's climbing ability are impaired because of the reduced

air density. The maximum trailer weight has to be reduced accordingly. The weight of the vehicle and trailer combination must be reduced by 10% for

every further 1,000m (or part thereof).

The gross combination weight is the

actual weight of the laden vehicle plus the actual weight of the laden trailer.

Where possible, operate the trailer with the maximum permitted draw bar

weight on the ball joint of the towing bracket, but do not exceed the specified

limit.

The figures for trailer weights and draw bar weights that are given on the

data plate of the towing bracket are for certification purposes only. The

correct figures for your specific model, which may be lower than these figures

for the towing bracket, are given in the registration documents and

⇒ Section “Technical data”.

Distributing the load

Distribute loads in the trailer so that heavy objects are as near to the axle as

possible. Loads carried in the trailer must be secured to prevent them

moving.

Tyre pressure

Set tyre pressure to the maximum permissible pressure shown on the sticker

on the inside of the fuel tank flap. Set the tyre pressure of the trailer tyres in

accordance with the trailer manufacturer's recommendations.

Exterior mirrors

Check whether you can see enough of the road behind the trailer with the

standard mirrors. If this is not the case you should have additional mirrors

fitted. Both exterior mirrors should be mounted on hinged extension

brackets. Adjust the mirrors to give sufficient vision to the rear.

WARNING

Never transport people in a trailer. This could result in fatal accidents.

altea_ingles Seite 183 Dienstag, 4. Oktober 2005 6:57 18

Page 215 of 288

Checking and refilling levels213

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Washer fluid and windscreen wiper bladesTopping up washer fluid

The water for cleaning the windscreen should always be

mixed with washer fluid.The windscreen washer and the headlight washing system are supplied with

fluid from the windscreen washer flui d container in the engine compartment.

The reservoir is located on the right-hand side of the engine compartment.

Plain water is not enough to clean the windscreen and headlights. We recom-

mend that you always add a product to the windscreen washer fluid.

Approved windscreen cleaning products exist on the market with high deter-

gent and anti-freeze properties, these may be added all-year-round. Please

follow the dilution instructions on the packaging.

WARNING

Any work carried out in the engine compartment or on the engine must be

carried out cautiously.•

When working in the engine compartm ent, always observe the safety

wa rnings ⇒ page

203.

Caution

•

Never put radiator anti-freeze or other additives into the windscreen

washer fluid.

•

Always use approved windscreen cleansing products diluted as per

instructions. If you use other washer fl uids or soap solutions, the tiny aper-

tures in the fan-shaped nozzles could become blocked.

Fig. 157 In the engine

compartment: Cap of

windscreen washer fluid

reservoir.

altea_ingles Seite 213 Dienstag, 4. Oktober 2005 6:57 18

Page 239 of 288

If and when237

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

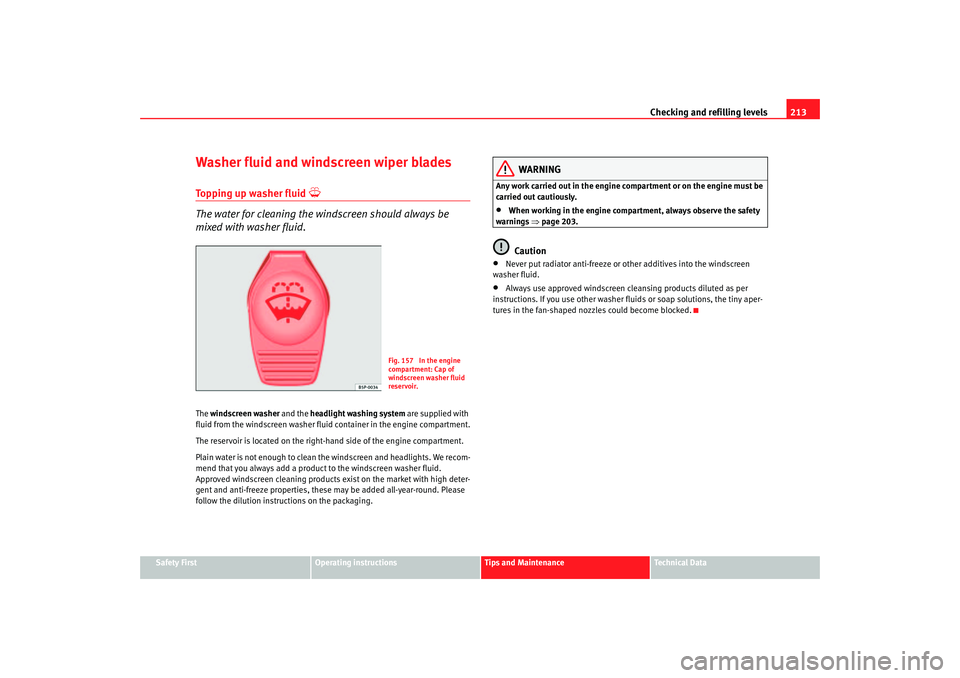

Fuses on left side of dash panelFuses

Number Electrical equipment Amperes

1 Electro-chromatic mirror / relay 50 5

2 Engine control unit 5

3 Lights switch / Headlight control unit / Right hand side headlight / Telephone 5

4 Telephone pre-installation 5

5 Flow meter, frequency tube 10

6A ir b ag 5

7 Vacant

8 Vacant

9 Power steering 5

10 Diagnosis, reverse gear switch 5

11 Heated windscreen 5

12 FSI measure 10

13 Trailer control unit 5

14 ESP/TCP, ABS/ESP control unit 5

15 Automatic gearbox 5

16 Heating controls / Climatronic / Pressure sensor / Heated seats 10

17 Engine 7,5

18 Vacant

19 Vacant

20 Engine fuse box supply 5

21 Gear lever 5

altea_ingles Seite 237 Dienstag, 4. Oktober 2005 6:57 18

Page 241 of 288

If and when239

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

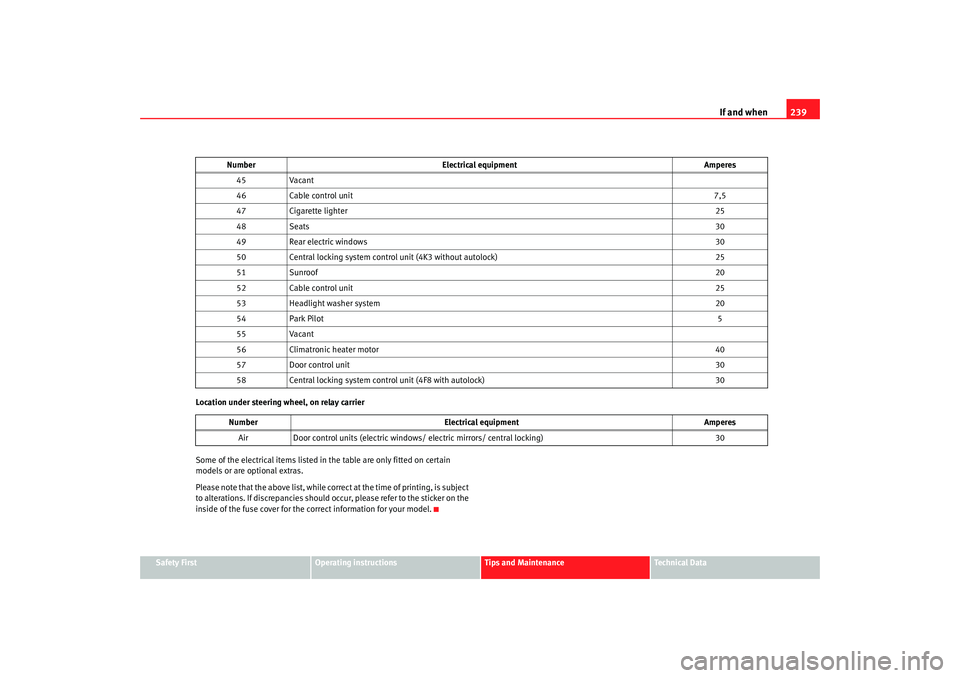

Location under steering wheel, on relay carrier

Some of the electrical items listed in

the table are only fitted on certain

models or are optional extras.

Please note that the above list, while correct at the time of printing, is subject

to alterations. If discrepancies should occur, please refer to the sticker on the

inside of the fuse cover for the co rrect information for your model.

45

Vacant

46 Cable control unit 7,5

47 Cigarette lighter 25

48 Seats 30

49 Rear electric windows 30

50 Central locking system control unit (4K3 without autolock) 25

51 Sunroof 20

52 Cable control unit 25

53 Headlight washer system 20

54 Park Pilot 5

55 Vacant

56 Climatronic heater motor 40

57 Door control unit 30

58 Central locking system control unit (4F8 with autolock) 30

Number Electrical equipment Amperes

Air Door control units (electric windows/ electric mirrors/ central locking) 30

Number

Electrical equipment Amperes

altea_ingles Seite 239 Dienstag, 4. Oktober 2005 6:57 18

Page 244 of 288

If and when

242Position in engine compartment: side boxFuses

Some of the electrical items listed in the table are only fitted on certain

models or are optional extras.

Please note that the above list, while corr ect at the time of printing, is subject

to alterations.Lamp changeGeneral notesBefore changing any lamp first turn off the equipment concerned.

Do not touch the lamp glass. Fingerprints vaporise in the heat, causing a

reduction in the lamp life and conden sation on the mirror surface, thus

reducing efficiency. A lamp should only be placed by one of the same type. The designation is

inscribed on the bulb, either on the glass part or on the base.

It is highly recommended to keep a box of spare lamps in the vehicle. At the

very least, the lamps that most affect

road safety should have spares in the

vehicle.

Main headlights

Dipped beam - H7

Full lights - H1

Position - W5W

Indicator - PY21W

Number

Electrical equipment Amperes

B1 Alternator < 140 W

150

Alternator > 140 W 200

C1 Power steering 80

D1 Multi-terminal voltage supply “30”. Internal fuse box 100

E1 Ventilator > 500 W / Ventilator < 500 80/50

F1 PTCs (Supplementary electrical heating using air) 100

G1 Trailer fuse voltage supply in internal fuse box 50

H1 Central locking control unit (4F8 with autolock)

altea_ingles Seite 242 Dienstag, 4. Oktober 2005 6:57 18

Page 245 of 288

If and when243

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Xenon headlights

19)

Dipped beam and full lights - D1S

20)

Light burst and additional full lights - H1

Position W5W

Indicators PY21W

Fog lights

Fog lights - H3

Upper rear light

Stop/Position - P21W

21)

Indicator - R10W

Lower rear light

Fog light - P21W

Reverse light - P21W

Side turn indicator

Side turn indicator - W5W

Registration plate light

Registration plate light - C5W

Note

•

Due to the difficulty in accessing the lamps, these must be changed by an

Authorised Service Centre. However, the following is a description of how to

change the lamps except for the fog lights* and interior lamps.

Main headlight lamps

Turn signals

Dipped headlights

Main beam headlights

Side lights

19)For these type of headlights, the bulbs must be changed by an Authorised Service

Centre, given that complex elements of the vehicle must be removed and that the au-

tomatic control system must be reset.20)Xenon discharge lamps emit 2.5 times as much light flux and have a useful life five

times greater than halogen lamps, this means that, except in case of an abnormal

fault, there is no need to change the bulbs during the vehicle life.21)Electronically controlled single filament lamp for Stop/Position lamp. If the lamp

blows it will not work in either position or Stop position

Fig. 173 Main headlight

lamps

AAABACAD

altea_ingles Seite 243 Dienstag, 4. Oktober 2005 6:57 18

Page 247 of 288

If and when245

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

– Remove the loops ⇒page 244, fig. 175 in the direction of

the arrow and remove the cover.

– Remove the connector ⇒page 244, fig. 176 from the lamp.

– Disengage the retainer spring ⇒ page 244, fig. 176 pressing

inwards and to the right.

– Extract the lamp and fit the replacement so that the rim of the attachment plate is on the reflector rebate.Main beam lights

– Raise the bonnet

– Remove the cover ⇒fig. 177 by pulling on this.

– Remove the connector ⇒fig. 178 from the lamp.

– Press the spring ⇒fig. 178 inwards and to the right.

– Extract the lamp and fit the replac ement so that it sits correctly

into the rebate on the reflector.

– Installation is done in the reverse order.

A1

A2

A3

Fig. 177 Main beam

headlights

Fig. 178 Main beam

headlights

AC

A1

A2

altea_ingles Seite 245 Dienstag, 4. Oktober 2005 6:57 18

Page 254 of 288

If and when

252How to jump startIn ⇒ fig. 193, the flat battery is A and the charged battery B.

Jump lead terminal connections

– Switch off the ignition on both vehicles ⇒.

1. Connect one end of the red jump lead to the positive ⇒fig. 193

terminal of the vehicle with the flat battery ⇒.

2. Connect the other end of the red jump lead to the positive terminal in the vehicle providing assistance.

3. Connect one end of the black jump lead to the negative terminal on the battery of the vehicle providing assistance. 4. Connect the other end of the black jump lead to a solid metal

component which is bolted on to the engine block, or onto the

engine block itself of the vehicle with the flat battery. Do not

connect it to a point near the battery ⇒.

5. Position the leads in such a way that they cannot come into contact with any moving parts in the engine compartment.

Starting

6. Start the engine of the vehicle with the boosting battery and let it run at idling speed.

7. Start the engine of the car with the flat battery and wait one or two minutes until the engine is “running”.

Removing the jump leads

8. Before you remove the jump leads, switch off the headlights (if they are switched on).

9. Turn on the heater blower and rear window heater in the vehicle with the flat battery. This helps minimise voltage peaks which are

generated when the leads are disconnected.

10. When the engine is running, disconnect the leads in reverse order to the deta ils given above.

Connect the battery clamps so they have good metal-to-metal contact with

the battery terminals.

If the engine fails to start, switch off the starter after about 10 seconds and

try again after about half a minute.

Fig. 193 How to connect

the jump leads

A+

A+

A-

AX

altea_ingles Seite 252 Dienstag, 4. Oktober 2005 6:57 18

Page 277 of 288

Technical Data275

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

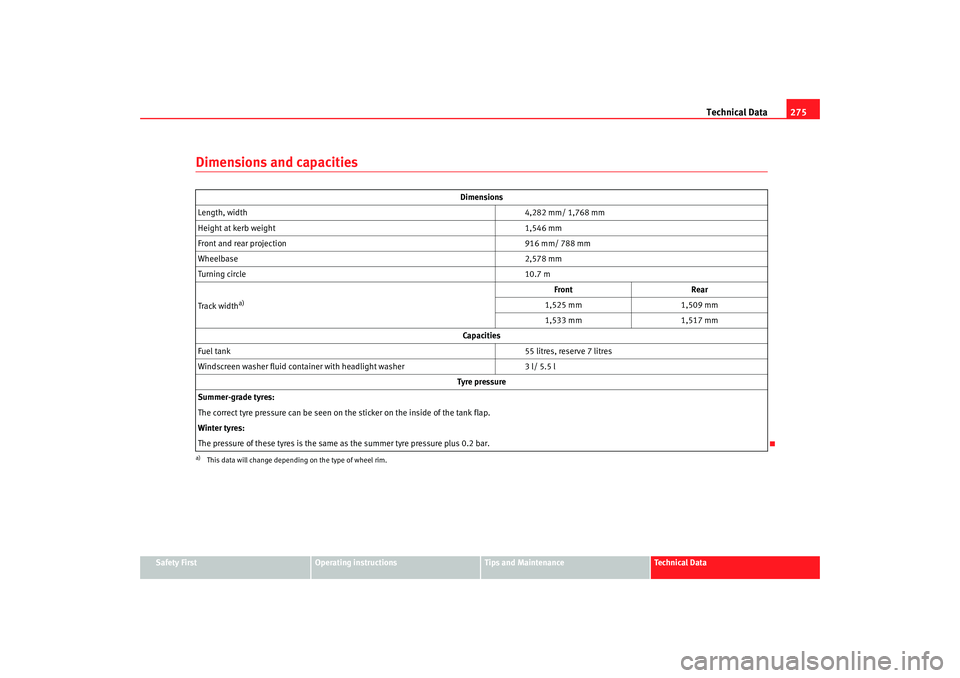

Dimensions and capacities

Dimensions

Length, width 4,282 mm/ 1,768 mm

Height at kerb weight 1,546 mm

Front and rear projection 916 mm/ 788 mm

Wheelbase 2,578 mm

Turning circle 10.7 m

Track width

a)

a)This data will change depending on the type of wheel rim.

Front Rear

1,525 mm 1,509 mm

1,533 mm 1,517 mm

Capacities

Fuel tank 55 litres, reserve 7 litres

Windscreen washer fluid container with headlight washer 3 l/ 5.5 l

Tyre pressure

Summer-grade tyres:

The correct tyre pressure can be seen on the sticker on the inside of the tank flap.

Winter tyres:

The pressure of these tyres is the same as the summer tyre pressure plus 0.2 bar.

altea_ingles Seite 275 Dienstag, 4. Oktober 2005 6:57 18